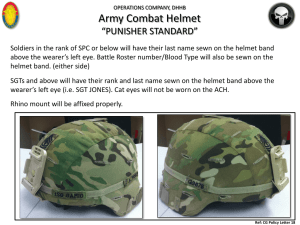

Head Protection

advertisement

PPE: Head Protection 29 CFR 1910.135, 29 CFR 1915.155, 29 CFR 1926.100 Session Objectives You will be able to: • Identify head hazards • Choose appropriate head protection • Know the limitations of head protection • Use and take care of your head protection © Business & Legal Reports, Inc. 0603 Hazard Assessments • Assess the workplace • Evaluate every job • Determine appropriate PPE • Certify the completion of the hazard assessment in writing © Business & Legal Reports, Inc. 0603 Head Hazard Assessment • Falling objects • Exposed electrical conductors • Low-hanging obstructions © Business & Legal Reports, Inc. 0603 Falling Objects • You are at risk when working below others • Incidents are difficult to anticipate • Most impact injuries occur to workers not wearing head protection • Most workers injured while doing normal jobs © Business & Legal Reports, Inc. 0603 Exposed Electrical Conductors • Electrical shock or burns could occur • Head protection insulates and protects • Select right class of head protection © Business & Legal Reports, Inc. 0603 Bump Hazards • Bumps, scrapes, bruises • Low-hanging pipes, steel structures, machinery components • Nonroutine cleaning or maintenance © Business & Legal Reports, Inc. 0603 Head Hazards and Injuries—Any Questions? • Any questions about workplace hazards to your head? © Business & Legal Reports, Inc. 0603 Hard Hat Design • Resist penetration • Absorb shock • High-density, lightweight polyethylene • Stamped with ANSI Z89 specifications © Business & Legal Reports, Inc. 0603 Hard Hat Types • Type I–Top impact and penetration protection • Type II–Top and side impact and penetration protection • ANSI Z89.1 © Business & Legal Reports, Inc. 0603 Hard Hat Classes • Class C – No electrical protection • Class G – Low voltage (tested at 2,200 volts) • Class E – High voltage (tested at 20,000 volts) © Business & Legal Reports, Inc. 0603 Hard Hat Testing • Temperature extremes • Impact resistance • Penetration resistance • Electrical insulation © Business & Legal Reports, Inc. 0603 Standard Head Protection • Wide profile and brim • Increased ventilation • Sun protection • Suspension system • Ratchet systems • Brow pads © Business & Legal Reports, Inc. 0603 Highly Protective Helmet • Impact and penetration resistance from all directions • Chin strap • Air vents molded into helmet • Crown pad and brow pad • Accessories © Business & Legal Reports, Inc. 0603 High Temperature Hats • Advanced thermoplastic materials • Utilities, welding, foundries, steel mills • Meet NFPA 1977-1998 Standard • Exposed to 350ºF for 5 minutes • Resistant to radiant heat and flame © Business & Legal Reports, Inc. 0603 Bump Caps • Protect against bumps, scrapes, cuts • Used when helmet or hard hat unnecessary • Made of lightweight hard plastic • May accommodate faceshields or visors • Do not meet ANSI Z89 standards © Business & Legal Reports, Inc. 0603 Hard Hat Selection—Any Questions? • Any questions about choosing appropriate head protection? © Business & Legal Reports, Inc. 0603 Wearing Hard Hats Backward • Type I hard hats have been tested • Crown must be symmetrical • Suspension must be reversed • Type II helmets should not be worn backward © Business & Legal Reports, Inc. 0603 Stickers or Markings • Adhesive stickers will not chemically damage helmets • Stickers may cover cracks or other signs of damage • Keep stickers at least 3/4 inch away from edge of helmet • Engraving is restricted to underside of brim • Do not engrave the crown area or near suspension sockets © Business & Legal Reports, Inc. 0603 Visibility • Increase visibility to equipment operators and vehicles • High-visibility colors • Fluorescent striping • Reflective striping © Business & Legal Reports, Inc. 0603 Objects Inside a Hard Hat • Maintain clearance between shell and head • Metal part may reduce electrical insulation properties • Do not place objects above or below crown straps • Fabric winter liners or sunshades are acceptable © Business & Legal Reports, Inc. 0603 Useful Life of a Hard Hat • Replace every 2 years if exposed to chemicals, sunlight, temperature extremes • Date codes are molded into brims • Replace if struck by a forcible blow © Business & Legal Reports, Inc. 0603 Maintenance and Care • Clean with mild detergent and hot water • Inspect shell for damage or excess wear • Inspect suspension straps for cuts, frays, chemical damage • Never drill holes • Do not use paints or cleaning solvents © Business & Legal Reports, Inc. 0603 Field Test Hard Hats • Compress shell sides inward 1 inch • Release pressure • Shell should return to original shape • Compare elasticity to new shell • Replace if not elastic or if it cracks © Business & Legal Reports, Inc. 0603 Head Protection—Any Questions? • Any questions about the use and care of hard hats? © Business & Legal Reports, Inc. 0603 Key Points to Remember • Follow recommendations in head hazard assessment • Wear the correct type and class of helmet for the hazards found • Inspect and clean hard hats daily • Limit stickers and other markings • Replace hard hats according to work conditions © Business & Legal Reports, Inc. 0603