Stability studies (emphasis on FPPs)

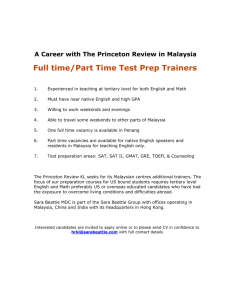

advertisement

Workshop on GMP and Quality Assurance of

Multisource Tuberculosis Medicines

Kuala Lumpur – Malaysia

21-25 February 2005

Stability Studies

(emphasis on FPPs)

Theo Dekker, D.Sc., consultant to WHO

Research Institute for Industrial Pharmacy

North-West University, Potchefstroom, South Africa

iiftgd@puk.ac.za

Feb 2005

1

TG Dekker – WHO, Malaysia

Abbreviations

API

BP

CEP

EOI

FDC

FPP

ICH

Int.Ph.

R&D

TB

USP

25ºC/60%RH

Feb 2005

Active pharmaceutical ingredient

British Pharmacopoeia

EU certificate of suitability

Expression of interest

Fixed dose combination

Finished pharmaceutical product

International Conference on Harmonization

International Pharmacopoeia

Research and development

Tuberculosis

United States Pharmacopeia

25ºC ± 2ºC / 60% RH ± 5% RH etc.

2

TG Dekker – WHO, Malaysia

The perspective

Pharmaceutical R & D provides the foundation of the

activities aimed at ensuring that the patient receives

an FPP (product) that consistently meets established

standards & specifications of

Safety

Efficacy

Quality

The FPP should be stable - and thus retain these

standards – throughout the shelf-life,

if kept in the original packaging and

when correctly distributed, stored & handled

Feb 2005

3

TG Dekker – WHO, Malaysia

Topics for discussion

1.

2.

3.

4.

5.

Objective of stability studies

Glossary / definitions

Example of transport monitoring

Study protocol/requirements

Rifampicin containing FDCs to exemplify

Expression of degradants

Assay / degradation analytical requirements

6. Closing remarks

Feb 2005

4

TG Dekker – WHO, Malaysia

The objective of stability studies

The purpose of stability testing is to provide evidence

on how the quality of a drug substance [API] or drug

product [FPP]

varies with time

under the influence of a variety of environmental

factors such as temperature, humidity, and light,

and

to establish a re-test period for the API (drug

substance) or

a shelf life for the FPP (drug product) and

recommended storage conditions.

ICH QA1(R2)

Feb 2005

5

TG Dekker – WHO, Malaysia

Glossary [ICH QA1(R2)]

Re-test period

The period of time during which the API is expected to remain

within its specification and, therefore, can be used in the

manufacture of a given drug product, provided that the API

has been stored under the defined conditions

After this period, a batch of API destined for use in the

manufacture of a FPP should be re-tested for compliance with

the specification and then used immediately

A batch of drug substance can be re-tested multiple times and

a different portion of the batch used after each re-test, as long

as it continues to comply with the specification

For most biotechnological/biological substances known to be

labile, it is more appropriate to establish a shelf life than a retest period. The same may be true for certain antibiotics

Feb 2005

6

TG Dekker – WHO, Malaysia

Glossary (2)

Re-test date

The date after which samples of the API should be examined

to ensure that the material is still in compliance with the

specification and thus suitable for use in the manufacture of a

given drug product [if stored under defined conditions]

Expiry (expiration) date

The date placed on the container label of an FPP designating

the time prior to which a batch of the FPP is expected to

remain within the approved shelf life specification

if stored under defined conditions, and after which it must

not be used {no re-testing !!}

Feb 2005

7

TG Dekker – WHO, Malaysia

Glossary (3)

Stress testing (API)

Studies undertaken to elucidate the intrinsic stability of the

IPA. Such testing is part of the development strategy and is

normally carried out under more severe conditions than those

used for accelerated testing.

Stress testing (finished product)

Studies undertaken to assess the effect of severe conditions

on the finished product. Such studies include photostability

testing (see ICH Q1B) and specific testing on certain products,

(e.g., metered dose inhalers, creams, emulsions, refrigerated

aqueous liquid products).

Feb 2005

8

TG Dekker – WHO, Malaysia

Glossary (4)

Accelerated testing

Studies designed to increase the rate of chemical degradation

or physical change of an API or FPP by using exaggerated

storage conditions as part of the formal stability studies. Data

from these studies, in addition to long term stability studies,

can be used

to assess longer term chemical effects at non-accelerated

(real-time) conditions &

to evaluate the effect of short term excursions outside the

label storage conditions such as might occur during

shipping

Results from accelerated testing studies are not always

predictive of physical changes

Current accelerated conditions for solid orals: 40ºC/75%RH

Feb 2005

9

TG Dekker – WHO, Malaysia

Example of shipping conditions (1)

UNICEF ↔ Kampala (1989): Temperature

Feb 2005

10

TG Dekker – WHO, Malaysia

Example of shipping conditions (2)

UNICEF ↔ Kampala (1989): Relative humidity

Feb 2005

11

TG Dekker – WHO, Malaysia

Stability protocol/report

The following elements (see Guidelines, Annex 2)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Feb 2005

Info on batches tested (commercial formula)

Unit composition (or cross-reference)

Container-closure system (commercial!!)

Literature and/or supporting data

Stability specifications (only for FPPs)

Analytical methods – stability indicating (cross-reference)

Stability plan (schedule)

Tabulated test results (including specifications)

Analysis/discussion of data (statistical if negative trend)

Re-test or shelf-life proposal (including storage condition)

Post approval commitments

12

TG Dekker – WHO, Malaysia

Stability batches

Stability data for three primary batches

The formulation and manufacturing process should be

the same as proposed for marketing

In container-closure system proposed for marketing

Preferably manufactured from different API batches

Full info on batches tested (tabulated format) e.g.:

Feb 2005

Batch number

Manufacturing date

Manufacturing site

Batch size (in kg & in number of units)

Container-closure (primary packaging)

Date of initial analysis (release)

API batch number

13

TG Dekker – WHO, Malaysia

Tablets – stability batches data - example

1st

2nd

3rd

Batch number

Manufacturing date

Manufacturing site

Batch size (kg)

Batch size (number of units)

Batch type (full-scale, pilot, etc.)

Primary packaging

Date initial analysis

Batch number of API

Feb 2005

14

TG Dekker – WHO, Malaysia

Stability specifications

Stability studies should include testing of those

attributes (parameters) of the FPP that are

susceptible to change during storage and thus

are likely to influence quality, safety, and/or efficacy.

The testing should cover, as appropriate, the physical,

chemical, biological, and microbiological attributes,

preservative content (e.g., antioxidant, antimicrobial

preservative), and functionality tests (e.g., for a dose

delivery system)

From ICH Q1A(R2)

Feb 2005

15

TG Dekker – WHO, Malaysia

Tablets – stability specifications

Parameters for tablets that are often omitted:

Tablet strength, friability and moisture can change

with time

– if not in release specs, include in stability

– these are interrelated, also with dissolution

– these are inexpensive

Microbial limit at release and end-of-shelf

Dissolution specification must be same as for

release

Feb 2005

16

TG Dekker – WHO, Malaysia

Example - FPP specs – uncoated tablets

Attribute

Release limits

Stability limits

Appearance

Full description

Same as release

Identification

At least 1 method

Dimensions

Diameter, etc

Average mass

w.r.t. theoretical

Mass uniformity

Ph.Eur/USP/Int.Ph

Not required for

stability studies.

Not regarded as

variables for

product.

Water content

Product specific

Tablet hardness* Product specific

Feb 2005

17

Same as release?

Same as release

TG Dekker – WHO, Malaysia

Example of FPP specs – uncoated tabs (con.)

Attribute

Release limits

Stability limits

Friability *

≤ 1 % (normally)

Same as release

Dissolution

Set per product

Same as release

Disintegration

Not required if dissolution is done

Related subs.

(degradants)

Only if formed

during production

95.0-105.0%,

unless justified

Required. Limits

to one decimal

May be 90.0105.0% if justified

Skip-testing

End-of-shelf

Assay (content)

Microbial limits

* Tests not necessary at release if done in-process

Feb 2005

18

TG Dekker – WHO, Malaysia

FPP stability specs. – special for FDCs

Degradants (related substances) must be stated &

calculated in % with respect to the parent API, not the

sum of the APIs, e.g.

Rifampicin / isoniazid tablets. Rifampicin quinone

(degradant) as % of rifampicin (not of all peaks in HPLC)

If 2 APIs react with each other, then the degradant to

be stated with respect to worst case, e.g.

Rifampicin / isoniazid tablets. Isonicotinyl hydrazone forms

from the 2 APIs. Specification: % hydrazone with respect

to rifampicin (worst-case in mass balance).

Unknown degradants – with respect to worst case

Dissolution – include all APIs (e.g. FDCs in the USP)

Feb 2005

19

TG Dekker – WHO, Malaysia

Isonicotinyl hydrazone expression

The reaction (simplified):

Isoniazid + rifampicin → hydrazone + ..

Rel. MM

137

829

845

MM Ratio (÷137) 1.0 mg

6.0 mg

6.2 mg

FDC mg

FDC ratio

75 mg

1.0 mg

150 mg

2.0 mg

At 100% reaction, no rifampicin left, 67% isoniazid intact

Hydrazone to be expressed with respect to rifampicin

Rifampicin worst-case in mass balance

Feb 2005

20

TG Dekker – WHO, Malaysia

Stability indicating analytical methods

Analytical methods must be suitable for the purpose

of stability testing (stability indicating), particularly in

the case of

Assay of the API(s) in the FPP

Determination of the degradants (related substances)

Determination of preservatives

If the same as release testing methods, a reference

will suffice

Release methods should include validation for stability

Compendial methods

May not be suitable (e.g. non-specific like titration)

May not exist for the particular purpose (e.g. degradants)

Feb 2005

21

TG Dekker – WHO, Malaysia

Rifampicin containing FDC

assay/degradation methods (1)

Particular degradants to consider:

1.

2.

3.

4.

5.

Isonicotinyl hydrazone

Rifampicin quinone

Rifampicin N-oxide

3-Formyl rifamycin (present in FDCs?)

25-Desacetyl rifampicin

All to be determined & expressed with respect to

rifampicin

Assay method(s) must be specific (considering

degradants)

A method for degradants to be developed

Feb 2005

22

TG Dekker – WHO, Malaysia

Rifampicin containing FDC

assay/degradation methods (2)

Examples of methods:

USP 28 (2, 3, 4 FDC capsules/tablets)

Assay method (stability indicating when tested in our lab)

C-18 column, gradient chromatography (see USP)

No specification/test for degradants

S. Singh et al. (NIPER)

Various HPLC methods, mainly related to isonicotinyl

hydrazone determination, simultaneously with rifampicin

and isoniazid (one example given here)

RIIP analysis (Research Institute for Industrial Pharmacy)

For assay of rifampicin and degradants – other APIs with

a separate method

Feb 2005

23

TG Dekker – WHO, Malaysia

USP FDC assay method

DAD1 A, Sig=238,4 Ref=360,100 (C:\HPCHEM~1\ASTERIX\AMR\03060406.D)

5.443 - Pyrazinamide

mAU

350

300

Pyrazinamide

250

Rifampicin

13.044 - Rifampicin

Isoniazid

150

4.182 - Isoniazid

200

switch

0

0

5

10

15

19.585

16.544

16.993

10.999

10.010

10.379

3.626

2.643

3.042

50

11.555

11.872

9.695

100

20

Isonicotinyl hydrazone in area of gradient “switch”,

difficult for quantification

Feb 2005

24

TG Dekker – WHO, Malaysia

A NIPER HPLC method

S. Singh et al., Pharm. Pharmacol. Commun., 6, 405-410 (2000)

Feb 2005

25

TG Dekker – WHO, Malaysia

RIIP HPLC chromatogram

27.413 - Rifampicin

DAD1 A, Sig=254,4 Ref=360,100 (AMR_RIF\07090407.D)

3-Formyl rifamycin

mAU

50

0

5

Quinone

Hydrazone

10

15

24.070 - 3-Formylrifamycin

0

18.861 - Rifampicin Quinone

10

14.171 - Hydrazone

20

7.389 - Rifampicin N-Oxide

30

N-Oxide

Other 3 APIs

40

rifampicin

20

25

30

min

C-18: methanol/phosphate buffer pH 7.0 : 6/4

Signals well separated

Feb 2005

26

TG Dekker – WHO, Malaysia

4FDC products – degradation results

Product

Primary container

A

Pvdc/Alu

B

HDPE

securitainer

8

C

Pvdc/Alu

Age (months)

N-oxide (%)

Hydrazone (%)

Quinone (%)

3-Formyl (%)

Total related subs.

10

7.2

1.3

5.0

10.2

2.6

8.5

5.0

12.8

8

The 4FDC tablets instable: Isonicotinyl hydrazone main degradant

Container permeability may play a role (Alu/Alu > Pvdc/Alu?)

Feb 2005

27

TG Dekker – WHO, Malaysia

Testing frequency & storage conditions

Solid oral dosage forms (tablets, capsules):

Condition▼

Month►

0

3

6

9 12 18 24 36

30ºC / 65% RH (zone IV) X X X X X X X X

40ºC / 75% RH (accel)

X X

25ºC / 60% RH (zone II)

X X X X X X X

Zone IV is real-time condition for prequalification

project, unless otherwise justified

Zone II only if justified (may be fall-back for zone IV)

ASEAN proposal for zone IV: 30ºC / 75% RH

Feb 2005

28

TG Dekker – WHO, Malaysia

Stability storage facilities

RIIP facilities (110 m3)

Three rooms: 25ºC/60%RH; 30ºC/65%RH; 40ºC/75%RH

Feb 2005

29

TG Dekker – WHO, Malaysia

Significant changes during stability

1. A 5% change in assay from its initial value (or failure to

meet acceptance criteria when using biological methods)

2. Any degradation product exceeding its acceptance criterion

3. Failure to meet the acceptance criteria for appearance,

physical attributes, and functionality test (e.g., colour, phase

separation, resuspendibility, hardness, dose delivery per

actuation);

4. and, as appropriate for the dosage form:

Failure to meet the acceptance criterion for pH; or

Failure to meet the acceptance criteria for dissolution for

12 dosage units

5. Dissolution specifications for release and stability must

be the same (otherwise possible BE change)

Feb 2005

30

TG Dekker – WHO, Malaysia

Pitfall

The assay value is still within the limits

but the change during stability is more than 5.0%

Example

Feb 2005

Release assay limit: 95.0 – 105.0%

Stability assay limit: 92.5 – 105.0%

Release assay: 101.0% (within spec)

24-Month assay: 93.0% (within spec)

Loss in potency: 8.0% !!

This is a significant change !!

31

TG Dekker – WHO, Malaysia

Reporting of stability data

Stability should be presented in well

constructed tables (stability data sheets)

See Annex 2 for an example

Relevant administrative information must appear

on sheet

Acceptance criteria for each attribute must be

included in the table for quick reference purposes

Result sheets must bear date and responsible

person signature / QA approval

Feb 2005

32

TG Dekker – WHO, Malaysia

Evaluation of stability data

1. The data show no/little variation with time

Statistical analysis not required (justify)

Proposed shelf-life = 2 x real-time data (R), but not more

than R + 12 months (30 months max)

2. The data show trend(s)

Statistical analysis required [see ICH Q1A(R2)]

Proposed shelf-life depends on the statistical analysis

3. Commitment

Feb 2005

For confirmation of provisional (tentative) shelf-life, realtime data are required

First 3 production batches on stability

Follow up stability testing (FUST) – one batch per year

33

TG Dekker – WHO, Malaysia

Closing remarks

Stability testing is an essential part of the

process of ensuring that the patient receives a

product that meets established standards of

safety, efficacy and quality

Sound planning and execution of stability

studies are important

Valuable time may be lost if the data are insufficient

Always include all attributes which may change with time

(e.g. water content, friability & tablet strength in the case

of uncoated tablets) – pay upfront and save later

Feb 2005

34

TG Dekker – WHO, Malaysia