LifeCycleCosts

advertisement

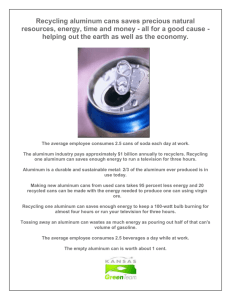

Environmental Costs of Linear Societies October 9, 2006 Life Cycle Analysis of Aluminum Cans • Americans use 102.2 BILLION aluminum cans/ year (368 per capita/year) • We throw away 49.6% of these cans (50.7 billion!) • Biggest environmental impact of this disposal is “upstream” from the consumer • Had these cans been recycled enough energy would have been saved to supply gasoline to over 1 million cars for an entire year Aluminum Can Production: Step 1 – Bauxite Mining • Most bauxite “ore” from open pit or strip mines in Australia, Jamaica and Brazil (99% of US needs is imported) • Bauxite mining results in land clearance, acid mine drainage, pollution of streams and erosion • 5 tons of mine “tailings” (waste) produced per ton of bauxite ore removed • Significant fossil fuel energy consumed in mining and transporting bauxite ore Land Degradation from mining For each ton of useful ore extracted, many tons of “overburden” have to be removed in the process. For bauxite ore, the ratio can be as high as 5:1. Mineral ores and metals are shipped all over the world, consuming vast quantities of energy in the process. Aluminum Can Production: Step 2 – Alumina Refining • Bauxite ore is mixed with caustic soda, lime and steam to produce a sodium aluminate slurry • “Alumina” is extracted from this slurry, purified and shipped to smelters • Leftover “slag” waste contains a variety of toxic minerals and chemical compounds • Alumina refining process is also fossil fuel energy intensive Refined alumina Alumina Refining Facilities Aluminum Can Production: Step 3 – Smelting • Powdered alumina is heated (smelted) in order to form aluminum alloy ingots • Aluminum smelting uses massive amounts of electricity (usually from coal) • One ton of aluminum production requires energy equivalent of 5 barrels of oil (210 gallons of gasoline) • Aluminum smelting also produces 7.4 tons of air pollutants (particulate matter, sulfur oxides, VOCs) for every 1 ton of aluminum produced Aluminum Ingots Aluminum Smelter Aluminum Can Production: Step 4 – Tertiary Processing • Aluminum ingots are melted (requiring more energy) and are extruded as sheets • Finishing process for rolled sheets involves several chemicals (strong acids and bases) that are toxic Aluminum Can Production: Step 5 – Finishing/Assembly • Aluminum sheet is fed into extrusion tubes and cut into shallow cups • Cups are fed into ironing press where successive rings redraw and iron the cup. This reduces sidewall thickness, making a full length can • The bottom is “domed” for strength • Cans are necked in at the top and flanged to accept the end • Little chemical pollution at this stage, just electricity use Aluminum Can Production: Step 6 – Filling/Distribution • Cans are shipped without end portion to beverage company • Beverage is injected under pressure – outward force strengthens the can • After filling, can is labeled and packaged • Cardboard and plastic is used, some toxic waste from making paint and ink used for labels • Finally, product in the can is trucked (diesel fuel use) to a wholesaler/distributor and then to retailer (multiple trips) Life Cycle Analysis of an Aluminum Can • Mining/Extraction of Bauxite – Ship to processing plants • Primary Processing – Convert bauxite to alumina • Secondary Processing – Convert alumina to aluminum ingots (smelting) • Tertiary Processing – Convert aluminum ingots into aluminum sheets • Finishing/Assembly – Convert aluminum sheets into aluminum cans • Filling/Distribution – Fill cans with beverage, transport to distributor/final consumers • ALL OF THESE STAGES use significant amounts of fossil fuel energy. MOST OF THESE STAGES generate large quantities of hazardous and toxic waste products Aluminum can, used once Steel can used once Recycled steel can Glass drink bottle used once Recycled aluminum can (65% less energy) Recycled glass drink bottle Refillable drink bottle, used 10 times 0 8 16 Energy (thousands of kilocalories) 24 32