Alliances.Intro.Preez.Nov1.01

advertisement

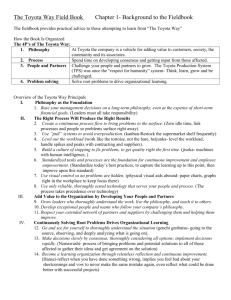

Copyright Jeff Dyer, 2001 U.S. MANUFACTURER COST STRUCTURE 55% Percent of Sales 8% 3% Purchased Goods* Copyright Jeff Dyer, 2001 Labor Overhead * This figure is 15-20 percent for service businesses Source: Fortune, Feb. 20, 1995, p. 75. OUTSOURCING IS INCREASING AUTOMOTIVE 100% 62% 64% 67% Purchased Goods as a % of COGS 0% 1975 1985 1995 COMPUTERS 100% 44% 48% 58% Purchased Goods as a % of Sales 0% Source: Cusumano 1985; Dyer 1996 Copyright Jeff Dyer, 2001 1985 1990 1995 Copyright Jeff Dyer, 2001 Future Competition: Network Versus Network GM S1 S2 Toyota S3 S4 S5 Future competition pits teams of companies against teams of companies. The extended enterprise that best achieves virtual integration will win. *S=Supplier Copyright Jeff Dyer, 2001 S6 WORLD CLASS COMPANIES HAVE A “LEAN” VALUE CHAIN THE VALUE CHAIN Supplier Raw Tool/ Component/ MRO Assembly Material Equipment Sub-Assbly. Distributor of Supplier Plant Supplier Supplier Services Supplier “LEAN” VALUE CHAIN • Low total systems costs (transaction costs, logistics, quality, product development) • Fast to market • High quality • New technology/Features • Responsive to market changes Copyright Jeff Dyer, 2001 DELIGHTED CUSTOMER SOME LEADING COMPANIES IN DEVELOPING VERTICAL ALLIANCES • • • • • Copyright Jeff Dyer, 2001 Toyota Corporation Bose Corporation Bain & Company American Express P&G/Wal-Mart Automaker Profitability (Average from 1982-1998) Pretax Return on Assets* 12% 10% 9.6% 8% 6.4% 6% 4.4% 4% 3.2% 2.8% 2% 0% Toyota Chrysler (Source: Annual reports, Daiwa Analysts Guide) * Pretax automotive income divided by automotive assets. Copyright Jeff Dyer, 2001 Ford Nissan General Motors Governance Profile (Toyota vs. GM and Ford) Percent of Total Component Costs Arm’s-length Suppliers Arms-length (Independent) Suppliers 35% 25% Partner Suppliers* Partner Suppliers+ 48% 10% Internally Manufactured Internally Manufactured 55% 27% * 2 or less suppliers for a product category + Kankei kaisha Copyright Jeff Dyer, 2001 General Motors and Ford Toyota Identifying Strategic Partners • High value inputs/services; suppliers with ability to influence your costs. • Inputs that can differentiate your product • Inputs that demand coordination to achieve desired fit/quality/performance • Inputs with “interaction effects” with other inputs; influence quality & speed to mkt. • Inputs that may be scarce Copyright Jeff Dyer, 2001 Three Key Sources of Inter-organizational Competitive Advantage Dedicated Asset Investments Knowledge -Sharing Routines Inter-firm Trust Copyright Jeff Dyer, 2001 Copyright Jeff Dyer, 2001 The Value of a Network Increases as Membership & Knowledge-Sharing Increases Single Firm Connections: Directions: 0 0 3-Firm Network 3 6 6-Firm Network 15 30 As the number of nodes in a network increases arithmetically, the value of the network increases exponentially (n2 growth). Small improvement efforts that ripple through the network can dramatically increase the value for all members. Copyright Jeff Dyer, 2001 900 700 Source: Adapted from M. Lieberman, 1994. “The diffusion of ‘lean manufacturing’ in the Japanese and U.S. automotive industry.” ‘Revolutionary Change’ Conference, Shizuoka, Japan. Copyright Jeff Dyer, 2001 19 92 19 90 19 88 19 86 19 84 19 82 19 80 19 78 19 76 19 74 19 70 19 72 Toyota Assemblers Suppliers 500 300 100 19 68 Growth in Annual Value-Added per Employee (Index = 100 Japanese Automotive Labor Productivity (1968-1992) Suppliers Learn Faster in Toyota’s Network GM A1 Toyota A2 A3 J1 U.S. suppliers improve their performance at a faster rate after joining Toyota’s knowledge sharing network. Copyright Jeff Dyer, 2001 J2 SUPPLIER QUALITY PERFORMANCE OVER TIME (For Toyota versus the Supplier’s largest U.S. Customer) 1500 Quality (Defects) 1250 1000 (852) Defects 750 (848) (parts per million) (798) (789) (603) (485) 500 (421) U.S. OEM 250 (208) 0 1990 Copyright Jeff Dyer, 2001 1992 1994 1996 Toyota SUPPLIER COST PERFORMANCE OVER TIME (For Toyota versus the Supplier’s largest U.S. Customer) Labor Productivity 400 (326) 300 Sale s pe r dire ct e mploye e (in thousands) 200 (331) Toyota (304) (273) (280) (301) (243) (295) U.S. OEM 100 0 1990 92 8 Inventories as a percent 4 of sales 96 Inventory to Sales (6.6%) 6 94 (6.2%) (6.2%) (6.0%) (6.1%) (4.7%) (5.9%) U.S. OEM (4.3%) Toyota 2 0 1990 Copyright Jeff Dyer, 2001 92 94 96 KNOWLEDGE SHARING IN THE TOYOTA GROUP Toyota Supplier Association • Meet monthly to share widely applicable best practices (cost, quality, safety, mgmt.) Copyright Jeff Dyer, 2001 Consulting Divisions (On-site Assistance) Quality Workshops Toyota Production System Workshops Jishuken Activities (Supplier Teams) • Rotate to each supplier’s plant for 1-2 months to assist with improvements (suppliers consult to each Logistic Workshops other) Organization of Toyota’s Supplier Association Frequency Divisional Meeting 1 Once/annum General Assembly Twice/annum Top Management Meeting 6 Times/annum Executive Meeting Divisional Meeting 2 Divisional Meeting 3 Frequency: once/month Agenda: - Information gathering from Toyota Motor Corp. - Plans and policies - Research activities Copyright Jeff Dyer, 2001 Quality Costing Committee Committee Safety/ General PR-Sports Health Affairs Committee Committee Committee Frequency: once/month Agenda: - Information sharing - Training - Know-how /best practice sharing Toyota’s Consulting Divisions • Toyota’s Operations Management Consulting Division (OMCD) in Japan has 55-60 consultants. These are the “gurus” of the Toyota Production System. • On average, suppliers receive 12 days of visits per year. • Toyota has replicated the concept in the U.S. with its Toyota Supplier Support Center (TSSC). • TSSC has 20 consultants and has achieved impressive results, having achieved an average of 124 percent labor productivity improvement and 75 percent inventory reductions (see next slide). Copyright Jeff Dyer, 2001 Toyota Supplier Support Center Project Results (31 Suppliers) % 500 PRODUCTIVITY INCREASE (Output per labor hour) 450 450 400 400 350 313 300 290 300 250 250 200 Percent Change 200 150 124 115 100 75 100 83 60 50 25 70 53 41 97 100 100 75 67 50 32 20 100 68 35 30 52 50 14 0 Supplier: A B C D E F G H I J K L M N O P Q R S T U V W X Y Z AA BB CC DD EE Avg. 0 10 20 40 50 60 50 50 50 55 60 70 80 75 83 100 96 98 96 120 % (Source: TSSC, November 1997) Copyright Jeff Dyer, 2001 90 80 85 86 97 75 81 95 80 79 89 INVENTORY REDUCTION (Inventory as a percent of sales) 75 75 80 93 55 87 83 75 Toyota’s Supplier “Study Teams” (Jishuken) Toyota • Each group consists of 6-12 suppliers. Direct competitors are not in the same group. Group composition changes every 3 years to keep groups “fresh.” • Each group meets with Toyota (OMCD) to decide the theme for the year. • The group visits each supplier’s plant over a 4-month period, examining the processes and offering suggestions for improvement. • Toyota organizes an annual meeting where each group presents the key learnings from the year's activities. Copyright Jeff Dyer, 2001 The Value of Supplier Learning Teams “ We get blinded just like everyone else. When you bring a whole new set of eyes into your plant you learn a lot. We’ve made quite a few improvements. In fact, after the (PDA) core group visits to our plant, we made more than 70 changes to the manufacturing cell.” - U.S. Supplier Plant Manager Copyright Jeff Dyer, 2001 Price of Entry: Little Proprietary Production Knowledge “That’s one of our requirements because if we take the time and effort to transfer the know-how, we need to be able to use the suppliers’ operations as a vehicle to help other suppliers.” -Lesa Nichols, TSSC consultant “They gave us a gift [TPS]; how can we not open our plant and share what we’ve learned with other Toyota suppliers.” -U.S. supplier plant manager Copyright Jeff Dyer, 2001 Knowledge Appropriation Rules “The fact that through BAMA we have made process improvements that saved us money and Toyota did not go after those savings speaks volumes.” - U.S. supplier plant manager “We don’t want to have a PICOS team poking around our plant. They will just find the “low hanging fruit”--the stuff that’s relatively easy to see and fix. We all have things in our plants that we know need to be fixed. They’ll just come in, see it, and ask for a price decrease. We’d prefer to find it ourselves and keep the savings.” - U.S. supplier plant manager Copyright Jeff Dyer, 2001 Barriers to Intra-Plant Knowledge Transfers • Network (Customer) Constraints – Customer policies or practices may prevent implementing new processes. Knowledge transfers often require customer approval and significant downtime to reconfigure the mfg. operations. • Internal Process Rigidities – Physical plant constraints; processes involve large capital investments in heavy equipment/machines (e.g., stamping, injection molding) which are bolted to floor, set into concrete, hardwired to utilities, trenching in floor. Cost (and time) to rearrange is high. Copyright Jeff Dyer, 2001 COLLECTIVE LEARNING IN TOYOTA’S NETWORK Leader/Orchestrator of Network-level KnowledgeSharing Processes Organizational Unit that Acquires, Stores, and Diffuses Network Knowledge Strong Norms of Reciprocity Optimal Size Learning Groups for Sharing for Sharing both Explicit & Tacit Knowledge Geographic Proximity and Location-Specific Learning Incentives/Rewards for Contributors of Knowledge Copyright Jeff Dyer, 2001 THE CHRYSLER EXTENDED ENTERPRISE Definition: A unified group of suppliers and supply tiers who strive together to maximize the effectiveness of vehicle development and minimize total system costs in order to maximize the value passed on to a common ultimate customer. Copyright Jeff Dyer, 2001 CHRYSLER’S SCORE PROGRAM • Supplier COst Reduction Effort (SCORE) program designed to create incentives and rewards for supplier initiatives that benefit Chrysler’s Extended Enterprise • Suppliers maintain or improve margins. Supplier shares at least 50 percent of value with Chrysler. Chrysler does not audit. • Chrysler gives SCORE targets/objectives and carefully tracks results • Chrysler recognizes and rewards top SCORE performers. Copyright Jeff Dyer, 2001 SCORE ENABLERS • • • • • Materials substitution Product substitution Product standardization Product redesign Process redesign Copyright Jeff Dyer, 2001 • Weight Reduction ($1 per pound) • Complexity Reduction ($20,000/part eliminated) • Optimization of mfg. location • New technologies CHRYSLER’S SCORE RESULTS $2,500 $2,092 Millions of Dollars $2,000 $1,500 $1,213 $1,007 $1,000 $500 $762 $504 $269 $0 1993 1994 Source: Chrysler Procurement & Supply Copyright Jeff Dyer, 2001 1995 1996 1997 1998 Chrysler’s Profit Per Vehicle (vs. Ford and GM) 2500 Dollar Profit Per Unit 2000 1500 1000 500 0 C F G C F G C F G C F G C F G C F G C F G 1990 1992 1993 1994 1995 1996 C F G C F G -500 -1000 1988 Chrysler (Source: Chilton’s Automotive Industries, April issue, 1988-1998) Copyright Jeff Dyer, 2001 1997 Ford 1998 GM