Pressuremeter Testin.. - My FIT - Florida Institute of Technology

advertisement

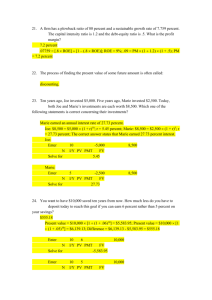

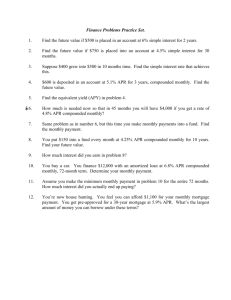

Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 I. Overview of In-situ testing: Advantages 1. larger samples tested 2. less disturbance 3. much faster than lab tests Disadvantages 1. can not control initial state of stress during testing (i.e. o’) 2. many times stresses induced during testing are horizontal while building loads are vertical 3. many times results are empirical Types (most common) pressuremeter (PMT) Monocell and Tricell Models cone penetrometer (CPT) Mechanical, Electrical and Piezocone Models dilatometer (DMT) vane shear (VST) standard penetration test (SPT) Hammers vary from donut to safety to automatic II. Pressuremeter (PMT) testing Introduction 1. developed in 1954 by Ménard at University of Illinois 2. insert long cylindrical balloon type device into soil and during inflation with water measure response of soil Theory and Data Reduction 1. during inflation long cylinder expands radially producing plain strain conditions 2. injected water volumes can be converted to volumetric strains or radial strains to produce a stress-strain plot that can be analyzed 3. typically elastic moduli (E), lift-off (or at-rest) (poh) and limit pressures (pL) are determined from plots Uses 1. lateral loads on foundations especially piles and drilled shafts (or piers) 2. empirical bearing capacity (i.e. ultimate soil capacity) predictions 1 3. empirical settlement predictions (have been shown to be more reliable than Terzaghi’s One-dimensional consolidation predictions) 4. elastic moduli for finite element programs, pavement designs, immediate settlement predictions Advantages 1. fast testing: field testing can be completed in 10-20 minutes 2. fast analysis: computerized data reduction (APMT) can be completed in a few minutes 3. large sample tested (10 to 18-inches length depending upon model used) 4. test simulates lateral loads on piles and piers 5. simple procedures available to determine settlement, bearing capacity, etc., 6. relatively simple testing procedure, especially with automation 7. equipment relatively inexpensive ($12,000 to $20,000); therefore costs can be recouped quickly 8. new FDOT procedures for pushing saves a SIGNIFICANT amount of time 9. new instrumentation software also save SIGNIFICANT time Disadvantages 1. test hole MUST be carefully prepared, if pre-bored 2. membrane failure causes ½ day delay 3. requires specialist to conduct test Overview of test procedure 1. Prepare borehole and lower probe to desired test depth (30 to 120 minutes) or 1. Hydraulically push cone or Pencel Pressuremeter to desired depth (5 to 10 minutes) 2. Inject equal volume increments of water; wait for system to stabilize and record corresponding pressures (5 or 60 cm3 depending upon model) 3. Test is complete once either 90 cm3 or 1200 cm3 is injected (depending upon model) 4. Apply three calibrations to raw data; one for inherent membrane resistance (i.e., resistance of balloon); a second for system or volumetric expansion (i.e. the tubing expands and membrane contracts) and a third for the test depth (i.e., hydrostatic pressure at test depth must be added to pressure read from control unit gage) 2 Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 III. Pressuremeter Models There are several PMT models currently available. They vary based on the length to diameter ratio and whether they are tri-cell or mono-cell probes. Ménard first developed a tri-cell probe as shown below. There are two outer cells, called guard cells, which are first expanded to ensure plain strain conditions during testing with a center cell. The center cell is expanded at predetermined pressure increments to complete the test. The disadvantages of the Ménard probe are that 1) a stress controlled test is conducted resulting in few data 2) the testing procedure is complex and 3) that a gas supply is required to conduct the test. Volume Measurement Pressure Gauge Gas Supply Gas Measuring Cell Guard Cells Gas Figure 1 Ménard pressuremeter 3 To simplify the testing procedure Briaud developed a mono-cell probe. This simplification yields a strain-controlled test producing more data points as about 20 equal volume increments of water are injected into the probe and the corresponding pressures are recorded. There are two mono-cell models currently available, the standard size PMT known as the TEXAM and the cone penetrometer size version, known as the PENCEL PMT. A schematic of a typical mono-cell PMT is shown below. As the actuator is turned a known volume of water is forced into the probe through nylon tubing and pressures are recorded from the pressure gage. For the TEXAM; 60 cm3 volume increments up to 1200 cm3 are injected while for the PENCEL; 5 cm3 increments are injected up to 90 cm3. Actuator Volume Indicator Piston Control Unit Pressure Gauge Cylinder Tubing Pressuremeter Figure 2 Schematic of Mono-Cell Pressuremeter Schematic of a mono-cell pressuremeter 4 Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 The smaller PENCEL PMT is depicted below (Figure 3). The diameter of the probe is 1.35inches which is nearly the same the diameter of the Cone Penetrometer (CPT). It allows this probe to be attached to cone rods and pushed into the soil. This feature allows a significant number of tests to be conducted quickly. A photograph of the internal components of the control unit is shown on the following page (Figure 4). It details the plumbing used to run the water from the cylinder to the probe. It also includes the latest digital instrumentation that enables operators to digitally acquire the reduced stress-strain data. The volume counter runs from 0 to 135 cm3 and the pressure gage typically included reads pressures up to 2500 kPa (about 310 psi). 5 Cylinder Digital Pressure Transducer Analogue Pressure Gage Linear Potentiometer Electronics’ Module Volume Counter and Crank Handle Assembly Figure 4 Internal components of PENCEL Pressuremeter Control Unit 6 Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 Limit Pressure pL 700 Elastic Phase Pressure (kPa) 600 Plastic Phase 500 Sr 400 Si 300 po 200 Elastic Reload Phase At-Rest Soil Pressure 100 Unloading 0 0 10 20 30 40 50 60 70 80 90 Volume (cm3) Figure 5 Typical reduced pressuremeter data with definitions of key portions A typical set of results is shown in Figure 5. This plot shows pressure versus volume of water injected into the probe. The initial slope and rebound slopes (Si and Sr) are used to determine elastic moduli. Often the initial modulus is related to the soil response for drilled shafts and the rebound slope is related to the soil response for driven piles. The unloading data can also be used to determine moduli over a variety of strains. This data could in turn be used to evaluate the soil responses in complex loadings that require finite element analyses. The data in Figure 5 indicates that after the soil reaches the existing at rest pressure of about 110 kPa, it displays a relatively linear response up to about 400 kPa and a nonlinear response typical of granular materials up to a limit pressure of about 650 kPa. To correctly estimate a limit pressure, Baguelin et al (1978) suggest that the data be extrapolated to twice the initial volume of the hole. This process requires two steps; a) the initial probe volume must be found based on the probe dimensions and b) the additional volume until the probe expands to the sides of the borehole (i.e. the At-Rest Soil Pressure point) should 7 be added to the volume from part a. This number s then doubled and the plot extrapolated to the estimated limit pressure. 8 Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 IV Applicable Pressuremeter Theories There are two key parameters that define any material, the stiffness and the strength. The stiffness is based on the elastic response of a material and for the pressuremeter test the soil response which is nonlinear must be evaluated. The basis for the pressuremeter theories is the assumption that the pressuremeter probe causes the soil to expand according to plane strain conditions. Plane strain typically occurs when one dimension is significantly very long compared to other dimensions (Holtz and Kovacs 1981). The pressuremeter probe is thus considered to be an infinitely long cylinder, expanding uniformly in the radial direction. This assumption allows the soil moduli to be determined based on linear elastic theory according to the equation: E 2 1 P V V m (1a) where, E = Young’s modulus P = change in stress V = change in volume related to P V m = average volume over P = Poisson's Ratio (typically assumed to be 0.3 for unsaturated conditions and 0.5 for saturated) The relative radius increase in probe radius can be substituted into Equation 1a, yielding the following equation used in analysis to determine moduli (Tucker and Briaud 1986): R 1 2 R 2 2 P E 1 1 1 2 2 R o R o R1 R 2 1 1 R o R o where, R 1 = radius increase at point 1 R 2 = radius increase at point 2 9 (1b) V. Bearing Capacity with the Pressuremeter Menard (1963a and 1963b) developed the basic bearing capacity equation using the net limit pressure (p*L) from PMT data. This pressure is defined as the difference between the limit pressure (pL) and the lift-off pressure (poh). The basic equation is: qL = k p*Le + qo with p*Le is the equivalent net limit pressure within the zone of influence of the footing which can be found as the nth root of the product of the individual net limit pressures in the zone to ± 1.5B above and below the footing depth or: p * Le p * L1 p * L 2 .... p * Ln qo is the overburden pressure in terms of total stress and k obtained from Figure 66 after Briaud (1986b) modification of the original charts shown in Figure 65. He in these charts is the embedment depth which can be found as: D 1 H e * pLi* zi pLe 0 with D being the embedment depth of the footing and p*Li being the net limit pressure in a zi thick layer. Figure 66 is for square or round footings. For strip footings k from Figure 66 should be divided by 1.2. See Briaud (1992) for additional information on inclined, eccentric and footings on slopes. 10 Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 11 VI. Settlement with the Pressuremeter Menard and Rousseau (1962) developed the basic settlement equation from PMT data. It is composed of two parts a deviatoric component and a spherical component. Several empirical factors are required to perform the calculations but the basic equation is: 2 B s qBo d qc B 9 Ed 9 Ec Bo (2) where: s = total footing settlement Ed = pressuremeter modulus within the deviatoric zone of influence Ec = pressuremeter modulus within the spherical zone of influence q= net bearing pressure of the footing d = shape factor for deviatoric term from the figure below d = shape factor for spherical term from the figure below =rheological factor from the Table 1 below Menard's Shape Factors for Settlement 2.5 2.25 d d Factor d, c 2 1.75 1.5 cc 1.25 1 0 1 2 3 4 5 6 7 8 9 10 Length/Width Figure 6 Variation in Menards shape factors versus footing dimensions To perform the calculations, divide the soil layers beneath the footing into layers B/2 thick. Us the PMT modulus within the first layer for Ec and an average 12 Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 modulus over a depth of 16 layers each B/2 thick for Ed. Briaud (1992) recommends a harmonic mean calculation for this deviatoric modulus. Soil Type Peat E/pL* Overconsolidated Normally Consolidated Weathered and/or Remolded Rock 1 Highly Fractured Clay E/pL* E/pL* Sand E/pL* > 16 1 > 14 2/3 > 12 1/2 > 10 1/3 9-16 2/3 8-14 1/2 7-12 1/3 6-10 1/4 7-9 1/2 1/3 Silt 1/2 Other 1/2 1/3 Slightly Fractured or Extremely Weathered Table 1Menard Rheological Factor 13 Sand & Gravel E/pL* 1/4 2/3 VII. Applications for Laterally Loaded Piles The Robertson et al, Pushed in PMT Method (1986) Robertson et al. (1986) suggested a method that uses the results of pushed-in PMT to evaluate p-y curves of a driven pile. According to the authors, the results provide an excellent comparison with lateral loaded pile test measurements. The pressure component of the PMT curve is multiplied by an α-factor to obtain the corrected p-y curve. Using finite element analysis Byrne and Atukorala (1983) confirmed this factor, which was initially suggested by Hughes et al. (1979), Robertson et al. (1986) corrected the factor α near the surface assuming that the PMT response is affected by the lower vertical stress. The factor increases linearly up to a critical depth, which is assumed to be four pile diameter (Dc = 4) Multiplying Factor a Relative Depth X/Bpile 0 0.5 1.0 1.5 2.0 Cohesive Soils (clay) 1 Cohesionless Soils (sand) 4 6 8 as shown in Figure 6. Figure 7 Correction Factor “α” versus Relative Depth (From Robertson et al,. 1986) To obtain the p-y curve, the PMT curve is re-zeroed to the lift-off pressure that is assumed to be equivalent to the initial lateral stress around the pile. The stress is R multiplied by the pile width and the strain component is multiplied by the R R V pile half width. For a small strain condition is assumed equal to R 2V where R and V are radius and volume of the PMT respectively. Since the installation of the pushed in PMT produces an initial pressure on the probe, an unload/reload sequence is often used. The portion of the corrected 14 Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 PMT curve from the beginning of reload through the maximum volume is recommended for determining p-y curves of driven piles, while the initial slope from the PMT tests is recommended for constructing p-y curves for augured piles. The following equations outline the process for driven piles: a) Determine the initial radius of the probe: Initial Circumfere nce of Probe 2 b) Calculate the initial volume of the probe (Vo): R0 (2) (3) V 0 * RP * Length of Membrane c) Determine P in units of force / length: First a correction factor, , is applied to P according to Figure 6, where the relative depth is the depth from the ground surface to the center of the z membrane. Note that for ppmt 4 for sands and for clays and if Bpile z ppmt 4 then can be found as follows: Bpile 1.5 * z ppmt for sands (4) 4 * Bpile 2 0.67 Then 2 * z ppmt 4 * Bpile (5) for clays P (Corr. Pressure from PMT) * ( Bpile ) * ( ) (6) where: Bpile = pile diameter or width. d) Determine y in units of length according to the following equation: y (Corr. Volume from PMT) Bpile * 2 * V0 2 (7) The Briaud et al, Method (1992) Briaud et al (1992) recommended that the p-y curves be constructed from the addition of the front and side resistance components along the pile. The total soil resistance P as a function of lateral movement y of the pile, is given by the equation: P =F+Q (8) where F = friction resistance 15 Q = front resistance Briaud suggested for the full displacement driven piles, that the reload portion of the PMT curves be used. Graphically, the p-y curve is shown as the addition of the F-y curve and the Q-y curve in Figure 7. Friction shear F P=Q+F Front Resistance p P PILE F Q F Q Pressure Q y (a) (b) (c) (d) Figure 8 Front and side resistance components for P-y curve construction Smith (1983) showed excellent correlations between the pressures obtained from the PMT response and those acting on the pile. The front pressure contribution, Q, is found from the net limit pressure pL* determined as: p L * p L p0 (9) where; pL is the limit pressure and p0 is the horizontal stress at rest pressure obtained from the PMT curve. The frontal resistance, Q is obtained by choosing pressure points from the reduced PMT plot and using the equation: Q( front) p ( pmt ) B( pile) S ( Q ) (10) The side friction, F(side), of the pile is taken as a constant with depth and is given by the equation: F( side) ( soil) B( pile) S ( F ) (11) To obtain the associated lateral pile deflections, choose PMT deflections and apply the following equation. The deflections must be less than those obtained from the PMT test and would equate to the change in radii obtained during expansion. R( pile) y ( pile) y ( pmt ) (12) R0 ( pmt ) Where: Q(front) = soil resistance due to front reaction with unit of force /unit length of pile F(side) = soil resistance due to friction resistance with unit of force /unit length of pile p(pmt) = pL* = net pressuremeter pressure B(pile) = pile width or diameter τ(soil) = maximum soil shear stress-strain at the soil-pile interface 16 Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 S(Q) = shape factor ( = 0.8 or π/4 for circular piles, 1.0 for square piles) S(F) = shape factor ( = 1.0 for circular piles, 2.0 for square piles) y(pile) = lateral deflection of the pile y(pmt) = increase in radius of the soil cavity in the PMT test or radial displacement. R(pile) = pile half-width or radius R0(pmt) = R0 = initial radius of the soil cavity in PMT test This method does rely on an accurate estimate of the shear strength, which could be found from other field-testing performed during the site investigation. The displacement of soil around the laterally loaded pile is also influenced by the ground surface. A reduction in the corrected PMT pressures is recommended for values near the ground surface. A critical depth (Dc), to which pressures and displacements are influenced, depends on the pile load, diameter and stiffness. Briaud suggested using a relative rigidity factor, RR, given by: 1 EI 4 (13) RR B( pile) p L * EI = pile flexural stiffness (E= pile modulus, I = pile moment of inertia) B( pile) = pile diameter or width pL* = net PMT limit pressure Briaud et al. (1992) relationship results in relative rigidities slightly greater than 10 for most laterally loaded piles in soft clays and the resulting critical depth will be near 4, therefore Robertson’s value of 4 is recommended. The critical depths for the PMT as recommended by (Baguelin et al., 1978) are 15 PMT diameters for cohesive soils, and 30 PMT diameters for cohesionless soils. The Briaud et al. (1992) suggested reduction factor is shown in Figure 8 as a function of relative depth (z/zc). The PMT curve is then corrected by using: p (14) pcorr 17 Reduction Factor 0.2 0.2 Cohesionless Relative depth z/zc 0 0.4 0.4 0.6 0.8 1.0 Cohesive 0.6 Cohesive soil zc = 15 ¯ pmt 0.8 Cohesionless soil zc = 30 ¯ pmt ¯ pmt = Pressuremeter Diameter 1.0 Figure 9 Briaud’s recommended PMT pressure reduction factor for values near the ground surface 18 Pressuremeter Testing Paul J. Cosentino, Ph.D., P.E. 3/23/2016 VII. References 1. Cosentino, Paul J., Edward Kalajian, Ryan Stansifer, ,J Brian Anderson, Kishore Kattamuri, Graduate Research Assistant, Sunil Sundaram, Graduate Research Assistant, Farid Messaoud, Thaddeus J. Misilo, Marcus A Cottingham (2006) Final Report, Standardizing the Pressuremeter Test for Determining p-y Curves for Laterally Loaded Piles, Florida Institute of Technology, Civil Engineering Department, Florida Department of Transportation, Contract Number BC-819. 2. Briaud, J.L., 1997. “Simple Approach for Lateral Loads on Piles”. Journal of Geotechnical and Geoenvironmental Engineering, ASCE, Vol. 123, No. 10 pp. 958-964. 3. Robertson, P. K., Campanella, R. G., Brown, P. T., Grof, I., and Hughes, J. M., (1985). “Design of Axially and Laterally Loaded Piles Using In Situ Tests : A Case History”, Canadian Geotechnical Journal, Vol. 22, No. 4, pp.518-527. 4. Robertson, P.K., Davis, M.P., Campanella, R.G.. (1989). “Design of Laterally Loaded Driven Piles Using the Flat Dilatometer”, ASTM Geotechnical Testing Journal, Vol.12, No. 1, pp30-38. 5. Robertson, P.K., Hughes, J.M.O., Campanella, R.G., and Sy, A., 1983. “Design of Laterally Loaded Displacement Piles Using a Driven Pressuremeter”. ASTM STP 835, Design and Performance of Laterally Loaded Piles and Piles Groups, Kansas City, Mo. 6. Robertson, P.K., Hughes, J.M.O., Campanella, R.G., Brown, P., and McKeown, S., 1986. “Design of Laterally Loaded Displacement Piles Using the Pressuremeter”. ASTM STP 950, pp. 443-457. 7. Robertson, P.K., and Hughes, J.M.O., 1985. “Determination of Properties of Sand from Self-Boring Pressuremeter Tests”. The Pressuremeter and Its Marine Applications, Second International Symposium. 8. Briaud, J-L., 1992, The Pressuremeter, ISBN 90 6191 125 7 9. Menard, L., 1963a, Calcul de la Force Portante des Foundations sur la Base des Resultats des Essais Pressuometriques, Sols-Soils, Vol 2, Nos 5 and 6 June. 10. Menard, L., 1963b, Calcul de la Force Portante des Foundations sur la Base des Resultats des Essais Pressuometriques, Seconde Partie, Expementaux et Conclusions Sols-Soils No. 6 September. 19 Homework Questions: Part I Pressuremeter Testing 1. What is the required Length to Diameter ratio needed to produce plain strain responses in soils? 2. How many cubic centimeters of water are injected into the TEXAM PMT probe during each loading increment? 3. Using the data shown in Figure 5 determine the following: a. Lift-Off Pressure b. Initial Elastic Modulus c. Elastic Reload Modulus d. Limit Pressure 20