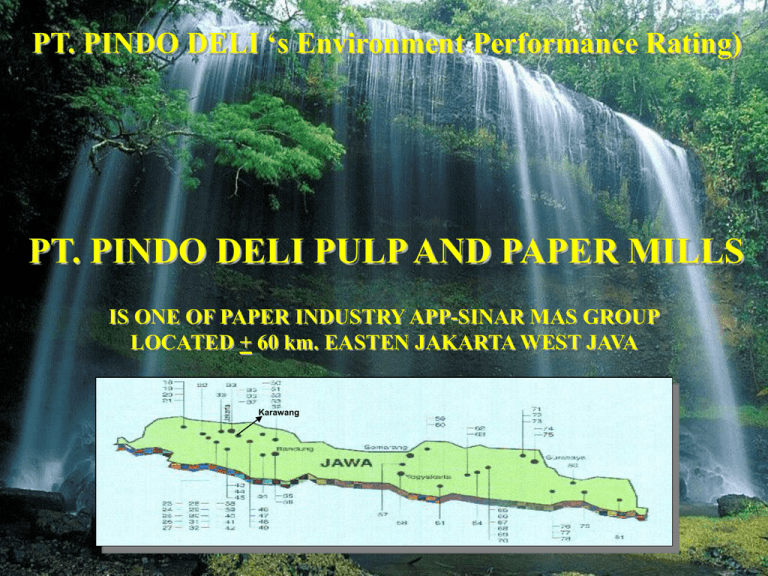

PT. PINDO DELI

advertisement

PT. PINDO DELI ‘s Environment Performance Rating) PT. PINDO DELI PULP AND PAPER MILLS IS ONE OF PAPER INDUSTRY APP-SINAR MAS GROUP LOCATED + 60 km. EASTEN JAKARTA WEST JAVA Karawang FACILITY TO PRODUCT : 4 1 1 1 1 7 2 Paper Machines Tissue Machine Corrugated Plant Chemical Plant Carbonless Paper Plant Coating Plant Converting Plant SUPPORTING FACILITY : • Power Plant • • • • • PLN FWT Plant WWT Plant Land Fill Pallet Work Shop 105 MVA 45 MVA 27.000 M3/D 35.000 M3/D 24.000 M3 6.000 M3/M Water Cleaner Refiner Cleaner Chest Pulper Pulper Tower Stuff Box Former Head Box Section Press Section Dryer Mixing Chest Refiner Chest Calender Pope Reel PAPER (FC/ BOARD PAPER) TISSUE (PASEO) CORRUGATED BOARD CHEMICAL 865.000 TON/ ANNUM 58.000 TON/ ANNUM 38.000 TON/ ANNUM NaOH CaCO3 110.000 TON/ ANNUM 240.000 TON/ ANNUM Copenhagen Amsterdam Warsaw Dusseldolf London Istanbul Brussels Toronto Amman Paris San Francisco New Jersey Tehran Tokyo Nagayo Kyushu Shanghai Taipei Manila Dhaka Hong Kong Milan Memphis Hokkaido New Delhi Karachi Madrid Chicago Seoul Beijing Bahrain Alexandria Los Angeles Riyadh Dubai Ho Chi Minh Brunei Mumbai Bangkok Chennai Colombo Penang Kuala Lumpur Singapore Mexico City Sydney Sao Paulo Auckland Buenos Aires Johannesburg Melbourne SALES : LOCAL + 20% EXPORT + 80% SAVE RESOURCES & POLLUTION CONTROL • NOT DEGRADE THE ENVIRONMENT IMPROVE COMPANY IMAGE & EFFICIENCY RELIGIOUS APPROACH : Don’t destroy what God/Allah has excellently created LEGAL APPROACH : Obey all State Acts and government regulations BUSINESS APPROACH : Improve efficiency Lower cost Increase profit EMS (Evaluation and Reporting) CLEANER PRODUCTION/CPEE SINCE 1996 - Good house keeping (Reuse, Recycle, Recovery) - Change of process - Change of technology final aim is to save resources & control pollution CSR : - Charity Giving fish - Community Development Giving rod to fish EKOLABEL : (Proper Mutual Requested) - Indonesia Ramah Lingkungan - Japan Ecolabel-Ecomark - Uero Ecolabe-Flower Ecolabel Issue since 7 July 2006 DEVELOPING PROPER : 2003 – 2004 BLUE 2004 – 2005 BLUE 2006 – 2008 GREEN* Proper Grade “ Green” CLEANER PRODUCTION 10 March 1996 ISO 9001 : 2000 Issue since 2 Jul.1996 Appreciation by UNEP for the Implementation Greenhouse Gas Reduction ISO 14001 : 2004 Issue since 14 Oct. 2004 IMPACT of PROPER ON THE COMPANY • smooth relationship & better communication with surrounding community • enhanced good image for all customers all over the world which promotes export • more intent to obey all the environmental laws, acts and regulations • Investment/ system change 2 PM USD 200,000 1 TM • Annual cost saving 2% X 1,118.000 X USD 10/ ton steam = USD 237,000/Year • Annual steam saving : 23.760 ton steam/yr Mean 23,760 X 77,3 = 1,836.648 NM3 EQ as 78975.864 tones gas EQ 229,030 tones CO2 (Ref. Simplified GHG calculator sheet) REFINER DIAGNOSTIC ( PLANNING ON END 2006 ) WHY ? OVER 1 (ONE) GRADE OF CSR FREENES MEAN ENERGY LOSS IS 72000 KWh FOR LINE PAPER CAPACITY PRODUCT OF 100 TON/D . (Ref. DR. GATOT IBNU SANTOSO PAPER ON 2004 DEPERINDAG) ENERGY LOSS IS FOR PT. PINDO DELI PM 8/9’S REFINER - AVERAGE PRODUCT AS 2 X 850 MT/D DIAGNOSTIC WAS DONE POWER: REDUCED FROM 200 KWh/TP to 140 KWh/TP represented as CO2 = 39,8 CO2 / TP Utilize paper process sludge as coal substitute (5% total caloric) for the CFB boiler • Coal consumption (100%) as 650 ton/day caloric value 5500 KCal/Kg Substitution : at 5% X 650.000 X 5500 = 178.750.000 Kcal. • By sludge caloric value as 2000 Kcal. As substitute - 178.750.000 / 2000 = 89.375 Ton Coal/day Mean CO2 reduce as 27,108 Ton/annum* Also solved sludge landfill problem (ongoing installation) * UNEP simplified calculator , www.uneptie.org/energy/tools/ghgin