CEBSM Tele-seminar June 11, 2009

advertisement

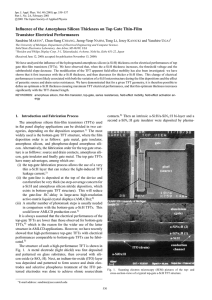

ESH Challenges and Opportunities in Large Area High Tech Manufacturing: Displays, Thin Film Photovoltaics, Solid State Lighting, and Flexible Electronics Greg Raupp Chemical Engineering Program Arizona State University +1-480-727-8752 raupp@asu.edu CEBSM Tele-seminar June 11, 2009 1 Principal Takeaways ● ESH manufacturing challenges in the maturing flat panel display industry and the emerging thin film photovoltaic, solid state lighting and flexible electronics industries are strikingly similar to those encountered in microelectronics manufacturing ● Philosophies, approaches and techniques successfully under development or adopted in the semiconductor industry can be leveraged to achieve success ● Large area manufacturing industries produce products where 30-50% of the manufacturing cost is in the materials substantial opportunity for green benefit for fab processes with higher materials utilization efficiency and/or reduction of steps CEBSM Tele-seminar June 11, 2009 2 Representative FPD Industry Thinking (Source: www.cmo.tw) CMO's Green Operations … plan for 2011 has been specifically conceived to meet the following goals: ● Implementation of 9 major initiatives in greening operations: Energy conservation, material conservation, recyclability, low toxicity, health-oriented, systems, water conservation, carbon emissions reduction, resource recycling ● 90% reduction in PFC greenhouse gases and NF3 emissions ● Increase in the waste resource recycling rate to 93% ● Reduction in water and electricity use per unit area to 90% of current levels (2008) CEBSM Tele-seminar June 11, 2009 3 Display Glass Manufacturing Generations Gen 10 = 2850 x 3050 mm (2010) (March 2006) Corning announced the commercial launch of Eagle XG, the first LCD glass substrate free of all heavy metals, including arsenic … is also free of antimony, barium, and halides … that can produce potentially harmful manufacturing by-products. CEBSM Tele-seminar June 11, 2009 4 Display Technology Types • Light Emitting Displays • Light Transmitting Displays (light valves) • Light Reflecting Displays Emissive (OLED) CEBSM Tele-seminar June 11, 2009 Transmissive with Backlight (LCD) Reflective (EPD) 5 Active Matrix Displays SVGA Super Video Graphics Array Array of 800 x 600 pixels Pixels Gate Line Source Line TFT Capacitor Dimensions Pixels: tens of microns Thin Film Transistors: several microns Single Pixel with 3 sub-pixels RGB CEBSM Tele-seminar June 11, 2009 6 a-Si:H TFT Fabrication PECVD a-SiNx:H IMDs PECVD n+ a-Si:H contact PECVD a-Si:H Channel Sputtered metallization Sputtered ITO Substrate Sputtered metal gate • • • • PECVD a-SiNx:H gate dielectric Patterning by conventional photolithography 3-5 masks for a-Si:H TFT arrays 6-7 masks for poly-Si TFT arrays Color Filter Arrays (CFAs) are also fabricated through conventional photolith processes CEBSM Tele-seminar June 11, 2009 7 Large Area a-Si:H Production Systems • • • • AKT PECVD Cluster Tool a-Si / a-SiNx / n+ a-Si GEN II 370 x 470 mm to GEN 8 2.2 x 2.5 m glass substrates Total worldwide areal capacity increased 250% over last 3 years to 25 MSF CEBSM Tele-seminar June 11, 2009 • • • • Applied SunFabTM Thin Film PV Production Line mc-Si / a-Si PECVD 5.7 m2 glass substrates Planned turnkey plants will represent dramatic increase in worldwide areal capacity 8 NF3 Emissions a Growing Concern Measured and modeled atmospheric NF3 concentrations and trends from 1978 to 2008. Northern Hemisphere NF3 measurements are shown as filled circles, together with the spline curve Northern Hemisphere trend (solid line) fitted to these measurements. The modeled Southern Hemisphere trend and modeled global mean trend (dotted line) are shown as dashed and dotted lines, respectively. Southern Hemisphere measurements are plotted as filled squares. Click to enlarge. “This rise rate corresponds to about 620 metric tons of current NF3 emissions globally per year, or about 16% of the poorly-constrained global NF3 production estimate of 4,000 metric tons per year … a significantly higher percentage than has been estimated by industry (FPD, PV, Microelectronics), and thus strengthens the case for inventorying NF3 production and for regulating its emissions.” Source: Weiss et al., Geophys. Res Lett. (2008) CEBSM Tele-seminar June 11, 2009 9 Emerging Technology: Flexible Displays Reflective Electrophoretic Displays Ultra-low power Sunlight readable Near-video rates Click here to play EPD video clip Emissive Organic Light Emitting Displays Low power Vibrant full color Full motion video Click here to play OLED video clip Source: Flexible Display Center at Arizona State University CEBSM Tele-seminar June 11, 2009 10 Beyond Flexible Displays Macrotechnology does not compete / replace Si-based devices; instead complements in applications where Si CMOS is not well-suited (new markets) Macrotechnology Unique Attributes: Less is not Moore! not driven by transistor downscaling (performance), instead driven by unique integrated functionality and form factors Bigger is Better! large area (as well as small) applications Sensors (ASU) Wearable Devices Be Flexible! compact, ultra-thin, rugged, lightweight, implantable, wearable, conformable, and (potentially) transparent Flexible Digital Radiography CEBSM Tele-seminar June 11, 2009 Inflatable spacecraft and extra-terrestrial habitats Flexible Solar Cell Phased-array Antenna Building-integrated PV and SSL 11 Flexible Microelectronics and Display Manufacturing Pathways • Adapt existing plate-to-plate toolset infrastructure Free-standing flexible substrates Substrate fixturing / framing Backside thinning: chemical etch or grind-polish Substrate temporary bonding – debonding Substrate coat - release Layer transfer • Adopt Roll-to-Roll manufacturing infrastructure Toolsets immature with significant issues – handling, layer alignment, resolution, reliability Metrology strategy undefined Take step-wise “R2R-compatible” approach focusing on critical issues CEBSM Tele-seminar June 11, 2009 12 Options with Existing Manufacturing Infrastructure Bond - Debond FDC SEC LG-D ITRI PV Coat – Laser Release IBM Philips (EPLaR) PVI Layer Transfer Seiko-Epson (SUFTLA) Sacrificial poly-Si on Carrier Substrate bonded with Temporary Adhesive to Carrier TFT Fabrication 130 – 180 C Spin-coated Polyimide on Carrier TFT Fabrication 300 – 380 C TFT Fabrication 280 - 300 C Temporary Substrate bonded with Water-soluble Adhesive Laser Release: Ablation Triggered Debond: Thermal Solvent Light Mechanical CEBSM Tele-seminar June 11, 2009 Laser Release: Interfacial Melting Bond to Flex then release 13 Capability/Limitation Comparison Capability/Limitation Temp Bonding EPLaR SUFTLA Flexible Substrate High surface quality polymer or metal foil Solution-castable polymers (PI, BCB) Any TFT Process Temperature Limit Substratedependent (180 C for HSPEN) Polymerdependent (280 C for PI) Typical glassbased TFT limits Flexible Substrate Distortion Can be significant – but can be controlled to negligible level ! Negligible Not applicable Release Process Rapid automated dry Laser interfacial melting Laser ablation Scale-ability ? ? ? CEBSM Tele-seminar June 11, 2009 14 Temporary Bonding – Debonding: Manufacturing Challenges • Temporary bonding with semiconductor-grade adhesive Compatible with Si-based TFTs Low total thickness variation (TTV) Defect (particle/bubble) free TFT and EO process flow and toolset compatible • Automated de-bonding Triggered release (thermal, radiation, chemical, mechanical) Residue-free TFT array and substrate (and carrier) damage-free Complexity of component interactions requires system-level substrate/barrier/adhesive/carrier/toolset solution CEBSM Tele-seminar June 11, 2009 15 Temporary Bonding Pitfalls HS-PEN on Si Blisters form at defect (bubble, particles) sites Exacerbated by adhesive out-gassing at temperature and in vacuum SS on Si “Teacup” failure due to CTE mismatch between substrate and carrier Adhesive viscoelasticity also crucial CEBSM Tele-seminar June 11, 2009 16 Effect of Bow on TFT Array Quality SS Substrates TFT Drive Current Array Maps Original Materials and Process CEBSM Tele-seminar June 11, 2009 New Materials and Process 3.8-in. QVGA EPD Display Module Low (Pilot Line) defectivity <0.01% point defects 0-5 line defects 17 Evolutionary Approach to Roll-to-Roll Manufacturing CEBSM Tele-seminar June 11, 2009 18 Towards Roll-to-Roll Manufacturing • (Some) Critical Issues o R2R incompatible processes (e.g., spin-on processes) o Layer registration in photolithography o Low defectivity handling including in-and-out-of vacuum • Example Approaches Mist coating Imprint lithography with dry etch All printing process (fully additive, no vacuum) CEBSM Tele-seminar June 11, 2009 19 Large Area Mist Coater High (> 90%) materials utilization efficiency High uniformity (< 3% non-uniformity across panel) Versatile: up to 4 materials; 0.5 to 15 mm films High uptime and throughput FDC Gen II System Scaled by EVG to Gen 3.5 for Plastic Logic CEBSM Tele-seminar June 11, 2009 20 HP Self-Aligned Imprint Lithography (SAIL) Circumvents Alignment-Distortion Issue Imprint Lithography: Mask removed Stack Top TFT metal etched andthinned down n+ contact toone theone etched to create Exposed Imprinted Bottom Then undercut metal area mask etched etch tolowered remove down to from Full stack with imprinted Imprint mask level bottom channel metal expose level under tothinnest expose gate contacts parts channel of mask polymer mask Photomask-free Process 4 levels in 0.5 μm steps Multiple mask levels Imprinted as single 3D structure SAIL TFT Etching Process Imprint polymer S&D metal Cr Si contact n+ uC Si contact a-Si:H channel a-Si semiconductor SiNx dielectric Gate metal Al Polymer substrate Plastic substrate O. Kwon, et al., IMID 2007, Daegu, ROK Compliments of Carl Taussig HP SAIL-fabricated AM-EPD on FDC thin film stack on HS-PEN CEBSM Tele-seminar June 11, 2009 21 Fully Additive Processing: Inkjet Printing Litrex 142 GEN II Printer Advantages Low Temperature Non-vacuum Fewer process steps High materials utilization CEBSM Tele-seminar June 11, 2009 Challenges Alignment ( ±15 mm ) Resolution (min. linewidth 30 mm) Manufacturability (yield, throughput) 22 Materials Requirements for Fully Additive Printing Fabrication • High performance functional materials Semiconductors Dielectrics Conductors • In form of solutions, dispersions, melts • Low temperature cureable • Adherent • Accurate linewidth and feature control A. Arias, et al., Flexible Displays and Microelectronics Conference 2007, Phoenix, AZ CEBSM Tele-seminar June 11, 2009 23 Small Molecule OLED Vapor Deposition Full Color RBG with Shadow-masking Source: A. Chang, et al., Information Display 22(6), 20-22 (2006). Source: S. Krishnamurthy, OLEDs Asia (2006). Poor materials utilization efficiency Low throughput High COO CEBSM Tele-seminar June 11, 2009 Sequential deposition RGBW adds 4th step No pixelation for white SSL but more complicated stack 24 Alternative OLED Approaches to Enhance Materials Utilization Other Approaches: White smOLED with CF Vapor jetting Solution processing of polymer OLEDs – several printing approaches for pixelation Source: S. Krishnamurthy, OLEDs Asia (2006). High materials utilization efficiency On demand vaporization: rapid response and high throughput CEBSM Tele-seminar June 11, 2009 25 Conclusions ● ESH manufacturing challenges in the maturing flat panel display industry and the emerging thin film photovoltaic, solid state lighting and flexible electronics industries are strikingly similar to those encountered in microelectronics manufacturing ● Philosophies, approaches and techniques successfully under development or adopted in the semiconductor industry can be leveraged to achieve success ● Large area manufacturing industries produce products where 30-50% of the manufacturing cost is in the materials substantial opportunity for green benefit for fab processes with higher materials utilization efficiency and/or reduction of steps ● Emergence of flexible electronics technology and migration to R2R manufacturing provides unparalleled opportunity to design green / sustainable solutions CEBSM Tele-seminar June 11, 2009 26 Acknowledgements • ASU gratefully acknowledges the substantial financial support of the U.S. Army through Cooperative Agreement W911NF-04-2-0005 • We also gratefully acknowledge the FDC’s Members for their technical and financial contributions to the Center CEBSM Tele-seminar June 11, 2009 27 FDC Team CEBSM Tele-seminar June 11, 2009 28 Thank You ! CEBSM Tele-seminar June 11, 2009 29