Food Safety & Foodborne Illness

advertisement

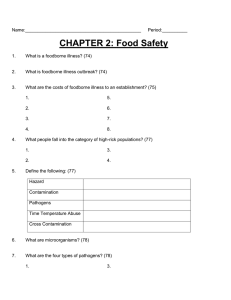

Keeping Food Safe Chapter 2 What is a Foodborne Illness? Foodborne illnesses are caused by agents that enter the body through the ingestion of food. Two or more people get the same illness after eating the same food No long-term health threat to average person Reaction may occur in a few hours or up to several days after exposure Symptoms Abdominal cramps, headache, vomiting, diarrhea (may be bloody), fever, death High Risk Populations Affected Those that have a higher risk of getting a foodborne illness: Immune system is the body’s defense system against foodborne illnesses Elderly people Infants and pre-school aged children Pregnant women People with cancer or on chemotherapy People with HIV/AIDS Transplant recipients What is the Cost of Foodborne Illness? Loss of customers and sales Negative media exposure Lawsuits and legal fees Increase insurance premiums Loss of reputation Lowered employee moral Employee absenteeism Staff retraining What is the Impact of Foodborne Illness? In the US annually: 76 million cases of foodborne diseases 325,000 hospitalization 5,000 deaths [fast fact] The US Department of Agriculture Economic Research Services developed a calculator to determine actual cost of a foodborne illness www.ers/usda.gov/Data/FoodbornIllness/ Forms of Contaminaton Types of Hazards Biological Chemical Physical Contamination Harmful things are present in food making it unsafe to eat Poor personal hygiene transfers pathogens from body to food Time-temperature abuse Cross-contamination Poor cleaning and sanitizing of work stations Purchasing from unapproved suppliers Biological Contamination Pathogens are microorganisms that humans carry and transfer to food Viruses Bacteria Parasites Fungi Biological toxins in food can occur naturally in certain plants or animals Seafood Mushrooms Cannot be seen, smelled, or tasted Fungi can change the appearance, taste, or smell but may not cause illness Pathogens need six conditions to grow FAT-TOM Food Acidity Pathogens grow best in food that contains little OR no acid Temperature Time Temperature danger zone 41°F – 135 °F The longer food is in the temperature danger zone, the more time pathogens have to grow Oxygen Some need oxygen to grow. Others grow when oxygen isn’t there. Moisture Food most likely to become TCS abused TCS- time control for safety Milk and dairy Meat Beef, pork, lamb Eggs Poultry Fish Shellfish and Crustaceans Baked potatoes Heat-treated plant food Cooked rice, beans Tofu or soy protein Sprouts and sprout seeds Sliced melons and tomatoes Untreated garlic and oil mixtures Viruses Do not reproduce in foods, but can be transmitted from people to food items then grow within the intestinal tract Contaminate food and water Usually contaminate food through improper personal hygiene To prevent viruses Stay home if you are sick Wash your hands at the right times, the right way Avoid using bare hands to handle ready-to-eat food Bacteria Can multiply rapidly in favorable conditions Can cause illness by producing toxins in food May be carried by a variety of means: Food Water Soil Humans Insects Some can survive freezing Preventing bacteria- follow FAT-TOM rules Other contaminates Parasites Need a host to survive Fungi Grow naturally in many animals Cows Chickens Pigs Fish Can also grow on a plant Molds Spoil food and can cause illness Grows well in food with naturally high acidic levels Yeasts Spoil food quickly Signs of spoilage Smell Taste of alcohol Pink discoloration Slime or bubbles Chemical Contamination Hazards that are dangerous to foods Cleaning supplies Pesticides Toxic Metals Lead Copper Zinc Preventing contamination Store chemicals away from food, utensils, and equipment used for food Physical Contamination When objects get into food Metal shavings from cans Glass from broken light bulbs Fingernails, hair, bandages Jewelry Fruit pits Prevention Inspect food closely, practice good hygiene, and follow preparation procedures Food Defense System against people purposely contaminating food Competitors Vendors Former employees Terrorists To prevent tampering Limit access to operation’s food storage and prep areas Uniforms and nametags help identify employees and vendors Security badges for those in restricted areas Having all staff report suspicious activity Food Allergens Major food allergens Milk and dairy Eggs and egg products Fish Shellfish Soy and soy products Peanuts Tree nuts Preventing an allergic reaction Tell the customer how each dish is made Tell the customer about any “secret” ingredients that may contain allergens Suggest alternative menu items that don’t have the food allergen Avoid cross-contact Hand-washing Hand-washing and the Risk of Cross-Contamination Preventing Cross-Contamination Cross contamination can happen at any point in the flow of food Separate equipment Clean and sanitize Prep food at different times Buy prepared food Time Temperature Issues Food is being temperature abused whenever it is handled in the following ways Cooked to the wrong internal temperature Held at the wrong temperature Cooled or reheated incorrectly The Flow of Food Purchasing Receiving Storing Preparation Cooking Holding Cooling Reheating Serving Purchasing and Receiving Purchasing Reputable, approved supplier Inspected by appropriate agencies Meets all local, state, and federal laws Good use of food safety practices Receiving Have enough trained staff to receive food Carefully and immediately inspect and put away the order Follow temperature, packing, and product quality on if to accept or reject orders Storing Food Food Should be Stored in the Following Order Ready-to-eat Seafood Whole cuts of beef and pork Ground meats and ground fish Whole and ground poultry FIFO – First in, first out Preparing Foods General Rules Keep all equipment clean and sanitized Remove only as much food as you can prep in a short amount of time Return prepped food to storage as quickly as possible Thawing Refrigeration Running water – 70 degrees or lower Microwave Cooking Cooling, Holding and Reheating Cooling Cooling Reheating Holding Holding Ice Water Bath Ice Paddle Blast chiller Cool from 135-41 or lower within 6 hours 1. 135-70 within 2 hours 2. Cool to 41 over next 4 hours. ** Pathogens grow faster between 125 and 70F Hot foods hot 135 or higher Cold foods cold 41 or lower Check temperatures every 4 hours Reheating Foods Food for Holding Food must reach an internal temp of 165 within 2 hours Serving Handle ready-to-eat foods with tongs, deli sheets, or gloves Use separate utensils for each food item Store serving utensils in food with handle extended above the rim of the container-OR- place on a clean and sanitized surface Off-Site Food Service Pack in insulated containers Check internal temperatures Use food-grade containers that wont mix, leak, or spill Clean inside of delivery vehicles Thermometers Bimetallic Stemmed Thermometers Thermocouples and Thermistors 0-220°F Hot and Cold foods Insert into the thickest part of the food Probe and screen Can be inserted into food and liquids Surface probes can check the temperature of flat cooking equipment Air probes can check the temperature of coolers and ovens Infrared Thermometers Checks food and surface temperatures Clean and Sanitary Kitchen Clean and sanitize sinks and work surfaces Scrape and presoak items, then sort First sink – wash in clean, hot detergent solution Second sink – rinse in clear, hot water Third sink – sanitize items using a chemical sanitizing solution or hot water for 30 seconds Air dry HACCP – Hazard Analysis and Critical Control Point The Seven Principles Conduct a Hazard Analysis Identify menu items that contain potentially hazardous food Recognize the flow of this food through your operation Identify possible hazards Determine Critical Control Points Points in the flow where possible hazards can be prevented, eliminated, or reduced to safe levels There may be more than one CCP for each menu item HACCP Establish Critical Limits Cook food to appropriate internal Temperature Hold cooked food at or above 135 Hold cold food at or below 41 Reheat foods to 165 for 15 seconds Establish monitoring procedures Determine the best ways to monitor CCPs Identify who will monitor CCPs and how often Identify corrective actions Steps to be taken when a critical limit is not met Continue cooking food Throw out HACCP Verify that the system works Review records and logs Determine if hazards are effectively prevented, reduced, or eliminated Establish procedures for record keeping and documentation Build a source of information about daily operations and trends Can be used to identify problem areas OSHA – Occupational Safety and Health Administration Governs rules and regulations that are enforced to ensure that all employees in an establishment are working in a place that emphasizes safety.