Ch1IntroductionTheRestOld

advertisement

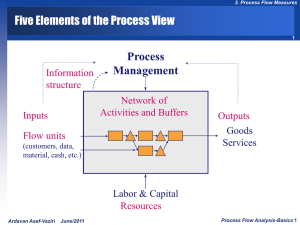

Process ManagementProcess and Strategy -1 Business Process Management 1 Building block of Operations Management – System view – Process chart – Schematic representation – Value stream mapping – Evaluation and trade-offs – Make-to-order vs. Make-to-stock – Risk-pooling - in Waiting lines, in Inventory – Reducing Inventory and Centralization – Removing variability Ardavan Asef-Vaziri Sep-09 Introduction 1 Process ManagementProcess and Strategy -1 Systems approach 2 “The whole is greater than the sum of the parts.” Suboptimization 2 > 1+1 Ardavan Asef-Vaziri Sep-09 Introduction 2 Process ManagementProcess and Strategy -1 Systems 3 A set of parts with interrelationships between parts organized to achieve a goal How systems grow up Performance measure of Sub-systems must be linked to the performance measure of the total system Ardavan Asef-Vaziri Sep-09 Introduction 3 Process ManagementProcess and Strategy -1 Systems approach 4 Systems approach and Sales Purchasing Production Link Performance of the subsystems to the performance of the total system. Ardavan Asef-Vaziri Sep-09 Introduction 4 Process ManagementProcess and Strategy -1 Schematic Representation of the Process (Flow Charts) Customer places order Raw Material Activity Cook Assemble Finished Goods Deliver Storage Mc Donald's make-to-stock system. Decision Ardavan Asef-Vaziri Sep-09 Flow (Prior to 1999) Introduction 5 5 Process ManagementProcess and Strategy -1 Value Stream Mapping 6 There are several key areas of concern in any product flow. Points where processing times are large. Activities that contains physical constraints – material or capacity constraints. Points where there is a high degree of resource sharing. When the same resource is required to process a variety of products. Divergence points where common materials are transformed into different product streams. Convergence points where multiple materials must come together. Points of excessive variation. Ardavan Asef-Vaziri Sep-09 Introduction 6 Process ManagementProcess and Strategy -1 Make to Stock vs. Make to Order 7 Will different companies intentionally choose different processes to accomplish the same goal? – in McDonald – in In & Out Process Evaluation – Different processes lead to different advantages and disadvantages. Is there a simply better process, i.e., no trade-offs? Ardavan Asef-Vaziri Sep-09 Introduction 7 Process ManagementProcess and Strategy -1 Analysis of Tradeoffs 8 Tradeoffs What are the pros and cons of models? Ardavan Asef-Vaziri Sep-09 Introduction 8 Process ManagementProcess and Strategy -1 Analysis of tradeoffs 9 Buying a new machine Additional Investment Integration with existing system Training Higher Productivity Better Quality More Flexibility Having more inventory Higher Carrying Costs More Obsolescence Ardavan Asef-Vaziri Sep-09 Lower Ordering Cost Purchasing Discount Product Availability Introduction 9 Process ManagementProcess and Strategy -1 Processing Time, Waiting Time; Long Waiting Line 10 We are interested in the management of processes. Selling a ticket seems easy, but … Ardavan Asef-Vaziri Sep-09 Introduction 10 Process ManagementProcess and Strategy -1 More Servers + Specialization 11 Ardavan Asef-Vaziri Sep-09 Introduction 11 Process ManagementProcess and Strategy -1 Polling: Lower Waiting Time, Longer Processing Time (Perhaps) Ardavan Asef-Vaziri Sep-09 Introduction 12 12 Process ManagementProcess and Strategy -1 Uncertainty: Potential Solution 13 Inventory – How much inventories? – If too many … opportunity cost, spoilage cost – If too few … loss of sales – It is costly to solve uncertainty using inventory. Notice that: – It is not difficult to deliver books very fast – It is not difficult to deliver books at a very low cost – But, it is very difficult to deliver book fast and at a low cost ? Ardavan Asef-Vaziri Sep-09 Introduction 13 Process ManagementProcess and Strategy -1 Amazon.com: Delivering Books 14 Example: In the early days of Amazon.com the company did not keep any inventory of books. – The supplier Ingram kept the books for Amazon. – Once Amazon received an order it was transmitted to Ingram. – Ingram would ship the book directly to the consumer. What are the advantages for such an arrangement for Amazon and Ingram? – Risking pooling (less inventory is needed) What are the disadvantages of this arrangement for Amazon and Ingram? – Allocation priority Ardavan Asef-Vaziri Sep-09 Introduction 14 Process ManagementProcess and Strategy -1 Lean Operations: The Real Cost of Inventory 15 Inventory adversely affects all competing edges (P/Q/V/T) Has cost – Physical carrying costs – Financial costs Has risk of obsolescence – Due to market changes – Due to technology changes Leads to poor quality – Feed back loop is long Hides problems – Unreliable suppliers, machine breakdowns, long changeover times, too much scrap. Causes long flow time Ardavan Asef-Vaziri Sep-09 Introduction 15 Process ManagementProcess and Strategy -1 Inventory Centralization 16 If centralization of stocks reduces inventory, why doesn’t everybody do it? – Longer response time – Higher shipping cost – Less understanding of customer needs – Less understanding of cultural, linguistics, and regulatory barriers These disadvantages my reduce the demand. Ardavan Asef-Vaziri Sep-09 Introduction 16 Process ManagementProcess and Strategy -1 Pareto phenomenon (ABC analysis) 17 Classifying items, activities, or tasks according to some measure of importance and allocating efforts and resources accordingly A vital few things are important for reaching an objective or solving a problem 80/20 rule – 80% of the problems are caused by 20% of the activities How do we identify the vital few? Ardavan Asef-Vaziri Sep-09 Introduction 17 Process ManagementProcess and Strategy -1 Pareto phenomenon, ABC analysis, & Recognition of Priorities Acknowledging the fact that certain aspects of any management situation are more important than others is called Recognition of Priorities. Ardavan Asef-Vaziri Sep-09 Introduction 18 18 Process ManagementProcess and Strategy -1 Models -Representations 19 A model is an abstraction of reality • Narrative • Tabular • Schematic (Some times Physical) • Mathematical – Linear programming – Transportation model – Inventory models – Waiting line models – Statistical models Ardavan Asef-Vaziri Sep-09 Introduction 19 Process ManagementProcess and Strategy -1 Recent Trends 20 Global Competition Operations Strategy Flexibility Cycle Time Reduction Business Process Re-engineering Supply Chain Management Workers Involvement Lean Manufacturing Total Quality Management Ardavan Asef-Vaziri Sep-09 Introduction 20 Process ManagementProcess and Strategy -1 Recent Trends 21 Global Competition Global Market Global Suppliers Operations Strategy Quality based Time based Flexibility Variety of products High Volume as well as Low Volume Cycle Time Reduction The less time RM (Raw Material), WIP (Work In Process), FG (Finished Goods) spend in the Manufacturing and Logistics process, the less opportunity they have to absorb costs. Ardavan Asef-Vaziri Sep-09 Introduction 21 Process ManagementProcess and Strategy -1 Recent Trends 22 Business Process Re-engineering Value added and NVA activities Supply Chain Management NOT from RM storage to FG warehouse, but from the original suppliers to final consumers Under separate ownerships Workers Involvement Workers are not costs, they are assets Lean Manufacturing Inventory is waste Variability is evil Total Quality Management Ardavan Asef-Vaziri Sep-09 Introduction 22 Process ManagementProcess and Strategy -1 Examples of Exam Questions 23 1. The following activities are all a part of system operations as opposed to system design a) b) c) d) e) long term forecasting, product design, capacity planning, inventory management. short term forecasting, product design, capacity planning, inventory management short term forecasting, production planning, capacity planning, inventory management short term forecasting, production planning, quality assurance, inventory management none of the above 2. Pareto Phenomenon is the same as a) b) c) d) e) Ardavan Asef-Vaziri ABC analysis analysis of trade-off systems analysis quantitative approaches none of the above Sep-09 Introduction 23 Process ManagementProcess and Strategy -1 Review Questions (cont.) 24 3. In ABC analysis a) b) c) d) e) 25% of items form 25% of the measure of importance 10% of items form 10% of the measure of importance 90% of items form 90% of the measure of importance 50% of items form 50% of the measure of importance 15% of items form 75% of the measure of importance 4. Given: (I) Lean operations, (II) Operations strategy, (III) Business process re-engineering (A) Inventory is waste, (B) Time based operations, (C) High Volume as well as Low Volume, (D) Value-added and NVA activities Which of the following selections is correct? a) b) c) d) e) (I) (I) (I) (I) (I) Ardavan Asef-Vaziri matches with (D), (II) matches with (C), (III) matches with (B) matches with (A), (II) matches with (B), (III) matches with (C) matches with (A), (II) matches with (B), (III) matches with (D) matches with (A), (II) matches with (D), (III) matches with (C) matches with (C), (II) matches with (D), (III) matches with (B) Sep-09 Introduction 24 Process ManagementProcess and Strategy -1 Review Questions (cont.) 25 5. Given (I) supply chain management, (II) Flexibility, (III) Operations strategy (A) Quality based operations, (B) Workers are asset, (C) Value added and NVA activities, (D) from suppliers to consumers, (E) High Volume as well as low volume Which of the following selections is correct? a) b) c) d) e) (I) matches with (D), (II) matches with (E), (III) matches with (C) (I) matches with (D), (II) matches with (E), (III) matches with (A) (I) matches with (A), (II) matches with (E), (III) matches with (D) (I) matches with (C), (II) matches with (D), (III) matches with (E) (I) matches with (E), (II) matches with (B), (III) matches with (D) Ardavan Asef-Vaziri Sep-09 Introduction 25