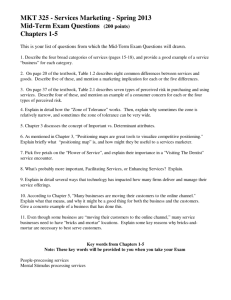

Radio Telescope - ECpE Senior Design

Ongo 2-C

Radio Telescope

Project Advisor:

John Basart

Ali Abdelsalam

Osman Abdelsalam

Greg Bonett

Laura Janvrin

Project Goal

Develop a working radio telescope for Iowa

State, thus increasing research opportunities for students and faculty on campus, especially in the Physics and

Astronomy Department

Concept Sketch

(carries radio signal)

System Block Diagram

Start of Year Status

Wiring issues on tower prevented operation of coaxial switch, noise source, and inhibited data collection

Limit Switch Relay board was not functioning properly, which prevented movement of the dish

Positioning software did not include tracking over time, and raster scan was inefficient

No documentation existed for limit switch relay board or terminal blocks within interface box

Deliverables

New Interface Box with permanent PCBs capable of reliable operation without frequent maintenance

Functional Tracking and Raster Scan software

Functioning positioning feedback, basic calibration routines, basic positioning correction

Limit Switch circuitry to stop motors when limits are reached

Complete, useful documentation

Operating Environment

Ambient temperatures range from -20 ºF –

110ºF

Strong wind, snow, ice, and rain

Vulnerable to lightning

Project Risks

Dish hardware is custom built for our observatory, and cannot be replaced if broken.

Outdoor hardware can withstand temperature extremes, but there is a potential for ice buildup to prevent telescope operation.

Much of the existing hardware is old and prone to breaking down, much of the wiring is unreliable.

As this project has moved to a phased approach, critical information about the system could be lost if the new group and the returning group do not work together.

Risk Management

Maintenance must be performed each semester to make sure all of the telescope hardware is working.

Outdoor work on the telescope was all performed when the weather allowed.

The team has been replacing old cables and resealing weatherproof boxes to ensure reliability of equipment.

In both the fall and spring, returning members worked with new members to help share knowledge of the entire system.

System Components

Positioning Specifications

Reported dish position shall be accurate to within

0.1 degrees for both azimuth and elevation.

Azimuth and Elevation calibration shall be performed automatically or through a very simple

(one or two step) process.

Continuous position updating shall allow tracking of objects and performing raster scans.

Positioning

This semester, the team focused on characterizing the positioning capabilities of the telescope and began calibrating the positioning.

Preliminary characterization and calibration was accomplished by aiming the dish at sun and comparing positioning feedback to the known coordinates of the sun.

Interface Box Specifications

Interface Box shall be properly labelled to allow ease of troubleshooting and maintenance.

Interface Box shall allow connection between the computer’s data acquisition card, and the receiver, limit switch circuit, coaxial switch actuation, and motor control box.

Interface Box circuitry shall be solid state components mounted on a printed circuit board.

Interface Box documentation shall include schematics for all circuits, as well as details for all wiring connections.

Interface Box – Limit Switch

Circuitry

In the fall, a PCB layout was designed based on the current limit switch relay board, but re-examination this semester revealed missing connections.

A much simpler circuit was designed and tested that performs the required functions.

The new circuit was created using a PCB, which will improve reliability of the limit switch circuitry.

Interface Box – Positioning

Circuit

Positioning circuit includes new Limit Switch circuit as well as a voltage divider circuit for positioning feedback

Interface Box – Positioning PCB

Layout

Interface Box – Power Relay

An existing power relay circuit was modified and installed into the interface box, and software was modified to allow the relay to be tripped remotely.

With the relay installed, all components of the interface box can be controlled using a Remote

Desktop connection.

Interface Box – Voltage

Regulator PCB

Voltage Regulator circuit maintains a constant voltage in the Interface Box

Interface Box – Coax Switch

Relay PCB

Coax Switch Relay circuit grounds the antenna when the switch is activated via software or physically.

It also powers the LNA, mixer, and noise source, and can switch on the receiver.

Interface Box – New Box

Old Interface Box

The new rack-mounted box will be neat and organized.

PCB boards will replace existing boards.

Ribbon cables and new connectors will be used to make the box reliable

New Interface Box

Software Specifications

Software shall support all system, component, and user interface specifications.

Software must possess an efficient raster scan function.

Software must be able to track celestial objects over time.

Software shall be organized according to semester and frequently backed up to prevent loss of work.

Software documentation shall allow future team members to pick up where previous team left off.

Software – Raster Scan

Old Raster Scan software in LabVIEW was modified to eliminate unnecessary and time-consuming motion of the telescope dish.

Software –

Raster Scan User Interface

Software – Software Limits for

Dish Movement

Only allow opposite voltage to pass to Motor Control

Box when dish is 2 degrees from each physical limit

Software - Wiki

To facilitate the passing of knowledge from semester to semester, the team has implemented a Wiki.

Existing documentation was uploaded to the Wiki and indexed on the Wiki. This will also allow team members to search through all the documentation contained on the Wiki for needed information.

The wiki can be accessed at: www.sscl.iastate.edu/wiki/

Complete System

Specifications

System shall be operable remotely.

Software shall be comprehensible to astronomy students.

System equipment shall not require maintenance more than twice per semester.

System Maintenance

In the fall, the team replaced faulty cable and conduit going up to the dish.

A weather-proof seal was added to the feedhorn cap to prevent water from leaking in.

Feedhorn was checked in the spring for water.

Testing Areas

RF Section – All components relating to radio signals (feedhorn, amplifier, mixer, coaxial line)

Positioning Hardware – Detection equipment and motors

Positioning Software – Software programs used to position the dish for data acquisition

Interface Hardware – All circuitry used to connect the computer to the other system components

Testing Objectives

Confirm basic operation of all components

Individual electrical components

RF Section

Positioning hardware

Positioning software

Interface hardware

Quantify system parameters

Measure RF losses

Determine positioning accuracy

Testing – RF Section

Individual RF components in the front-end box

(mixer, LNA, noise source) were tested using a signal generator and spectrum analyzer

The entire signal path was tested using a signal generator at the observatory

Noise Source off

Testing - RF Section

Measured appropriate gain/loss through the entire system and through the front-end components

System Bandwidth

400

350

300

250

200

150

100

50

0

-50

1405 1410 1415 1420

Input Frequency (MHz)

1425 1430

Testing – RF Section

Component Gain/loss

Low-noise amplifier 28 dB

Converter

Noise source

19 dB

10 dB

Testing - Positioning Hardware

Confirmed dish will move to known degree limits

Verified position detection hardware is accurate

After calibration, software (without software limits in place) shows 0 ° for minimum elevation, 86.5° for maximum elevation, etc.

Verified that position output is precise

Positioning variation is less than 0.05 degree if dish is not moving

Testing - Positioning Software

Confirmed software function by measuring

DAQ output

Verified functionality by running positioning software

Input coordinates of known source (the sun)

Positioning software with correction placed dish in proper position

Verified tracking software functionality

Verified raster scan software functionality by performing raster scan of area of sky including the sun

Testing – Intensity Graph

Tested the intensity graphing capabilities of our system

Performed a manual scan across the sun and recorded the intensity every 10 ms

Amplitude of 385 corresponds to a solar flux value of 490000 Jansky

Testing - Interface Hardware

Performed continuity checks to ensure components are properly connected

Confirmed all software programs properly activate appropriate hardware relays

Verified input and output voltages meet component specifications

Work Descriptions

Green = Task Complete Yellow = Task In Progress

End of Semester Status

We are testing the new Interface Box.

All three new PCBs in the Interface Box have been installed.

Raster Scan and Tracking software have been tested.

The RF system has been extensively tested and recommendations made for repairs.

All relevant interface box circuitry and positioning circuitry has been documented and labelled.

Earned Value Analysis

The old Interface box has been causing problems since its creation. The new box will reduce the amount of maintenance required.

The preliminary positioning calibration done this semester will give future teams a basis for more precise calibration and correction.

Documentation that has been created will improve future teams’ abilities to familiarize themselves with the project quickly and solve problems faster.

For the Next Team

Now that the basic software is available and working, unified user interface software should be written to make the system more user-friendly.

Pointing correction software can be written to further calibrate the positioning of the telescope.

The impedance of the feed horn should be matched to the line.

The raster scan software should be modified to do successive scans to reduce image noise.

Lessons Learned

Conscious effort needs to be made to stay on schedule.

Proper documentation saves time and work in the long run.

It is impossible to plan all tasks at the beginning and work through them – problems will always arise and require adjustments and new planning.

Conclusions

The new Interface Box will be a great benefit to future teams in terms of reliability and ease of understanding.

The intensity of the sun has been successfully measured, and all components of the RF system have been characterized.

All of the software needed to run the telescope is complete, but improvements can still be made in terms of making one unified program.

At the end of this semester, the radio telescope system will be operational for future teams to add additional astronomy features.

Acknowledgements

Dr. John Basart for work as advisor

Dr. Gregory Smith for feedback and providing funds for parts

Matt Nelson for help with PCB ordering

Jesse Griggs and Matt Clausman for Eagle software training

Ryan Cragg for help with making a lid for the

Motor Control Box