Chapter 17 - McGraw Hill Higher Education - McGraw

advertisement

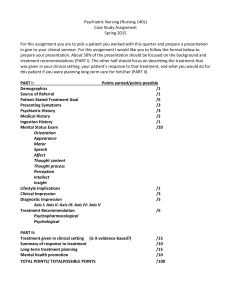

* © 2014 by McGraw-Hill Education. This is proprietary material solely for authorized instructor use. Not authorized for sale or distribution in any manner. This document may not be copied, scanned, duplicated, forwarded, distributed, or posted on a website, in whole or part. *You’ve come a long way! You understand manufacturing and machining, and are now totally ready to study CNC! * !!!! * * * Starting with Chapter 17, we begin the lessons on how to manage a programmed machine tool in a CNC world. * It’s a bigger job than just putting parts into the setup and hitting the green button—although that’s where you’ll probably begin your career: operating a CNC. * It’s about managing data, making setups, editing programs and solving problems when they arise! * In order to manage this level of responsibility we must study some underlying techno-facts. * We’ll first learn about the systems that make it work in Chapters 17 and 18. * While they may look like technical beasts when taken one aspect at a time, the whole subject is easy to learn. That’s the way we’ll proceed in Intro to CNC, the third part of Machining and CNC Technology. The subject is broken down into individual units of learning, easily digested, leading to competency! After completing Part III you’ll have the baseline knowledge and be ready to safely and confidently learn to setup and run your own CNC machine. * Like all other PowerPoint sets for this text, this presentation is not intended to teach the subject, but rather to show why the units are important using a sampling of what you’ll be learning. * Details have been omitted but will be explained in the textbook. * * 17.1 World Axis Standards 17.1.1 Primary linear axes – X,Y and Z 17.1.2 Primary rotary axes – A, B and C 17.1.3 Secondary Linear – U, V and W 17.1.4 Rules for determination 17.2 Coordinate Systems and Points 17.2.1 Absolute and incremental values 17.2.2 Four quadrants 17.2.3 Points for geometry and reference (A) Absolute (B) Incremental 17.2.4 Conventions in program commands 17.3 CNC Machine Motions 17.3.1 Axis moves (A) Rapid travel (B) Linear Interpolation 17.3.2 Axis combinations: 2½- and 3-D motion 17.4 Polar Coordinates 17.4.1 Absolute and incremental polar values 17.4.2 Positive and negative direction (C)Metric (C) Circular * There are 14 standard axes defined by the Electronics Industries Association (EIA) used for Unless it’s a multiplexed machine with several motion and position. auxiliary rotary and linear axes, these nine are * In this text we’ll study nine of them. adequate to define most of the equipment in 3 Primary industry today. Linear Axes X, Y and Z 3 Primary Rotary Axes A, B and C However, for tomorrow’s manufacturing world, Secondary Linear Axes U,V & W to that’s3another question. Machines continue evolve as central processors are able to handle more and more calculations per nanosecond, thus more functions simultaneously. * * Whenever you are assigned to a new CNC machine, the axis set must be identified as the first order of business. * Here are the sets for three common machines. * * It’s easy to identify the Z axis: it’s the spindle or it faces the spindle—it’s the drilling axis! * Then apply the Right Hand Rule by pointing your right middle finger in the positive Z direction. * Your fingers and thumb then form the orthogonal axis frame (mutually at 90º). * * *First identify the Z axis. It’s parallel to the spindle axis and brings the work toward and away from the spindle. *Pointing your middle finger in the positive Z direction, your index finger and thumb form the other positive axes. * *All CNC machines use the X-Z or X-Y-Z frame, with each axis mutually perpendicular to the others. The set (my fingers) * That relationship stays the same no matter remain in the same how the axis set is rotated to suit the orientation to each machine. other no matter their *Toward stronger or more efficient machines world orientation► manufacturers arrange the set any way convenient, but they don’t change the interrelationship between axes. * The X axis on many turning centers, is not parallel to the floor, itXslants forward. Slanted * That provides easy access to the turret for setup work, since the machine isn’t as wide as level X axis machines. Z * Plus chips and coolants slide 90º right off to the catch basin below. * This lathe’s world axis orientation is not level but it’s still an orthogonal set. Whenever a machine features a rotary axis, we identify it this way: * If it rotates around a line parallel to X it’s an A axis * Y it’s B Z it’s C * * Rotary axes capable of feed rates can move a cutter head in an arc during machining. * Or they can move the workpiece in an arc. * In this video we see A and B auxiliary axes moving simultaneously with X, Y and Z to cut this complex turbine blade ►. Only intelligent 5 axis CAM software can compile this program. * To determine the direction of rotary motion, either plus or minus A,B or C (clockwise or CCW), we use the Rule of Thumb. Y+ Z+ X+ Point the thumb of * It’s based on the line about which the rotary your right hand axis pivots, X, in Y or Z. the + direction of the axis of the rotation, X, Y or Z positive direction. Positive Cisdirection Bthis? WhatPositive motion A * * * CNC machines move and locate with reference to the axis origin. * TheyFor move to locations identified with coordinates. example, on this flat screen: * Co meaning working together. * Ordinate meaning a single line of position. X2.50, Y1.750 This point is identified with a set This is of ancoordinates ordinate – on thethis plane. Thissay linethis is parallel to the Yto Lets line is parallel point to be identified lies of axis lies 2.50 to right the Xand axis, and 1.750 above somewhere the X-Y origin. the X-Y originalong it. * When we want coordinates to refer to * In CNC work, the place where theitcoordinates Where All Begins theare PRZ putZ0,a code in the X0,we Y0, is known as program the Program G90Reference telling theZero control (PRZ)“this and all Youare may hear different terms for the others until changed absolute * It’s the starting point for coordinates PRZ: “program zero,” “program data values.” CAM programs are almost all * Most coordinates in the program refer their point,” distance from the PRZ. “the origin” (a math term) or absolute values. Theexample. tip of theothers, drill is depending on the region in * For at which you live. PRZ is the most commonly used, but they all X2.250, Y1.00, Z-1.00 mean the place where Relative to theX=0.0 PRZ which is on the top Y=0.0 corner on thisZ=You part. know * When moving across the origin line using absolute coordinates, the +/- values change depending on the quarter circle quadrant in which the point lies. * For example: * * Point A has positive X and Y values: X1.54, Y1.13 * Point C is X-1.54, Y-1.13 * What are the coordinates of Points B and D? * They are also called “relative” coordinates since they relate to the current location for * Occasionally we encounter the need for a different kind It’s asreference. though the current a their Incremental coordinates are position useful forishandof coordinate. mini-PRZ. if PRZ, I want arather millprograms spindle to small setup or but tooling * Theycompiling do not refer toSo the to their last position. written machinist go to by thetheleft, I write.at the machine. They * Incremental are jumps fromofwhere you are to are alsocoordinates used in a limited number where you wish to go we’ll next.study later. To use commands that G91 X 1.00 incremental coordinates in a program, the So when I push cycle start, it will then control must read a G91 code or be told in moveother fromway where it is are 1.0not inch to the some that they absolute. - left. * To go to a position either at rapid rate or at a feed rate, we use significant points on the part geometry to create program coordinates. * Trade Tip In Chapter 25, you will be drawing a part image using Mastercam, readying it for programming. Each line and arc on the drawing will be created by defining significant points. *Points occur at the ends of lines and arcs. *They also occur at the center of arcs and at tangent points where lines join arcs. * *CNC machines move their axes in five different Due to computer evolution with ways: ever-higher computation rates, Rapid Travel most new CNC controls today Linear Single or multi-axis straight-line motion canmotion perform 3-D motion. Circular withintrue a single plane Circular/Linear, also called 2½-D motion. Two axes move in an arc while the third moves in a straight line. 3-D motion Few older controls have the ability to move in an arc using three axes simultaneously. Most approximate these arcs through the power of the cam software. Trade Tip Caution! Depending on the power of the Rapid—as as CPU, yourfast machine the canof willmachine rapid in one move but withsure to two ways—be the abilitywhy to in the discover reduce speed text. Older through controllers take an operator unexpected route! override control. * * * The next four motions all move one or more axes at the machining rate specified in the program. * The differences lies in how many axes are involved—in a straight line or arc. * As motions become more complex, the CPU must handle far more calculations per second by interpolating each axes’ drive commands. * To move axes simultaneously, to produce a constant velocity along the line A-B, say at 400 inches per minute. * Neither the X or Y axis drive will be moving at 400 IPM. * They will run at lower speeds that combine to create the tool motion of 400 IPM. Interpolating means to find an intermediate value: in this case a feed rate value for each axis that combines to create the programmed rate. * * B 137.81 IPM Y Axis A 375.87 IPM, X Axis Motion * * The operator can override the resultant tool motion from 0% (no movement) up to 100% or 150% on some machines. * When the feed rate is changed by the machinist, the controller must change each drive proportionately to achieve the rate. * * For arc motion at feed rate, the controller is also interpolating, as with linear. * The difference is that it is constantly changing the ratio between the axes involved, as the curvature changes slants. * *Sometimes engineering information comes not in Trade Tip the form of rectangular dimensions, but rather as Using polar coordinates the radius and angle from aoften starting point. a trigonometry step defined during using polar *Thosesaves points are more easily drawing or bolt handcircle program coordinates—a for writing! example. *PolarIfcoordinates aren’t used inside the needed significant point is CAM-generated programs, they are veryrather useful for drawing the definedbut in radius-angle, than part X-Y, geometry doing hand program writing why dooranwhen unnecessary of polar entities.Define it with an R-A calculation? coordinate on your geometry drawing. * * While one could operate a machine without the knowledge of Chapter 17, remember that you are in training to become a full journeylevel machinist. * The goal is to be a manager of your CNC machine—more than an operator. * That requires complete oversight including CNC motions and how axis drives work, coming up in Chapter 18.