Delivery Programme

advertisement

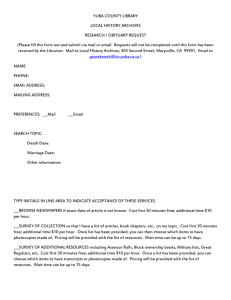

Delivery Programme Delivery Office Site Inspection Purpose To complete a site inspection of the Delivery Office and record the required changes to support the implementation of improved indoor work. Work your way through the document and complete all the sections. Check the NDC Site Drawing downloaded from ‘Gleedsspace’ matches the ‘reality’ of the Unit. NOTE: Whilst this document should be completed by a Manager it is important that the site inspection should include the following invitees: DOM, Project Manager, Planner, CWU Area Safety Rep and local CWU Rep 1. Delivery Office Name & Location Detail 1.1 Address: Add the Name of the Delivery Office and Address 1.2 Contact Details: Name DO Manager: Person in Control: Deputy Person in Control: Contact/s Outside of Normal Hours : DM Project Manager: CDSM: 2. Site Inspection Details & Delegates 2.1 Date of Inspection: Mob. Email 2.2 Attendees: Role Name Contact Details DOM Project Manager Planner CWU Area Safety Rep Local CWU Rep MTC (Measured Term Contractor) Central Deployment Manager 3. Basic Mail Flow 3.1 Yard Space Number of parking spaces: Number vehicle loading spaces: 3.2 Mails Arrival / Platform Area Detail the space available for Mails arrivals and the process for receiving mail from the lorry and conveying to Inward Reception 3.3 Inward Reception Detail the space available for Inward Reception and the process for distributing mail to the correct area of the office 3.4 Fire Exits & Walkways Are Fire Exits and all Walkways in the Unit clearly marked? Are there any walkways that do not comply with Royal Mail space standards? Are all walkways required? Where Issues are identified above these must be actioned as part of the Layout requirements. 4. Letter Sortation 4.1 Primary Sorting Frames Where are York’s waiting Primary sorting situated? Detail the process for conveying mail from York’s to the IPS frames for sortation. Equipment: Stream Number of Frames Number of Selections No. of Seats Letters Flats 4.2 Secondary Sorting Frames Where is mail awaiting Secondary Sorting situated? Detail the process for conveying mail from Primary to Secondary Sorting Equipment: Stream Letters Flats Number of Frames Number of Selections No. of Seats 5. Packet Sortation 5.1 Primary Packets Detail the process for primary packet Sortation? Drop Bag Fittings: Detail the configuration, number of selections. Frame # Shape Where are packets awaiting Primary sorting stored? 5.2 Secondary Packets Detail the process for secondary packet Sortation? Selections Drop Bag Fittings: Detail the configuration, number of selections Frame # Shape Selections . How are packets conveyed from primary to secondary sorting? Where are packets awaiting secondary sortation stored 5.3 Heavy & Large Detail the process for sorting, distributing, and storing Heavy & Large Items awaiting delivery 5.4 Other Packet Sortation Processes: Detail any other processes & methods not covered by the above (Eg Firms / secondary DBF’s) 5.5 Method for storing Door 2 Door items 5.6 Other equipment in use List below all other equipment in use and quantities…Yorks, Alts, Mini Yorks, Bag Storage, etc. 5.7 Lighting Are there any areas of the office which are insufficiently lit? Is Task Lighting in use? How easy would it be to alter the configuration of overhead lighting as part of a new floor layout, or is provision or extension of task lighting required? 6. Mail Preparation 6.1 RM2000 How are the frames identified? Are they clearly defined and in a position that promotes efficient flow? Are CSS batches aligned to frame locations? Are D2D daily prep requirements clearly marked? Are personal effects stored on Prep Frames? All missing or defective parts to obtained via FM Helpdesk Walk Number Missing Components Defective Components 6.2 Other Prep Frames in Use Detail any other equipment in use for preparation of mail including seating: 6.3 Delivery Equipment Where is delivery equipment stored? (HCT/LWT/Pouches) Is Delivery Equipment easily identifiable and accessible by each walk? 6.4 Heavy & Large Packet Storage Where are heavy & large packets awaiting delivery stored in relation to prep areas? 7. MPU Operation/CSS Machines Where is inward mail for CSS processing received? Where are the CSS machines located in relation to the CSS inward reception area? Where is mail awaiting CSS processing stored? Where is CSS processed mail stored awaiting dispatch? Is the space for storage of CSS mail sufficient/excessive? 8. RLE Where are PDAs stored? (location of cabinet) Is the caller’s office accessible from the RLE? Where are callers office items stored? Where are Tracked & SD Items processed? Where are Tracked & SD items stored awaiting delivery? 9. Locker Room/Area Could this be moved to make better use of the space? Specify options for alternative location. Could full size lockers be replaced with half lockers? 10. Drying Room Could this be moved to make better use of the space? Specify options for alternative location. 11. Office Signage Is office signage compliant? If not raise via FM Helpdesk 12. Surplus Equipment List all surplus / broken / unused equipment that is identified for disposal (remember to include any equipment that maybe stored outside / behind unit) Equipment Location 12.1 New Equipment Please also list if the unit already has some of the new equipment Equipment Backless sorting frames Porter Trolleys Mini York’s Detail 13. Deep Clean Detail the actions identified to complete the deep clean What is the condition of the Toilets? When was the office last decorated? What other facilities are on site? Eg Restaurant, rest / quite area, games room etc 14. Safety Reporting Provide a summary of any Accidents that have occurred indoors within the past 3 months and any improvements that could be made to the building that could have prevented them Accident Preventative Improvement 15. Site Log Book Detail the location of the Site Log Book Is the Site Log Book up to date 16. Indoor Flow Equipment Delivery (e.g. Backless Fittings) Where will new equipment deliveries be unloaded and stored? Add initial thoughts on where you would store frames and equipment Acceptance of Vehicles to Site Maximum vehicle size that can deliver to site. E.g. 7.5 tonne, 17 tonne or Artic. Site Entry Point for Vehicles Contact on Arrival at DO Dock and Parking Area Holding Area for Vehicles prior to Offloading DO Able to take Delivery in the following time slots Offloading Method for Offloading from Vehicle to Dock 17. Other Comments Please detail anything else that you wish to note as part of this exercise NOTE: Although this document asks for lots of information the delivery programme does not have the funds to renovate and decorate delivery offices, priority must be given to improving performance and flow before other work is considered.