D30_AIAA_STC100411

advertisement

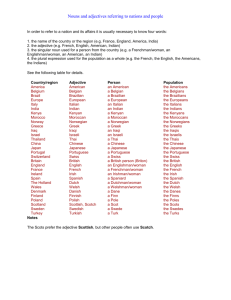

Committee D30 on Composite Materials Current Work in Standard Test Methods Development Carl Rousseau, D30 Chairman (LM Aero) Adam Sawicki, D30 Vice-Chairman (Boeing) Jen Rodgers, D30 Staff Mgr (ASTM) Outline ASTM D30 Overview and Overall Objective D30 Organization ASTM Process Description D30 Standards Summary New Standards – 2005 to 2009 Current Work Items Future Objectives Relationships 2 ASTM International Fast Facts Formed in 1898 World-Wide Development of Voluntary, FullConsensus Standards for Materials, Products, Systems & Services 12,000 Standards Developed by 138 Technical Committees are Administered, Published, and Distributed by ASTM International Over 32,500 Members from 125 Countries Participate on ASTM Committees ASTM Standards are Living Documents, Continually Revised to Meet Stakeholder Needs, Reflecting Current Technology Each member – not a company or country – gets a vote 3 Committee D30 on Composite Materials Committee D30 formed in 1964 (with heritage to the early ‘50s) out of Committee D20 on Plastics Current (2009) D30 Scope “The Committee will develop standard test methods, practices, terminology, and guides; sponsor symposia; stimulate research; and exchange technical information pertaining to composite materials (primarily those with fibrous reinforcement), as well as to reinforcing fibers with a Young's modulus greater than 20 GPa (3 Msi). This Committee will not develop standard specifications.” D30 Objective A complete, effective, and coordinated suite of testing standards for composites 4 D30 Committee Membership OEMs Testing Laboratories Material Suppliers Component Fabricators Academic & Research Institutions Government and Certification Agencies US Army, Air Force, Navy, NASA FAA, CAA NIST, non-US standards groups 5 ASTM Technical Committee Organization MAIN COMMITTEE Subcommittee .01 Subcommittee .02 Technical Committees form to address specific industry issues. They develop scopes to define their jurisdiction. Subcommittees are established to address subsets Subcommittee of specialized subject matter .03 under the scope of the Main Committee. Subcommittees further Task Group Task Group organize their expertise into small Task Groups. 1 2 This is the level at which documents are first The 138 Technical Committees, 2,000+ developed and are Subcommittees, & thousands more Task Groups subsequently revised. produce 1,200 drafts, or revisions to drafts, annually. 6 D30 Committee Organization D30.01 Editorial and Resource Standards D30.02 Research and Mechanics D30.02.03 Test Method Reconstruction D30.02.04 Interlaminar Fracture Analysis Benchmarking D30.03 Constituent/Precursor Properties D30.04 Lamina and Laminate Test Methods D30.05 Structural Test Methods D30.05.01 Civil and Marine D30.06 Interlaminar Properties D30.09 Sandwich Construction D30.90 Executive D30.91 Planning D30.92 Awards D30.94 Technical Specialists 7 ASTM International Balloting Process COMMITTEE ON STANDARDS (COS) MAIN COMMITTEE SUBCOMMITTEE TASK GROUP 4) As a final check, a standing committee (COS) of the ASTM Board of Directors reviews the process by which each standard is developed or revised, to ensure compliance with ASTM regulations. 3) After S/C approval the Main Committee votes. If approved it is presented to the Committee on Standards for final review. Otherwise it returns to the Task Group for re-work & balloting is repeated. 2) A completed draft is voted on by the Subcommittee. If approved, it moves to a Main Committee vote. If not, it returns to the Task Group for re-drafting. 1) Starting Point. Documents are drafted, and continually revised, in the Task Group by a few members who specialize in the subject matter. This is where the bulk of the activity occurs. 8 D30 Standards Breakdown, 2009 Subcommittee Standards No. Name Published Draft D30.01 Resource Standards 6 0 D30.02 Research and Mechanics NA NA D30.03 Constituent/Precursor Properties 8 0 D30.04 Lamina/Laminate Test Methods 20 3 D30.05 Structural Test Methods 13 6 D30.06 Interlaminar Properties 5 1 D30.09 Sandwich Construction 20 4 72 13 Total 9 2009 D30 Standards Summary (with most pre-existing standards updated) Constituent Fiber Tension Fiber Density Tow Density Fiber Content Resin Content Volatiles Content Fiber Areal Weight Core Density Core Thickness Core Shear Core Compression Core Shear Fatigue Core Water Absorption (and more) Lamina(te) Structure Other Tension Open-Hole Tension Terminology Compression Open-Hole Compression Fabrication Practice Shear Filled-Hole Tension Orientation Code Unnotched Fatigue Filled-Hole Compression General Test Guide Short-Beam Strength Bearing Textile Test Guide Flexure Response Bearing-Bypass Interaction Database Records Fiber Volume Bearing Fatigue Mode I Fracture Damage Impact Resistance Mixed-Mode Fracture Residual Strength After Damage Mode I Fracture Fatigue Sandwich Beam Flexure Ply Thickness Sandwich Panel Flexure Moisture Absorption Sandwich Flexure/Creep Glass Transition Fastener Pull-Through (and more) (and more) 10 D4762 –Gateway to D30 Standards Standard Guide to Testing Polymer Matrix Composite Materials – The major 2004 revision now briefly summarizes the scope, advantages, and disadvantages of related D30 standards, as well as other commonly referenced related standards of other ASTM committees. – An aid in education and selection of appropriate standards for use with advanced composite materials – 2008 update has been published, includes information on standards published 2004-07 11 2005-09: New D30 Standards D 7078/D 7078M: Test Method for Shear Properties of Composite Materials by the V-Notched Rail Shear Method D 7136/D 7136M: Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event D 7137/D 7137M: Test Method for Compression Residual Strength Properties of Damaged Polymer Matrix Composite Plates D 7205/D7205M: Tensile Properties of Continuously-Reinforced Polymer Matrix Composite Bars D 7248/D7248M: Test Method for Bearing/Bypass Interaction Response of Polymer Matrix Composite Laminates Using 2-Fastener Specimens D 7249/D7249M: Test Method for Facing Properties of Sandwich Constructions by Long Beam Flexure D 7250/D7250M: Practice for Determining Sandwich Beam Flexural and Shear Stiffness D 7264/D7264M: Test Method for Flexural Properties of Polymer Matrix Composite Materials D 7290: Practice for Evaluating Material Property Characteristic Values for Polymeric Composites for Civil Engineering Structural Applications D 7291/D7291M: Test Method for Through-Thickness "Flatwise" Tensile Strength and Elastic Modulus of a Fiber-Reinforced Polymer Matrix Composite Material D 7332/D7332M: Test Method for Measuring the Fastener Pull-Through Resistance of a Fiber-Reinforced Polymer Matrix Composite D 7336/D7336M: Test Method for Static Energy Absorption Properties of Honeycomb Sandwich Core Materials D 7337/D7337M: Tensile Creep Rupture of Fiber Reinforced Polymer Matrix Composite Bars 12 2005-09: New D30 Standards (cont) D 7028: Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA) D 7522/D 7522M: Test Method for Pull-Off Strength of FRP Bonded to Concrete Substrate 13 Recent Efforts: Updates C271/C271M: Core Density C272: Sandwich Water Absorption C273/C273M: Sandwich Shear 9 D30.09 standards C274: Sandwich Terminology updated to standard C297/C297M: Sandwich Flatwise Tension Strength D30 format to improve C363/C363M: Honeycomb Core Node Tensile Strength consistency. C364/C364M: Sandwich Edgewise Compression Strength C365/C365M: Core Compressive Properties C366/C366M: Core Thickness Measurement C393/C393M: Sandwich Core Properties by Long Beam Flexure C394: Sandwich Shear Fatigue C480: Sandwich Flexural Creep C481: Sandwich Laboratory Aging D6416/D6416M: Sandwich 2D Plate Flexure Properties D6772: Core Dimensional Stability D6790: Core Poisson’s Ratio D7249/D7249M: Sandwich Facing Properties by Long Beam Flexure D7250/D7250M: Determining Sandwich Beam Flexural & Shear Stiffness D7336/D7336M: Honeycomb Core Static Energy Absorption F1645/F1645M: Honeycomb Core Water Migration 14 Recent Efforts: Sandwich Long Beam Flexure Standards In 2006, C393-00 was replaced with 3 standards: C393: core shear stiffness and strength by long beam flexure (test method) – 3-point loading configuration is standard; alternative configurations retained for historical continuity. – Includes guidelines for specimen design to promote core shear failure. D7249: facing stiffness and strength by long beam flexure (test method) – 4-point loading configuration is standard. – Includes guidelines for specimen design to promote facing failure. D7250: determining sandwich beam flexural and shear stiffness (practice) – Data reduction and calculations for flexural and shear stiffness determination using C393 and D7249. C393 D7249 15 Recent Efforts: Civil Infrastructure Standards D30.05 subcommittee working with ACI Committee 440 to publish civil infrastructure composite test methods. – TG consists of about 20 D30 and ACI subject matter experts. – Key contacts are Drs. Abdul Zureick and Russell Gentry (Georgia Tech). – D30 met jointly with ACI in March 2009 (San Antonio, TX). 17 ACI 440 documents being transitioned into ASTM documents. Four ACI standards are currently published as ASTM standards: – D 7205/D7205M: Tensile Properties of Continuously-Reinforced Polymer Matrix Composite Bars – D 7290: Practice for Evaluating Material Property Characteristic Values for Polymeric Composites for Civil Engineering Structural Applications – D 7337/D7337M: Tensile Creep Rupture of Fiber Reinforced Polymer Matrix Composite Bars – D 7522/D 7522M: Pull-Off Strength for FRP Bonded to Concrete Substrate Another ACI standard is in D30 committee ballot: – WK17184: Tensile Properties of Fiber-Reinforced Polymer Matrix Composites used for Strengthening of Civil Structures 16 Recent Efforts: New DMA Tg Standard D 7028 for glass transition temperature by Dynamic Mechanical Analysis (DMA) was published in 2007. – Based upon process improvements derived from a round-robin study. – Significant efforts by Mike Stuart (Cytec) and Joy Wu (Hexcel). Key process improvements: – Guidance on equipment calibration. – Methods for characterizing and interpreting DMA thermograms. A research report from the round-robin testing is in preparation. 17 Current Standards Initiatives • Draft standard test methods are currently in-work for a number of other items, including: – Open-hole fatigue testing – Additional testing modes for interlaminar fracture – Sandwich cleavage fracture toughness – Non-ambient environmental testing – Sandwich panel impact resistance – Sandwich panel residual strength 18 Possible New Standards Other technical areas for possible D30 standards development include: – HPLC and FTIR – Large-scale CAI – Creep – Stress-rupture – Notched laminate testing guide – FEM-based VCCT benchmarking 19 BENCHMARK PROBLEM: DCB SPECIMEN • DCB benchmark • 2D plane strain and plane stress analysis • Virtual Crack Closure Technique (VCCT) UD24: [0]24 T300/914C 2h=3.0 mm 2L=150.0 mm B=25.0 mm a=30.5 mm • Full 3D solid analysis 1 Fy i v v* l l 2ab 1 GII Fxi u u* l l 2ab GI 20 MANUALLY CREATING A BENCHMARK SOLUTION FOR A DCB SPECIMEN* • Load/displacement plots for different delamination lengths a (/2=1.0 mm) 80 70 60 50 load P, N • Benchmark case 80 70 G= 0.30 kJ/m2 a=30mm a=31mm a=32mm a=33mm a=34mm a=35mm a=40mm G= 0.27 G= 0.24 G= 0.22 G= 0.19 G= 0.17 40 kJ/m2 kJ/m2 kJ/m2 kJ/m2 kJ/m2 60 50 Ic 0.17 kJ/m 2 2 G= 0.11 kJ/m 20 10 20 10 • G= G = load P, 40 N 30 30 0 0.0 a=30 mm a=31 mm a=32 mm a=33 mm a=34 mm a=35 mm a=40 mm b enchmark 0 0.0 /2=1.0 crit 0.2 0.4 0.6 0.8 /2=0.75 1.0 1.2 1.4 0.2 0.4 0.6 0.8 1.0 1.2 21 applied opening displacement /2, mm 1.4 applied opening displacement /2, mm 0.2 0.4 0.6 0.8 1.0 1.2 applied opening displacement /2, mm 1.4 80 Mathematical relationship between load and energy release rate 2 P 2 CP GT P G 2 2 A Gc Pcrit Gc Pcrit P , GT Gc crit GT * R. Krueger, NASA/TM-2008-215123, 2008. 70 b enchmark ABAQUS 60 50 load P, N 40 30 20 10 0 0.0 Future D30 Objectives • Add more quantitative precision statements based on accurate and effective round-robin test programs • Improve balance between a concise lab procedure and detailed explanatory guidance or requirements • Increase exposure and acceptance in non-aerospace and international markets • Expand into non-aerospace statistical assurance of measured properties 22 Current and Future Relationships Cooperation with CMH-17 (MIL-HDBK-17) on consensus test methods and testing guidance Cooperation with SAE Committee P-17 on test methods for consensus standard composite material specifications Cooperation with ACI Committee 440 on civil infrastructure standards Standards supporting marine product development Collaboration and joint meetings/conferences with CMH-17, ASC,and SAMPE Future interaction with independent test lab certification organizations, such as PRI/NADCAP 23 D30 Committee Contacts D30 Officers (2008-2009) Chairman, Carl Rousseau (LM Aero) Vice-Chair, Adam Sawicki (Boeing IDS) Recording Secretary, Mark Chris (Bell Helicopter) Membership Secretary, James Ratcliffe (NASA) Past Chairman, Rich Fields (LM M&FC) Past Chairman, Gene Camponeschi (US Navy) D30 Members-At-Large Bill Bertelsen (Gougeon Brothers) Paul Lagace (MIT) Jian Li (Boeing IDS) Steve Ward (Consultant) ASTM Staff Jen Rodgers, D30 Staff Mgr Barbara Lake, D30 Admin Asst Karen Wilson, D30 Secretary Jessica Rosiak, D30 Editor D30 Subcommittee Chairs .01, Editorial/Resource, Paul Lagace (MIT) .02, Research & Mechanics, Ron Kreuger (NIA) .03, Constituent/Precursor, Bill Grant (Specialty Materials) .04, Lamina/Laminate, Mark Kistner (USAF) .05, Structural, Mark Chris (Bell Helicopter) .06, Interlaminar, James Ratcliffe (NIA) .09, Sandwich, Steve Ward (consultant) 24 ASTM International Committee D30 on Composite Materials www.astm.org www.astm.org/COMMIT/D30.htm