The Stabilizing Effect of Moisture on the Solid-State

advertisement

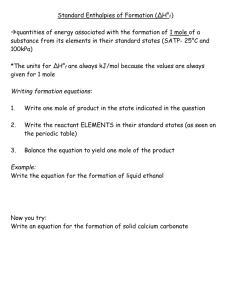

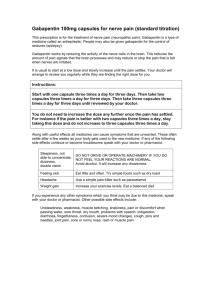

Linking Drug Stability to Manufacturing Physical Chemical Foundations Gabapentin L. E. Kirsch Stability team leader Stability Team Group Team member Minnesota Raj Suryanarayanan (Co-PI) Aditya Kaushal (post-doc) Kansas Eric Munson (Co-PI) Dewey Barich (post-doc) Elodie Dempah, Eric Gorman (grad. students) Iowa Lee Kirsch (Co-PI) Greg Huang (Analytical Chemist) Salil Desai, Zhixin Zong, Tinmanee Radaduen, Hoa Nguyen, Jiang Qiu (grad students) Duquesne (Unit-op team Interface) Ira Buckner Linking manufacturing to stability (Unstable form) (Stable form) 3 Gabapentin as a model drug substance • Multiple crystalline forms • Susceptible to stress-induced physical transformations • Susceptible to chemical degradation KEY QUESTIONS 1. Are physical and chemical instability linked? 2. How can manufacturing-induced stress be incorporated in a quantitative chemical instability model? 4 Some Crystalline Forms of Gabapentin Ibers., Acta Cryst c57, 2001 and Reece and Levendis., Acta Cryst. c64 2008 API form Crystalline Hydrate I II III Stable polymorph (API) Intramolecular H-bonding IV Transition between forms by mechanical stress, humidity, and thermal stress 5 Physical transformation by Mechanical Stress Form II Milled Gabapentin Form III 4 6 8 10 12 2Theta 14 16 18 20 22 Physical transformation by Humidity Intensity 47 hrs in 40C 31 %RH 29 hrs 17 hrs 7 hrs 0 hr 2theta 7 Physical transformation by Thermal Stress Kaushal and Suryanarayanan., Minnesota Univ. AAPS poster 2009 8 Chemical Degradation of Gabapentin – nucleophilic attack of nitrogen on carbonyl O NH Gabapentin Gabapentin _lactam toxic USP limit: < 0.4% 9 Aqueous degradation kinetics Irreversible cyclization O OH O NH2 NH + H2O gabapentin lactam Solid state degradation kinetics 40 C 5% RH, milled gabapentin 7 Lactam (mole %) 6 autocatalytic lactam formation 5 4 3 2 1 rapid degradation of process-damaged gaba initial lactam 0 0 100 200 300 hours 400 500 600 Solid state Degradation Model autocatalytic branching k1GD L spontaneous dehydration GABA (G) GABA (D) (stable form) (unstable form) k3 G D k2 D LACTAM (L) branching termination Hypothesis: Manufacturing stress determines initial conditions (G0, D0 and L0) Environmental (storage) stress determines kinetics (k1, k2 and k3) 12 Building a quantitative model Environmental Stress Drug Stability Manufacturing Stress Compositional Factors (e.g. excipients) 13 Effects of Manufacturing Stress: Initial Lactam and Instability Thermal stressed at 50 °C, 5%RH 2.5 60 min milled Milling caused faster degradation rate 2.0 % lactam 45 min milled 1.5 1.0 15 min milled 0.5 Lactam generated during milling (in-process lactam)0.0 API as received 0 5 10 15 20 time(days) 14 25 30 Effects of Milling Stress: Specific Surface Area Is the increase of lactamization rate solely due to increase of Surface Area? 20 2 Surface Area(m /g) 16 12 8 4 0 0 20 40 Milling Time (min) 15 60 Can Surface Area account for Lactamization Rate Changes upon Mechanical Stess? Lactamization Rate(mole%/day 50 °C) 1 0.8 Samples milled for different time 0.6 0.4 Sieved aliquots of 15min milled sample 0.2 Sieved aliquots of unmilled sample 0 0 5 10 15 20 Specific Surface Area(m2/g) NO, ALSO increased regions of crystal disorder caused by the mechanical stress. 16 Effects of Milling based on Change in Initial Condition: lactam formation (50 °C) milling time effect 3.5 D0 Treatment (%) Lactam mole % 3 60min mill 2.5 2 45min mill 1.5 15min mill 1 0.5 unstressed 0 0 200 400 600 unstressed 15min milled 45min milled 60min milled (%mole-1hr-1) k2 (hr-1) 0.6 0.017 k1*104 0.02 0.59 1.28 1.62 800 1000 1200 1400 Time (hr) 17 Effects of Environmental Stress: temperature and humidity Environmental Stress Drug Stability Manufacturing Stress Compositional Factors (e.g. excipients) 18 15 Lactam (%mole) Lactam kinetics under controlled temperature (40-60 C) and humidity (550% RH) 20 10 5 0 0 100 200 300 400 Hours 500 600 700 800 Effects of Temperature: predicted values based on parameterization of autocatalytic model 25 Gaba 60C 5%RH 20 Gaba 50C 5%RH Lactam mole% 15 10 Gaba 40C 5%RH 5 0 0 100 200 300 time(hours) 400 500 600 Effects of Moisture 21 Is the decreased lactam rate due to reversible reaction? • Thermal stress of solid state (milled) or aqueous gabapentin_lactam – No detectable loss of lactam and no appearance of gabapentin in solution and solid state O NH COOH NH2 +H20 Gabapentin Gabapentin_lactam Zong et.al., Draft submitted to AAPS Pharm Sci Tech. 2010 22 Why moisture appears to slow and shut down lactam formation? • In general, effect of moisture is NOT to slow reaction rates • Analytical issue? Most gaba-L could be recovered from solid powder, only ignorable gabaL was detected in saturated salt solution. • Reversible reaction? No gabapentin formed from gaba-L in solution or solid state • Formation of stable hydrate? No hydrate found from XRD patterns Moisture-facilitated termination of branching 23 Effect of Moisture: Shut down Lactam Formation Thermal stress: 50°C 5%RH Gaba-L Concentration (Mole %) 4 Pretreated at 5% RH 25°C for 24 hours before thermal stress 3 2 Pretreated at 81% RH 25°C for 24 hours before thermal stress 1 0 0 20 40 60 Hours 24 80 100 Effects of Moisture moisture effect gaba simulation 5 k1 k2 (%mole-1hr-1) (hr-1) D0 (%) 0.000021 0.0074 1.05 k3(%mole-1hr-1) Lactam mole % 4 5%RH 3 ̴0 40 C 5%RH 2 L0 (% mole) 0.37 11%RH 30%RH 50%RH 0.014 0.030 0.099 40 C 11%RH 40 C 30%RH 1 40 C 50%RH 0 0 100 200 300 400 500 Time (hr) 25 Effects of Compositional Factors: excipient effects Environmental Stress Drug Stability Manufacturing Stress Compositional Factors (e.g. excipients) 26 Excipient Effects Comparison of lactam formation kinetics between neet gabapentin and gabapentin/HPC controlled temperature (40-60 C) and humidity (5-50% RH) Gabapentin & 6.5% HPC 60 60 50 50 40 40 Lactam (% mole) Lactam (%mole) Gabapentin 30 20 10 30 20 10 0 0 0 100 200 300 400 Hours 500 600 700 800 0 100 200 300 400 Hours 500 600 700 800 Evaluation of the role of excipients in gabapentin SS degradation – Mixtures of gabapentin & excipients – Co-milled – Storage conditions: 5 to 50% RH at 50 ˚C Saturated solution 50˚C 5RH 4:47:40 AM 10/22/2010 50 Lactam mole % • Excipients (50% w/w) – CaHPO4.2H20 (Emcompress) – Corn starch – Microcrystalline cellulose (Avicel PH101) – HPMC 4000 – Colloidal SiO2 (Cab-O-Sil) – Talc (Mg silicate) – HPC (6.5% w/w) 40 CaHPO4 SiO2 30 HPC Avicel HPMC Talc 20 Starch 10 Gaba 0 0 100 200 300 Time (hr) 400 500 ga Av HP Ca Ta HP Ca co ga ca co Av HP Ca Ta HP Model parameterization using excipient-induced variation in crystal damage during milling and termination rate 50 CaHPO 4 Excipient k1 k2 SiO2 k3104 5.55 D0 (%) 21.1 40 SiO MCC Talc 0.016 Starch 0.000074 CaHPO4 2.37 10.6 2.62 Lactam (% mole) 2 7.80 1.35 HPMC 1.20 HPC (6.5%) 4.04 4.5 Starch 30 7.2 MCC 8.4 7.4 Talc 20 6.5 HPC (6.5%) HPMC 10 Excipient effects •Crystal damage (D0) during milling 0 0 •Kinetics of branching and termination(k3) 100 200 300 Hours 400 500 Effect of Excipients based on Change in Initial Conditions and Rate Constants: under low humidity 4 k1 *10 SiO2 Talc 0.27 0.33 0.0208 0.0116 D0 (%) 21.16 8.44 Starch HPMC Avicel 0.35 0.41 0.49 0.0150 0.0123 0.0148 4.54 7.42 7.21 0.30 0.30 0.26 HPC (6.5%) Gaba 0.55 0.74 0.0209 0.0149 6.52 1.05 0.30 0.37 (%mole-1hr-1) k2 (hr-1) L0 (% mole) 2.6 0.98 30 Effect of Excipients based on Change in Rate Constants: under low humidity k2 k3*102 HPMC Talc 0.012 0.014 D0 (%) 7.42 8.44 CaHPO4 0.023 10.6 0.60 0.041 0.056 0.078 0.260 ̴0 6.52 21.1 7.21 4.54 1.05 0.30 2.60 0.26 0.30 0.37 k1 (hr-1) 0.016 HPC (6.5%) SiO2 Avicel Starch Gaba 0.000074 (%mole-1hr-1) (%mole-1hr-1) L0 (% mole) 0.30 0.98 31 B D F H Moisture and excipient effects 0RH 11RH 30RH 50RH Data 10 moisture effect gaba50RH No excipient 20 Co-milled excipient (SiO2) 50 30 %RH Lactam mole % 40 15 5 %RH 11 %RH 30 10 50 %RH 20 5 %RH 5 0 0 11 %RH 30 %RH 10 50 %RH 0 0 100 200 300 400 500 600 700 800 100 200 300 400 500 600 Time (hr) 32 Linking Stability in Design Space Manuf. Design Space Model L0 D0 PostManuf. Degradation Model Lt End of Expiry • Key Research Findings • Manufacturing Stress impacts drug stability upon storage: L0 (in-process lactam) D0 (unstable gabapentin) • Predictive model for drug stability includes: • • • Environment factor: temperature () & humidity () Compositional factors: both kinetic and initial condition effects Manufacturing factors: L0 and D0 • Model validation: completion of long term stability Measuring the manufacturing stress effects • Physical methods – Raj Suryanarayanan (University of Minnesota) – Eric Munson (University of Kentucky) • Chemical and kinetic measurements – Lee Kirsch (University of Iowa Solid State NMR Raman spectroscopy Powder x-ray diffraction (XRD) DSC/TGA Water vapor sorption HPLC Kansas Minnesota Minnesota All Minnesota Iowa Chromatographic methods 1.50 Detector 1-210nm hydBt24H Area Name Retention Time Detector 1-210nm hydAt0H 1.25 Area Name Retention Time 4 20 Detector 1-210nm lotAHbefore Area Name Retention Time 20 1.00 1 2 4 5 6 7 8 9 10 Minutes Comparison of HPLC chromatograms before (black) and after (red) thermal stress: ∆ lactam = 0.004%. 1 2 10 3.618 Lactam 10 1 5 0 3 5 6 7 8 9 10 Minutes 1 2 3 5 287843 0 4 7.572 (Lactam) Gabapentin 0 0.00 15 m AU 7.307 0.25 3 8278 m AU 1 2 15 4635741 0.00 2 3.668 9.117 2388 Gabapentin 0.25 3 0.50 3853 5.390 3.658 0.50 0.75 4339 0.75 m AU Lactam 7.288 3 4093741 m AU Detector 1-210nm lotAH m AU m AU 1.00 4 Detector 1-210nm hydAt24H Gabapentin 1.25 Detector 1-210nm hydBt0H 2801635 1.50 4 5 6 7 0 8 9 10 Minutes Comparison of HPLC chromatograms before (black) and after (red) thermal stress: Comparison of HPLC chromatograms before (black) and after (red) thermal stress: ∆ lactam = 0.059%. ∆ lactam = 0.174%. Manufacturing-stability measurements • In process lactam (L0) – Change in lactam levels during specific treatment or unit operation in % lactam/gabapentin on molar basis • Initial Rate of Lactam Formation (V0 or STS) – Daily rate of lactam formation upon thermal stress at 50°C under low humidity • D0 from Chemical Analysis V0 k 2 D0 V0 D0 k2 k 2 (50o C ) 0.37 / %day Insert Sury Insert Eric Applied Manufacturing-stability Measurements to Design Space and Risk Assessment • Laboratory scale stability design space • Pilot scale stability design space • Risk assessment using Manufacturingstability Measurements