AS project example

advertisement

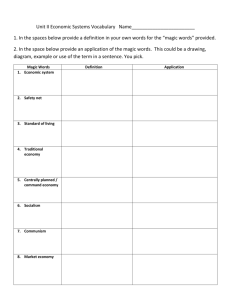

MENTALISM MAGIC GIMMICK PROBLEM AND JUSTIFICATION. The problem and why it needs a solutionFor four years I have been studying magic. For the last two years I have been street performing and performing at private functions. There are several types of magic, including coin, card, close up, street, stage and mentalism. Mentalism is and area of magic that is severely lacking in purchasable knowledge. One effect I am particularly interested in goes by the name of secret selection. The effect goes that a spectator chooses either a single or several objects from a group and puts them in his/her pocket(s), then covers up the remaining items. All this goes on while the magician’s back is turned, who then turns round and can instantly tell the audience which items were picked, whether it be by handing them a prediction, or by reading their body language. this effect is widely spoken about and is often used by stage magicians, but all the methods of achieving this feat are floored in one way or another. There are two ways to achieve this affect. The first is to use a stooge, someone the performer knows, i.e. someone who is in on the trick. This can be done by either the stooge choosing the items, or by the stooge signalling to the performer and telling him what the items are. While of course this does achieve the effect, it means that the performer cannot be working alone, and that the spectators can’t know each other, or they would notice the extra person. The second method is to use a gimmick. In magic a gimmick is a tool which assists the performer in stunning an audience. The gimmicked method uses a box or container of some kind which hold the items. The lid of the box is transparent from certain angles, so when the items have been taken and the performer turns around again he can see through the lid and can then tell which items have been taken. This method means that the performer can be on his own .The downside to this method is that the box isn’t examinable i.e. On inspection the spectator would see that the lid was transparent from the performer’s view. Another problem is that the performer cannot tell what order the items where removed in. Both of these methods work and when used right create a great effect, but each has floors, as I have just outlined. The clients- My client base for this profile will be hobbyist and professional magicians alike. By creating a mid-range product few potential buyers and users will be cut out. It will be a product of the right standard and price to sit on the front shelf of a magic shop. briefDesign and make a gimmicked container (or objects) which allows a performer to accurately predict which items out of a group will be taken and in what order, without the use of a stagehand/stooge, and where the container and/or objects can be examined without anything out of the ordinary being noticed. SECTION 1 TIME PLAN 5th sept Plan all research (completed) Prepare notes for interviews (completed) consumer focus group (completed) Davenports magic shop (completed) Chris Ballinger (completed) Available technologies (completed) Materials (completed) sensing methods (completed) communication methods (completed) indication methods (completed) Specification 12th sept 19th sept 26th sept 3rd oct PLANNED PRIMARY RESEARCH (INTERVIEWS) Focus groupMy main primary research will come from focus groups. I have arranged several sessions with the pentacle magic club in Cambridge, part of the Ipswich magical society, a club which consists of hobbyist and professional magicians alike. As my product develops I plan to go back to my focus group for opinions and suggestions. While I should get plenty of ideas for potential methods the main thing I hope to get out of these sessions is a clear image of what it is consumers want. The first focus session is due to happen on Tuesday the 13th September. Logo for the davenports magic company. Ipswich magical society The magic geek website. Chris Ballinger The Pentacle magic club A small selection of Chris’s creations. Retailer interviewI am also planning to speak with several magic retailers. To me this is important because ultimately it is the retailers who will be buying this product to pass on to the consumers. I am currently planning to speak with someone from Davenports magic, the most famous London magic retailer who are based in charring cross underground arcade. I am still waiting for final confirmation of a date, but I have been guarantied that if I go into the shop within opening times there will be someone able to talk to me. My second retailer interview is with Chris Ballinger, a professional magician from America who has created several of his own tricks, and works for magicgeekint, a large online retailer based in Santa Barbara California. Due to Chris living overseas I am speaking with him through online communication methods including email, facebook and Skype. NOTES FOR INTERVIEWS 1. 2. 3. 4. Explanation •What I’m doing (time scale etc) •What I want out of this session •What is the effect? (mentalist, selection etc) •Methods I know of- stooge (spectator or participant), gimmick •Any others? Names? •What I like in a trick, your opinion? (Simple to perform, straight out of the box routine, stooge less, inspect able, gagety?) •My brief•Any questions? Size/category? •Stage •Parlour •Close up (walk about?) •Street? Appearance? •Old •New •Casket •Cigar box •Electronics hidden? •Spaces for items •Extra compartments? (for show, for convenience (for before a performance?) •Any more ideas? Items? (contents) •Something that can be used again for another trick? (cards, esp maybe)as a convincer? •Cards •Snooker balls •Coins •Rings (linking?) •Borrowed objects (coins, keys, phones, wallets (could create a gag?) •Or the performers choice? •Suggestions if so •Any more ideas? 5. Revelation? •Prediction (swami or multi select) •Reactions (body language?) •Within box (screens behind flap) •Any more ideas? 6. Indication? •Lights (just to cover everything) •Vibration •Pressure •Any more ideas? •Leg •Pocket •Body? •Wireless? •Fibre optics (do you prefer it gagety, from a selling point of view) •If non wireless Wire along floor, up leg Hinge touch, choice memory in electronics, hinges (on box) act as contacts, 2 hidden contacts in hands (with a pull for cleaner ending?) when hinges are touched, signal is sent to indication device on the body. Suspicious? •Any other ideas? Cost? Rap up •Specification (key points) •Research ideas •Thank you for listening, hope to come back etc 7. 8. RESEARCH CONSUMER FOCUS GROUP On the 13th of September I met up with the Pentacle magic club at the tram shed, a pub in Cambridge. It was an informal meeting with five magicians, two of whom were professionals. It was a great chance to talk about what makes a good trick, and what consumers want in a trick, as well as picking up a few tips for systems, and areas to research. Here is the main feedback I got. 1) explanation- The main feedback I got from this section was that the method should 2) size- The general view of my group be simple, so patter can be concentrated on. They told me that gadgets sell great, and to have it inspectable is always a plus. I found that most magicians don’t like to be given long patter but instead learn the method to the trick and then develop their own patter to go with it, so I should be concentrating on the functionality of the gimmick. I also got a great lead on an existing gimmicked version, so their will later be a section on an affect performed by a man named Graham P Jolley. 3) was that close up magic is the most popular, so the box should be small enough to be held by a performer or a spectator or to be placed on a small area, because if you are performing at a dinner or a restaurant there won’t be much table space. Although it could be suitable for stage and most definitely parlour as well. appearance- The main points from this section where that old would be less suspicious, wood may be a good material. Plastics should be avoided as people always find them suspicious, and magicians like to use expensive looking materials like wood and polished metals like brass. The biggest point which was made was that there should be no visible electronics. Extra compartments where not recommended 4) items- common items was the general view for this section, something people recognise. Decks of card was a well received suggestion. 5) revelation- In this section everyone agreed that the revelation should not be on a screen in the box, as it then stops being a trick and becomes a piece of technology. So the sequence must be indicated to the magician without the spectators’ knowledge. 6) Indication- Going into this section I assumed that lights would be an instant dismissal, but the idea came out that if LEDs were place under a thin wooden venire they would only be seen when on. Wires were a no go, as it restricts movement and would require a lot of setup. If the indicator was on the body, it should be strapped to a leg or arm, to free up pocket space, but as long as it was discrete and not too complicated, it would also be good if everything was self contained. 7) Cost- The average price someone would expect to pay is between £20 and £60. Factors research response types how will it be incorporated Into the mechanical side? sensors costs How will it be fitted together? Materials components Factors to consider Means of production circuitry availability Available technologies function Size School supplies/ orders Electrical/system subtlety Number of devices Quality assessment EXISTING METHODS In my focus group I found out that the effect I am creating is often performed by a man named Graham P Jolley. After searching themagiccafe.com, a huge internet forum for magicians, I found that the trick was called Mento-spheres. The box work using waited ball which when removed release marbles which fall into a tube so the magician can see the order. To me this seemed over complicated. The box itself is not inspectable. The price of the trick is £105, and is in massive demand. So a cheaper, better product would have great success. The magic café website. The Mento-spheres trick AVAILABLE TECHNOLOGIES I have decided to carry out this research early on so I know while looking at other research what my limitations are while prototyping. Laser cutter The laser cutter allows materials such as plastics like acrylic, MDF and thin sheet metal to be cut on a single plane. The cutter can cut to a very high accuracy, more so and much faster than can be achieved by hand. The laser cutter is great for rapid prototyping especially for gears and mechanical processes. Line bender The line bender allows acrylic to be bent by melting a strip of the plastic in a straight line by using a fixed heated wire. Spray developer The spray developer is an all in one unit which allows PCBs to be etched quicker and cheaper than using traditional methods. Wire sculptor The wire sculptor is used to carve shapes out of ….. Foam. The fixed vertical wire and the additional free form tool uses heat to carve intricate shapes. This is a quick way to model shapes and cases. Vacuum former The vacuum former can form any thermo moulding plastic around a solid mould. A limiting factor is that there must be a 5 degree draft angle or the mould bill become stuck. SENSING METHODS REED SWITCH A reed switch is a switch which when brought close to a magnet will change The switch state from on to off or This is a board above is quite vice versa. This is a mounted switch. It small and so silent component but to is quite bulky but discrete, but use this a magnet will can easily be may be hard to have to be concealed mounted onto a mount well. inside whatever objects PCB. are being used. Most reed switches are normally open, and these are cheaper than the normally closed variety, so this may be something to keep in Rare earth magnet. mind. To test this solution I concealed a rare earth magnet inside a sharpie permanent marker, an Pen in vice to object commonly used by be taken apart. magicians. While the Dismantled pen. magnet did fit, and wasn’t noticeable, it wasn’t strong enough to trigger a reed switch, so I would have to use a stronger neodymium With considerations of both possible solutions, I have decided magnet. that reed switches will be a better method due to noise levels and mechanical simplicity. MICRO SWITCH A micro switch is a small switch which is closed by a small amount of pressure. The switches are quite small and therefore discrete. Pictured above is an example of a micro switch. Bellow is an example of a lever system I designed using 3D CAD software, which could incorporate a micro switch. An advantage to this solution is that the objects used for the selection will not need to be gimmicked. However, this solution would require perfectly balanced levers to keep it discrete. Also when pressed the switch makes a very audible clicking sound, which may be heard with out significant background noise. COMMUNICATION METHODS One of the main challenges I face with this project is how the two devices (the container and the hidden indicator on the body) will communicate. As I found with my focus group any indicator on the box may be spotted by a spectator, or will involve the performer touching the container, which would lower the standard of the effect. So this section of research is based on trying to find an adequate method for the devices to communicate with each other. One thing I will be considering is that two devices will require two power sources, which is always an extra inconvenience. Another option would be to have everything in the box self contained, this would solve the challenge of communication and potentially make the system much simpler to use, after all the best magic tricks are easy to use so the performer can concentrate on performance and interaction with the audience. On the other hand this may increase the probability of being discovered. INFRA RED The first system I looked at was infra red. Infra red is a cheap method of communication used in remote controls. It also has applications for data transfer in devices like mobile phones, although in the last 5 years this use has been made obsolete by Bluetooth (high radio frequency) technology. I tested out a circuit I found in a projects book so I could assess the potential of this method. The circuit I used was quite simple. The transmitter circuit was simply an infra red LED in series with a push to make switch and a resistor to reduce the voltage across the LED. The receiver circuit had an infra red receiver as the input, a potentiometer as a control, an op amp as a process tied to a transistor witch controlled an LED as an output. When the infra red LED is off so is the regular LED. When the infra red LED is on, so is the regular LED. Conclusion One of the main things my focus group said that any electronics should be hidden. So with this in mind, and the fact that my brief is that it must be inspectable by the audience I have decided that infra red will not be a viable Using a multimeter to ensure the correct voltage is put across the rails. most digital cameras pick up infra red light with a frequency close to visible light, so using my smart phone I could tell when the LED was on or off.. ADVANTAGES DISADVANTAGES •It’s a cheap method of wireless communication •The transmitter can simply be a single LED tied to the output of the device •The LED and receiver must be able to see each other so the LED must be external on the device seen by the spectator. •Other infra red devices could easily interfere with the system’s functionality. RADIO The use of radio would allow the two devices to be entirely separate, which would be a real advantage in terms of practicality. A downside is that it can be a very expensive system. It would also need an antenna which can be easily disrupted (shown in image bellow). I tested this as a possibility using two transceiver chips (also shown bellow). The problem was that to function you also require encoder and decoder chips as well as clock inputs and signal generators. This would have made both circuits very bulky, meaning concealment on the body would be difficult. For the reasons I have stated I will not be using this solution. HARD WIRED My focus group told me that fixed wires would not work for most magicians, and would restrict movement, but if the wires were concealed and could easily be attached and detached, then it could still be a viable solution. If this idea was used, the indicator would still be on the body, but communication would be simple, keeping production costs down. The downside is that contact must be kept at all times for the signal to be communicated. For these reasons I will be incorporating this into my design. After looking at several solutions for communication if I decide to have two devices I will use hard wiring. This is because it is a cheap and simple method which will not be complicated, but will also be easily concealed. INDICATION METHODS LED When LEDs and LED displays are placed behind a thin wood veneer, they can be seen when on, but not when off. This would allow a performer to see a signal telling them the sequence in which objects were removed. This is better than vibration because it will be completely silent, but the magician must be far more aware of angles, meaning that this would not be suitable for a table hopping situation. Sound At first it seemed to me that an indication noise would be too obvious, but then while in Cambridge, watching a street performer, I noticed that he had an earphone in one ear. After that I noticed that although people wearing two earphones with the cable hanging down they seem antisocial, but one earphone coming from under a shirt isn’t noticed, and if it is, nothing is thought of it. A lot of magicians also use ear mounted personal microphones. This opens the opportunity to have the device literally tell you the sequence in which the balls were taken out. Type1; off centre circle. This type of vibrator tends to make the motor shift around more than most so it can be noisy and there is a loss of power. Type 2; semi circle. This type gives a smooth vibration so little noise, but there can be a slight loss in power. This seems like the best type for a discrete purpose. Type 3; circle segment. This type outputs a very powerful vibration but can be a very jerky, and so uncomfortable. Vibration Vibration is a very attractive solution for indication as it can be felt through clothes. The effectiveness of this method and it’s discreteness is shown by it’s universal use in mobile phones. I have researched three types of vibrator motor (detailed above) and dismantled a mobile telephone as analysis for the vibrator’s use (detailed bellow). The mobile phone I analysed was a NOKIA brand, a company famed for their product quality. To the left are three images showing the location of the vibration device (circled). The image to the right shows the small motor used in the phone. The type of vibrator used is the semi circle type, reassuring me that it is the best type for my product as telephones need a vibration that is noticeable to the owner but not noisy or disrupting CONTAINER The container for my items should look classy and be something that a magician would be proud to own, so I went to an antique showroom to look at some different boxes. The first type of boxes I found were ornate oriental boxes with intricate detail on the case. Throughout history there has always been a mystique with things from the orient, in fact it was where magic originated. This may work in the performer’s favour but because it doesn’t look like something you would use every day to keep things safe it may cause suspicion to spectators. the second type I saw were made from hard wood. These boxes looked classy but at the same time would be something you would keep precious possessions in. (above) in the photograph is two jewellery boxes in the oriental style I discussed. While these are very ornate, they are not something you would get out while performing to a small crowd in a parlour or restaurant situation. (left) A playing card case with for sections and card design detail on each section. Seeing this box makes me think that decks of card would be good objects to use for selection as they can be used after the effect and are something that all magicians are expected to carry. (above) Here is one of the wooden boxes I looked at. In my opinion this box is a bit too ornate and in your face, but the wood does give a nice effect which would certainly add some class to an act. (right) This is another playing card box but this time it is made from hard wood. This box has further inspired me to make a box for playing cards. Because wood is a material we have been using for years, it doesn’t have a connection with electronics or gadgets in people’s minds. Bringing out a wooden box with playing cards set in specially sized spaces shows how a magician cares for his props and portrays an image of respect for a magician’s most important utility. MATERIALS HIPS High Impact Polystyrene is a very useful plastic because I could use it to make the casing. This is because it is easy to quickly create a shell with the vacuum former which covers the mechanisms, protecting it from things, as it is waterproof and impact resistant. This is also useful if my product were to be mass produced as I could use HIPS, but it would be injection moulded, not vacuum formed. Hardwood Hardwood is a non composite wood made from a solid trunk of a slow growing tree. This is expensive, but gives attractive patterns when finished. Acrylic Acrylic is a very good material to use in school as it is very easy to work with. Any part that is needed can be cut out on the laser cutter to ensure accuracy of the cuts and it works at a very high speed. It can also be stuck together with simply with solvent glue. This could be used for modelling my product, or for making a structure to keep everything internal in place. Going by my focus group visible plastic should be avoided as it makes people suspicious of a gimmick. 18 MDF Medium density fibreboard is a useful and cheap wood because it is recycled and is a composite of many woods. MDF is a useful material which I could easily use in my project. It is cheaper than solid woods, although looks less appealing. If however I were to cover it in a wood veneer, the box containing the objects and electronics would look more expensive. This would also allow me to use my LED indication idea. Another use for this wood is to make cheap and easy to work with moulds for vacuum forming (it can easily be cut into intricate shapes on a 3D router). This means that I would probably use MDF to make mould for a holder for the objects. SPECIFICATION • User control- The Product should be simple to operate so the magician can concentrate on his/her performance. The reset must be quick, the more time spent setting up the trick for the next performance, the less time can be spent entertaining. The magician should be in full control of when he/her receives the signal to indicate the order of selection. • the Angles- The final effect should be as angle proof as possible. When magicians refer to angles they mean position the audience must be in so they don’t see any secret moves. This effect should be able to be performed surrounded. • Discretion- It is vital that from the outside no electronics can be seen. This would ruin the effect as the audience would purely think that it’s technology, not magic. It can require the performer to be wearing long sleeves, as long as the hands can be shown empty at the end of the routine. Any noise or lights must not be heard or seen by the audience. The device doesn’t have to be silent, but it must be quiet enough to not be heard in a restaurant or populated room (ambient noise levels). The main must for this point is that as far as the spectator is concerned, It’s just a box. • Pocket space- Space in pockets is a very competitive area for any magician, so any devices should not need to be kept inside a pocket, but can have the option to. • Aesthetics- Performers want to look smart, so their props must look smart to mach, therefore the casing should be pleasing to the eye, but not be too bold. The cards should be held firmly but without compromising looks, a velveteen should be used to coat whatever is holding the cards. The cards should be useable after the trick. also • Materials- For the main box a hard wood will be more appropriate, as plastic or metal will suggest something gimmicked. For the parts which can’t be seen, an appropriate material should be chosen on purely it physical properties. • time Mobility and size- The box should be large enough to hold four decks of playing cards, but at the same be small enough to easily be carried. The dimensions should be 300-400mm by 150-200mm to fit these needs. The box should be easy to move around, so it cannot need to be attached to a table or have any running across the floor. Also there should be no complicated set up needed each time the trick is performed. I have put this point in with mobility because it is more of an issue with moving around than wires INITIAL IDEAS & DESIGNS 555 TIMER The first electronic solution I investigated was Using a 555 monostable circuit. With this solution when a deck of cards is removed the motor will be turned on for a set time period indicating which deck was removed. The problem with this is that it is instant and the performer would need to be in constant contact with the container. When the reed is opened, the relay will be triggered. When the relay is closed, current will flow through the pole sending pin 2 low. When the capacitor charges the current will be stopped sending pin 2 high again. The reed switches are normally open, but because the magnets will be in contact with them they will be closed. This would mean pin 2 would be constantly low, which would turn on the motor from pin 3. to counter this I have designed a simple solution (above)using a relay and an electrolytic capacitor. While this does solve the problem, the relays would make an audible noise when turned on, so a transistor will need to replace this. Bellow is the system shown on the monostable circuit. Because each monostable circuit can only have one time delay, a separate circuit will be needed for each input. Above is what the final circuit would need to look like. This is quite a big circuit and may need multiple power sources to prevent power loss to the ICs. This solution could work but because indication is instant constant contact will need to be kept with the container, so I am no longer considering this as a viable solution. Micro controllers (genie ICs) Design 1 Micro controllers are integrated circuits (ICs) which can process data received from inputs pins and control output pins accordingly. Micro controllers can be programmed using basic coding or with the use of flow chart software. They have many functions including turning outputs on/off, creating time delays, questioning the status of both digital and analogue signals and creating variable which can be compared later for differentiation, just to name a few. This method uses small circuits, as all logic/processing is in the IC which is an advantage. Also because the triggers can be chosen to be high or low the add on I designed for the 555 monostable is not required, again keeping the circuit simple and compact. Another advantage is the ability to make complex process systems and change them at a later date to suit different users, or improve the general function of the circuit. For these reasons this is the solution I will be taking further. A disadvantage is that the ICs need programming after PCB manufacture and can be costly. Sends the output high These decision boxes ask whether or not an individual input is high. If it is, the flow passes on to the next. If it is low, i.e. the reed switch is open, then the output is sent high for a period of time depending on which deck of cards has been removed. System loops to restart the decisions. Sets the time delay Sends the output low again Above is a basic circuit (without standard connections i.e. programming pins) with the inputs (the reed switches) and an led as an output (in replacement for the motor for simulating) To the left is a flowchart which functions the same as the 555 circuit chain I designed previously. DESIGN 2 My second flow chart design is to be one in which the magician can decide when he is indicated of the order in which the cards are removed. This requires some sort of memory, and a trigger for a sequence to be released indicating the order of the three decks removed all in one go. When a deck is lifted, the decision box diverts the flow down a chain to the right, where a compare box asks if the variable has a value above 0. If it doesn’t, then an increment is added. From then on every time the chart loops, an increment is added to any triggered variable. I have added a trigger represented by a PTM switch (circled left). I have decided to use variables to create my ‘memory’. Variables allow differentiation, so if the variables are increased individually starting when an object is removed, the first input will have a larger variable value than the last (see right). Now there are variables to distinguish between input order, it is a case of comparing the variables so the largest variable’s output sequence is played first, then the second largest, then the third. The chart section bellow shows one line showing what would happen if deck 1 was chose first, then box 2. the last decision shows how the variables can be differentiated to output the right sequence. To save space and memory I have created a sub routine for each variable, which can be called, the returned back to the chart. To decisions From variables (above) The subroutines with different time intervals for the different inputs. The next stage was to build up all possible paths for deck 1 being chosen first. Points for the other paths to be added. For the final stage I mapped out all other outcomes insuring that the right sequence was created for the order in which the decks were taken. This slide shows the final flow chart all together. Here is where the variables are set. The system will loot until the PTM (push to make) switch is pressed. CIRCUIT DESIGN The circuit I showed in the previous slide was a basic IC circuit, which is a diagram without programming or power pins. The basic makes initial set up and chart testing easier, but to design a PCB the standard view is required. (bellow) The circuit complete with programming and power pins. While the circuit worked when simulated on the computer, when I bread boarded it the flowchart was too large to fit on the C14 chip, so I have had to upgrade it to an E18 (E stands for elite range), which has more memory. This increases unit cost but is required for me to have the desired system. The elite chips have the addition of a reset pin (R on diagram bellow), but to reset I intend to just turn the circuit off and on again, removing the need for two switches. The reset needs to be tied to the positive rail by a 4.7K resistor, but the PTM can and will be removed. When breadboarding I also found that the inputs need to be tied to ground, so the chip can differentiate between high and low, so each switch has been tied to ground with a 10K resistor. Above shows how I simulated the function of my circuit and flow chart. In this view I can see and change the inputs, while still following the flow chart. FINAL AMENDMENTS Improvements as a result of testing When testing the circuit the outputs sequence was never the order in which the inputs were sent low. The problem was that when I simulated the flow chart, the flow between actions was slowed down so the path could be followed. In real life the variables were reaching their maximum and resetting in a matter of seconds. To fix this I have added a time delay between each increment. I have also removed the compare boxes and the extra increment boxes as they were not necessary. The second improvement I have made was not necessary but makes the system more user friendly. Instead of a timed output varying for each input, I have changed the sub-routines so there is a number of pulses which when counted will tell which deck was removed when (1 pulse for deck 1, 2 for deck 2 etc). Production plan 31st Week Jan Lesson 1 2 14th 7th Feb Feb. 3 1 2 3 1 2 28th Feb. 3 1 2 14th 7th Mar mar 3 1 2 3 1 2 28th 21st mar mar 3 1 2 3 1 2 Design PCB Eche pcb drill holes in pcb solder components onto pcb test pcb catch up on folder work design casing (box) manufacture casing Design Insert manufacture Insert Construct final box Design and manufacture body piece test and evaluate final prototype finish all outstanding folder work Design and model mechanical Design and manufacture final table Finish all outstanding folder work Health and safety and quality control The most important point is to where appropriate protective clothing (eye protection, apron) and always concentrate entirely on the process in hand. If a job needs more than two hands, get help, and never cut corners to save time. For quality control it is important to insure the upmost care is taken in good production. If a part of manufacture is not of the highest standard it is to be redone, and I will be checking for quality at all times when manufacturing taking measurements to insure correct dimensions. 4th apr 3 1 2 PCB MANUFACTURE The first step was to design the PCB. To do this I used the same simulation software I use to design my circuit (left). I then printed the PCB using the spray etching machine explained in my research. When the PCB comes out of the etch tank the areas which have not been etched off are coated with a plastic film (bottom left). To solder components the copper on the surface must be exposed. I removed the film using wire wool before drill the holes for the components (bottom right), using 1.5mm drill bits for the terminal blocks and 1mm bits for the rest. When soldering components I held them down using masking tape (left). This not only makes things easier it also insures a straight connection. Bellow is the completed PCB ready for testing. When I tested the PCB for the first time I used a buzzer in place of a motor to make it easier to tell when the sequence is working, so I could concentrate on checking the connections using a multimeter. CASING DESIGN AND MANUFACTURE BOX DESIGN I started out by designing my box using 3D computer aided design (CAD) software, Solidworks. From there I drew up 2D plans for cutting the sides and lid for my box, including all dimensions and angled edges. I also designed a mounting for the on/off switch, to be cut from 3mm acrylic. 3D design (above) (above) Lid and base dimensions. (bellow) long side dimensions (above) Short side dimensions. (left) design for switch mount THE COMPLETED BOX I have made the box out of hardwood, keeping the design simple, so as not to take away anything from the effect itself, but to still look classy. Base glued in place. 45° angle for more surface area contact and so better adhesion. It also leaves a better looking join. CORNER PLATES Brass corner plates (pictured left) not only add a nice finish but give an opportunity to make contacts to my circuit. The corners will be the trigger for the sequence output, and the hinges will be the contacts for the output. Because the inner corners of the plates are rounded (see bottom left), sharp corners prevent the plates from sitting flush with the box. For this reason I have used a disk sander to sand flat spots on the corners (top right). I also drilled guide holes for the screws to insure a straight join (top right). For the contacts I drilled a hole through the flat spot to the inside of the box and soldered a length of wire to one of the corner plates (right middle). I then screwed the plates down and the hidden contacts were complete (seen bottom right). HINGES The hinges are where the main contacts will be, so they need to look as innocent as possible. The hinges I have chosen are small (centre left) and will sit above the level of the card slots, so it will seem as if there couldn’t be a wire coming from it. I drilled the guide holes for the hinges as well as a central hole drilled at an angle of 60° from the horizontal (top left). The bare wire is folded over and coiled around one of the screw holes. The friction between the wood, wire and hinge is plenty enough to hold the wire in place, and it cannot be seen. To ensure the wire won’t come loose I secured it with a small amount of two part epoxy resin (bottom left). I repeated this process on the other hinge to make the second contact (bellow). CARD HOLDER INSERT DESIGN For the insert I have decided to use an acrylic holder covered in a velveteen fabric. This is because as I found in my research acrylic is easily cut very accurately, and if it is covered then it’s appearance is not a concern. Green is a colour often associated with playing cards, if for nothing else because it is the most common colour for a poker/blackjack table. The velveteen I have chosen has a pattern incorporating the four suits (left). The holder itself will be made of 4 sheets of 3mm acrylic, with four deck sized holes and a final 6mm rectangle for the base with centred holes for the capacity sensors (bellow). ADHESIVE TESTING FOR FABRIC BONDING To find out what will be the best adhesive to use to bond the velveteen to the acrylic I have tested four glues, an epoxy and double sided tape. To test the adhesives I took the scrap pieces of acrylic from making my holder and some sample swatches from my velveteen. To allow a good adhesion I first lightly scored the surface of the acrylic to open up some more surface area. I then stuck the swatches down and labelled them with white correction fluid for visibility and easy identification. Before Adhesive Pros Cons summary Super glue Very strong hold, removing swatch required a lot of force. Stops fraying edges. Glue soaked through slightly giving the material a rough feel. Will be useful for sealing edges and fixing down the unseen edges Hot glue Strong hold, swatch was difficult to remove. Glue did not soak through fabric. Left an uneven surface. It is a bit messy to apply. Will be used for adhesion in contours and where the fabric will be visible. copydex Flat bond. Allowed correction after placement. Weak bond put up little resistance before giving way. Better adhesives have been found so no use. Pritt stick Did not soak through fabric. Barely any adhesion observed. Little to justify use. Epoxy Allowed correction after placement. Bond was surprisingly weak, gave good resistance but less than hot glue. Not a bad adhesive but hot glue is a better choice. Doublesided tape Easy and clean to apply. Again gave little bonding force. Futile. After FABRIC ADHESION Fig.1 Fig.2 Fig.3 To glue the velveteen to my holder I surrounded the inner edge of the first slot with hot glue (fig.1) and used a deck of cards to push the fabric into place (remembering to put the proximity sensor in first) (fig.2). This leaved a perfectly formed slot with a sensor concealed within (fig.3). I repeated this process four times to glue all for slots into shape (fig.4). I then tested the size of the slots using four decks of cards (fig.5). The last step was to trim of the excess, fold the fabric round to the bottom and seal with super glue (fig.6). Fig.4 Fig.5 Fig.6 FINAL ASSEMBLY For the final assembly I first drilled guide holes for my PCB and battery holder (top left). I then glued supports in each corner for the insert (second left), along with the holder for the on/off switch (third left). The picture in the bottom left shows the interior so far, including the wires from the hinges and corner plates. All that was left then was to screw in the battery pack and the PCB. For the battery pack I used countersunk screws so they would sit flush with the base and not obstruct the batteries. Bellow Is an image of the final box assembly. PHOTO EVIDENCE OF FINAL PRODUCT BODY PIECE I wanted to keep the body part of the product simple so it will simple be a motor with a vibrator attachment and two wires to connect to the hinges and also the corner plates to trigger the output sequence. First I designed using 2D design the pieces for the vibrator (made from 3 pieces of 3mm acrylic) and the circular piece with stress holes for the wires (left). The vibrator I have designed uses the semicircle design, the one I decided would be most appropriate in my research. Once these pieces were made it was a simple task of gluing all the pieces together. Pictures of the device can be seen bellow. After everything had been made it was time for testing and evaluation. The picture above to the right shows how the device is fitted to the body. The motor is in the inside jacket pocket, and the wires run down the sleeves. The pictures to the left show how the wires would be attached to the box. The first is a shot from above, showing how the wires are hidden. The second is from bellow, showing how the wires are connected. TESTING AND EVALUATION Motor problem When I came to test the function of my product I found that when the sequence was triggered, the motor would come on briefly then stop and not come back on. I tested it again only this time using an LED with a 470Ω resistor in series to protect it. When I did this the process worked perfectly. I connected the genie chip on my PCB to a computer so I could run the program through simulation software but still using the relevant inputs/outputs and the chip’s processor. When it came to the output the circuit stopped as if power had been lost to the chip when the motor was connected. From this I deduced that the motor was drawing too much current and the chip could no longer run. To solve this I wired up a transistor and connected it to the PCB with a 10Ω resistor in series with the motor connections. The resistor was to drop the voltage drop across the motor to its minimum, so it would still work but not draw too much current. this solution worked and the product does now work. However, the motor has lost some power and sometimes struggles to get started, so as a future development a secondary separate power supply may be required. This would allow the chip to run interrupted and the motor to run at full power. ANALYSIS OF THE MEETING OF SPECIFICATION For further reading of full specification please refer to slide 19 User control- The final product does meet the needs of ease of use, as it can be operated with ease and little thought. The reset time is fairly quick, although to lift the insert easily two deck of cards need to be removed to get a good grip. An easier way to lift the insert may be an area for further development. As it is the magician’s choice when the output sequence is triggered, he/she is in full control of when they receive the indication signal. • • Angles- unless the spectator is looking from bellow the box the wires from the sleeves cannot be seen. For this reason I believe I have satisfied this requirement, because most angles that a spectator is likely to be viewing from are covered. • Discretion- This was one of my main requirements for this effect. Firstly, no wires or electronics can be seen without lifting the insert. The insert fits very snugly in the box, so lifting out the cards will not move it. The hinges of the lid lie above the level of the insert, so wires connected to them doesn’t seem possible. This may seem very minor but will add a real subconscious conditioning to convince the audience it is a normal box. • Pocket space- While the body device has been designed to sit in a jacket pocket, it could easily be taped/sewn under the armpit. • Aesthetics- The box itself looks pleasing to the eye and the corner plates add a look of quality, but it is still quite simplistic and will not draw attention from the effect. The cards are held securely and will not fall out in transit. The green velveteen looks good and is relevant to the playing cards, thus justifying having a box to hold them. Because the magnets are built into the card boxes the playing cards themselves can be used after the trick. • Materials- The box has met the material specifications where materials can be seen. The body piece is made from tough acrylic which will withstand impact if dropped, thus protecting the motor. • Mobility and size- the box is within the size guidelines measuring 360mm by 170mm. The box can be easily carried and has no attachments or wires hanging out. Of course the box easily holds four decks of cards. Apart from putting on the device at the start of a session, all that needs to be done between performances is to turn the on/off switch on and off. So I believe I have fulfilled this point, although further development may be to consider building an indicator into the box to further reduce overall setup. FOLDING TABLE PROBLEM AND JUSTIFICATION Requirement and reasoning Requirement- A suitable table for the mentalism magic gimmick. Reasoning- One of the requirements for my magic gimmick was that it was mobile. For this to be viable the surface it sits on needs to be mobile too. For this reason I will be designing a possible solution for a mobile and portable table. To the left is a picture of my current table, which I use for street performances and walk around at paid events. The problem I find with it is that when flat it is still quite large and awkward to carry. This makes it difficult to transport to location but it is also difficult to move around spots. The image on the bottom left shows the table folded up, It is very bulky and also takes a while to fold up. While it is easier to carry it around open when at a gig it then takes up both hands and it is easy to hit someone with it accidentally. Brief My brief is to design a solution for a compact table for use with my mentalism gimmick. The table should pack small, be easy to assemble and should be able to carried with one hand. Telescopic The first solution I have designed is using a telescopic design. This would mean the legs would extend then retract into a shorter length. Bellow is the net design for a telescopic arm I have made out of modelling card cut out using a laser cutter. The sides get gradually thinner so they will lock when pulled out. The thinner pieces are spacers so each smaller section can fit in the larger one. Spacers The picture to the left shows the arm closed and the picture to the right shows it extended. While this does give plenty of length, it is not very strong and retracts with little force. When closed it is not very compact and each leg would need shortening individually, so it will be no better than my existing table. Scissor system My second design uses a scissor type system. These mechanics pack small and can extend to a large differential. Above are the 2D CAD drawings I made and bellow is the finished model. The legs do fold small and give a good height when extended, but has little strength side to side. For a further design I will add cross bars for better rigidity. Closed legs Locking mechanism Extended table Working model To further this design I designed an acrylic model including the cross bar improvement. The top left image shows a net for the model. The circular pieces are end caps to hold the arms together. The images below show the finished model and prove that it can stand on its own. The next slide will show a video of the table’s operation. The table was quick to assemble and take down and can be carried with one hand. End caps Open table Locking piece Cross bars Closed table THE END