OPS-LB-PS-004 Automatic Distillation by Herzog

advertisement

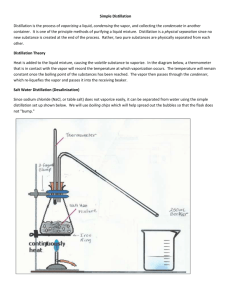

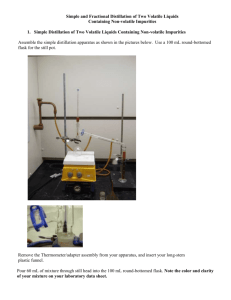

Automatic Distillation by Herzog Area 3 Job Hazards Unit Lab Yes Operating Procedure # OPS-LB-PS-004 Job Hazards Access and Egress Moving Parts Activities of Others Noise Adverse Weather Rail Movement Chemical Exposure Sharp Edges Electricity Slips, Trips, and Falls Fatigue Static Electricity Fire and Explosion Trip Injuries Ground Contamination Trapped Pressure Manual Handling Working at Height Yes Certified by Revision # Date 09.20.2011 Scope / Objective Page 1 of 2 PPE Use Y Standard (SSP-0011) Full Face Shield / Goggles Hood Clothing—Chemical Protection Gloves—Chemical Personal Fall Protection References / Documents Respirator / Filter Mask Supplied Air MSDS on gasoline. Unit Safe Upper & Lower Limits Spreadsheet Other: Equipment Materials and Reagents Special Instructions Environmental Automatic Distillation by Herzog 1 Clean all glassware and thermometer thoroughly prior to beginning analysis. 2 Swab condenser tube with a chamois cloth fastened to a long piece of wire. 3 Fill the measuring cylinder (receiving cylinder) with sample to 100% by volume mark ensuring that bottom of meniscus is exactly at the mark. 4 If glassware is new or was cleaned in muffle furnace so that no burned material remains on bottom of flask, add one or two boiling chips to flask to reduce bumping. 5 Pour sample from cylinder into flask ensuring side arm of flask is pointed upward. 6 Place the correct flask support board on the heater – use 38 mm hole board for Group 1 or 2 samples (gasoline) or 50 mm hole board for heavier samples such as diesel or kerosene. 7 Insert sample thermometer into flask such that the top edge of the PT 100 (in the tip of thermometer) lines up exactly even with the lower inside edge of the sidearm (see diagram below). 8 Place flask on support board and adjust heating plate by turning the small hand wheel until the end of the silicone stopper on side arm fits snugly into the condenser opening. 9 Ensure flask sits precisely in center of support board hole and is in a vertical position (not leaning sideways). 10 Attach the metal drop plate in receiving cylinder so that tip of plate touches inside of cylinder wall. Completed Date: Note: Prepared By: Thermometer Sidearm PT 100 Approved By: This procedure is only valid at the time of printing. The control version can be found on the Meraux Refinery intranet. Automatic Distillation by Herzog Continued Area 3 Unit Lab Operating Procedure # OPS-LB-PS-004 Certified by Revision # Date 09.20.2011 Page 2 of 2 Automatic Distillation by Herzog Continued 11 Place receiving cylinder in chamber oriented so that tip of drop plate is to the front. 12 Close door to receiver chamber. 13 Double-click “Units” (located at top left of screen) or double-click icon for particular ADA using the HLIS 32 software program on the PC to bring up the “Measurement” screen for the selected unit. 14 Click the NEW button to reset the screen for the new sample info to be entered. 15 Choose the “Measurem.Prog” from the drop down menu. 16 Type the Sample ID number in the “Sample Number” field and enter the sample description in the box just below – ex. Plat Chg. 17 For the “Sample Class” select “General” and for “Operator” select “Labtech”. 18 Click the Start button to begin the distillation. 19 Once the distillation is complete, the instrument will signal with an audible alarm; press the ACK key on the unit to turn off the signal or allow it to continue until it shuts off after about a minute. 20 Remove and clean all glassware including thermometer – place thermometer in glass receptacle at oven corner to store. 21 Check distillation data to ensure all parameters are within limits specified by ASTM D86, ex. Distillation rate between 4-5 ml/min. 22 If all parameters are acceptable, click on the “Acknowledge” button on display screen on PC and a box will pop up where the amount of residue is entered to 1 decimal place. 23 Click “Okay” to initiate data transfer to Labworks. Completed Date: Note: Prepared By: Approved By: This procedure is only valid at the time of printing. The control version can be found on the Meraux Refinery intranet.