Process View & Operations Strategy: Key Concepts

advertisement

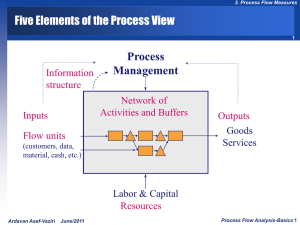

Process View & Strategy Based on the Book: Managing Business Process Flow. Processes Products or services must meet customer expectations; physical (comfort, safety, convenience), psychological (relaxation, peace of mind), social and spiritual; and they must do so within a budget. Business processes provide products and services: new car financing, producing an engine, making a hamburger, delivering a book from Amazon to a customer, teaching a course. How do organizations categorize customer expectations? How do they develop processes capable to fulfill customer expectations? What Metrics are used to measure? Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 2 Process view Process view: any organization or any part of an organization is Input Process Output Inputs: tangible or intangible items that flow into the process from the environment: natural or processed resources, parts and components, energy, data, customers, money, etc. Outputs are any tangible or intangible items that flow from the process back into the environment: products, energy, information, served customers, cash, etc.. Raw material Manufacturing Process Finished goods Data Accounting Process Financial Statements Accounts Receivable Billing Process Cash Unsatisfied customer demand Transformation Process Satisfied customer demand Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 3 Five Elements of the Process View Information structure Inputs (natural or processed resources, parts and components, energy, data, customers, cash, etc.) Process Management Network of Activities and Buffers Outputs Goods Services Flow Unit Human & Capital Resources Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 4 Flow Unit: The Item to be analyzed A flow unit may be a unit of input, such as a customer order, or a unit of output such as a finished product, or the value of input or output. Process Flow Unit Input-Output Transformation To From Order fulfillment Orders Receipt of an order Delivery of product Outbound logistics Products End of production Delivery to customer Supply cycle Supplies Issuing a purchase order Receipt of the supplies Customer service Customers Unsatisfied customer Satisfied customer Product R&D Projects Recognition of the need Launching the project Cash cycle Cash Expenditure (costs) Collection of revenue Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 5 Systems approach System: A set of parts with interrelationships between parts organized to achieve a goal. How systems grow? The whole is greater than the sum of the parts. 2 > 1+1. Systems approach and; Sales, Purchasing, and Production. A serial system with two stations. Principle: Performance measure of Sub-systems must be linked to the performance measure of the total system. Performance of a sub-system must be measured in terms of its impact on the performance of the total system Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 6 Systems-Thinking We do not have questions on these videos in our quizzes. You may watch them at your own will. Deming-Ackoff on Systems Thinking in Education Three truth about Systems Thinking Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 7 Product Attributes & Process Competencies Customers Define product attributes. Operation Managers Create process competencies to meet and exceed customer expectations. Product Attribute (External) Price Process Competency (Internal) Cost Response time Flow time Variety Flexibility Quality Quality Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 8 Product Attributes Product Price (cost for customer): purchase price, service, maintenance, repair, insurance, and disposal costs. Total cost of ownership. Product Delivery-response time: total time before receiving the product. Is the product on shelves, in a distribution center, or somewhere along the production line. Reliability in response time? Low standard deviation. Product Variety: the choices offered to the customer: At a lower level; options offered for a particular model, colors, styles. At a higher level; number of product lines and product families. Product Quality: the degree of excellence, how well the product works. Features (what it can do), Performance (how well it functions), Reliability, Serviceability (how quickly), Aesthetics, Conformance to expectations. Reliability in quality? Quality over time; consistent quality. Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 9 Customer Value Proposition Customer Value Proposition: a set of benefits (in four dimensional space) that the firm offers to customers. Order Qualifiers: Characteristics that convince customers to consider the product. Order Winners: Characteristics (in four dimensional space) that convince customers to buy the product. They differ among market segments. Commercial airplane vs. private jets. Customers purchase based on the value they derive from a product. It is the greatest amount a customer is willing to pay (the reservation price). If this value > price, the customer enjoys positive net value (consumer surplus). Customers will buy the products that offers highest consumer surplus. Zara's business is design/manufacture/distribution/retailing. Zara differentiates itself by timely fashion for the masses. CVP timely yet limited variety at modest cost and quality. Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 10 Process Competencies: Cost Process cost: the total cost of producing and delivering outputs. Remove non-value adding activities and buffers (Business Process Re-engineering). Allocation of appropriate recourses. Lower than appropriate is cheap, but quality goes down. Higher than appropriate, adds to the costs. High utilization. Division of labor. Henry Ford High standardization. Low variations. Shouldice Hospital in Canada, focus on hernia operations only. Standardized repeatable outpatient surgical procedure, very high quality at a low price. Do not accept patients with any risk factor (blood pressure, allergic, ..) People of India are vulnerable to cataracts. Millions go blind in their 50s. Aravind eye hospital started by treating paying patients and using the profits to offer free care to the poor. To support patients who could not afford transportation and required a Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 11 High Utilization, Standardization, Low Variations relative to accompany them, Aravind also added its own buses and a group of assistants. To keep costs low, surgical equipment is used all day, doctors focus only on performing surgery, pre- and post-operative care handled by nurses. Aravind served 2.5 million outpatients and performed 3 hundred thousands cataract surgeries in less than one year. Despite providing 2/3 of the outpatient visits and 3/4 of the surgeries as free service to the poor, Aravind generated healthy profits that it used to fund its growth. The key concept in lowering production cost is to allocate appropriate recourses to each operation. Appropriate? Lower than appropriate is cheap, but quality goes down. Higher than appropriate, adds to the costs. Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 12 Process Competencies: Cost Flow Time The cataract surgery at Aravind, the hernia surgery at Shouldice are example of implementing Ford Production line in healthcare. Process flexibility: How Chevrolet got Ford. the ability to produce and deliver a variety of products at high and low production volumes. cross trained workers + general purpose equipment + short set-up time + delayed differentiation, Job-Shop layout or U-shaped layout + small batch size. Process quality: How Japanese got US auto industry. the ability to produce and deliver quality products. Effective design as well as production that conforms to design. Quality at the source. Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 13 Process Competencies: Flexibility, Quality Process flow time: the total time to transform a flow unit from input into output. Effective layout and smooth material flow. Remove variability in arrival rate, processing rate, and quality. No starvation or blockage. No defect and re-work. If I am forced to define Operations Management in one line Create a Smooth Flow. Smooth flow means (i) low cost production cost because flow units do not have time to collect cost, (ii) high quality because as soon as quality problem is observed, we must stop production, i.e., no smooth flow, and (iii) system is flexible because we do not have too much inventory and can easily respond to technological advances and changes in customer preferences and switch to new products. Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 14 Process Competencies: Flexibility, Quality Corolla: flow shop, decentralized assembly plants close to market, short flow time, low cost. Ferrari: job shop, only a single plant in Italy, longer flow time, high cost. McMaster-Carr: a materials, repair, and operations (MRO) product distributor, a process with high flexibility, high quality, short response time, but at a high price WalMart: Operations Strategy: Short flow times, low inventory. Operations Structure: Cross docking, Electronic Data Interchange, Fast transportation system, Focused locations, Communication between retail stores. Inventory turns at retail stores: Wal-Mart: 9 times, Target: 6 Sales per square foot: Wal-Mart: $425/sqf, Target: $270/sqf Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 15 Operations Management Operations management Structure the process competencies in the direction of the customer value proposition. Develop measures to evaluate the effectiveness and efficiency of the processes. Apply methods and techniques to improve process performance. By measurement we find the relationship between controllable process competencies and desired product attributes, and will be able to set appropriate performance standards. Financial performance measures External performance measures Internal performance measures Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 16 Process Competencies: Flexibility, Quality If I am forced to provide another short definition for Operations Management OM is the concepts, ideas, methods, models, and the whole body of knowledge to understand trade-offs. If I am forced to provide still another short definition for Operations Management OM is the concepts, ideas, methods, models, and the whole body of knowledge to remove variability. OM is the concepts, ideas, methodologies, models, and the whole body of knowledge to create a smooth flow, understand trade-off, and remove variability. Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 17 The advantage of process view is a. It can be adopted at a very broad level, such as the supply chain, or at a very micro level, such as a workstation in both manufacturing and service organizations. b. By incorporating buffers, accounts for handoffs or interfaces between different activities-typically the areas where most improvements can be made. c. Identifies value added and none-values added points, and enables managers to improve the process and add value at every step. d. Represents any organization as a collection of interconnected processes where its success requires alignment of effort across all its processes. *e. All of the above Process View & Operations Strategy Ardavan Asef-Vaziri August , 2013 18