Final Report - ECpE Senior Design

advertisement

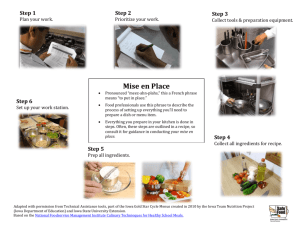

Iowa State University Ridgeline Meteorological Sensor Network Final Report Stephen Copeland, Xau Moua, Joseph Lane, Robert Akerson 12/9/2010 Table of Contents List of Figures ................................................................................................................................................ 4 List of Tables ................................................................................................................................................. 4 List of Definitions .......................................................................................................................................... 5 1. Project Overview ....................................................................................................................................... 6 1.1 Executive Summary ............................................................................................................... 6 1.2 Acknowledgements............................................................................................................... 6 1.3 Problem Statement ............................................................................................................... 6 1.4 Problem Solution................................................................................................................... 7 1.5 Operating Environment ........................................................................................................ 8 1.6 Limitations............................................................................................................................. 8 1.7 Expected End Product and Other Deliverables ..................................................................... 9 2. Design Requirements .............................................................................................................................. 10 2.1 Design Objectives ................................................................................................................ 10 2.2 Functional Requirements .................................................................................................... 10 2.3 Non-Functional Requirements ............................................................................................ 10 2.4 Design Constraints .............................................................................................................. 11 2.5 Technology Requirements .................................................................................................. 11 2.6 Technical Approach Considerations.................................................................................... 11 2.7 Testing Approach Considerations ....................................................................................... 11 3. Detailed Design ....................................................................................................................................... 12 3.1 Wireless Mesh Network Protocol Technology .................................................................... 12 3.2 UHF Wireless Transceiver/Communication Module........................................................... 14 3.3 Serial Interface Modes ........................................................................................................ 17 3.4 UHF Antenna ....................................................................................................................... 17 3.5 Power Supply ...................................................................................................................... 21 3.6 Microcontroller ................................................................................................................... 21 3.7 Casing .................................................................................................................................. 22 4. System and Unit Level Testing Cases ...................................................................................................... 23 4.1 UHF Transceiver/Communication Module Unit Level Testing Cases .................................. 23 4.2 UHF Antenna Module Unit Level Testing Cases .................................................................. 24 4.3 Microcontroller Unit Level Testing Cases ........................................................................... 24 Iowa State University Page 2 4.4 Casing Unit Level Test Cases ............................................................................................... 25 5. Implementation ...................................................................................................................................... 26 5.1 Hardware............................................................................................................................. 26 5.2 Software .............................................................................................................................. 30 6. System and Unit Level Test Case Results ................................................................................................ 31 6.1 UHF Transceiver/Communication Module Unit Level Testing Results ............................... 31 6.2 UHF Antenna Module Unit Level Testing Case Results ....................................................... 33 6.3 Wind Sensors Testing Case Results ..................................................................................... 34 6.4 PCB Signal Converter Circuit Testing Case Results .............................................................. 35 6.5 Microcontroller Unit Level Testing Case Results ................................................................ 36 6.6 Casing Unit Level Test Cases ............................................................................................... 37 7. Recommendations for Project Continuation .......................................................................................... 38 7.1 Technology Continuations .................................................................................................. 38 8. Estimated Resources and Schedule ........................................................................................................ 39 8.1 Estimated Resources ........................................................................................................... 39 8.2 Schedule .............................................................................................................................. 41 8.3 Task Breakdown .................................................................................................................. 42 9. Closure Material ...................................................................................................................................... 43 9.1 Project Team Information ................................................................................................... 43 9.2 Closing Summary ................................................................................................................. 44 References .................................................................................................................................................. 45 Iowa State University Page 3 List of Figures Figure 1: Mesh Network Solution ................................................................................................................. 7 Figure 2: Scout Tower System Block Diagram............................................................................................... 8 Figure 3: Building Blocks for Mesh Network Solution ................................................................................ 10 Figure 4: Micro-controller to transceiver interface connections................................................................ 15 Figure 5: Horizontal and Vertical Radiation Map of Dipole 1/2-Wave Antenna ........................................ 18 Figure 6: Horizontal and Vertical Radiation Map of Dipole 1/4-Wave Antenna ........................................ 19 Figure 7: Horizontal and Vertical Radiation Map of Yagi Antenna ............................................................. 20 Figure 8: Printed Circuit Board .................................................................................................................... 26 Figure 9: Signal Converter PCB.................................................................................................................... 27 Figure 10: Transceiver ................................................................................................................................. 27 Figure 11: Arduino Microcontroller ............................................................................................................ 28 Figure 12: Full system device ...................................................................................................................... 28 Figure 13: Wind Vane and Anemometer .................................................................................................... 29 Figure 14: Wind Sensor Mount ................................................................................................................... 29 Figure 15: Latency Testing Case .................................................................................................................. 32 Figure 16: Latency Testing Results .............................................................................................................. 33 Figure 17: Antenna S11 Parameters ........................................................................................................... 33 Figure 18: Anemometer Testing Results ..................................................................................................... 34 Figure 19: Wind Vane Testing Results......................................................................................................... 35 Figure 20: Signal Converter Circuit Test Results ......................................................................................... 35 Figure 21: Data Communication Aggregated .............................................................................................. 36 Figure 22: Data Communication Results ..................................................................................................... 37 Figure 23: Project Schedule ........................................................................................................................ 41 Figure 24: Task Breakdown ......................................................................................................................... 42 List of Tables Table 1: Estimated Cost for a Single Unit .................................................................................................... 39 Table 2: Estimated Development Labor Cost.............................................................................................. 39 Table 3: Estimated Project Cost .................................................................................................................. 40 Iowa State University Page 4 List of Definitions CFD Data Logger Ethernet Mesh Network Met Tower NEMA4 Enclosure RF SCADA Scalable System Self Healing Network Wireless Transceiver Iowa State University Computational Fluid Dynamics; a numerical computer model that calculates wind (mass) flow given a digital model of the terrain and the expected wind dynamics A device which obtains data from various sensors and stores the gathered information in a form of memory for future reference A type of connection used for data transfer between the data logger and the transceiver A network type where each node may act as a router, relaying information for other nodes. Meteorological tower; central collection station tower Enclosure standard set by NEMA, which type 4 enclosure is constructed for indoor or outdoor to provide a degree of protection to personnel access, the equipment inside against foreign objects, harmful effects such as water, rain, sleet, snow, and external formation of ice on enclosure Radio Frequency Supervisory control and data acquisition refers to a monitoring and controls system for industrial processes The ability to add and expand more to the system which will increase performance of the system A network that is able to re-route the path by which data is transferred in case of the loss of a node in the network A device which is capable of receiving and transmitting signals wirelessly Page 5 1. Project Overview 1.1 Executive Summary There has been a push for renewable energy in the 21st century and wind energy is among the main sources. Mountain ridgelines are a common topology for wind energy projects. The ridgeline is valuable to capture high elevation wind potential, but due to the complex terrain, collecting meteorological data is difficult. The current solution of retrieving meteorological data involves dispatching people to download the data from data loggers. The data collected from the ridgeline is difficult to retrieve by dispatch and is expensive to transmit through cell phone and satellite MET towers. The need for the project is to develop a mesh network system of remote sensors to transmit the meteorological data to a single source, home, without having to worry about retrieving the data, as well as to collect much more data at a lower cost than before. With more data collected, a more accurate representation of the area can be achieved leading to increased productivity. The mesh network system would solve the problem of transmitting through complex terrain, and there will be no need to dispatch anybody to retrieve the data. The mesh network is a reliable solution because of its self healing ability to revert to alternative paths if connection is lost or a device failure occurs. The end product will be a mesh network system that is stable through its self healing network, have a one to two kilometer range between each node, capable of withstanding rough weather and easy to configure. The building blocks of the mesh network are the wireless transceivers, antenna, and microcontroller. 1.2 Acknowledgements The team would like to thank Doug Taylor from John Deere Renewables out of Des Moines, Iowa for his guidance and support on this project. The team would also like to give thanks to, Benazir Fateh, Iowa State University PhD student, on Energy-aware Resource Management in Networked Embedded Systems research focus, for providing help with transceiver technology considerations and for demonstrating a sensor network. 1.3 Problem Statement Meteorological data must be collected for analysis of complex terrain wind projects placed on a mountain ridgeline to assess the potential of wind power. The benefit of placing wind Iowa State University Page 6 turbines on a mountain ridgeline is the ability to capture high-elevation winds in locations that do not have adequate wind power in the valley floor. It is difficult to capture accurately the assessment of potential wind power in the complex terrain due to the harsh conditions. The more data that is able to be acquired, the more accurate the assessment will be. Currently the method of collecting data is done with a small number of large MET towers that have three levels of sensors. These towers are expensive and not easily transported. What is needed is a solution that can acquire more data at a cheaper cost. 1.4 Problem Solution The proposed solution is to incorporate a large number of smaller scout towers that will be capable of wirelessly transmitting their measurements to the large MET towers. Wireless communication will be accomplished via radio transceivers located on each scout tower and MET tower. The transceiver will have a built-in mesh networking protocol that will enable towers to be added and removed from the network on demand, as well as self healing. Figure 1 below shows a complete mesh network solution with four scout towers on a mountain ridgeline. The mesh network will be in sync with real-time while collecting the meteorological data. Figure 1: Mesh Network Solution The scout tower will consist of four measurement sensor devices, a temperature sensor, a barometric sensor, an anemometer to measure wind speed, and a wind vane to measure wind direction. The measurements will be logged into the data logger with one to three second resolution. A microcontroller will control the data measurements from the Iowa State University Page 7 interface of the data logger and tell the data to be transmitted through the transceiver. The transceiver will transmit the data measurements through the antenna, which will communicate with the other scout towers. Figure 2 below shows a complete system of a scout tower that will be deployed. Figure 2: Scout Tower System Block Diagram 1.5 Operating Environment The unit will be exposed to a harsh outdoor environment. The device must be operable in temperatures ranging from -30 to 100 °F. The transceiver is required to have a NEMA Type 4 enclosure, which must protect against rain, sleet, snow, splashing water, and hose directed water. The antenna shall be able to communicate with the transceiver under high elevation winds. 1.6 Limitations The limitation on this project is the lack of knowledge and access of the area. We are limited to the knowledge of the terrain and topography. We will not have the ability to test our equipment in a similar environment with harsh weather and complex terrain. Our testing will heavily rely on our estimation and research to determine the best transceiver. Iowa State University Page 8 1.7 Expected End Product and Other Deliverables At the end of the project, our client expects three to four transceivers to be ready to deploy in the field to be field test. The transceivers must be capable of minimally transmitting over a one to two kilometer area range of subsidence, compatible with the data logger, withstand harsh weather conditions and have plug-in play. Iowa State University Page 9 2. Design Requirements 2.1 Design Objectives 2.1.1 Obtain a working proof-of-concept of the wireless mesh network system consisting of the basic building blocks shown on figure 3. 2.1.2 Develop a microcontroller to communicate between the data logger interface and the transceiver Figure 3: Building Blocks for Mesh Network Solution 2.2 Functional Requirements 2.2.1 2.2.2 2.2.3 2.2.4 2.2.5 2.2.6 2.2.7 2.2.8 The minimum range of the transceiver must be 1-2km Network shall utilize a mesh network protocol Data shall be sent home a minimum of once a day Data shall be logged onto the towers own memory device Components shall be enclosed in a NEMA4 type enclosure Low power consumption and efficient (optional) Network will be synchronized with real-time Data will be collected in 1-3 second resolution 2.3 Non-Functional Requirements 2.3.1 2.3.2 2.3.3 2.3.4 Network shall be self healing in that a broken path shall be re-routed Wireless signal shall be able to penetrate rough terrain Wireless signal shall be able to penetrate precipitation Network shall be plug-and-play in that little configuration shall be needed to increase or decrease network size 2.3.5 The data acquired from the logger shall be buffered at the scout towers before being transmitted 2.3.6 The network shall be a scalable system Iowa State University Page 10 2.4 Design Constraints 2.4.1 Terrain can attenuate wireless signal 2.4.2 Topography could create unforeseen bottlenecks in mesh routing 2.4.3 Climate could stress operability of components 2.5 Technology Requirements The chosen wireless technology must have the ability to penetrate dense forestry. The electrical components must be able to handle extreme environment at a temperature range of -30 to 100 °F. 2.6 Technical Approach Considerations During the design phase of the project, we will conduct research on mesh network capability in the transceivers research on out to overcome the range issue site testing at small-scale lab setting to overcome obstacle issues research solutions relating with RF network issues 2.7 Testing Approach Considerations Testing will be done in a two step process. First we will use an indoor small scale laboratory setting to test the wireless communication to ensure that the system is working, followed by outdoor field testing. Tests conducted will include, range transmit tests, interference, reception, and power tests. Testing will need to be done at both low and high areas. Initial outdoor testing will be done at a park that contains dense forestry in Ames, Iowa. Some places to consider testing high elevated areas are the roofs of Iowa State University buildings, which will also be good for testing the range of the wireless devices. Once initial testing is done, further testing will be done on the field. Iowa State University Page 11 3. Detailed Design 3.1 Wireless Mesh Network Protocol Technology A wireless mesh network is needed to transmit and receive data. The current design uses cellular wireless technology to transmit data, which is not a mesh network. Different wireless technology protocols were considered and evaluated according to the design function requirements to implement a wireless mesh network. 3.1.1 Cellular Advantages Very long transmission range Very fast data rate and reliable Security Disadvantages Very high cost Very high power consumption Disadvantages High cost High power consumption 3.1.2 802.11/Wi-Fi Advantages Respectable transmission range Fast data rate and reliable Security 3.1.3 Point-to-Multipoint Advantages Statically configured Good data movement Low cost Disadvantages Not scalable Single points of failure (no way to route around changing conditions) Need coordinator to start Disadvantages Routers must always be powered Need coordinator to start 3.1.4 802.15.4/ZigBee Advantages Very low power Very scalable Security Low cost Iowa State University Page 12 3.1.5 DigiMesh Advantages Reliable (time synchronized) Peer-to-peer network; self healing Very low power Low cost Security Scalable Disadvantages Latency (router sleeping) 3.1.6 Detailed Design Through evaluation, the Zigbee and DigiMesh protocols were the best options for the wireless mesh network mainly because of cost and low power. Cellular was the current form of data transmission and its costs were too high, which applies to Wi-Fi also. Though Zigbee and DigiMesh protocols have lower data rates, they are reliable, low cost, secure, and scalable. Through evaluation, the DigiMesh protocol is the most attractive method. The DigiMesh protocol is a homogenous network. There is only one node type and the nodes are interchangeable. The network setup is simple, reliable and flexible to expand. The DigiMesh protocol also has a built-in feature called the Sleep Mode, which would allow the network to be power efficient. Sleep mode allows the RF module to enter a low power state. The XBee-PRO DigiMesh 900 module support a network synchronized sleep to conserve power when it is not being used. One node in a sleeping network acts as the sleep coordinator. During normal operations, at the beginning of a wake cycle the sleep coordinator will send a sync message as a broadcast to all nodes in the network. This message contains synchronization information and the wake and sleep times for the current cycle. All cyclic sleep nodes receiving a sync message will remain awake for the wake time and then sleep for the sleep period specified. The sleep coordinator will send one sync message at the beginning of every cycle with the currently configured network wake and sleep times. All router nodes which receive this sync message will relay the message to the rest of the network. If the sleep coordinator does not hear a rebroadcast of the sync message by one of its immediate neighbors then it will re-send the message one additional time. A sleeping router network is robust enough that an individual node can go several cycles without receiving a sync message (due to RF interference, for example). As a node misses sync messages the time available for transmitting messages in the wake time is reduced to maintain synchronization accuracy. By default a module will also reduce its active sleep time progressively as sync messages are missed. Iowa State University Page 13 3.2 UHF Wireless Transceiver/Communication Module The following section describes each transceiver technology that was considered. Different technology approaches were evaluated in detail according to their advantages and disadvantages. 3.2.1 XBee-PRO DigiMesh 900 extended range module Advantages Built-in DigiMesh protocol Scalable and interoperable with devices from different vendors Module is manufactured and readily made by Digi UHF can penetrate dense forestry Self-healing and discovery for network stability Disadvantages No knowledge on cases on range tests 3.2.2 DigiMesh 9XTend OEM RF module Advantages Built-in DigiMesh protocol Longest LOS range capability up to 40 mile range according to specification Very High Frequency can easily penetrate dense forestry Module is manufactured and readily made by Digi Disadvantages The transmission of the 9Xtend was only tested to reach approximately 2.5 miles with line of sight 3.2.3 Analog Devices 7021 Advantages Cost effective Feature rich Iowa State University Disadvantages No built in mesh protocol Build from scratch more external parts are required Page 14 3.2.4 Detailed Design XBee-PRO DigiMesh 900 was the chosen solution to test and prove the concept of wireless mesh networking system. This solution was chosen because of its benefits from both XBee and DigiMesh protocols, whereas the 9Xtend module only consists of the DigiMesh protocol. 3.2.4.1 Network Protocol The data logger is designed to be part of an ad hoc wireless mesh network protocol. One of the main advantages of choosing the XBee-PRO DigiMesh 900 is because of its built-in DigiMesh protocol, which allows a very simple set-up. 3.2.4.2 Pin Connections The only required pin connections are VCC, GND, DOUT and DIN. Where VCC and GND are the power supply connections, and DOUT and DIN are the input and output USART connections. However we will also be using the CTS and RTS pins. CTS and RTS are the flow control pins. When CTS is switched it tells the microcontroller not to send any more data to the transceiver so that the transceiver has time to transmit the data in the nearly full buffer, as well as vice versa for the RTS pin. An illustration of these connections is shown in figure 4. Figure 4: Micro-controller to transceiver interface connections Other pins that we will be using are the Associate LED pin (pin 15), and the commissioning button pin (pin 20). The Associate LED pin is used to indicate the status of the transceivers association with the network. The commissioning button pin will be connected to a push button. The function of the push button Iowa State University Page 15 will be to set various functions in the field without the need to send commands to the transceiver. These features can be implemented as shown in figure 5. Figure 5: Pin Configuration of XBee-PRO DigiMesh 900 3.2.4.3 Channel hopping Channel hopping is a method of transmitting wireless signals by rapidly switching the operating channel. The largest advantage this serves in our project is to greater security. The transmitter and the receiver only know a pseudo-random channel switching sequence. For an eavesdropper to intercept the message they must know the switching sequence. 3.2.4.4 Encryption The chosen transceivers are capable of built in AES encryption. AES is among the very best in publicly available block cipher encryption schemes. AES is a symmetric key based scheme where only one key is used for encryption and decryption. Every node in the networks transceiver will be programmed with the same encryption key. Our chosen transceiver makes use of a fixed 128-bit key for the AES encryption. Since the confidentiality of this key is paramount it will be wise to not let a human chose the key since computers are far better at choosing random elements. To choose a key the use of the openssl encryption suite will be used to generate our random key. The below command will output a random sequence encoded in hexadecimal of 16-bytes for our 128-bit key. $ openssl rand -hex 16 Iowa State University Page 16 3.3 Serial Interface Modes There are two modes of serial operation in the transceiver that effect how data is communication is handled by our microcontroller application. 3.3.1 Transparent Mode In transparent mode, the module simply queues up data received by the application and sends it out over the DOUT pin. Configuration commands are handled by entering a command mode. Advantages Easy to implement Less debugging Disadvantages Must enter command mode to send to multiple nodes Source node information not available to receiver Remote configuration not possible 3.3.2 API Mode Frame-based API extends the level to which a host application can interact with the networking capabilities of the module. When in API mode, all data entering and leaving the module's UART is contained in frames that define operations or events within the module. Advantages Easy to send data to multiple destinations Received data indicates senders address Remote configuration of nodes Disadvantages Complicates design Most features not needed Sleep Mode 3.4 UHF Antenna An antenna is needed in order for the signals to be transmitted for the wireless mesh network system. It is important to have an antenna that is capable of withstanding extreme environment and range. The antenna must be able to fit and work with the XBeePro DigiMesh 900. 3.4.1 Conductive Sleeve Dipole Half-Wave Antenna Iowa State University Page 17 At a defined frequency of 900 MHz, the longer the length of the antenna and the higher antenna gain, the longer the range of the antenna. Advantages Easy to implement Inexpensive Higher antenna gain than 1/4 Omni-directional Disadvantages Range may be limited due to omni-directional aspect The radiation pattern maps are shown vertically, horizontally and in 3-Dimensional in figures 5 below. The ½ wave dipole antenna has a respectable gain and is omnidirectional, which is necessary to communicate with multiple nodes. Figure 5: Horizontal and Vertical Radiation Map of Dipole 1/2-Wave Antenna Figure 5a: 3-Dimensional Radiation Map of Dipole 1/2-Wave Antenna Iowa State University Page 18 3.4.2 Conductive Sleeve Dipole Quarter-Wave Antenna The ¼ wave dipole antenna is similar to the ½ wave dipole antenna except the fact that the wavelengths are smaller by half. Advantages Easy to implement Inexpensive Less antenna gain than 1/2 Omni-directional Disadvantages Range may be limited due to omni-directional aspect Although the ¼ wave dipole antenna have the same radiation patterns, the ¼ wavelengths produce less gain than the ½ wave lengths, thus will have less range than the ½ wave dipole antenna. Figure 6: Horizontal and Vertical Radiation Map of Dipole 1/4-Wave Antenna 3.4.3 Yagi Antenna The Yagi antenna is an antenna made up of an array of simple dipole antennas. It can vary in gain based on the length of the elements and the number of elements. If more antenna elements are implemented, the gain will increase, but the directivity will not be as good. Iowa State University Page 19 Advantages Easy to implement Inexpensive High gain antenna High range Disadvantages Directed line of sight, not omnidirectional Figure 7: Horizontal and Vertical Radiation Map of Yagi Antenna Although the range of the Yagi antenna may fit well for the design situation, the antenna can only focus in a direct line of sight range. To allow the function of a selfhealing mesh network, the antennas must be able to transmit to multiple nodes. The trade offs for using the Yagi antenna may not benefit the mesh network solution design because it does not allow more than one node in its sight. Figure 7a: 3-Dimensional Radiation Map of Yagi Antenna Iowa State University Page 20 3.4.4 Detailed Designs The need for the antenna is to help obtain a range greater than 2 km. Since the specifications refer to line of sight ranges, the conductive sleeve dipole antenna is the best option. The antenna is inexpensive and will be shielded properly to filter unwanted frequency and from extreme weather. 3.5 Power Supply Poor power supply can lead to poor radio performance especially if the supply voltage is not kept within tolerance or is excessively noisy. To help reduce noise, a 1.0 µF and 8.2 pF capacitor are recommended to be placed as near to pin1 on the PCB as possible. Other problems can arise with the use of a switching power supply but in our case the switching power supply is unlikely so details will not be given. 3.6 Microcontroller A microcontroller is needed in order for the wireless communication module to communicate with the data logger. The microcontroller will take the data from the data logger and tell the transceiver module to send the specified data to the end point. 3.6.1 Development platform for LPC2148 Advantages Powerful processor Feature rich Lots of memory Socket for storage Built in accelerometer Disadvantages Highest price Less support base Disadvantages Not as easy to code as others 3.6.2 Development board for PIC18F4550 Advantages USB programmable Feature rich Multiple coding languages Abundant support Iowa State University Page 21 3.6.3 Arduino Advantages Lowest cost Massive base of supporters Very simple coding Very modular Disadvantages Least feature rich Slowest processor 3.6.4 Detailed design The chosen microcontroller is the Arduino. The Arduino is the lowest cost and easiest to use solution. For our application we only need the microcontroller to act as a proxy to the transceiver and data logger. In the future if more features are needed, for example an Ethernet or Storage device, the Arduino has many commercially available drop-in modules to add functionality. 3.7 Casing An enclosure that has the ability to protect the unit is important because this unit will be operating in extreme weather conditions. 3.7.1 Industrial Casing The industrial casings are made of polycarbonate to house electrical components and meet industry standards. These casings are customizable for all shape and sizes. 3.7.2 Detailed Design The industrial casing fulfills the requirements of industrial standards meeting the National Electrical Manufacturers Association (NEMA) standards. The enclosure standard type NEMA 4 is required to meet the operating environment. Iowa State University Page 22 4. System and Unit Level Testing Cases 4.1 UHF Transceiver/Communication Module Unit Level Testing Cases Preliminary tests will be tested in the laboratory to ensure transceiver to transceiver communication with each transceiver. Using Digi’s firmware, data will be sent from one transceiver to another to ensure that communication has been made between each unit. The ad hoc mesh network protocol will be tested when communication has been established between each transceiver. Data will be sent from each transceiver to test and verify the mesh network protocol. 4.1.1 Range Testing The communication module was tested under different ranges. Computer notebooks were used as monitors of the data being transmitted as well as temporary power sources which aided the testing of the range between each transceiver. Range testing was first done indoors from transceiver to transceiver within the lab. Data was then sent from one transceiver to another from low to high distances between each node. Testing was done under outdoor conditions including the following: Flat terrain, such as the intramural fields High elevated areas, such as various points on rooftops of Coover Hall Dense forestry areas, such as Ames local parks Areas with congestion, such as Iowa State Campus grounds 4.1.2 Power Consumption Testing The overall power consumption of our design will be determined using National Instrument’s LabView software in conjunction with digital multi-meters to measure the current and voltage both during the active and inactive modes of data transmission. Probes used to measure voltages will be placed at the VCC and GND pins of the XBee module as well as the Vin and GND nodes of the development board. Current readings will be made by connecting the ammeter in series with a spliced USB cable which connects the Arduino to a computer being used as a power source. After measurements are collected, the equation P(watts)=I(amps)*V(volts) will be used to find the total power consumed by our product. This will produce a better understanding of which functions, carried out by the device, consume the most power. Based on our findings, we will then decide which source or combination of sources will be adequate for long term operation of our final design. Iowa State University Page 23 4.1.3 Self-healing Testing The self-healing feature of the mesh protocol will be tested using various methods such as turning off or unplugging one transceiver. Data will be sent continuously to test the self-healing network. Multiple transceivers will also be turned off or unplugged to test the self-healing network capability. 4.1.4 Security Testing Channel hopping To test channel hopping capability we will send data between two transceivers and analyze the frequency spectrum with a spectrum analyzer to verify that the message is not transmitted on a single channel and that hopping is indeed occurring. Encryption As specified by the client further testing of encryption other than verification of transceiver configuration is beyond the scope of the project. 4.1.5 Latency Testing A way to test for latency is to send and receive different data packages and analyze the sending and receiving rate versus data size. To achieve this we will use a computer to act as the data logger, which will be running a simulation program. The program will simulate various data sizes and append a time stamp that will be analyzed later to determine latency. The computers running the simulation program will be time synchronized prior to testing. 4.2 UHF Antenna Module Unit Level Testing Cases The transceiver/communication module will be tested under ideal conditions and then under its operating environment. The university’s antenna laboratory equipment will be used to measure the radiation pattern for the antenna. 4.3 Microcontroller Unit Level Testing Cases 4.3.1 Basic data communication We shall verify that communication from the simulation program and other devices is successful. 4.3.2 Message integrity Iowa State University Page 24 We will send large amounts of data with the simulation program and verify that the message received is uncorrupted. 4.3.3 Throughput Our simulation program will calculate throughput by sending a set amount of data e.g. 100,000 bytes, and timing how long it takes to receive the message. The following formula will be used to calculate throughput. Throughput Message length Transmition time 4.3.3 Power Consumption Power Consumption of the micro controller will be measured using both the voltmeter and ammeter functions of multi-meters. Voltage readings will be taken by placing probes at VCC and GND pins. Current values will be measured by placing probes in series with the VCC pin of the microcontroller. LabView will be used to determine the microcontroller’s power consumption over time. This will provide information about which functions of the microcontroller require the most power. 4.4 Casing Unit Level Test Cases To test the durability and resistivity to meet the operating environment, these tests will be performed: Realistic and measurable force impact on the enclosure at operating environment temperatures Shock and vibration tests with a test circuit within the case. The test circuit will be tested after the shock and vibration tests to check the functionality of the circuit. Contact in a variety of materials such as water, ice, and snow. Iowa State University Page 25 5. Implementation 5.1 Hardware The assembly and implementation of the hardware is described in this section. We have both a physical mount and an electrical hardware that is implemented for the project. We have four transceivers with shields plugged into an Arduino. The hardware will be populated to match the number of transceivers. The electronic hardware includes a printed circuit board layout, antenna, transceiver, Arduino microcontroller with shield, 4 AA battery pack, and wire cables. The physical mount includes PVC piping, hose clamps and brass pipes. 5.1.1 Printed Circuit Board Layout The PCB layout was done using Eagle. The main function of this PCB is to convert the sinusoidal-wave signal from the anemometer into a square-wave signal. From the square-wave signal, we can measure the time between each period of the squarewave and calculate the wind speed. The PCB layout was simple; therefore each component on our board contained an associated footprint. Due to time constraint, our team did not order a printed circuit board based off our layout, but assembled the electronic components and the layout onto the PCB by hand. Figure 8: Printed Circuit Board Iowa State University Page 26 Figure 9: Signal Converter PCB 5.1.2 Transceiver Configuration The transceiver contains two modes as described in the previous sections. The transceiver is configured to be in transparent mode to ensure which node is the transmitter and which is the receiver. Figure 10: Transceiver Iowa State University Page 27 5.1.3 Arduino Microcontroller Due to the versatility of the Arduino Microcontroller, we implemented code to the Arduino to function similar to a data logger for our system. The program can be configured to average, collect, log, and transmit both wind speed and wind direction at the user’s desired timeframe. Figure 11: Arduino Microcontroller Figure 12: Full system device Iowa State University Page 28 5.1.4 Wind Sensors and Mounting The wind vane and anemometer provided by John Deere were implemented and attached to a mount for testing. Figure 13: Wind Vane and Anemometer In order to interface with Iowa State University’s EE491 senior design wind turbine project, we need to collect real-time data from the rooftops of Coover Hall. The strategy to design and implement the mounting is to place the anemometer and the wind vane together using PVC pipes and clamping the PVC pipe with hose clamps onto piping located on the rooftops of Coover Hall. It should be noted that we did not have visual of what the rooftop looked like; we only had some specifications concerning the pipes and ledge height with the advice from the Coover Hall building manager. After assembling the mount, we realized that we had to trim the mounting in order to minimize wind interference by putting all the hardware components more compact together. Figure 14: Wind Sensor Mount Iowa State University Page 29 5.2 Software 5.2.1 Arduino microcontroller Our microcontroller software was written and compiled with the Arduino microcontroller IDE (Integrated development environment). The software’s job on the microcontroller was to take measurements from the sensor devices connected to the microcontroller input ports and convert the raw data into the appropriate unit of measurement. After measurements are taken the software averages the readings over a specified time period and averages the data. The averaged data is then sent out to the transceiver via an onboard serial connection. 5.2.2 Data aggregation and display At the receiving node the microcontroller is connected to a computer via a serial connection where a program running on the computer takes incoming data from multiple nodes and averages over a specified time. After the data is averaged it is written to a file for logging. The log file read by a graphing program in real time to graphically display changes in wind speed over the individual nodes, as well as an aggregate average. Iowa State University Page 30 6. System and Unit Level Test Case Results 6.1 UHF Transceiver/Communication Module Unit Level Testing Results Preliminary tests were tested in the laboratory to ensure transceiver to transceiver communication with each transceiver. Using Digi’s firmware, data was sent from one transceiver to another to ensure that communication was made between each unit. The ad hoc mesh network protocol was tested after communication was been established between each transceiver. Data was sent from each transceiver to test and verify the built in mesh network protocol. 6.1.1 Range Testing Results The range testing for our transceivers provided us with some issues initially. We tried simply holding each of the nodes at a height of about 4 feet off the ground for our first set of tests. After discovering that our range was much lower than anticipated we decided to raise the transceivers to a greater height. This allowed the Fresnel zone between the antennas to be relatively free of obstacles that could impede the signal being transmitted. The maximum distance that we were able to reach for transmission of data between two nodes was approximately 1.75 kilometers over unobstructed terrain. Our next step was to find the maximum transmission distance over rough terrain. For these tests, trees and other solid objects were placed within the Fresnel zone between nodes. The distance that we were able to achieve during these tests came out to be approximately 0.8 kilometers. 6.1.2 Power Consumption Testing Results The Use of Ohms law allowed us to calculate the power used by our product. Based on our findings, we were able to determine that the required current and voltage was 103mA and 4.89V respectively with the sensors connected. When we disconnected the sensors we found that the current was reduced to 90mA while the voltage remained at 4.89V. This brought us to the conclusion that our scout tower devices would require 0.504W while our central node would only require 0.4401W. With this information we determined that our current battery pack configuration of 4 AA (1.5 Volt) batteries could power each of our modules for approximately two and a half days. Iowa State University Page 31 6.1.3 Self Healing Results We were able to prove the existence of the mesh network protocol by place three of the nodes in series with a distance between the first and first node that would prevent direct communication from the first to last node without the existence of a middle transceiver. By removing the middle node we found that the signal was no longer able to reach its destination at the final node. Upon replace the middle node, communication was restored. We then added a fourth node to the system at approximately the same distance that the middle node was between the first and last node. This gave us the opportunity to prove the mesh network protocol by removing one of the middle nodes while still maintaining a line of communication between the three remaining nodes due to the built in rerouting capabilities of the transceiver. 6.1.4 Security Results The transceiver was configured to enable encryption by setting the AES keys in the transceiver configuration. As per our requirements, the fact that communication occurred between two nodes with encryption enabled, and did not on a node with encryption disabled was sufficient proof of concept. 6.1.5 Latency Testing Results Through our latency testing we were able to identify at which points we experience latency, and also how latency scales with the increase of nodes on the network. Latency was found at three main points: From computer to microcontroller, microcontroller to transceiver, and transceiver to other transceivers. We also observed that the latency followed a linear pattern as the number of nodes a message goes through is increased as shown in the graph below. Figure 15: Latency Testing Case Iowa State University Page 32 Figure 16: Latency Testing Results 6.2 UHF Antenna Module Unit Level Testing Case Results To test the performance of the quarter-wave dipole antenna we used a network analyzer to test the reflection S-parameters. The antenna had frequencies that were accepted, but for the 900Mhz frequency range, most of the frequency was reflected according to the SParameter test. Figure 17: Antenna S11 Parameters Iowa State University Page 33 The antenna was very sensitive when testing with the network analyzer. We made sure the antenna was positioned the way that the antenna was going to be positioned when implemented into the system. 6.3 Wind Sensors Testing Case Results 6.3.1 Anemometer Testing Case Results The anemometer was tested directly using an oscilloscope in the lab to ensure that it is functioning appropriately. Below is the output signal of the anemometer. The anemometer acts as a generator. Figure 18: Anemometer Testing Results 6.3.2 Wind Vane Testing Case Results The wind vane was tested connected to a 5 volts power supply directly using an oscilloscope in the lab to ensure that it is functioning appropriately. Below is the output signal of the wind vane. The wind vane acts as a potentiometer, which is why we connected the wind vane to a power supply. The voltage varies as wind vane changes direction from 0 to 360 degrees. The wind vane will be connected directly to the Arduino microcontroller. Iowa State University Page 34 Figure 19: Wind Vane Testing Results 6.4 PCB Signal Converter Circuit Testing Case Results The signal converter circuit’s purpose is to convert the anemometer’s sinusoidal-wave signal into a square-wave signal. Once the signal is converted into a square-wave, a frequency relative to the sinusoidal-wave will be produced with a pulse, allowing the microprocessor to calculate the wind speed. Figure 20: Signal Converter Circuit Test Results Iowa State University Page 35 6.5 Microcontroller Unit Level Testing Case Results 6.5.1 Basic data communication Using two nodes each connected to a computer via the serial port, we were able to test basic data communication by typing messages to each computer. The flow of data starts from the computer via a terminal program, goes through the computers serial port to the microcontroller, then the microcontroller sends that data though another serial connection to the transceiver were the process is reversed at the destinations transceiver. Figure 21: Data Communication Aggregated Iowa State University Page 36 Figure 22: Data Communication Results 6.5.2 Throughput & Integrity Testing Results Due to our scope change and time constraints, we were unable to perform throughput or integrity testing and suggest that future continuations of our project perform this testing if throughput is a concern. 6.6 Casing Unit Level Test Cases Our NEMA-4 enclosure testing consisted of temperature range testing. We were able to keep the enclosures outdoors in 6℉ temperature without any compromising of the structure’s integrity. The other portions of our testing concluded that our enclosure could maintain a watertight seal while being held under running water and that, once some padding was applied to the inner walls, the enclosure could prevent the contents from being damaged by dropping, shaking, or other possible vibrations that could take place if this product were to be deployed. Iowa State University Page 37 7. Recommendations for Project Continuation 7.1 Technology Continuations In the case that this project is chosen in an upcoming semester, there are several ways in which the new team could build upon what we have accomplished. Firstly the use of an alternative energy source such as solar or even a small wind turbine could be implemented as the power source for each of the scout towers. Once this is incorporated, the completion of senior design team MAY11-01’s project will future teams to fully interface with our project. This will allow the wind turbine, which is coupled to a motor, to be driven using the text file containing our anemometers’ aggregated wind speed data. This joining of projects would also allow for a more in depth look at the efficiencies of the turbine used for MAY11-01’s project. Computational fluid dynamics calculations could be done to determine the maximum theoretical output that the turbine should be generating. In order to do these tests the addition of a few extra sensors would be needed. Connecting both a barometer and a temperature sensor would provide the necessary data to undergo further research with regard to the full capabilities of the given wind turbine in a specific location on campus or otherwise. The fact that this device can transmit data over rough terrain using mesh protocol allows for many more uses aside from what we have established during the past two semesters. There are countless ways in which these devices could be used. The two major ideas that we have come up with include the use of our system to transmit data from transmission lines wirelessly. This would provide a better early detection system for potential fault conditions on transmission lines through the use of various sensors, which could alert system operators when an issue arises within the grid. The second potential use for these devices could be implemented with the addition of GPS to our current design. The devices could then be mounted on vehicles operated by Cyride, Iowa State University’s bus system. This would give the Cyride staff the capability of locating exactly where individual buses are at any given time. Cyride could then not only insure that bus drivers remain on their predetermined schedule, but they could also provide passengers with a real-time update of the bus’ location in relation to the nearest bus stop in case the conditions near the bus stop are less than favorable. Iowa State University Page 38 8. Estimated Resources and Schedule 8.1 Estimated Resources Based on the technology considerations, the estimated total cost of the technology on a single scout tower is $4292.00 if we included the anemometer, wind vane, barometric pressure sensor, temperature sensor and the data logger. The estimated total cost for the scope of this project is $282.00. Item Estimate Cost ($) Transceiver Microcontroller Enclosure RF Antenna Ethernet Interface Total (Communication) Anemometer Wind Vane Barometric pressure sensor Temperature sensor Data Logger Total (Scout Tower Technology) $82.00 $15.00 $50.00 $100.00 $35.00 $282.00 $285.00 $205.00 $325.00 $195.00 $3,000.00 $4292.00 Table 1: Estimated Cost for a Single Unit The total development labor cost is estimated in table 3 with and hourly rate of $20 per hour. The hours were based on each task, included individual work, team meetings, and meetings with the client and advisors. The development labor cost will be donated. Task Estimated Hours (hrs) Estimated Cost ($20/hrs) Problem Definition Technology Research/Selection Product Design Product Implementation Product Testing Presentation Documentation Total 70 60 150 150 300 40 100 910 $1400 $1200 $3000 $3000 $6000 $1600 $2000 $18,200 Table 2: Estimated Development Labor Cost Iowa State University Page 39 The total estimated cost for the project is $20233, which includes development labor and four total units for the communication aspect. Description Communication Unit Development Labor Costs Total Estimated Unit Cost Estimated Quantity $282/unit 4 units $20.00/hour 910 hours Extended Cost $1128 $18,200 $19,328 Table 3: Estimated Project Cost We would like to give our acknowledgements to John Deere. The funds for the technology for this project including the towers, data loggers, and sensors will be provided by John Deere. Iowa State University Page 40 8.2 Schedule Figure 23: Project Schedule Iowa State University Page 41 8.3 Task Breakdown Figure 24: Task Breakdown Iowa State University Page 42 9. Closure Material 9.1 Project Team Information 9.1.1 Client Information John Deere Renewables Contact: Doug Taylor Wind Assessment and SCADA Manger, Email: TaylorWilliamD@JohnDeere.com 9.1.2 Advisor Information Dr. Manimaran Govindarasu 3227 Coover Hall Ames, IA 50011 Phone: 515-294-9175 Email: gmani@iastate.edu Dr. Venkataramana Ajjarapu 1122 Coover Hall Ames IA 50011-3060 Phone: 515-294-7687 Email: vajjarap@iastate.edu 9.1.3 Student Information Stephen Copeland 2124 Fredericksen Ct. Ames, IA 50010 Phone: 214-802-0813 Email: ohmantic@iastate.edu Xau Moua 171 University Village Apt. H Ames, IA 50010 Phone: 612-309-2068 Email: xmoua@iastate.edu Joseph Lane 2520 NW Heritage Ave Ankeny, IA 50023 Phone: 515-975-3444 Email: jrodericklane@iastate.edu Robert Akerson 9107 Buchanan Hall Ames, IA 50013 Phone: 563-826-2151 Email: rakerson@iastate.edu Iowa State University Page 43 9.2 Closing Summary Our former client, John Deere Renewables, presented us with the task of improving their current meteorological communication system. We were charged with developing a deployable wireless mesh network which could aid in the long range transmission of valuable data. Despite the loss of our client, we were able to successfully complete our project within the two semester time period provided. Despite minor setbacks along the way the end result of this project has met our system requirements and the joining of our project with that of senior design team MAY11-01’s will undoubtedly provide the electrical and computer engineering department of Iowa State University with an adequate means of obtaining meteorological data over long distances by means of a wireless mesh network. Iowa State University Page 44 References Balanis, Constantine A. Antenna Theory: Analysis and Design. Hoboken, NJ: John Wiley, 2005. Digi. 15 Feb 2010 <http://www.digi.com/>. "Mesh Network." Wikipedia: The Free Encyclopedia. Wikimedia Foundation, Inc. 15 Feb 2010. Web. 15 Feb 2010. <http://en.wikipedia.org/wiki/Mesh_network>. "SCADA." Wikipedia: The Free Encyclopedia. Wikimedia Foundation, Inc. 2 Mar 2010. Web. 2 Mar 2010. <http://en.wikipedia.org/wiki/SCADA>. Sparkfun. 15 Feb 2010 <http://www.sparkfun.com/commerce/categories.php>. Iowa State University Page 45