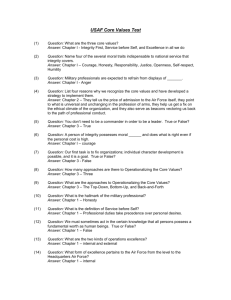

AFCESA-EESOH-MISProgramReview

advertisement

Headquarters U.S. Air Force Enterprise Environmental Safety and Occupational Health Management Information System (EESOH-MIS) Ms Catherine B. Hargrave HQ AFCESA/CEOI Integrity - Service - Excellence EESOH-MIS Overview Why EESOH Legacy Systems Key Benefits Governance Structure Key Performance Parameters Development Schedule EESOH Implementation Performance Air Force Data Service Integrity - Service - Excellence 2 Why EESOH-MIS? Implements SAF/IEE policy letter supporting the ESOH information integration vision Optimize base efficiencies Eliminates multiple data entry in multiple environmental systems Provides operational mission risk mitigation versus reactive actions EESOH-MIS is a comprehensive webbased automated information system for the aggregation and collection of Environmental, Safety & Occupational Health data Integrity - Service - Excellence 3 Current Reality EMIS Shop MSDS Data HazMat Authorizations Organization Data Use Information Personnel Data Equipment Location Data Controls BEE SAF/IEE ? Env SE LG HMMS Zones MSDS Data HazMat Authorizations Organization Data Use Information Personnel Data Equipment Location Data Controls BEE Env Wing ? SE LG CCS Shop MSDS Data Exposure Groups Organization Data Processes Personnel Data Hazmat Consumption for Air Location Data Emission (APIMS) Use Information BEE Shop Floor ? Env Equipment Controls Integrity - Service - Excellence 4 Vision STEWARDED DATA MSDS Data SAF/IEE Organization Data Personnel Data Location Data BEE Env Wing SE LG SHARED DATA Shop Process Shop Floor Materials Equipment Integrity - Service - Excellence 5 Legacy Systems vs EESOH-MIS Older systems are “base-specific” Each has it’s own system for documenting and reporting environmental data via stove-pipe systems (access data bases, excel spreadsheet, etc) Each base has its own versions of National Stock Numbers (NSNs), Products, Chemical Lists, MSDS’s, Manufacturers Inconsistencies in data from base to base Each base duplicates work done at other bases Stove-pipe systems do not comply with AF mandates Altus: WD-40, W D 40, & wd 40 Robins: WD-40, W D 40, & wd 40 EESOH-MIS: WD-40 AF Wide! Integrity - Service - Excellence 6 Key Benefits of EESOH-MIS Designed to help manage environmental risks and costs in a single application EESOH-MIS is both role-based and process-based Ability to perform various functions based on user role Structured to allow users to perform functions in much the same manner as their day-to-day HMMP tasks on their installations Approved Media: Hazmat HazWaste Air Cleanup Integrity - Service - Excellence 7 Key Benefits of EESOH Enterprise system providing consistent and valid data across the AF Data Stewarding for MSDS and Chemical data eliminates redundancy Leveraging Air Force Data Service for reporting EESOH Designed to Comply with all Standards Business Enterprise Architecture (BEA) Standard Financial Information Structure (SFIS) Business Transformation Agency/Business Management Modernization Program (BMMP/BTA) DoD Net Centric data strategy (DIG) Open Application Group standards Joint Technical Architecture GCSS-AF and Global Information Grid CAC/PKI enabled NDAA Certified for 2007 Integrity - Service - Excellence 8 Key Benefits of EESOH (Cont.) EESOH-MIS consolidates existing systems Air Force Environmental Management Information System (AF-EMIS) Hazardous Material Management System (HMMS) Air Force Restoration Information Management System (AF-RIMS) Air Program Information Management System (APIMS) Air Compliance System (ACS) Air Quality Utility Tracking System (AQUTS) Air Quality Information Management System (AQIMTS) Hazard Communication Program (HAZCOM) Waste Information Tracking System (WITS) System Management Analysis and Reporting Tool (SMART) Environmental Tracking System (ETS) Housing of Mandatory Environmental Requirements (HMER) Integrity - Service - Excellence 9 EESOH-MIS Governance Structure FRB (Strategic Vision) PMO EESOH IPT Requirements Execution FUGs (Defines Requirements) (Execute development based on requirements) Communication Requirements Strategic vision Requirements (Compares vision to requirements) Developer Integrity - Service - Excellence 10 EESOH-MIS Governance Structure (Cont.) FRB – AF/A7CV Strategic Vision Quarterly meetings IPT – Action Officers representing FRB Ensures vision reflected in requirements Quarterly meetings Focus Group (FG) leads MAJCOM Reps FG’s – Define requirements (HazMat, HazWaste, Air, Water, Cleanup, Shared Functions) Anyone can enter a requirement via the EESOH-MIS.com web site…all requirements vetted through the FG PMO – Executes development of requirements Integrity - Service - Excellence 11 EESOH-MIS Master Schedule FY07 FY08 4th Qtr 1st Qtr 2nd Qtr 3rd Qtr HAZMAT 4th Qtr 1st Qtr 2nd Release Release CLEANUP HAZWASTE Support Build and Test DN AIR I Release Des B&T DN AIR II Release Des B&T WATER DN DNR SRS FY09 Qtr 3rd Qtr 4th Qtr PDR Define Need DR CDR Design TRR 1 TRR 2 Release Des B&T FRR Build & Test Integrity - Service - Excellence Release & Support 12 Performance Upgrades Independent audit revealed slow response time among bases using EESOH-MIS Mitigation in progress Oracle 10G Upgrade release in Feb 2008 Continued performance tuning scheduled for major releases Integrity - Service - Excellence 13 Headquarters U.S. Air Force EESOH-MIS Deployments Ms Nadine Gawlak, Ktr HQ AFCESA/CEOI Integrity - Service - Excellence Hazardous Material Deployments Bases Implemented Martinsburg ANG Pease ANG Bangor ANG Springfield IAP Dobbins AFRC Randolph AFB Rickenbacker ANG Charlotte ANG Kadena Air Base Grissom AFRC Youngstown AFRC Bases In Progress Hill AFB Pittsburg AFRC Malmstrom AFB Shaw AFB Ellsworth AFB Peterson AFB Cheyenne Mountain AFB Schriever AFB Integrity - Service - Excellence 15 Current Sites Malmstrom AFB Youngstown AFRC Ellsworth AFB Rickenbacker ANG Bangor ANG Pease ANG Pittsburgh AFRC Hill AFB Martinsburg ANG Shaw AFB Capital-Springfield ANG Kadena AFB Charlotte ANG Dobbins ARC Randolph AFB Integrity - Service - Excellence 16 Deployment Process New Deployment Process initiated in June 2007 Re-written to incorporate lessons learned Consists of phases with exit criteria to continue process Base gets opportunity to review migrated data 30 days out Bases identified as candidates for deployment MAJCOM coordination to avoid AEF cycles & conversions EMIS Migration Utility is basis of candidate list Download EMU, run - provides snapshot of data to AFCESA AFCESA developing tools to assist base, which include: Users Guide Train-the-trainer course and materials completed “How to” Job Aids Web-Based Training Integrity - Service - Excellence 17 EMU Snapshot BAD Better Possible Candidate Integrity - Service - Excellence 18 Deployment Process Once approved, base receives deployment memo Pre-Site visit to demo capabilities, capture preferences Base/AFCESA develops business plan defining Initial Operating Capability (IOC) What shops are implemented? What Hazmarts are implemented? Who gets trained? Business Plan drafted at beginning of process (T-100) Business Plan follows process Status briefed during inbrief Document Updated at outbrief is agreement how EESOH-MIS will be implemented on the base Integrity - Service - Excellence 19 Updated Summary/Process Checklist New checklists/Plan Summary created for process Visibility of who needs do be doing what & when Checklist incorporated into online Project Plan Accessible to base during pre-site visit MAJCOM also has access Installation specific Plans Integrity - Service - Excellence 20 Updated Summary/Plan Checklist (Example of page 1) Integrity - Service - Excellence 21 Updated Summary/Process Checklist Installation Specific Project Plan Integrity - Service - Excellence 22 Updated Summary/Process Checklist Installation Specific Details Integrity - Service - Excellence 23 Updated Summary/Process Checklist Project/Task Details Integrity - Service - Excellence 24 IOC/FOC Initial operating capabilities (IOC): “Preliminary” operation” Basis for fully integrating the application into its daily operations within a timeline that can be reasonably met by the installation Based on lessons learned, IOC at each installation will include: A member from each ESOH functional team will be trained to operate EESOH-MIS One fully-operational HAZMART and eight HAZMART trained personnel. Fully operational is defined as: Five shops are trained and fully operational using EESOH-MIS. Trained and operational is defined as: Fully Operational Capabilities (FOC): All ESOH professionals are trained and using EESOH-MIS to perform all hazardous material process authorization reviews All shops on the installation are trained and using EESOH-MIS to perform all process authorization requests Personnel have access and are trained in the capabilities of ordering materials from their respective HAZMART All HAZMARTs are fully functional and supporting all shops using EESOH-MIS All HAZMART personnel are proficient in performing all tasks relating to job function. The installation does not rely on any other hazardous materials tracking system for reporting or daily operations Integrity - Service - Excellence 25 Headquarters U.S. Air Force GCSS-Air Force Data Services Civil Engineer Requirements Integrity - Service - Excellence AFDS Data Warehousing Program Description Enables the AF to leverage existing enterprise data for analytical and decision-making functions Improves decision-making capabilities at all levels Provides a flexible, easy to use, easy to share analysis tool that improves capability and productivity Relieves the impacts and cost of reporting on transaction systems performance and infrastructure Separates applications from the data Reduces the data footprint of transaction systems Consolidates reporting and reporting data Presented through a central presentation layer (AF Portal) Integrity - Service - Excellence 27 HQ USAF/IL Policy Memo, 26 Feb 02, Subj: “Logistics Information Systems Policy on Databases” The IL community must stop the proliferation of non-authoritative databases currently being fielded to meet the specific needs of local projects, organizations, or functional communities Data stewards from each system of record to take responsibility for the accuracy and timeliness of information Not going to secondary sources for Installation and Logistics (e.g. DAAS) data Applications to maintain the minimum amount of transaction data necessary within their applications to support day-to-day business All other data in either an Operational Data Store (ODS) or Enterprise Data Warehouse (EDW) The ODS will house near real-time aggregated data to support management's needs and provide asset and intransit visibility to the operational community All extensive decision support data will be stored in the EDW to support AF user’s need for on-line analytical processing (OLAP) Any new database being developed to contain Installation and logistics data must be approved in writing by AF/IL Integrity - Service - Excellence 28 HQ USAF/IL Policy Memo, 7 Feb 05, Subj: “Installations and Logistics (IL) Data Access Policy” IL data producers must provide on-demand data without restriction Restricting access to IL data and information should be the exception rather than the rule i.e. Public Law, security classification, or other DoD regulatory publication Restriction is applied only to the data element(s) identified and not the entire system or collective group of data AFKS is designated as the authoritative data repository for all AF IL historical data stored therein All unrestricted IL data and information within AFKS will be openly accessible to all DoD agencies without undo hindrance Goal is to reduce Interface Control Documents (ICDs) Some may be required until data is available for use in AFKS Integrity - Service - Excellence 29 GCSS-AF Data Services Capabilities Corporate Reports Pre-defined reports that are required on a recurring basis (monthly, semi-annually, yearly, etc.) on select data for viewing anytime Parameters can be set to filter data for specifics, such as MAJCOM, base, date range, types of facilities, etc. Designed to answer very specific business needs such as providing visuals for metrics and status; can include both detail level and aggregate data; multiple formats Ad Hoc Reporting Allows selection of specific data and ability to filter Ad Hoc reports can be validated and codified as a Corporate Report Both Corporate Reports and Ad Hoc reports can be downloaded to an Excel spreadsheet or an Adobe pdf file for distribution Integrity - Service - Excellence 30 AFDS Data Warehousing Update EOD PR 1 270 FD 173 Housing Management GCSS-AF Enterprise Service Bus (ESB) GCSS-AF Data Services (AFDS) 84 AFDS Real Property Data Warehouse 1 196 Command Real Property Database Project Management 1 MFH & UH AF Portal Login ACES RPI FIM MQ Series Q Manager EESOH EESOH 1 Integrity - Service - Excellence 31 Integrity - Service - Excellence 32 Integrity - Service - Excellence 33 Integrity - Service - Excellence 34 Integrity - Service - Excellence 35 Integrity - Service - Excellence 36 EESOH-MIS Air Force Data Service Current Focus: Implement requirements for latest version of EESOH-MIS (v1.2.2) Includes compliance with BEA 4.1 architecture and additional reports 39 Reports (29 Cleanup, 10 HazMat) Delivered Oct 07 AFDS on task to complete additional 20 Reports by Dec 07 Defining reporting requirements for new functionalities (HazWaste, Air) Integrity - Service - Excellence 37 EESOH-MIS Recap Why EESOH Legacy Systems Key Benefits Governance Structure Key Performance Parameters Development Schedule EESOH Implementation Performance Air Force Data Service Integrity - Service - Excellence 38 UNITED STATES AIR FORCE I n It ne tg er gi rt yi t-y S- eSr ev ri vc ie c-e E- xEc xe cl el el lnecne c e 39