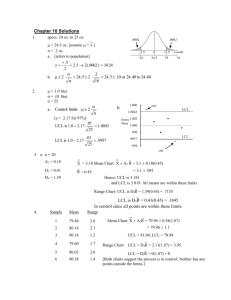

Chapter 7 Exercise Solutions

advertisement

Chapter 7 Exercise Solutions

Note: Several exercises in this chapter differ from those in the 4th edition. An “*”

indicates that the description has changed. A second exercise number in parentheses

indicates that the exercise number has changed. New exercises are denoted with an “”.

7-1.

ˆ x 74.001; R 0.023; ˆ R d 2 0.023 2.326 0.010

SL 74.000 0.035 [73.965, 74.035]

USL LSL 74.035 73.965

Cˆ p

1.17

6ˆ

6(0.010)

ˆ LSL 74.001 73.965

Cˆ pl

1.20

3ˆ

3(0.010)

USL ˆ 74.035 74.001

Cˆ pu

1.13

3ˆ

3(0.010)

Cˆ pk min Cˆ pl , Cˆ pu 1.13

7-2.

In Exercise 5-1, samples 12 and 15 are out of control, and the new process parameters are

used in the process capability analysis.

n 5; ˆ x 33.65; R 4.5; ˆ R d 2 1.93

USL 40; LSL 20

USL LSL 40 20

Cˆ p

1.73

6ˆ

6(1.93)

ˆ LSL 33.65 20

Cˆ pl

2.36

3ˆ

3(1.93)

USL ˆ 40 33.65

Cˆ pu

1.10

3ˆ

3(1.93)

Cˆ pk min Cˆ pl , Cˆ pu 1.10

7-1

Chapter 7 Exercise Solutions

7-3.

ˆ x 10.375; Rx 6.25; ˆ x R d 2 6.25 2.059 3.04

USL x [(350 5) 350] 10 50; LSL x [(350 5) 350] 10 50

xi (obsi 350) 10

USL x LSL x 50 (50)

Cˆ p

5.48

6ˆ x

6(3.04)

The process produces product that uses approximately 18% of the total specification

band.

USL x ˆ 50 10.375

Cˆ pu

4.34

3ˆ x

3(3.04)

ˆ LSL x 10.375 (50)

Cˆ pl

6.62

3ˆ x

3(3.04)

Cˆ pk min(Cˆ pu , Cˆ pl ) 4.34

This is an extremely capable process, with an estimated percent defective much less than

1 ppb. Note that the Cpk is less than Cp, indicating that the process is not centered and is

not achieving potential capability. However, this PCR does not tell where the mean is

located within the specification band.

T x 0 10.375

3.4128

S

3.04

Cˆ p

5.48

Cˆ pm

1.54

1V 2

1 (3.4128) 2

Since Cpm is greater than 4/3, the mean lies within approximately the middle fourth of

the specification band.

V

ˆ

ˆ T 10.375 0

3.41

ˆ

3.04

Cˆ pkm

Cˆ

1.54

pk

0.43

1 3.412

1 ˆ 2

7-2

Chapter 7 Exercise Solutions

7-4.

n 5; x 0.00109; R 0.00635; ˆ x 0.00273 ; tolerances: 0 0.01

USL LSL 0.01 0.01

Cˆ p

1.22

6ˆ

6(0.00273)

The process produces product that uses approximately 82% of the total specification

band.

USL ˆ 0.01 0.00109

Cˆ pu

1.09

3ˆ

3(0.00273)

ˆ LSL 0.00109 (0.01)

Cˆ pl

1.35

3ˆ

3(0.00273)

Cˆ min(Cˆ , Cˆ ) 1.09

pk

pl

pu

This process is not considered capable, failing to meet the minimally acceptable

definition of capable Cpk 1.33

T x 0 0.00109

0.399

S

0.00273

Cˆ

1.22

p

ˆ

C pm

1.13

1V 2

1 (0.399) 2

Since Cpm is greater than 1, the mean lies within approximately the middle third of the

specification band.

V

ˆ

ˆ T 0.00109 0

0.399

ˆ

0.00273

Cˆ pkm

Cˆ

1.09

pk

1.01

2

2

ˆ

1

0.399

1

7-3

Chapter 7 Exercise Solutions

7-5.

ˆ x 100; s 1.05; ˆ x s c4 1.05 0.9400 1.117

(a)

USL LSL (95 10) (95 10)

Potential: Cˆ p

2.98

6ˆ

6(1.117)

(b)

ˆ LSL x 100 (95 10)

Cˆ pl

4.48

3ˆ x

3(1.117)

USL x ˆ (95 10) 100

Actual: Cˆ pu

1.49

3ˆ x

3(1.117)

Cˆ min(Cˆ , Cˆ ) 1.49

pk

pl

pu

(c)

pˆ Actual Pr{x LSL} Pr{x USL}

Pr{x LSL} 1 Pr{x USL}

LSL ˆ

USL ˆ

Pr z

1 Pr z

ˆ

ˆ

85 100

105 100

Pr z

1 Pr z

1.117

1.117

(13.429) 1 (4.476)

0.0000 1 0.999996

0.000004

85 95

105 95

pˆ Potential Pr z

1 Pr z

1.117

1.117

(8.953) 1 (8.953)

0.000000 1 1.000000

0.000000

7-4

Chapter 7 Exercise Solutions

7-6.

n 4; ˆ x 199; R 3.5; ˆ x R d 2 3.5 2.059 1.70

USL = 200 + 8 = 208; LSL = 200 – 8 = 192

(a)

USL LSL 208 192

Potential: Cˆ p

1.57

6ˆ

6(1.70)

The process produces product that uses approximately 64% of the total specification

band.

(b)

USL ˆ 208 199

Cˆ pu

1.76

3ˆ

3(1.70)

ˆ LSL 199 192

1.37

Actual: Cˆ pl

3ˆ

3(1.70)

Cˆ min(Cˆ , Cˆ ) 1.37

pk

pl

pu

(c)

The current fraction nonconforming is:

pˆ Actual Pr{x LSL} Pr{x USL}

Pr{x LSL} 1 Pr{x USL}

LSL ˆ

USL ˆ

Pr z

1 Pr z

ˆ

ˆ

208 199

192 199

Pr z

1 Pr z

1.70

1.70

(4.1176) 1 (5.2941)

0.0000191 1 1

0.0000191

If the process mean could be centered at the specification target, the fraction

nonconforming would be:

192 200

pˆ Potential 2 Pr z

1.70

2 0.0000013

0.0000026

7-5

Chapter 7 Exercise Solutions

7-7.

n 2; ˆ x 39.7; R 2.5; ˆ x R d 2 2.5 1.128 2.216

USL = 40 + 5 = 45; LSL = 40 – 5 = 35

(a)

USL LSL 45 35

Potential: Cˆ p

0.75

6ˆ

6(2.216)

(b)

USL ˆ 45 39.7

Cˆ pu

0.80

3ˆ

3(2.216)

ˆ LSL 39.7 35

0.71

Actual: Cˆ pl

3ˆ

3(2.216)

Cˆ min(Cˆ , Cˆ ) 0.71

pk

pl

pu

(c)

V

Cˆ pm

x T 39.7 40

0.135

s

2.216

Cˆ p

0.75

0.74

2

1V

1 (0.135) 2

Cˆ pkm

Cˆ pk

0.71

0.70

1V

1 (0.135) 2

The closeness of estimates for Cp, Cpk, Cpm, and Cpkm indicate that the process mean is

very close to the specification target.

2

(d)

The current fraction nonconforming is:

pˆ Actual Pr{x LSL} Pr{x USL}

Pr{x LSL} 1 Pr{x USL}

LSL ˆ

USL ˆ

Pr z

1 Pr z

ˆ

ˆ

35 39.7

45 39.7

Pr z

1 Pr z

2.216

2.216

(2.12094) 1 (2.39170)

0.0169634 1 0.991615

0.025348

7-6

Chapter 7 Exercise Solutions

7-7 (d) continued

If the process mean could be centered at the specification target, the fraction

nonconforming would be:

35 40

pˆ Potential 2 Pr z

2.216

2 Pr{z 2.26}

2 0.01191

0.02382

7-8 (7-6).

ˆ 75; S 2; ˆ Sˆ c4 2 0.9400 2.13

(a)

USL LSL

2(8)

Potential: Cˆ p

1.25

6ˆ

6(2.13)

(b)

ˆ LSL 75 (80 8)

Cˆ pl

0.47

3ˆ

3(2.13)

USL ˆ 80 8 75

2.03

Actual: Cˆ pu

3ˆ

3(2.13)

Cˆ min(Cˆ , Cˆ ) 0.47

pk

pl

pu

(c) Let ˆ 80

pˆ Potential Pr{x LSL} Pr{x USL}

LSL ˆ

USL ˆ

Pr z

1 Pr z

ˆ

ˆ

72 80

88 80

Pr z

1 Pr z

2.13

2.13

(3.756) 1 (3.756)

0.000086 1 0.999914

0.000172

7-7

Chapter 7 Exercise Solutions

7-9 (7-7).

Assume n = 5

Process A

ˆ xA 100; sA 3; ˆ A sA c4 3 0.9400 3.191

USL LSL (100 10) (100 10)

Cˆ p

1.045

6ˆ

6(3.191)

USL x ˆ (100 10) 100

Cˆ pu

1.045

3ˆ x

3(3.191)

ˆ LSL x 100 (100 10)

Cˆ pl

1.045

3ˆ x

3(3.191)

Cˆ min(Cˆ , Cˆ ) 1.045

pk

pl

pu

x T 100 100

0

s

3.191

Cˆ p

1.045

Cˆ pm

1.045

2

1V

1 (0) 2

pˆ Pr{x LSL} Pr{x USL}

Pr{x LSL} 1 Pr{x USL}

V

LSL ˆ

USL ˆ

Pr z

1 Pr z

ˆ

ˆ

90 100

110 100

Pr z

1 Pr z

3.191

3.191

(3.13) 1 (3.13)

0.00087 1 0.99913

0.00174

Process B

ˆ xB 105; sB 1; ˆ B sB c4 1 0.9400 1.064

Cˆ

p

USL LSL

6ˆ

(100 10) (100 10)

3.133

6(1.064)

ˆ LSL x 105 (100 10)

Cˆ pl x

4.699

3ˆ x

3(1.064)

USL x ˆ x (100 10) 105

Cˆ pu

1.566

3ˆ x

3(1.064)

Cˆ pk min(Cˆ pl , Cˆ pu ) 1.566

7-8

Chapter 7 Exercise Solutions

7-9 continued

x T 100 105

V

4.699

s

1.064

Cˆ p

3.133

Cˆ pm

0.652

1V 2

1 (4.699) 2

90 105

110 105

pˆ Pr z

1 Pr z

1.064

1.064

(14.098) 1 (4.699)

0.000000 1 0.999999

0.000001

Prefer to use Process B with estimated process fallout of 0.000001 instead of Process A

with estimated fallout 0.001726.

7-10 (7-8).

Process A: ˆ A 20(100) 2000; ˆ A 20ˆ 2 20(3.191) 2 14.271

Process B: ˆ B 20(105) 2100; ˆ B 20ˆ 2 20(1.064)2 4.758

Process B will result in fewer defective assemblies. For the parts

indicates that more parts from Process B are within

Cˆ

1.045 1.566 Cˆ

pk , A

pk , B

specification than from Process A.

7-9

Chapter 7 Exercise Solutions

7-11 (7-9).

MTB > Stat > Basic Statistics > Normality Test

Probability Plot of 1-kg Containers (Ex7-9Wt)

Normal

99

Mean

StDev

N

AD

P-Value

95

90

0.9968

0.02167

15

0.323

0.492

Percent

80

70

60

50

40

30

20

10

5

1

0.950

0.975

1.000

Ex7-9Wt

1.025

1.050

A normal probability plot of the 1-kg container weights shows the distribution is close to

normal.

x p50 0.9975; p84 1.0200

ˆ p84 p50 1.0200 0.9975 0.0225

6ˆ 6(0.0225) 0.1350

7-12.

LSL = 0.985 kg

ˆ LSL 0.9975 0.985

C pl

0.19

3ˆ

3(0.0225)

LSL ˆ

0.985 0.9975

pˆ Pr z

Pr z

(0.556) 0.289105

ˆ

0.0225

7-10

Chapter 7 Exercise Solutions

7-13.

MTB > Stat > Basic Statistics > Normality Test

(Add percentile lines at Y values 50 and 84 to estimate and .)

Probability Plot of Disk Height (Ex7-13Ht)

Normal

99

95

90

84

Percent

80

Mean

StDev

N

AD

P-Value

20.00

0.009242

25

0.515

0.174

70

60

50

40

30

50

19.99986

10

5

1

19.98

19.99

20.00

Disk Height, mm

20.00905

20

20.01

20.02

A normal probability plot of computer disk heights shows the distribution is close to

normal.

x p50 19.99986

p84 20.00905

ˆ p84 p50 20.00905 19.99986 0.00919

6ˆ 6(0.00919) 0.05514

7-11

Chapter 7 Exercise Solutions

7-14.

MTB > Stat > Basic Statistics > Normality Test

(Add percentile lines at Y values 50 and 84 to estimate and .)

Probability Plot of Cycle Time (Ex7-14CT)

Normal

99

95

90

84

Percent

80

Mean

StDev

N

AD

P-Value

13.2

4.097

30

0.401

0.340

70

60

50

40

30

50

20

1

13.2

5

5

17.27

10

10

15

20

Reimbursement Cycle Time, Days

25

A normal probability plot of reimbursement cycle times shows the distribution is close to

normal.

x p50 13.2

p84 17.27

ˆ p84 p50 17.27 13.2 4.07

6ˆ 6(4.07) 24.42

7-12

Chapter 7 Exercise Solutions

7-15.

MTB > Stat > Basic Statistics > Normality Test

(Add percentile lines at Y values 50 and 84 to estimate and .)

Probability Plot of Response Time (Ex7-15Resp)

Normal

99

95

90

84

Percent

80

Mean

StDev

N

AD

P-Value

98.78

12.27

40

0.463

0.243

70

60

50

40

30

50

20

1

98.78

5

70

80

110.98

10

90

100

110

Response Time, minutes

120

130

A normal probability plot of response times shows the distribution is close to normal.

(a)

x p50 98.78

p84 110.98

ˆ p84 p50 110.98 98.78 12.2

6ˆ 6(12.2) 73.2

(b)

USL = 2 hrs = 120 mins

USL ˆ 120 98.78

C pu

0.58

3ˆ

3(12.2)

USL ˆ

USL ˆ

120 98.78

pˆ Pr z

1 Pr z

1 Pr z

ˆ

ˆ

12.2

1 (1.739) 1 0.958983 0.041017

7-13

Chapter 7 Exercise Solutions

7-16 (7-10).

MTB > Stat > Basic Statistics > Normality Test

(Add percentile lines at Y values 50 and 84 to estimate and .)

Probability Plot of Hardness Data (Ex5-59Har)

Normal

99

95

90

84

Percent

80

Mean

StDev

N

AD

P-Value

53.27

2.712

15

0.465

0.217

70

60

50

40

30

50

20

1

53.27

5

46

48

50

52

54

Hardness

55.96

10

56

58

60

A normal probability plot of hardness data shows the distribution is close to normal.

x p50 53.27

p84 55.96

ˆ p84 p50 55.96 53.27 2.69

6ˆ 6(2.69) 16.14

7-14

Chapter 7 Exercise Solutions

7-17 (7-11).

MTB > Stat > Basic Statistics > Normality Test

Probability Plot of Failure Times (Ex7-17FT)

Normal

99

Mean

StDev

N

AD

P-Value

95

90

1919

507.1

10

0.272

0.587

Percent

80

70

60

50

40

30

20

10

5

1

1000

1500

2000

Ex7-17FT

2500

3000

The plot shows that the data is not normally distributed; so it is not appropriate to

estimate capability.

7-15

Chapter 7 Exercise Solutions

7-18 (7-12).

LSL = 75; USL = 85; n = 25; S = 1.5

(a)

USL LSL 85 75

Cˆ p

1.11

6ˆ

6(1.5)

(b)

0.05

2

12 / 2,n 1 0.975,24

12.40

2

2/ 2,n 1 0.025,24

39.36

12 / 2,n 1

2/ 2, n 1

ˆ

ˆ

Cp

Cp Cp

n 1

n 1

1.11

12.40

39.36

C p 1.11

25 1

25 1

0.80 C p 1.42

This confidence interval is wide enough that the process may either be capable

(ppm = 27) or far from it (ppm 16,395).

7-19 (7-13).

n 50

Cˆ 1.52

p

1 0.95

2

12 ,n 1 0.95,49

33.9303

2

Cˆ p 1 ,n 1 C p

n 1

1.52

33.9303

1.26 C p

49

The company cannot demonstrate that the PCR exceeds 1.33 at a 95% confidence level.

1.52

12 ,49

49

1.33

2

1.33

49

37.52

1.52

1 0.88

2

1 ,49

0.12

7-16

Chapter 7 Exercise Solutions

7-20 (7-14).

n 30; x 97; S 1.6; USL 100; LSL 90

(a)

USL x ˆ x 100 97

Cˆ pu

0.63

3ˆ x

3(1.6)

ˆ LSL x 97 90

Cˆ pl x

1.46

3ˆ x

3(1.6)

Cˆ pk min(Cˆ pl , Cˆ pu ) 0.63

(b)

0.05

z / 2 z0.025 1.960

1

1

C pk Cˆ pk

Cˆ pk 1 z / 2

2

2(n 1)

9nCˆ pk

1

1

1 z / 2

2

2(n 1)

9nCˆ pk

1

1

1

1

0.63 1 1.96

C pk 0.63 1 1.96

2

2

9(30)(0.63)

2(30 1)

9(30)(0.63)

2(30 1)

0.4287 C pk 0.8313

7-17

Chapter 7 Exercise Solutions

7-21 (7-15).

USL = 2350; LSL = 2100; nominal = 2225; x 2275; s 60; n 50

(a)

USL x ˆ x 2350 2275

Cˆ pu

0.42

3ˆ x

3(60)

ˆ LSL x 2275 2100

Cˆ pl x

0.97

3ˆ x

3(60)

Cˆ pk min(Cˆ pl , Cˆ pu ) 0.42

(b)

0.05; z / 2 z0.025 1.960

1

1

1

1

ˆ 1 z

Cˆ pk 1 z / 2

C

C

pk

pk

/

2

2

ˆ 2 2( n 1)

2(n 1)

9nCˆ pk

9

nC

pk

1

1

1

1

0.42 1 1.96

C pk 0.42 1 1.96

2

2

9(50)(0.42) 2(50 1)

9(50)(0.42) 2(50 1)

0.2957 C pk 0.5443

7-22 (7-16).

from Ex. 7-20, Cˆ pk 0.63; z / 2 1.96; n 30

1

1

Cˆ pk 1 z / 2

C pk Cˆ pk 1 z / 2

2(n 1)

2(n 1)

1

1

0.63 1 1.96

C pk 0.63 1+1.96

2(30 1)

2(30 1)

0.47 C pk 0.79

The approximation yields a narrower confidence interval, but it is not too far off.

7-23 (7-17).

OI 0; ˆ I 3; ˆ Total 5

2

2

2

ˆ Total

ˆ Meas

ˆ Process

2

2

ˆ Process ˆ Total

ˆ Meas

52 32 4

7-18

Chapter 7 Exercise Solutions

7-24 (7-18).

(a)

n 2; x 21.8; R 2.8; ˆ Gauge 2.482

MTB > Stat > Control Charts > Variables Charts for Subgroups > X-bar R

Xbar-R Chart of Part Measurements (Ex7-24All)

30

1

Sample M ean

U C L=27.07

25

_

_

X=21.8

20

15

1

2

4

6

8

1

1

10

Sample

12

14

16

18

LC L=16.53

20

U C L=9.15

Sample Range

8

6

4

_

R=2.8

2

0

LC L=0

2

4

6

8

10

Sample

12

14

16

18

20

Test Results for Xbar Chart of Ex7-24All

TEST 1. One point more than 3.00 standard deviations from center line.

Test Failed at points: 8, 12, 15, 20

The R chart is in control, and the x chart has a few out-of-control parts. The new gauge

is more repeatable than the old one.

(b) specs: 25 15

6ˆ Gauge

P

6(2.482)

100

100 49.6%

T USL LSL

2(15)

7-19

Chapter 7 Exercise Solutions

7-25 (7-19).

MTB > Stat > Control Charts > Variables Charts for Subgroups > X-bar R

Xbar-R Chart of Part Mesaurements (Ex7-25All)

102.0

1

U C L=100.553

Sample M ean

100.5

99.0

_

_

X=98.2

97.5

96.0

LC L=95.847

1

1

2

3

4

6

5

7

8

9

10

Sample

Sample Range

6.0

U C L=5.921

4.5

3.0

_

R=2.3

1.5

LC L=0

0.0

1

2

3

4

6

5

7

8

9

10

Sample

Test Results for Xbar Chart of Ex7-25All

TEST 1. One point more than 3.00 standard deviations from center line.

Test Failed at points: 2, 3

The x chart has a couple out-of-control points, and the R chart is in control. This

indicates that the operator is not having difficulty making consistent measurements.

(b)

x 98.2; R 2.3; ˆ Gauge R d 2 2.3 1.693 1.359

2

ˆ Total

4.717

2

2

2

ˆ Product

ˆ Total

ˆ Gauge

4.717 1.3592 2.872

ˆ Product 1.695

(c)

ˆ Gauge

ˆ Total

100

1.359

100 62.5%

4.717

(d)

USL = 100 + 15 = 115; LSL = 100 – 15 = 85

6ˆ Gauge

P

6(1.359)

0.272

T USL LSL 115 85

7-20

Chapter 7 Exercise Solutions

7-26 (7-20).

(a)

Excel : workbook Chap07.xls : worksheet Ex7-26

x1 50.03; R1 1.70; x2 49.87; R2 2.30

R 2.00

n 3 repeat measurements

d 2 1.693

ˆ Repeatability R d 2 2.00 1.693 1.181

Rx 0.17

n 2 operators

d 2 1.128

ˆ Reproducibility Rx d 2 0.17 1.128 0.151

(b)

2

2

2

ˆ2

ˆ2

ˆ Measurement

Error Repeatability Reproducibility 1.181 0.151 1.418

ˆ Measurement Error 1.191

(c) specs: 50 10

6ˆ Gauge

P

6(1.191)

100

100 35.7%

T USL LSL

60 40

7-21

Chapter 7 Exercise Solutions

7-27 (7-21).

(a)

ˆ Gauge R d2 1.533 1.128 1.359

Gauge capability: 6ˆ 8.154

(b)

MTB > Stat > Control Charts > Variables Charts for Subgroups > X-bar R

Xbar-R Chart of Part Measurements (Ex7-27All)

1

1

Sample M ean

25.0

U C L=23.58

22.5

_

_

X=20.7

20.0

LC L=17.82

17.5

1

15.0

1

1

2

3

4

5

6

7

8

Sample

9

10

Sample Range

6.0

11

12

1

1

13

14

15

U C L=5.010

4.5

3.0

_

R=1.533

1.5

0.0

LC L=0

1

2

3

4

5

6

7

8

Sample

9

10

11

12

13

14

15

Test Results for R Chart of Ex7-27All

TEST 1. One point more than 3.00 standard deviations from center line.

Test Failed at points: 11, 12

Out-of-control points on R chart indicate operator difficulty with using gage.

7-22

Chapter 7 Exercise Solutions

7-28.

MTB > Stat > ANOVA > Balanced ANOVA

In Results, select “Display expected mean squares and variance components”

ANOVA: Ex7-28Reading versus Ex7-28Part, Ex7-28Op

Factor

Ex7-28Part

Ex7-28Op

Type

random

random

Factor

Ex7-28Part

18, 19, 20

Ex7-28Op

Values

1, 2,

Levels

20

3

3,

4,

5,

6,

7,

8,

1, 2, 3

Analysis of Variance for Ex7-28Reading

Source

DF

SS

MS

Ex7-28Part

19 1185.425 62.391

Ex7-28Op

2

2.617

1.308

Ex7-28Part*Ex7-28Op

38

27.050

0.712

Error

60

59.500

0.992

Total

119 1274.592

S = 0.995825

1

2

3

4

9, 10, 11, 12, 13, 14, 15, 16, 17,

R-Sq = 95.33%

Source

Ex7-28Part

Ex7-28Op

Ex7-28Part*Ex7-28Op

Error

F

87.65

1.84

0.72

P

0.000

0.173

0.861

R-Sq(adj) = 90.74%

Variance

component

10.2798

0.0149

-0.1399

0.9917

Error

term

3

3

4

Expected Mean Square

for Each Term (using

unrestricted model)

(4) + 2 (3) + 6 (1)

(4) + 2 (3) + 40 (2)

(4) + 2 (3)

(4)

2

ˆ Repeatability

MSError 0.992

MSP×O MS E 0.712 0.992

0.1400 0

n

2

MSO MSP×O 1.308 0.712

2

ˆ Operator

=

0.0149

pn

20(2)

MSP MSP×O 62.391 0.712

2

ˆ Part

=

10.2798

on

3(2)

2

ˆ Part×Operator

The manual calculations match the MINITAB results. Note the Part Operator variance

component is negative. Since the Part Operator term is not significant ( = 0.10), we

can fit a reduced model without that term. For the reduced model:

ANOVA: Ex7-28Reading versus Ex7-28Part, Ex7-28Op

…

1

2

3

Source

Ex7-28Part

Ex7-28Op

Error

Variance

component

10.2513

0.0106

0.8832

Error

term

3

3

Expected

Mean Square

for Each

Term (using

unrestricted

model)

(3) + 6 (1)

(3) + 40 (2)

(3)

7-23

Chapter 7 Exercise Solutions

(a)

2

2

ˆ Reproducibility

ˆ Operator

0.0106

2

2

ˆ Repeatability

ˆ Error

0.8832

(b)

2

2

2

ˆ Gauge

ˆ Reproducibility

ˆ Repeatability

0.0106 0.8832 0.8938

ˆ Gauge 0.9454

(c)

6 ˆ Gauge

6 0.9454

0.1050

USL-LSL

60 6

This gauge is borderline capable since the estimate of P/T ratio just exceeds 0.10.

P /T

Estimates of variance components, reproducibility, repeatability, and total gauge

variability may also be found using:

MTB > Stat > Quality Tools > Gage Study > Gage R&R Study (Crossed)

Gage R&R Study - ANOVA Method

Two-Way ANOVA Table With Interaction

Source

Ex7-28Part

Ex7-28Op

Ex7-28Part * Ex7-28Op

Repeatability

Total

DF

19

2

38

60

119

SS

1185.43

2.62

27.05

59.50

1274.59

MS

62.3908

1.3083

0.7118

0.9917

F

87.6470

1.8380

0.7178

P

0.000

0.173

0.861

Two-Way ANOVA Table Without Interaction

Source

Ex7-28Part

Ex7-28Op

Repeatability

Total

DF

19

2

98

119

SS

1185.43

2.62

86.55

1274.59

MS

62.3908

1.3083

0.8832

F

70.6447

1.4814

P

0.000

0.232

Gage R&R

Source

Total Gage R&R

Repeatability

Reproducibility

Ex7-28Op

Part-To-Part

Total Variation

VarComp

0.8938

0.8832

0.0106

0.0106

10.2513

11.1451

%Contribution

(of VarComp)

8.02

7.92

0.10

0.10

91.98

100.00

Study Var

Source

StdDev (SD)

(6 * SD)

Total Gage R&R

0.94541

5.6724

Repeatability

0.93977

5.6386

Reproducibility

0.10310

0.6186

Ex7-28Op

0.10310

0.6186

Part-To-Part

3.20176

19.2106

Total Variation

3.33842

20.0305

Number of Distinct Categories = 4

%Study Var

(%SV)

28.32

28.15

3.09

3.09

95.91

100.00

7-24

Chapter 7 Exercise Solutions

7-28 continued

Visual representations of variability and stability are also provided:

Gage R&R (ANOVA) for Ex7-28Reading

Reported by :

Tolerance:

M isc:

G age name:

D ate of study :

Components of Variation

Ex7-28Reading by Ex7-28Part

100

% Contribution

30

Percent

% Study Var

25

50

20

0

Gage R&R

Repeat

Reprod

1

Part-to-Part

2

3

4

5

R Chart by Ex7-28Op

Sample Range

4

1

2

6

7

8

Ex7-28Reading by Ex7-28Op

3

UCL=3.757

30

25

2

_

R=1.15

0

20

LCL=0

1

2

Ex7-28Op

Xbar Chart by Ex7-28Op

1

2

3

Ex7-28Op * Ex7-28Part Interaction

3

30

30

25

UCL=24.55

_

_

X=22.39

20

LCL=20.23

Average

Sample Mean

9 10 11 12 13 14 15 16 17 18 19 20

Ex7-28Part

Ex7-28Op

1

2

3

25

20

1

2

3

4

5

6

7

8

9 10 11 1 2 13 14 1 5 16 17 18 1 9 20

Ex7-28Part

7-25

Chapter 7 Exercise Solutions

7-29.

2

2

ˆ Part

10.2513; ˆ Total

11.1451

ˆ P

2

ˆ Part

10.2513

0.9198

2

ˆ Total 11.1451

SNR

DR

2 ˆ P

2(0.9198)

4.79

1 ˆ P

1 0.9198

1 ˆ P 1 0.9198

23.94

1 ˆ P 1 0.9198

SNR = 4.79 indicates that fewer than five distinct levels can be reliably obtained from the

measurements. This is near the AIAG-recommended value of five levels or more, but

larger than a value of two (or less) that indicates inadequate gauge capability. (Also note

that the MINITAB Gage R&R output indicates “Number of Distinct Categories = 4”;

this is also the number of distinct categories of parts that the gauge is able to distinguish)

DR = 23.94, exceeding the minimum recommendation of four. By this measure, the

gauge is capable.

7-30 (7-22).

1 2 3 100 75 75 250

12 22 33 42 42 22 6

Pr{x 262} 1 Pr{x 262}

262

1 Pr z

262 250

1 Pr z

6

1 (2.000)

1 0.9772

0.0228

7-26

Chapter 7 Exercise Solutions

7-31 (7-23).

x1 ~ N (20, 0.32 ); x2 ~ N (19.6, 0.42 )

Nonconformities will occur if y x1 x2 0.1 or y x1 x2 0.9

y 1 2 20 19.6 0.4

y2 12 22 0.32 0.42 0.25

y 0.50

Pr{Nonconformities} Pr{ y LSL} Pr{ y USL}

Pr{ y 0.1} Pr{ y 0.9}

Pr{ y 0.1} 1 Pr{ y 0.9}

0.1 0.4

0.9 0.4

1

0.25

0.25

(0.6) 1 (1.00)

0.2743 1 0.8413

0.4330

7-32 (7-24).

Volume L H W

L H W ( L L ) H W ( H H ) L W (W W ) L H

ˆ Volume L H W 6.0(3.0)(4.0) 72.0

2

Volume

L2 H2 W2 H2 L2 W2 W2 L2 H2

6.02 (0.01)(0.01) 3.02 (0.01)(0.01) 4.02 (0.01)(0.01)

0.0061

7-33 (7-25).

Weight d W L T

d W L T (W W ) L T ( L L ) W T (T T ) W L

ˆ Weight d [ W L T ] 0.08(10)(20)(3) 48

2

ˆ Weight

d 2 ˆW2 ˆ L2ˆT2 ˆ L2ˆW2 ˆT2 ˆT2ˆW2 ˆ L2

0.082 102 (0.32 )(0.12 ) 202 (0.22 )(0.12 ) 32 (0.2 2 )(0.32 ) 0.00181

ˆ Weight 0.04252

7-27

Chapter 7 Exercise Solutions

7-34 (7-26).

1

(5 x 2); 2 x 4

26

4

4

4

1 5 3

1

E ( x) x xf ( x)dx x (5 x 2) dx x x 2 3.1282

2

26 3 2

2 26

4

4

4

1 5

2

1

E x 2 x 2 f ( x)dx x 2 (5 x 2) dx x 4 x3 10.1026

26 4 2 3 2

2

26

s (3 0.05 x) 2 and f ( x)

x2 E ( x 2 ) E ( x) 10.1026 (3.1282) 2 0.3170

2

s g ( x) 3 0.05( x ) 3 0.05(3.1282) 9.9629

2

g ( x)

x

2

s

2

2

x2

x

(3 0.05 x) 2

x

2

x2

x

2(3 0.05 x )(0.05) x2

2 3 0.05(3.1282) (0.05)(0.3170)

0.1001

7-35 (7-27).

I E ( R1 R2 )

I E (R R )

1

I2

2

E

( R1 R2 )

2

E

2 R2

2 R

(R R )

1

1

2

2

7-28

Chapter 7 Exercise Solutions

7-36 (7-28).

x1 ~ N ( 1 , 0.4002 ); x2 ~ N ( 2 , 0.3002 )

y 1 2

y 12 22 0.4002 0.3002 0.5

Pr{ y 0.09} 0.006

0.09 y

1

Pr z

(0.006)

y

0.09 y

2.512

0.5

y [0.5(2.512) 0.09] 1.346

7-37 (7-29).

ID ~ N (2.010,0.0022 ) and OD ~ N (2.004,0.0012 )

Interference occurs if y = ID – OD < 0

y ID OD 2.010 2.004 0.006

2

2

y2 ID

OD

0.0022 0.0012 0.000005

y 0.002236

Pr{positive clearance} 1 Pr{interference}

1 Pr{ y 0}

0 0.006

1

0.000005

1 (2.683)

1 0.0036

0.9964

7-38 (7-30).

0.01

0.80

2

12 ,4 0.20,4

5.989

1 2 1 ,4 1 2 0.01 5.989

299

2 4

2 0.01 4

2

n

7-29

Chapter 7 Exercise Solutions

7-39 (7-31).

n = 10; x ~ N (300,102 ); 0.10; 0.95 ; one-sided

From Appendix VIII: K = 2.355

UTL x KS 300 2.355(10) 323.55

7-40 (7-32).

n = 25; x ~ N (85,12 ); 0.10; 0.95 ; one-sided

From Appendix VIII: K = 1.838

x KS 85 1.838(1) 83.162

7-41 (7-33).

n = 20; x ~ N (350,102 ); 0.05; 0.90 ; one-sided

From Appendix VIII: K = 2.208

UTL x KS 350 2.208(10) 372.08

7-42 (7-34).

0.05

0.90

2

12 ,4 0.10,4

7.779

1 2 1 ,4 1 2 0.05 7.779

77

2 4

2 0.05 4

2

n

After the data are collected, a natural tolerance interval would be the smallest to largest

observations.

7-30

Chapter 7 Exercise Solutions

7-43 (7-35).

x ~ N 0.1264, 0.00032

(a)

= 0.05; = 0.95; and two-sided

From Appendix VII: K = 2.445

TI on x : x KS 0.1264 2.445(0.0003) [0.1257, 0.1271]

(b)

0.05; t / 2,n1 t0.025,39 2.023

CI on x : x t / 2,n1 S

n 0.1264 2.023 0.0003

40 [0.1263, 0.1265]

Part (a) is a tolerance interval on individual thickness observations; part (b) is a

confidence interval on mean thickness. In part (a), the interval relates to individual

observations (random variables), while in part (b) the interval refers to a parameter of a

distribution (an unknown constant).

7-44 (7-36).

0.05; 0.95

n

log(1 ) log(1 0.95)

59

log(1 ) log(1 0.05)

The largest observation would be the nonparametric upper tolerance limit.

7-31