Geodise Component – CAD system

advertisement

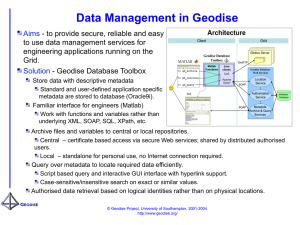

Geodise Component – CAD system Overview Wenbin Song Email: w.song@soton.ac.uk Geodise Project, e-Science Centre School of Engineering Sciences University of Southampton Aim – provides robust parametric CAD models for CFD simulation; Requirements for CAD models Data flows and problem specific data definition RR Negatively Scarfed Engine Intake © Geodise Project, University of Southampton, 2003. http://www.geodise.org/ Geodise Component – CAD system Requirements for CAD model: Parametric: ability to respond automatically to the latest parametric changes; Generic: ability to produce different geometries from one model; Robust: low rate of failure for combinations of parameters Pro/Engineer ICAD FEM (ANSYS, SC03) CFD (Fluent, Hydra) Unigraphics Cost estimation IGES/STEP, CADfix © Geodise Project, University of Southampton, 2003. http://www.geodise.org/ Geodise Component – CAD system Dataflow in simulation CAD Command script Condor, Grid/Web service Meshing Command script Condor, Grid/Web service Pro/E model part file; Trail file; Input data file; Solver Command script Condor; Grid/Web service CADfix: Seamless geometry exchange is not effortless, but often problematic, usually requires repairs: - solution is robust modelling in CAD systems, such as avoiding very short entities, etc. IGES/STEP file; Gambit Journal file; Mesh file; Fluent journal file; © Geodise Project, University of Southampton, 2003. http://www.geodise.org/ Geodise Component – CAD system Availability of CAD system: Pro/Engineering (version 2001200 for Windows), running locally; Model data files for geometry creation: Model part file (defining the shape paramterization, input parameters, etc.) Trail file (script file used to generate IGES/STEP file in batch mode); Input file (text file containing name-value pairs); Three files need to be in local working directory and and resulting IGES file is also stored in it and with the same name; MATLAB function proe_iges() running locally generates an IGES file based on input file; Transfer of IGES/STEP file for mesh generation: Use of gd_putfile to transfer geometry file and Gambit journal file onto remote server; © Geodise Project, University of Southampton, 2003. http://www.geodise.org/ Geodise Component – CAD system Application One: Negatively Scarfed Engine Intake (Rolls-Royce) Problems definition: maximize noise reduction without (significant) loss aerodynamic performance for all operating conditions. Parameters: Intake geometry is defined using Pro/E by a list of parameters, parameters that are expected to be used in optimisation are listed below: Scarf_angle = 10 (degree), shown as d1 (d1=90-scarf_angle) in the following figure; Top_radius = 1243 (mm), shown as d220; Bottom_radius = 1390 (mm), shown as d221; Side_radius = 1430 (mm), not shown; Fanface_radius = 1241 (mm), not shown; Figure: (a) A3XX-100; (b) three dimensional Fanface_axial_distance = 1818.43 (mm), shown as d2; shape of negatively scarfed engine intake; Center offset = 5 (mm), shown as d5; (c) parameters of intake vertical layout. © Geodise Project, University of Southampton, 2003. http://www.geodise.org/