NP-SCADA2CC-FINAL-B - Nor

advertisement

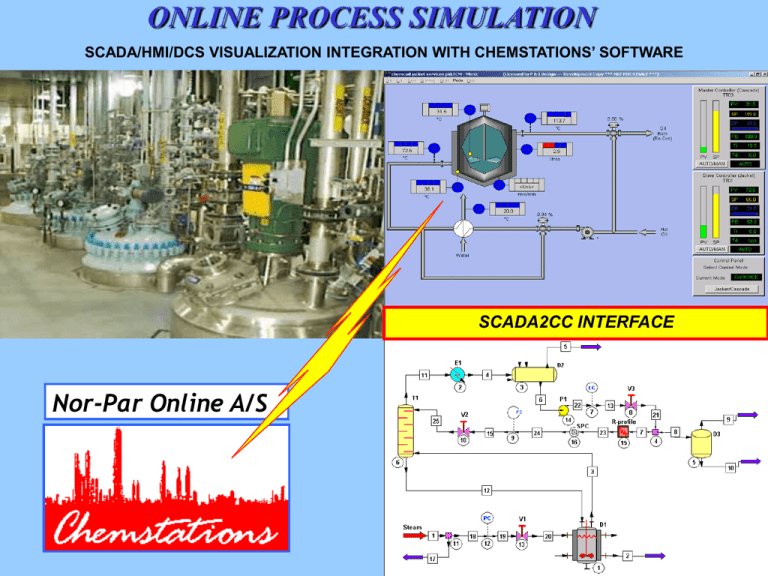

ONLINE PROCESS SIMULATION SCADA/HMI/DCS VISUALIZATION INTEGRATION WITH CHEMSTATIONS’ SOFTWARE SCADA2CC INTERFACE Nor-Par Online A/S 1 All the terms below mean exactly the same thing • SCADA = Supervisory Control And Data Acquisition • HMI = Human-Machine Interface • Process Visualization software • DCS console software SCADA/HMI/Visualization/DCS console is a class of software that presents data available at DCS (Distributed Control System) or PLC (Programmable Logic Controller) in a form that a human can understand. The plant personnel can also manipulate the settings of DCS/PLC directly from such SCADA systems, as a modern alternative to a traditional control room. SCADA systems come from independent software houses or from DCS vendors. The most popular independent SCADA systems are Intellution’s FIX, OSI’s PI, and Wonderware’s Intouch. All stateof-art SCADA systems are compatible with Microsoft Excel. 2 The Online and Real-Time Process Simulation from Nor-Par Online A/S • SCADA2CC runs online process simulation driven by true production data in CHEMCAD • SCADA2CCD runs real-time process simulation driven by true production data in CC-ReACS and/or CC-DCOLUMN • SCADA2CCP runs real-time process simulation driven by true production data in CC-POLYMER and/or CC-DCOLUMN • You need to have a SCADA/HMI/Process Visualization/DCS console software compatible with Excel as well as respective Chemstations’ software to use the SCADA2CC/SCADA2CCD/SCADA2CCP solution 3 SCADA/HMI/VISUALIZATION SYSTEM STRUCTURE OPERATOR WORKSTATIONS PLANT INFORMATION MANAGEMENT SYSTEMS PIMS CLIENT PROCESS MODEL CLIENT ETHERNET DATA HIGHWAY DATA SERVER DATA SERVER FIELDBUS OPC SERVERS VALVES & SENSORS PLC’S DCS CONTROLLER HARDWARE CONTROLLER HARDWARE CONTROLLER HARDWARE FIELD DEVICES FIELD DEVICES FIELD DEVICES 4 OFFLINE DATA HANDLING HOW DO YOU DO IT? SCADA/HMI/ VISUALIZATION ANALYSIS DECISION DATA OVERLOAD TIME!!!! INADEQUATE UNCERTAINTY FLIES!!!! 5 SCADA SCADA2CC CHEMCAD • Supervisory Control and Data Acquisition SCADA – – – – • Also known as Human Machine Interface (HMI) or DCS Visualization Process visualization displays process parameters in real time Trend and history displays of process parameters Alarm monitoring and logging SCADA2CC provides ONLINE link SCADA to CHEMCAD – – – – • Measured parameters to CHEMCAD in real time Calculated parameters from CHEMCAD to SCADA in real time Excel interface provides parameter optimization tool Troubleshoot with calculated and measured parameter comparison CHEMCAD CC-ReACS CC-DCOLUMN CC-POLYMER – Process modeling software in steady and dynamic states – Calculates parameters for process streams and equipment 6 SOFTWARE STRUCTURE Client’s SCADA System CC-ReACS** Batch Reactors SCADA2CC* SCADA2CCD CHEMCAD** Steady State * SCADA2CCP* CC-POLYMER** Polymer Reactors *) From Nor-Par Online A/S **) From Chemstations Inc. CC-DCOLUMN** Dynamic Column 7 Software Packages SCADA2CC Online Process Simulation (uses CHEMCAD) SCADA2CCD Real Time Process Simulation SCADA-2-CCR (uses CC-ReACS) SCADA-2-CCDC (uses CC-DCOLUMN) SCADA2CCP Real Time Process Simulation SCADA-2-CCDC (uses CC –DCOLUMN) SCADA-2-CCPLMR (uses CC-POLYMER) Reality Training Simulator Uses either SCADA2CCD or SCADA2CCP Uses CC-ReACS, CC-DCOLUMN, or CC-POLYMER respectively 8 SCADA2CC SYSTEM ARCHITECTURE SCADA CLIENT OPTIMIZER PC STEADY STATE PROCESS MODEL: CHEMCAD Modem Option ETHER NET DATA SERVER DYNAMIC PROCESS MODEL: CC-REACS, CC-DCOLUMN, CC-PLMR CONTROLLER 4 9 8 TC 3 Heat Transfer Oil Return 5 2 7 T 49 W 13696 11 5 TC 1 10 T 49 W 45000 15 T 138 6 W 45000 T 49 W 31304 FIELD DEVICES 17 13 18 8 12 13 10 4 12 6 7 2 T 138 W 0 16 Coolant CUSTOMER T 138 Heat Transfer Oil Supply 3 T 138 W 45000 1 T 300 W 13697 W 45000 11 NOR-PAR ONLINE A/S DEALERS 9 DATA FLOW and CONTROL in Excel (driven by SCADA2CCD) CC-ReACS CC-ReACS Reads Writes SYSTEM RULES UNIT OP & DESCRIPTION DATA FORMAT Equipment 1 REACTOR SCADA-2-CCR Ref. Row SCADA Ref. Row UNIT OP & DESCRIPTION Common Ref. Row Equipment 11 Reactor Contents Temperature Controller PARAMETERS CONTROLLED BY CHEMCAD Contents Temperature UnitOp Blank Description Data Units 0.00 DATA FORMAT Data Units CC-ReACS Reads Reactor Wall Contents Temperature Pressure 0.00 0.00 Liquid Volume 0.00 PARAMETERS CONTROLLED BY SCADA Contents Controller Proportional Temperature SP On/Off Band 120.00 1.00 25.00 °C % Integral Time 0.00 Mins Derivative Time 15.00 Mins PARAMETER CONTROLLED BY EXCEL SCADA Reads SCADA Writes ADAPTIVE CONTROL IF((D21-D13)<10,30,0) SCADA Reads 10 ONLINE STEADY STATE PROCESS OPTIMIZER PROCESS PLANT SCADA SYSTEM SCADA2CC CHEMCAD MODEL C U ST O M E R SCADA VISUALIZATION MIMIC S C A D A N O R PA R SCADA2CC AND CHEMCAD O N L I N E A / S 11 ONLINE STEADY STATE PROCESS 4 3 7 8 7 2 6 6 5 4 5 1 3 2 22 8 12 11 28 23 10 27 13 20 11 13 9 1 10 9 ONLINE DATA 16 12 SCADA2CC wild 15 30 33 14 14 Feed 1: BZ INPUT 31 29 15 17 MODEL 32 18 34 controlled MODEL RESPONSES ECONOMIC OPTIMIZATION Minimum/Maximum 12 STEADY STATE OR DYNAMICS Steady State SCADA integration Dynamic SCADA integration Based on Online Process Simulation Based on Real Time or Accelerated Dynamic Process Simulation principle principle, modeling the plant behavior by continuous series of steady state approximations Requires least effort to construct and calibrate the flowsheet Ideal for economic analysis and online optimization Requires CHEMCAD only Can only be applied to process units between intermediate and storage tanks Takes into account true dynamic behavior of the plant, including equipment size, accumulation, and control system unit operations Ideal for troubleshooting, control loop tuning and real time optimization Requires CHEMCAD and CCReACS or CC-DCOLUMN or CCPOLYMER 13 CONTINUOUS PROCESS DYNAMICS 2 10 8 11 12 11 9 10 09 Steady 9Dynamic 24 BZ wildSCADA visualization BZfeed state 35 01 REAL DATA CALC DATA 14 12 14 ONLINE DYNAMIC PRODUCTION OPTIMIZER SCADA VISUALIZATION MIMIC PROCESS PLANT SCADA SYSTEM SCADA2CCD SCADA2CCP CC-ReACS CC-DCOLUMN CC-POLYMER C U S T O M E R S C A D A SCADA2CCD, SCADACC2P N O R P A R O N L I N E DYNAMIC PROCESS MODEL 4 2 3 7 T 49 W 13696 11 5 TC 1 6 10 T 49 W 45000 15 T 138 W 45000 T 49 W 31304 17 13 18 A / S 9 8 TC Heat Transfer Oil Return 5 8 12 13 10 4 12 6 7 2 T 138 W 0 16 T 138 Coolant W 45000 11 Heat Transfer Oil Supply 3 1 CC-REACS, CC-DCOLUMN, CC-PLMR T 138 W 45000 T 300 W 13697 15 REALITY TRAINING SIMULATOR TRAINING SIMULATOR CUSTOM MIMIC OFFLINE PLANT SCADA MIMIC SCADA2CCD SCADA2CCP CC-ReACS CC-DCOLUMN CC-POLYMER N O RP A R O N L I N E A / S SCADA2CCD, SCADA2CCP DYNAMIC PROCESS MODEL DE AL ER S 4 2 3 7 T 49 W 136 11 5 TC 1 6 10 T 49 W 45000 15 T 138 W 45000 T 49 W 31304 17 13 18 VIRTUAL PLANT 9 8 TC Heat Tra Ret 5 8 12 13 10 4 12 6 7 2 T 138 W 0 16 T 138 Coolant W 45000 11 Heat Tran Supp 3 CC-REACS, CC-DCOLUMN, CC-PLMR T 138 W 45000 1 T 300 W 136 16 ONLINE SIMULATION BENEFITS INTEGRATED PRODUCTION SOLUTION MONITORING OPERATIONS DATABASE MAINTENANCE ECONOMIC TRAINING HISTORY Integration with client’s own Production Management System like SAP 17 MONITORING BENEFITS CHEMCAD “Virtual Plant” PROCESS MODEL INTERFACE SCADA2CC Soft sensor (no instrument installed or available) Component composition prediction Prediction of inferred measurements Estimation of unmeasured process conditions Component concentrations in reactor Temperature profiles in reactors and columns SCADA SYSTEM PROCESS PLANT Concentration profiles in the columns Heat transfer coefficients,fouling,specific heat Study interactions of dependent variables Estimation of physical properties All calculated stream properties in CHEMCAD can be returned to Excel for analysis 18 OPERATIONAL BENEFITS CHEMCAD “Virtual Plant” PROCESS MODEL INTERFACE SCADA2CC SCADA SYSTEM Allows calibration of process model Using true data from the production Calibration of process and control models Aids prediction of optimum performance Tool for speeding up troubleshooting Predict the onset of production problems Identify problems from SCADA and model history Learn to start up and shut down the plant for increased safety Provide help for improving the process model PROCESS PLANT Model inaccuracy easier to detect and correct Online optimization based on true data Cost savings Historical data 19 MAINTENANCE BENEFITS CHEMCAD “Virtual Plant” PROCESS MODEL INTERFACE SCADA2CC SCADA SYSTEM PROCESS PLANT Fault diagnosis & Data reconciliation Fouling and scaling monitoring Condition monitoring of expensive equipment Instrument fault diagnosis Instrument calibration frequency Maintenance planning Use of historical data for process and mechanical maitenance planning, integrated with SAP or other Process Information Management Systems 20 REALITY TRAINING BENEFITS SCADA Mimic SCADA2CCD SCADA2CCP PROCESS MODEL CC-ReACS CC-DCOLUMN CC-POLYMER “Virtual Plant” Improve production efficiency SCADA operator interface is identical to real plant model Operators understanding of the process enhanced Operators can study effect of control settings Operators can study parameter interactions Downtime due to operator error reduced Learning start-up and shutdown procedures Consequences of operator actions to environment (Environmental Impact factors by WAR technology) Improve production safety Operational plant safety improved Learning without the consequences of risk/damage 21 ECONOMIC BENEFITS CHEMCAD “Virtual Plant” PROCESS MODEL INTERFACE SCADA2CC SCADA SYSTEM PROCESS PLANT Capital cost savings Infer measurements from calibrated model Reduced installed instrumentation Production cost savings Economic calculations based on model Integration with SAP system Reducing cost on maintenance, start-up and shutdown On-line optimization Adjust process to minimize production cost Optimize plant throughputs Better control of purity, increasing the product value Better control of emissions and waste from the process, reducing environmental penalties Sensitivity analysis Sensitivity of yields to process changes Sensitivity of energy usage to process changes 22 SAVINGS The savings that can be achieved by using the integration of SCADA with Chemstations software will be result of: Running the plant with high quality product, less pollution, and faster using the existing equipment Online optimization of the production Maintaining better product and production documentation, according to FDA and other procedures/standards Reducing the duration and cost of start-up Limiting shutdowns only to planned ones Avoiding breakdowns and unpleasant failures Optimizing, calibration and tuning the control system in short period of time Training operators to higher level of understanding 23 SAVINGS EXAMPLE We are talking about substantial savings. We have a client that makes and operates many 5 kt/y units for on-site production of Chlorine Dioxide. This is one the smallest production capacities at which continuous processes are operated. This technology was mastered by the client who had been using CHEMCAD and a SCADA system for several years. Yet, applying the SCADA2CC has brought the client additional savings estimated to $70,000 yearly per each of aforementioned small units. 24 ECONOMIC JUSTIFICATION We have understood from works we have done under secrecy agreements with some of our clients that: For a well operated advanced plant producing commodity chemicals and already using SCADA systems for several years, the savings could be estimated to 1 – 1½ % of operating cost For a commodity chemical manufacturer who has just started using SCADA systems, the savings could be at least 1½ 3% of the operating cost For a large plant such as Oil Refinery already using SCADA systems for several years, the savings could be estimated to 0.2 – 0.5% of the operating cost For a large plant such as Oil Refinery that has just started with SCADA systems, the annual savings could be at least 0.5 – 0.8% of the operating cost 25 WHAT ARE THE OTHER SAVINGS? If you could deliver the product with better specifications, and every production unit could be better controlled… What are the savings? Ask yourself If you could quickly change to make another product with existing equipment, especially if you need to follow the FDA rules and get the FDA acceptance… What are the savings? Ask yourself If you could get a large contract based on better production planning, better documentation, and better product quality What are the savings? Ask yourself For some it could be 50% savings, and for some 5%. We believe 10% of savings first year will return many times the investment in CHEMCAD and the SCADA integration 26