Protein Foods

advertisement

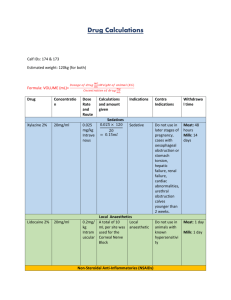

Food Biotechnology Dr. Kamal E. M. Elkahlout Food Biochemistry 4 Protein Foods Eggs • A hen requires 24-26 hours to produce an egg. Thirty minutes later she starts all over again. • If an egg is accidentally dropped on the floor, sprinkle it heavily with salt for easy clean up. • Egg yolks are one of the few foods that naturally contain vitamin D. • Yolk color depends on the diet of the hen. Natural yellow orange – Substances such as marigold petals may be added to light-colored feeds to enhance colors. Egg Functions 1. Flavor, color, nutrition 2. Emulsifying agent 3. Aids in thickening/structure 4. Binding/coating agent 5. Leavening agent 6. Interfering substance Composition & Nutritional Value 1. One medium egg contains between 4-5 grams of fat 2. High cholesterol • ~200 mg/egg 3. High in Complete Protein 4. Little to no CHO 5. High in vitamins & minerals • Vitamins A,D,E,K, some B vitamins, selenium, iodine, zinc, iron, copper Cross Section of an Egg SHELL • The first line of defence against the entry of bacteria can be brown or white; nutritional value of the egg is the same • Composed mainly of calcium carbonate • Approximately 8,000 to 10,000 tiny pores allow moisture and gases in (O2) and out (CO2) SHELL MEMBRANES • There are two membranes on the inside of the shell One membrane sticks to the shell and one surrounds the white (albumen) • The second line of defense against bacteria • Composed of thin layers of protein fibres GERMINAL DISC • Appears as a slight depression on the surface of the yolk • The entry for the fertilization of the egg WHITE (ALBUMEN) • Two layers: thin and thick albumen • Mostly made of water, high quality protein and some minerals • Represents 2/3 of the egg's weight (without shell) • when a fresh egg is broken, the thick albumen stands up firmly around the yolk CHALAZA • A pair of spiral bands that anchor the yolk in the centre of the thick albumen YOLK MEMBRANE (VITELLINE MEMBRANE) • surrounds and holds the yolk • the fresher the egg the stronger the membrane YOLK • the egg's major source of vitamins and minerals, including protein and essential fatty acids • represents 1/3 of the egg's weight (without shell) • yolk colour ranges from light yellow to deep orange, depending on the Xanthophyll content of the ration fed to the hen. AIR CELL • forms at the wide end of the egg as it cools after being laid • the fresher the egg the smaller the air cell Characteristics of Fresh/High Quality Eggs • Yolk is high & firm above the white • Small yolk diameter • Yolk is centered in white • High ratio of thick to thin white • High standing thick white Which is the Highest Quality Egg Deterioration Changes in Eggs • Enlargement of air cell due to loss of moisture spoils the appearance of an egg cooked in the shell. • Quality – loss of CO2 ,permits the egg white to become more alkaline • PH of egg white may increase from about 7.6 (freshly laid) to 9.0 -9.7 in few days. • The white becomes thin and spreads when broken • White eventually becomes yellow and even cloudy. • The yolk flatens. • The thinner white is no longer able to keep the yolk in the centre . Egg Candling Measures quality or freshness without breaking Characteristics of older, low quality eggs: • Larger air cell • Yolk off center • Speckled appearance Sizes • U.S. sizes are defined by the weight of a dozen eggs. (Not individual eggs. An egg in a carton of Extra Large eggs need not weigh at least 27/12 ounces, but the dozen must weigh at least 27 ounces.) • Most recipes that call for eggs usually mean Large eggs. Size Weight of a dozen eggs Jumbo 30 ounces Extra Large 27 ounces Large 24 ounces Medium 21 ounces Small 18 ounces Peewee 15 ounces Preparation of Eggs Dry Heat – Fried – Scrambled – omelets Moist heat – “Boiled” eggs – Coddled eggs prepared in a cup – Poached eggs – A variety of custards – Eggs that are prepared using the microwave Effects of heat on Eggs protein Eggs are useful in binding, thickening and gelling agents because they contain proteins that are denatured by heat leading to : – Coagulation – Gelation Egg white • changes from a viscous ,transparent sol to an opaque ,elastic solid . Egg yolk • increases in thickness as it is heated becoming either a pasty or mealy solid depending on heat Coagulation Temperature White begins near 60°C yolk begins near 65°C Coagulation temperature is influenced by pH of the dispersion Presence of salts How fast the temperature rises Foam Formation • Foams are used as angel food, sponge cakes, meringues,etc • When the bubbles of air are incorporated in egg white (colloidal dispersion of protein in water) with a wire whip or the blades of a beater, individual proteins contribute aspects of its film – forming potential. • The presence of hydrophobic groups with an affinity for air and hydrophilic groups that are soluble in water are essential in lowering surface tension which enable the incorporation of air possible and denaturation of surface protein molecules by heat alter the native conformation and thus stabilize the foam. Volume & Stability Factors Sugar – increases stability – delays foam formation – added at foamy or soft peak stage Acid – increases stability – doesn’t delay foam formation Fat – decreases foam Formation Temperature – room temperature Utensils used size of the bowl, type of beater the finer the wire the thinner the blade, the smaller the cells and the finer the foam. Problems with cooking Eggs • Boiled egg if overcooked a green ring is formed around egg yolk due to the presence of iron and sulfur. • Can also happen if there is too much iron in cooking water.-chill egg in cold water • Cooking leads to the oxidation of cholesterolincreases risk of heart disease Health issues • Eggs have cholesterol-increases risk of heart diseases • Contamination by salmonella a pathogenic bacteria-hence commercially eggs should be washed with a sanitizing solution after being laid • Cook eggs to kill pathogenic bacteria • Food allergy esp in infants due to egg albumin hence introduction of egg white to infants is not recommended • Raw egg whites contain a protein called conalbumin that binds iron as well as avidin that binds biotin &can impair function of other B vitamins Milk and Milk Products Milk Milk should contain 8.25% milk-solid-not-fat 3.25% milk fat Milk is ... a true solution for salts, lactose, water-soluble vitamins milk is a colloidal dispersion for proteins and some Ca phosphate a dilute emulsion for fat globules Milk • pH of milk: 6.6 at 25oC – when heated, pH decreases, H+ are liberated when Ca phosphate precipitates • Freezing Point: slightly lower than water • Lower surface tension than water due to presence of milk fat, protein, free fatty acids, & phospholipids: easy to foam • Components of milk varies with the feed, breed, nutrition & the physiological condition of the cow Nutritional Components of Milk • • • • Water: 87%, aw = 0.993 Proteins: caseins, whey proteins, enzymes Lipids: mainly triglycerides Carbohydrates: mainly lactose, also glucose, galactose, & other saccharides • Salts (<1%), • Vitamins Milk Proteins - Caseins • Phosphoproteins, account for 80% of total milk proteins • Easily precipitated by adding acid to pH 5.24.6 Milk Proteins - Caseins • Acid precipitates caseins • Rennin casein: enzyme rennin coagulates caseins • Caseinates: salts of caseins, highly soluble, used as emulsifier, binder, thickening, foaming & gelling Milk Proteins - Whey proteins • Not precipitated by acid, but easily denatured by heat (>60C) • Four Fractions: – lactoglobulins (50%), – lactalbumins (25%), – serum albumin – immunoglobulins • rich in sulfur-containing amino acids Milk Proteins Whey proteins • Use of whey protein products: – Dried Whey: puddings, cakes, baked products – Whey protein concentrates: binder in sausage (up to 3.5%) – Ultra Filtered Skim Milk : coffee whiteners – Cheese Whey: animal feed Milk Proteins - Enzymes • Most of the enzymes are inactivated by pasteurization • alkaline phosphatase is an index of adequacy of pasteurization (phosphatase test) • Lipase may cause hydrolytic rancidity in dairy products if it is not deactivated Milk Lipids • Triglycerides = 98% of total milk lipids • Other lipids: phospholipids, free fatty acids, sterols, carotenoids, fat-soluble vitamins • Distinctive dairy flavor due to short-chain saturated fatty acids (C4-C10) : butyric (C4:0), caproic (C6:0), caprylic (C8:0), capric acids (C10:0) • Fat content in milk decreases as cow ages • Fat in feed does not appreciably affect fat content of the milk Milk Carbohydrates • Mainly lactose (4.8%), small amount glucose • Lactose is the source of lactic acid, formed by bacteria as milk sours • As milk is coagulated, lactose is in the whey • Problems associated with lactose – lactose intolerance – crystals from condensed milk or ice cream – lumping and caking of dried milk during storage Milk Carbohydrates • Use of lactose – browning – dispersing agent – topping & icing – carrier for flavor – color ingredients – body & viscosity Vitamins • Riboflavin – water-soluble, light sensitive – light yellowish & greenish color • Carotene – fat-soluble, yellowish color of milkfat – skim milk is fortified with retinyl palmitate to replace the carotene in milk fat • Milk also provides thiamine & niacin • Vitamin D is added to almost all milk Minerals • Rich in Ca and P • trace elements: Fe, Mg, Mo, Ni, Zn Pasteurization of milk • Heating milk at a definite temp for a definite time to destroy pathogens but not all bacteria – 62oC for 30 min – 70oC for 15 sec to 100oC for 0.01 sec (HTST) – 138oC for 2 sec (UHT) • to inactivate enzymes (lipase), control rancid & oxidized flavor, and increase shelf life Pasteurization of milk Fermentation of Milk All fermented milk contains lactic acid Undesirable (spoiled products) Desirable (buttermilk, yogurt, cheese) streptococcus lactis initiates the process with lactobacilli spp. continuing the fermentation Increased thickness due to the association of casein micelles, often accompanied by ß-lactoglobulin. Homogenization of Milk • Forces milk through small openings and break up the fat globules. • The fat globule membrane is disrupted as new surfaces are created • Homogenized milk is whiter in color, more viscous, more bland in flavor, and foam easily. • Less heat stable (curdle more readily), form softer curd Kinds of milk • Homogenization – the process of making a stable emulsion of milk fat and milk serum by mechanical treatment and rendering the mixture. Homogenized milk has a creamier structure, bland flavor and a whiter appearance • Drying of Milk • Dry milk products – whole dry milk powder (WDM) – nonfat dry milk (NFDM) – dry butter milk – dried whey – dry cream – malted milk powder Evaporation & Canning of Milk • Evaporated milk – sterilized canned milk that has been concentrated to about half its original volume by evaporation under a partial vacuum. – 25% total milk solids including >7.5% milk fat – high temp canning may give cooked flavor (methyl sulfide) – storage at high temp for long time may develop offcolor (Maillard reaction) Evaporation & Canning of Milk • Sweetened condensed milk – 15% sugar is added after concentration of whole milk through evaporation – total CHO concentrations of approx. 56% which is sufficient to prevent spoilage by microorganisms Milk Foams • Milk can form gas-in-liquid foams because the milk proteins have – low surface tension - easier to spread the liquid proteins into thin films – low vapor pressure - reduces the evaporation • In fluid milk, the protein concentration is too low to produce a foam with any stability • Foams can be formed in evaporated milk or dried milk solids. Effect of Heat on Milk Products • Scorching – Some of the whey proteins (-lactoglobulin and lactalbumin) denature and ppt to form a thin layer of protein on the bottom. – This protein gradually undergos the Maillard reaction with lactose, leading to scorching. • Scum formation – denatured protein molecules join together – evaporation of water from the surface (increasing the concentration of casein and salts) Effect of Heat on Milk Products • Casien is quite resistant to ppt when heat is applied, but severe heating can cause it to form a curd at pH 7. MEAT & POULTRY • Meat is the flesh of animals Composition • Water content-Appro.75% • About 15-20% protein mainly high quality • Fat content ranges from 5-30%-varies with the type of animal with the breed, feed and age, pigs convert high % of their feed to fatty tissue • Minerals eg Ca in bones, lean muscle rich in Fe and P.Liver excellent source of Fe and Vit.A • Vitamins-excellent source of niacin and riboflavin. Pork rich in thiamin. meat is deficient in vit.C. Structure of meat • Cut meat consists of lean tissue which is mainly protein with some bone and fatty tissue. • lean meat consists of one or more muscle fibers that is the basic structural unit of meat. • Connective tissue provides support for the muscle fibres, fat and bones of meat. • Fat is deposited in the connective tissue within the muscle and is known as marbling. Color of meat • Fresh meat-color differences in color is due to the content of myoglobin concentration in meat (75%) remainder is due to haemoglobin(25%) • beef has more myoglobin. Exercised muscles tend to be deeper red eg heel of hound • Sometimes there is color change in meat-due to change in the pigment myoglobin • Molecules of myoglobin contain the iron porphyrin as shown: • Resonance of the conjugated double bonds in the porphyrin ring gives rise to the color of meat pigments. • Myglobin like haemoglobin can unite temporarily & reversibly with oxygen • In live animal, the myoglobin takes O2 from haemoglobin.When the animal dies, O2 supply is cut off. Hence unoxygenated myoglobin in fresh beef is purplish-red in color. • Upon exposure to O2,oxymyoglobin is formed which is a bright cherry red color • At low levels of O2,the myoglobin- O2 complex dissociates ,oxidising the Fe to ferric state resulting in brownish red metamyglobin Cured Meat Pigments • When meat eg. bacon, ham, corned beef is cured myoglobin unites with nitric oxide forming nitric oxide myoglobin giving it a light pink color • When meat is exposed to low heat during curing, part of the nitric oxide myoglobin is changed to a stable complex (Fe still in ferrous state) The pigment is now called nitric oxide hemochrome. Storing Meat • Meat is highly perishable-refrigeration at 4°C or lower reduces the growth of microorganisms on the cut surfaces and maintains freshness. • Meat should be frozen if they are not to be used within three days • Raw meats carry pathogens-surfaces they contact should be washed thoroughly to prevent cross contamination • Store : – ground meat & variety meat-no longer than 2days – Processed meats eg slices of ham, frankfurters & lunchen no longer than 5 days in refrigerator – Bacon smoked sausage and smoked ham up to 1 week Cooking meat • Destroys microorganisms that may have contaminated the surface of meat-should be heated to a temp of 70°C or until juice from meat is clearnot pink in color • Affects tenderness • Changes color • Alters water holding capacity • Develops flavor and characteristic aroma Methods of cooking • Meat can be cooked by either dry of moist methods • Dry methods –meat is cooked added water and uncovered so that the moisture from the meat can evaporate. meat is in contact with hot air, a hot frying pan or hot fat from which heat is conducted • Methods include-roasting, broiling, panboiling and frying • Recommended for tender cuts of meat • Moist cooking-meat is cooked in a covered utensil, water is added or meat is cooked in the steam/liquid released from the meat as the proteins coagulate • Braising (pot roasting &breading) and cooking in water are moist methods of cooking • Tough cuts of meat are ideal for moist cooking Storage of cooked meat • Leftover cooked meat should be cooled promptly and refrigerated at 4°C if they are to be used within 3-4 days • Otherwise they should be frozen at-18°C Effects of cooking on pigments and color • When meat is heated the myoglobin is first converted first to oxymyoglobin (bright red color) • With further heating, protein moiety of the pigment is denatured, ferrous Fe is oxidized-meat color becomes grayish brown due to denatured globin hemichrome Effect of cooking on meat protein and tenderness • Connective tissue-cooking decreases toughness of meat since the tensile strength of meat comes from fibres of collagen that are part of connective tissue • Muscle fibres- proteins of muscle fibres are denatured but are not solubilized. • They lose their ability to associate with water esp with high temperatures • This results in shrinkage of fibres and firmness of tissue • Flavor-cooking decomposes one or more precursers in the lean meat to give the basic cooked meat taste Less tender cuts of meat have more extractives-more flavorful Lactones and sulfur containing compounds eg sulfides, mercaptans and cyclic cpds such as pyrazine make important contributions to the flavor of cooked meats • Initial fat content-meat cooked by pan frying and broiling differ little in fat content. Fat melts, causing browning on the surface and increase in flavour. • Effect on nutritive value-retention of B vitamins when meat is cooked is good, however there is greater loss of thiamine Poultry • Includes meat obtained from ducks, geese, guineas, pigeons, turkeys and chickens Market class of poultry • Different classes of poultry are marketed on the basis of their age that influences tenderness& fat content & dictates the cooking methods. • Birds <6 weeks-have no hair on skin and little subcutaneous fat weigh <1kg • Broiler-fryer birds-6-8 weeks weigh 1-1.5 kg • Roasters-2.5-5 months-weigh 1-2kg • Capon -<8 months-weigh2-4kg • Hens->1year-weigh 1-2.5kg Preparing poultry for market • Birds are killed by cutting the jugular vein • Dip in hot water(52-54°C loosens feathers without damaging the cuticle of the skin • Feathers are removed using machine • Evisceration-abdominal cavity is slit &entails removed • Head, feet &oil gland are removed • Bird is chilled-to prevent bacterial growth • Tenderness of the meat depends on the way meat is cooledprompt cooling in ice water-meat is tender; slow cooling in air–meat is tough (pH of meat is low 6.3 due to accumulation of lactic acid) Inspection and Grading • The following characteristics are considered when grading poultry for quality: - Shape and meatiness - Distribution of fat - General appearance of bird Breaks in skin, bruises and feathers lower the grade Quality grades for poultry are A,B and C Quality considerations in poultry selection • Skin-moist but not sticky, unmarked, light cream in color,slightly blue at the thigh area • Flesh-pink, no bruising • Bones-unbroken; flexible breastbone. • Pin feathers-none • Smell-freash and clean • Temperature-refrigerated at 0-2°C Common Chicken Cuts Breast Popular way to buy chicken Ideal size for single portion Can be bought with or without skin Meat is usually lean If skin is removed, the meat can dry out during cooking Wing Dark meat Fairly inexpensive cut Quite fatty contains a large amount of bone Ideal for barbecuing Leg Darker meat Contains more fat than breast Cheaper way to buy chicken but bone in drumstick increases weight so less meat per kilo than breast. Ideal for roasting and frying Handling raw poultry • Raw poultry spoils quickly-should be held in the coldest part of the refrigerator and cooked within 2-3 days • Frozen poultry should be thawed in the refrigerator or in changes of cold water • Once thawed it should be cooked promptly • Surface contacted by poultry –wash with warm water and detergent. Cutting boards should be rinsed with sanitizer. • this is to prevent cross contamination of other foods-as incidence of Salmonella is high in poultry Composition and structure • Comparable to red meat in composition and nutritive value • Has high quality proteins • Good source of B vitamins, Iron and phosphorous. Dark meat is rich in riboflavin. Light meat higher in niacin. • Fat content of meat varies-depends on age, feed color of meat. Skin has more fat. • The muscles are made of muscle fibres and connective tissue. Cooking poultry • Cooking method depends on the basis of tenderness. Young poultry can be cooked by broiling, frying, roasting • Stuffing poultry before roasting-not recommended-stuffing raises temp. slowly –microorganisms (salmonella and staphylococcus) multiply. • Microwaving –not recommended as heat is not distributed evenly. Pathogens such as Clostridium perfringens, salmonella and staphylococcus aureus survive microwave cooking • Mature birds-moist methods allow time to tenderise meat such as stewing and braising. • Poultry is cooked when its juice is free of pink color Cooking losses • Cooking has little effect on vitamin B retention -90% retention of riboflavin -80% retention of thiamin Leftover cooked poultry-cool promptly and refrigerate at 4°C if it is to be eaten within 2-3 days. Otherwise it should be frozen and held at -18°C Frozen poultry • Once thawed-do not refreeze • When young chicken are cooked, discoloration in meat next to larger bone may occurfreezing and thawing release haemoglobin from the red cells in the bone marrow as the bones of young chicken is porous and heating denatures the pigment-discoloration • Discoloration is not a problem in older birdsbones are dense. Flavor of cooked poultry • Volatile carbonyls such as hydrogen sulfidegive cooked chicken its flavor • Otherwise the sulfur compounds present will give only meaty of beef like aroma