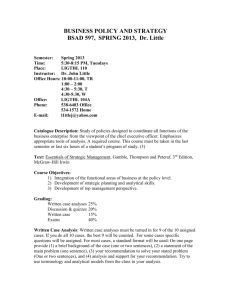

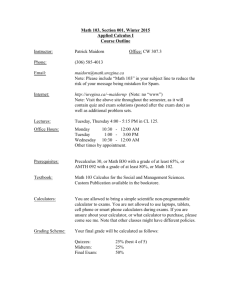

IENG Introduction to Industrial Engineering Course Outline

advertisement

EASTERN MEDITERRANEAN UNIVERSITY Department of Industrial Engineering IENG/MANE112 Introduction to Industrial/Management Engineering COURSE OUTLINE COURSE CODE COURSE TITLE CREDIT VALUE PREREQUISITES DURATION OF COURSE IENG112 Introduction to Industrial Engineering (4, 1, 0) 4 One semester WEB LINK http://ie.emu.edu.tr/lec/ Instructors Assistant(s) Name (group) Béla Vizvári, Prof.Dr. Arman Nedjati COURSE LEVEL COURSE TYPE ECTS VALUE COREQUISITES Semester and year Third year Department Core 6 CMPE110 FALL e-mail bela.vizvari@emu.edu.tr Arman.nedjati@cc.emu.edu.tr 2012 - 2013 Office C105 C207 Telephone 1103 1055 CATALOGUE DESCRIPTION This course is designed to introduce the fundamental concepts of Industrial Engineering and give answers to the first questions that are usually asked by the prospective Industrial Engineering students. The course surveys both the traditional and modern topics of Industrial Engineering, providing a historical as well as an academic perspective of the whole profession. Related software applications, together with fundamentals of modeling & optimization, and production system design and control (methods engineering, work measurement, ergonomics, facilities planning and design, production planning, inventory control and quality control) will also be covered in the course. AIMS & OBJECTIVES Course objectives (CO): 1. Define IE and know its historical roots (PO h, & i). 2. Know the concepts and fundamental areas of IE (PO a, c, e, h, j, & k). 3. Be able to solve IE problems numerically (PO a, e, h & k). 4. Be able to understand problems of different technological environments (PO c, d, e, g, h & k) GENERAL LEARNING OUTCOMES (COMPETENCES) On successful completion of this course, all students will have developed knowledge and understanding of: The origin and history of IE (Course Objectives (CO) No. 1), Different technologies in industry and service sector (CO No. 2, 3 and 4), Basic methods of the most important areas of IE (CO No. 2 and 3), MPS, MRP, BOM, scheduling (CO No. 2 and 3), Work study and human factors (MRP) (CO No. 2 and 3), Economic factors of production (CO No. 2 and 3), Project and resource management (CO No. 2 and 3), Quality control (CO No. 2 and 3), Facility location and layout (CO No. 2 and 3), Just-In-time and pull systems (CO No. 2 and 3). On successful completion of this course, all students will have developed their skills in: Calculation of simple production plans as MPS and MRP (CO 2), Applying basic techniques engineering economics (CO 2), Carrying out routing calculations (CO 2) Designing facilities consisting of rectangular cells (CO 2), Scheduling production in simple cases (CO No. 2 and 3). On successful completion of this course, all students will have developed their appreciation of, and respect for values and attitudes to: The importance of human factors (CO 1 & 2), Natural resources like water, clean air, etc. (CO 2 & 4), The wide range of IE (CO 1, 2, 3 & 4), The history of IE (CO 1). LEARNING TEACHING METHODS The function of teaching is to enable students to learn. Therefore students are suggested to read the chapters of the textbook before coming to class and solve the related end of chapter questions after each lecture. ASSIGNMENTS According to Course Objective #3, the assignments are relevant calculations on computers. The students must prove individually that they are able to carry out the calculations. METHOD OF ASSESSMENT All Examinations will be based on lectures, discussions, textbook, lab work and assigned work. To enter a formal examination, a student has to present her/his EMU student Identification card to the invigilator. Quizzes: There will be three quizzes designed to test familiarity and basic understanding of various topics. Midterm Exam: The midterm exam will be held in the midterm week. It will cover all of the material up to the date of examination. Final Exam: The final exam will cover the whole course material. In form it will be a longer version of the midterm exam. Make-up and Re-sit Exams: Make-up and re-sit examinations will only be offered according to the regulations of EMU to students who provided adequate documentation for the reason of their absence within four working days at the latest after the examination date. No makeup for cheating! (See also ACADEMIC HONESTY – PLAGIARISM below!) Any objection to the grade or mark should be made latest within a week following its announcement. Grading Policy: Attendance Quizzes Midterm Exam Lab Quizzes Final Exam 10 % 15 % (3 quizzes, 5% each) 20 % 20 % 35 % To get a passing grade it is necessary to achieve at least 50 percent as total result and 10 percent from Lab Quiz. Be aware that 49.99 and 9.99 per cent, respectively, is not enough! Note that the instructor reserves the right to modify these percentages in case it is found necessary. You will be informed from the changes, if any. ATTENDANCE Attendance is mandatory. NG (Nil Grade) means failure due to poor attendance and/or failure to complete assigned work including exams. Attending less than 70 % of the classes, and/or not meeting the obligations in the method of assessment of the course may lead to an NG grade. TEXTBOOK/S Wayne C. Turner, Joe H. Mize, Kenneth E. Case, John W. Nazemetz: Introduction to Industrial and Systems Engineering, (Third Edition), Prentice Hall, 1993 COURSE CONTENT AND SCHEDULE Tuesday Friday Wednesday Office Hour Week 1 2 3 4 5 6 7 8-9 10 11 12 13 14 15 16 - 18 Lecture Hall Time IE-D102 12:30-14:20 IE-D102 12:30-12:20 IE-D102 16:30-17:20 (Tutorial) Wednesdays 15:30-16:30 Topics The origin and history of industrial engineering Technology: manufacturing and process industry, service sector. Facilities location and layout Material handling, distribution and routing Work design Forecast and inventory control Operations scheduling Midterm week Quality control Human factors Resource management Engineering economy Project management Contemporary topics of IE Final Exams Contribution of the Course to meeting the requirements of Criterion 5 Mathematics and Basic Sciences: Engineering Science : 75 % Engineering Design : 25 % General Education : - Relationship of Course to Program Outcomes Program Outcomes Level of Satisfaction of the Program Outcomes : Not Applicable : Low Level of Satisfaction : High Level of Satisfaction (a) an ability to apply knowledge of mathematics, science and engineering (b) an ability to design and conduct experiments, as well as to analyze and interpret data (c) an ability to design a system, component, or process to meet desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability, and sustainability (d) an ability to function on multi-disciplinary teams (e) an ability to identify, formulate, and solve engineering problems (f) an understanding of professional and ethical responsibility (g) an ability to communicate effectively (h) the broad education necessary to understand the impact of engineering solutions in a global, economic, environmental, and societal context (i) a recognition of the need for, and an ability to engage in life-long learning (j) a knowledge of contemporary issues (k) an ability to use the techniques, skills, and modern engineering tools necessary for engineering practice ACADEMIC HONESTY - PLAGIARISM Cheating is copying from others or providing information, written or oral, to others. Plagiarism is copying without acknowledgement from other people’s work. According to university by laws cheating and plagiarism are serious offences punishable with disciplinary action ranging from simple failure from the exam or project, to more serious action (letter of official warning suspension from the university for up to one semester). Disciplinary action is written in student records and may appear in student transcripts. I read and understood the rules of the course. Name, surname: Student ID. Signature: