Presentation-Qual Mgmt Sys CCAC RSI

advertisement

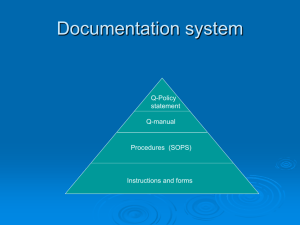

Introduction to Quality Management Systems for Medical Devices 1 Introduction to Quality Management Systems of for Medical Devices Sponsored by: Community College of Allegheny County Presented by: Calvin W. Eggers, Quality and Regulatory Consultant 2 Purpose of the course This course is intended to review the quality management system (QMS) requirements for medical device manufacturers and specifically the implementation of the QMS at Renal Solutions, Inc. 3 Expected Learning Review the regulatory requirements for the Quality Management System (QMS) Understand the concept and structure of a quality system Identify the common elements and processes of a QMS and key requirements that apply to them Differentiate between the medical device QMS and that of other industries Locate information in the RSI quality manual Learn personal quality system responsibilities 4 Triage of Knowledge All employees Aware of system requirements, able to use the quality manual and follow procedures All Leaders Able to understand policy, write procedures, and apply regulations Regulatory Leaders and Professionals Detailed knowledge and application of regulations 5 Course Agenda Medical Regulatory Requirements Compliance with ISO 13485 and FDA QSR RSI Quality System Documents System Clauses and Elements Management Responsibility Resources Realization Processes Measurement and Improvement Additional Learning 7 Medical Regulatory Requirements for QMS US/FDA: Quality Management System per 21 CFR820, Quality System Regulation Europe, Canada, and Other International: QMS per EN/ISO 13485:2003, Medical devices – Quality management systems – Requirements for regulatory purposes Additional directives, regulations, and standards as they pertain to the QMS 8 Is 13485 = 9000? More emphasis on: Specific records related to medical device requirements Risk management Work environment and cleanliness Complaint handling and corrective action Others Less on customer satisfaction and continual improvement 9 What is a System? A regularly interacting or interdependent group of items forming a unified whole 10 What is a Quality System? The quality management system consists of the organizational structure, responsibilities, procedures, specifications, processes, and resources that work together to comply with the company’s quality policy and meet the requirements of our customers and applicable regulatory requirements Quality is the degree to which a set of inherent characteristics fulfils requirements 11 ISO 13485 Model 5.0 Mgmt 8.O Measure 4.0 QMS 6.0 Resources 7.0 Processes 12 Documented System? We don’t use no stinking documents We don’t keep no stinking records 13 Requirements for a Documented Quality System QSR 820.40 Document Controls 820.180 to 198: Records ISO 13485 Clause 4, Quality Management System 4.2.2 Quality manual 4.2.3 Control of Documents 4.2.4 Control of Records 14 RSI Quality System Document Pyramid Quality Manual Procedures Work Instructions Forms Work Work Instructions Instructions Quality Records 15 RSI QMS Implementation Quality Manual QSM-001, Controlled document Describes the QMS Set policy for the organization based on External regulations Company business practices and plans Company culture Remainder of class will be based on QSM-001 16 Quality System Procedures Implement policy through Definition of processes Assignment of responsibility and authority Establishment of review and approval mechanisms Maintenance of records QSP-0xx; non-significant numbering Referred to in quality manual section for respective process 17 Who is Responsible to Establish and Maintain Procedures? Process Owner as Identified in Quality Manual Establish = design process, write, validate Maintain = respond to audits, revise for corrective action, changing conditions Owner: ………………. 18 Third and Lower Tier Documents Work Instruction (build, test, inspect, purchase) Form or template for developing documents or keeping records Can be established by procedures within the process Records 19 Quality Manual Road Map 1 to 3 -- Policy and introduction 4– QMS description Requirements for documents and records 5 to 8 -- Requirements for processes 9 --Trace of compliance 20 Typical Section Outline General Policy Detailed policy in outline form Sub-processes Specific requirements Reference to owner and procedures 21 1.0 Introduction and Scope This section is intended to describe the scope of the quality management system (QMS) Organization Products Compliance (Regulations and Standards) Manual is intended for both external and internal purposes 22 2.0 Quality Policy Mission Quality Policy 23 3.0 Organization High level Responsibility for elements 24 4.0 Quality Management System This section describes the quality management system (QMS) in general terms. The requirements of this section establish a basic structure for the QMS in the form of documents and records 25 Document Control Changes only with approval by same persons or functions as original Communicate changes and documents Use only latest revision Record of changes On line version is only controlled copy Control over standards and other documents of external origin 26 Document Control Procedures QSP-002 Document Management Document Control Group All originators and users QSP-030 Change Control Document Control Group All originators and users Owner: Document Management 27 Record Control Record is a document that furnishes objective evidence of activities performed or results achieved Quality record is one that relates to the quality management system 28 Procedures Required Identifying, collecting, indexing, accessing, filing, storing, maintaining, and disposition Storage location and archiving Storage media (may be electronic) Retention times Methods of disposition 29 Why Quality records? Provide objective evidence of the achievement of customer and internal quality requirements Verify effective operation of the QMS Comply with regulatory requirements Provide for traceability of devices and components Provide information for corrective and preventative action and continuous improvement 30 Record Control Procedures QSP-004 Record Management All employees Specific instructions in procedures for your process Specific directions from your leaders Owner: Compliance and Regulatory Affairs 31 9.0 Demonstration of compliance 9.1 21 CFR 820 Quality System Regulation (FDA) 9.2 ISO/EN 13485:2003 9.3 Other Regulations and Standard Medical Devices Directive Other 21 CFR (e.g., Clinicals, 510(k), etc.) 32 9.0 Demonstration of compliance 4.2 Documentation requirements 4.1.3 Structure of the Quality Management System 4.2.1 General 4.1.3 Structure of the Quality Management System 4.2.2 Quality manual 4.1.3 Structure of the Quality Management System 4.2.3 Control of documents 4.2 Document Management 4.2.4 Control of records 4.3 Control of Quality Records 5 Management responsibility 5.0 Management Responsibility 5.1 Management commitment 5.1 General Policy 5.2 Customer focus 5.1 General Policy 5.3 Quality policy 2.3 Quality Policy 5.2 Establishment of Quality Policy 33 9.0 Demonstration of compliance 820.150(a) Control of storage 7.6.2 Storage of Finished Goods 7.5.8 Preservation of Product 820.150(b) Authorizing receipt and dispatch 7.5.3 Inspection and Testing 820.160 Distribution 7.6 Distribution 820.160(a) Procedures for control 7.6.3 Distribution Activities 820.160(b) Distribution records 7.6.4 Distribution Records 820.170 Installation 7.7.4 Installation 820.180 Records -- General requirements 4.3 Control of Quality Records 34 Course Agenda Medical Regulatory Requirements RSI Quality System Documents System Clauses and Elements Compliance with ISO 13485 and FDA QSR Management Responsibility Resources Realization Processes Measurement and Improvement Additional Learning 35 ISO 13485:2003 Model 4.0 Quality System 5.0 Management Controls Document Control 6.0 Resources Record Control 7.0 Realization Processes 8.0 Measure and Improve 36 5.0 Management Responsibility Executive Responsibility Direction to establish Quality Policy Management Representative Alternate Authorized Representative Management Review Quality Planning 37 Management Review Hold regularly with inputs including Status of QMS Audits, Complaints, Corrective and Preventive Action Metrics of processes Actions for improvement Records of meeting, including conclusion on suitability of QMS 38 Management Review Procedure QSP-005 Management Review (Management and QA) Owner: CEO and Management Representative 39 Resources 6.1 6.2 6.3 6.4 6.5 6.6 General Human Resources Infrastructure Working Environment Measurement Equipment Information Systems 40 6.2 Human Resources Sufficient personnel with appropriate background, education, and experience Determine required competence Provide training to ensure competence Ensure that the assigned tasks are performed in accordance with the quality system and associated policies, procedures, and work instructions Include instruction on the importance of the associate’s activities and their contribution to the quality objectives 41 Training Identify the training needs and plan the training Identify of device defects or nonconforming conditions that may occur as a result of improper performance Identify types of defects that may be encountered on validation, verification, inspection, or test activities, Include training on any special processes, and any need to work under special environmental conditions Conduct the training Evaluate effectiveness of training Records of all training 42 Training Procedure QSP-006 Training (All Leaders) Everyone: Get trained; do quality system jobs only if trained Owner: Chief Financial Officer 43 6.3 Infrastructure Controlled conditions to ensure that devices meet their requirements and are shipped free of contamination Buildings adequate, orderly, to prevent contamination and mix-up Processing Equipment Selected and designed to meet requirements Cleaned, maintained, and adjusted 44 Infrastructure Procedures None at this time Owner: Senior VP, Operations and Engineering 45 6.4 Working Environment Processes in compliance with all applicable Environmental, Health, and Safety requirements Where necessary, control environmental conditions Cleaning where necessary to meet specifications and prevent device or equipment contamination Handle items sensitive to electrostatic discharge (ESD) per procedures. Smoking prohibited Eating and drinking limited to designated areas Each associate help maintain a clean and safe work environment Inform all associates who contact devices or components of requirements for health, cleanliness, personal practices, and attire as well as any adverse effects that the health of the associates could have on product quality Train any employee who may be exposed to Blood Born Pathogens (BBP) in personal protective measures and the handling of BBP contaminates 46 Working Environment Procedures None at this time Owner: Senior VP, Operations and Engineering 47 6.5 Measurement Equipment Measuring equipment used to provide evidence of conformity to requirements Ensure that it is suitable for its intended use and to assure confidence in the measurements Include selection, qualification, identification, preservation, calibration, and corrective action Calibration based on primary standards that are traceable to National Institute of Standards and Technology (NIST) standards Suppliers of calibration services shall be qualified 48 Measurement Equipment Procedure QSP-007 Control of Measuring Equipment (QA and all who use equipment) Procedure is based on outsourcing calibration Owner: Everyone: use only if Compliance and Regulatory in current calibration Affairs 49 6.6 Information Systems Systems that support the quality management system shall be developed, operated, and maintained under controlled conditions Adequate equipment, environment, software, procedures, and personnel Validate all systems and software Electronic record requirements Electronic signature requirements 50 Information System Procedures None at this time Owner: Chief Financial Officer 51 ISO 13485 Model 5.0 Mgmt 4.0 QMS 7.0 Processes 6.0 Resources 52 7.0 Realization Processes Plan, define, implement, and maintain processes to meet customer requirements Consider quality objectives Comply with the requirements of the quality management system, and any unique requirements of the products. Use risk management methods Changes to manufacturing or service processes shall include appropriate quality planning, with provision for any required quality controls, verification, or validation 53 7.0 Realization Processes 7.3 Design Control 7.4 Supply Management 7.2 Customer Service 7.8 Regulatory 7.5 Manufacturing 7.9 Clinical 7.6 Distribution 7.7 Service 54 7.2 Customer Processes Ensure effective communication with customers Receipt and entry of orders and order status Product information, pricing, inquiries, contracts, service-level agreements Changes affecting the products and services Recording customer complaints Collection of customer feedback Provide clinical training necessary for effective use of the product 55 Order Entry Offers and orders only for products that have been released for sale and which RSI is capable of providing within a reasonable time Review any customer requirements for delivery and post-delivery activity Each standard product shall be assigned a material number for ordering identification 56 Customer Process Procedures QSP-008 New Customer Contact and Initial Order Entry QSP-023 Existing Customer Contact and Order Entry (Customer Service and Warehouse) Owner: Senior VP, Operations and Engineering 57 7.3 Design Control Plan and control the design and development of all products and their labeling in order to assure the safety, clinical utility, effectiveness, and reliability of the device design and to ensure that specified design requirements are met 58 Design Control Sub-processes Design and Development Planning Design Input Design Output Design Review Verification Validation Control of Changes Design Transfer 59 Device Master Record A compilation of records that completely describe the device and the processes by which the device is produced, inspected, tested, labeled, stored, and distributed Contain -- or refer to the location of -- all applicable: Device specifications and software specifications Process and production environment, including appropriate equipment specifications, work instructions, and drawings Component specifications Identification of any special processes Packaging and labeling specifications and copies of all labeling Quality control procedures and specifications, including acceptance criteria and equipment Installation, maintenance, and servicing procedures Record of all changes 60 Design History File/Technical File DMR = the recipe for the device DHF = How we got there Technical File = MDD version of DHF, showing conformance to Essential Requirements 61 DHF/TF Contents Design reviews including the design, the date, and individuals performing the review Design verification including the design, date, methods, identification of how design outputs meet design inputs, and individuals performing the verification Design validation including the design, date, methods, and individuals performing the validation Evidence of clinical utility and acceptance, including the records of any clinical studies performed as part of the development of the device Records of all risk management activities 62 Labeling Design Designed to help the user achieve safe and effective operation of the device, prevent mixup, and prevent any compromise to the safety and effectiveness Meet the provisions of 21 CFR Part 801 Include only approved claims For EU, meet the requirements of the Medical Devices Directive Article 17 and Annex 1, paragraph 13 For Canada meet the requirements of Canadian Medical Devices Directive, Sections 21 to 23 Translate if necessary for user countries 63 Design Control Procedures Owner: QSP-009 Design Controls Director of Engineering QSP-010 Design Reviews QSP-011 Risk Management QSP-012 Design Verification and Validation QSP-013 Creation of Design History File, Technical File, and Declaration of Conformity 64 Labeling Procedure QSP-015 Labeling Design Owner: Senior VP Commercial Operations 65 7.4 Supply Management Manage the supply of material and outsourced products and services Ensure that all purchased or otherwise received products, components, and services conform to specified requirements 66 Supply Management Sub-processes Evaluation of Suppliers Control of Contract Manufacturers Purchasing Information Verification of Purchased Product Inspection Records Monitoring of Suppliers 67 Supplier Evaluation Evaluate and select based on ability to supply products or services in accordance with the specified requirements Maintain record of approved suppliers and their evaluation Type and extent of control applied to the supplier and the purchased product shall depend on the effect on the final product Suppliers of goods or services that do not directly affect the QMS may be selected based on their ability to meet purchase order requirements. Contract manufacturers of outsourced finished good items Establish contracts that include a supplier agreement Ensure compliance with all process control requirements Ensure development of a quality plan by the supplier Sterile product suppliers Provide evidence of process validation Maintain records of the parameters for the sterilization of each batch. 68 Supply Management Procedures QSP-014 Supplier Qualification QSP-016 Purchasing Controls QSP-018 Receiving, Inspection and Acceptance QSP-037 Return of Purchased Material Owner: Senior VP, Operations and Engineering 69 7.5 Manufacturing Processes performed under controlled conditions in accordance with written instructions or drawings by qualified and trained personnel to assure that the devices conform to the approved original or modified design Policies of this section concerning product identification, traceability, preservation of product, and labeling apply to all areas of the quality management system 70 Manufacturing Requirements Process Control Process Validation Inspection and Testing Rework and Reprocessing Preservation of Product 71 Identification and Traceability Identify all materials by material number and, as necessary, by status, or by other appropriate method at all stages Distinguish devices returned for service or reprocessing Control and trace by means of a unique control number: All electromechanical therapy equipment All serviceable accessories Any other therapy accessories that might present a risk requiring recall or other corrective action Control number on the device or on its label, if possible For all traced devices any components or subassemblies that can reasonably be expected to require corrective action shall be traced 72 Control of Labeling Labeling accompanying the device (i.e., product labels, package labeling, or user instructions) Have a revision designation specified Identify and store to prevent mix-up Control, distribute, and maintain marketing literature to prevent mix-up. Labels or labeling that contain significant warnings, cautions, or warning instructions Traceable through part number, revision, or other appropriate means 73 Device History Record DHR is a compilation of records containing the production history of a device or a batch of devices to: Document the production history in the “as built” configuration Demonstrate the device has been built in accordance with the DMR Provide traceability information A DHR shall be maintained for each device or batch of devices produced including directly or by the reference to the location thereof: Date of manufacture Quantity manufactured and quantity released for distribution The acceptance record that demonstrates the device is manufactured in accordance with the DMR The primary identification label and labeling Any identification and control number Record of rework or revaluation activities Record of any special processes 74 Manufacturing Procedures QSP-017 Product Identification and Traceability QSP-019 Manufacturing, Storage, and Distribution Owner: Senior VP, Operations and Engineering 75 7.6 Distribution Process Includes handling, storage, preservation, and distribution Prevent damage, mix-up, and contamination Identify finished goods with a part number Account for the inventory and verify accuracy Remove time-sensitive finished goods before expiration Label and handle hazardous Material per regulatory requirements Distribute finished goods only from RSI manufacturing facilities or designated RSI distribution centers Ensure that distribution occurs only after devices have been authorized for release Ship in first-in/first-out order to the extent possible 76 Distribution Records For all finished good and rental items, except for promotional literature, include: Name and address of consignee Material number Description of the item Quantity shipped Date shipped Control number, if applicable • Provide for product traceability 77 Distribution Procedures QSP-019 Manufacturing, Storage, and Distribution QSP-026 Handling of Biohazardous Material Owner: Senior VP, Operations and Engineering 78 7.7 Servicing Ensure that customer expectations for service are met and serviced devices meet specified requirements Develop, update, and control service documentation Identify and validate tools, test equipment, work environment, and safety Qualify and train service personnel Timely distribution of replacement parts (only replacement parts distributed or authorized by RSI) Material identification and traceability throughout the process Care and identification of customer owned devices Cleaning and decontamination of returned equipment, and protective equipment for service associates Packaging, storage, and handling Communicate and implement mandatory product changes. 79 Servicing Procedure QSP-021 Servicing Owner: Senior VP, Operations and Engineering 80 7.8 Regulatory Processes QSP-024 Regulatory Submittals Specialty knowledge by leaders and professionals Owner: Compliance and Regulatory Affairs 81 7.9 Clinical Studies QSP-022 Clinical Site Selection, Initiation, and Assessment QSP-025 Clinical Site Monitoring Specialty knowledge by leaders and professionals Owner: Compliance and Regulatory Affairs 82 ISO 13485 Model 5.0 Mgmt 4.0 QMS 7.0 Processes 6.0 Resources 83 Measurement and Improvement Goals Processes Results Feedback 84 8.0 Measurement and Improvement Processes 8.1 Feedback and Complaints 5.0 Management Controls 8.2 Internal Audits 8.3 Control of Nonconforming Material 8.4 Corrective and Preventive Action 7.0 Realization Processes 85 8.1 Feedback and Complaints Collect feedback and complaints from all sources, including customers A quality complaint is any written, electronic, or oral communication from any source that alleges deficiencies related to the identity, quality, durability, reliability, safety, effectiveness, labeling, packaging, or performance of a device after its release for distribution 86 Complaint Process Receive and record complaints from any source Review and evaluate complaints Determine if an investigation is required and the level of investigation Implement corrective action where required Respond to complaints Maintain complaint records and trends 87 Adverse Events/Incidents Reporting requirements of FDA, the European Union (Vigilance), and the Canadian Medical Device Regulations Review complaints for any information that reasonably suggest that a device manufactured or distributed by RSI may have caused or contributed to a death or serious injury, or may have malfunctioned and that the device would be likely to cause or contribute to a death or serious injury if the malfunction were to recur Review internal failures for adverse events 88 Complaint Procedures QSP-028 Complaint Handling Process QSP-038 Customer Returned Product QSP-033 Medical Device Incident Reporting QSP-035 Post Market Surveillance Everyone: Report complaints to Customer Service Owner: Compliance and Regulatory Affairs 89 8.2 Internal Quality Audits Conduct at planned intervals to Schedule at planned intervals based on the status and importance of the activity and results of previous audits Each element of the QMS audited at least annually. By qualified auditors without direct responsibility in audit area Verify implementation of corrective and preventive actions Reports to the management of the area being audited ensure that all aspects of the QMS are effectively implemented and maintained ensure continuous compliance with applicable regulatory standards identify areas for improvement Take timely action to eliminate detected nonconformities and their causes Report results to Management Review 90 Audit Procedure QSP-027 Internal Quality Audits (Quality Assurance, Management) Owner: Compliance and Regulatory Affairs 91 8.3 Control of Nonconforming Material Identify nonconforming material (NCM) and prevent its inadvertent use or delivery Clearly identified and appropriately segregated from acceptable material Prevent inadvertent use or shipment Identify responsible internal function or supplier Process for review and disposition of nonconforming material, including initiating corrective and preventive action, where appropriate Maintain records 92 Control of Nonconforming Material If released under concession the release shall be recorded and the concession shall be reviewed to ensure that it does not increase the safety risk above that allowed by regulatory or internal quality requirements If reworked or sorted to meet quality requirements, any rework or sort process that is part of the disposition shall be in accordance with approved written instructions 93 Delivery Holds If investigation of a indicates nonconforming products have been manufactured and are available for distribution, a delivery hold shall be placed on the item in question Release upon correction of the nonconforming condition, or determination that there is no further likelihood of nonconforming finished goods being available for distribution 94 Post Market Take appropriate corrective action (recall) to address potentially nonconforming product that has already been distributed Use field corrections or safety advisory notifications if more appropriate than a product recall Monitor progress of product recalls and reconcile the amount of product returned Evaluate for reporting under 21 CFR Part 806, Article 10 of the Medical Devices Directive, the Canadian Medical Device Regulation, and any requirements of other governments If a safety issue with a CE-marked device, inform the Notified Body and the Authorized Representative 95 NCM Procedures QSP-031 Control of Nonconforming Material (QA, Operations, Everyone) QSP-034 Corrections and Removals (QA, Customer Service, Management) Owner: Compliance and Regulatory Affairs 96 8.4 Corrective and Preventive Action (CAPA) Ensure that the causes or potential causes of nonconforming product, material or processes are identified, evaluated, documented, and corrected, to prevent recurrence of the problem (CA) to prevent the problem from initially occurring (PA) Provide a systematic, problem-solving approach to continuous quality improvement with the objective of detecting and eliminating all causes of nonconforming product, material, and processes Implementation commensurate with the significance of the problem or potential problem Verify actions so they don’t adversely affect the device Report as part of Management Review 97 Sources of information Complaints service records, and returned product External regulatory agencies Receiving inspection records and data on supplier quality or audits Nonconforming material reports Production quality data and process capability Nonconformities in production processes, tools, equipment, or facilities Delivery holds and production shut-downs Internal quality audits Reports of noncompliance with procedures or of inadequate procedures Customer relationship performance (e.g., delivery, billing, etc.) Management Review, or other management meetings Associate surveys 98 Preventive Action Process Help prevent the occurrence of nonconforming conditions by identifying, analyzing, and eliminating potential quality problems, and analyzing and trending information on quality Same sources of information as for CA, plus: Information from processes that affect product quality; audit results; quality records; service reports; customer complaints and Adverse Event Reports Product and process risk management and reliability analyses Design reviews Product and process verification and validation Changes in the product, the process, or suppliers 99 Corrective and Preventive Action Procedure •QSP-029 Corrective and Preventive Action (QA and Everyone) Owner: Compliance and Regulatory Affairs 100 Expected Learning Review the regulatory requirements for the Quality Management System (QMS) Understand the concept and structure of a quality system Identify the common elements and processes of a QMS and key requirements that apply to them Differentiate between the medical device QMS and that of other industries Locate information in the RSI quality manual Learn personal quality system responsibilities 101 Course Agenda Medical Regulatory Requirements RSI Quality System Documents System Clauses and Elements Compliance with ISO 13485 and FDA QSR Management Responsibility Resources Realization Processes Measurement and Improvement Additional Learning 102 Additional Learning Path Regulatory Requirements Class Quality System Class Seminars and Self-study Classes on Procedures (Include review of policy from quality manual) Trained Worker On-the-job Training 103 Any Questions? 104