display

advertisement

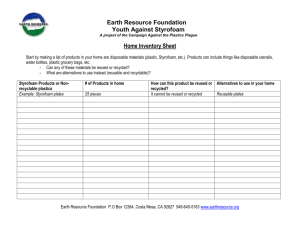

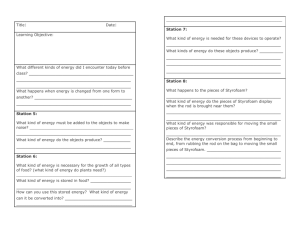

Sub-Systems Design Review P14416 Concrete Arborloo Base October 29, 2013 Team Intro Member Role Victoria Snell (ISE) Project Manager Evan Burley (ME) Engineer Joe Omilanowicz (ME) Engineer Mac Keehfus (ME) Engineer Anthony Deleo (ISE) Engineer Agenda • • • • Background Functional Decomposition/Architecture Updated Customer Requirements Subsystems – Geometry – Composition • Compression Test Results – Features • Cost/Trade-off Analysis • Engineering Requirements • Project Management Updates Arborloo • A latrine-like sanitation device designed to function over a small pit and to be moved to a new pit when filled • Utilize compost by planting tree in used pit • Purpose to provide affordable sanitation in poor, underdeveloped areas – Originally designed for use in Zimbabwe (Peter Morgan) Functional Decomposition Functional Architecture Meeting with Francius Estimable (Johnny) • Weight • Price: ~25 USD = 1100 HTG • Type of Cement is still unknown • Prefers a DIY kit to educate locals • Design should be simple Updated Customer Requirements 1) Cost • 25 dollars • Make it available to all Haitians coming from different economic states 2) Weight • Make it transportable through all environments • Can be moved by 1-2 people comfortably 2) Simpler the better • Easy to make • Simple mold • Limited materials/ ingredients Meeting with Manitou • Self consolidating Concrete – Self Leveling – Higher Slump – No Vibration – Chemical Needed (Water Reducer) • More Efficient Mix Ratio – More Aggregate – Less Cement • Specific Gravities • Finishing Tools • Use of Fibers Geometry • Shape • Thickness • Feasibility of Molds Theoretical Analysis Θ b: width into the board 𝐹∗sin(𝑡ℎ𝑒𝑡𝑎) σcomp= 𝑑∗𝑏 𝐹∗cos(𝑡ℎ𝑒𝑡𝑎) σflex= (3∗ 𝐿−𝐿𝑖 )/(𝑏∗𝑑 2 ) • Maximum allowable flexural and compressive strength for each mold design: • Assume square slab • To make up for the lack of stress concentrations due to the hole: Factor of Safety of 3 Theoretical Graph Flexural Strength vs Theta Compressive Stress vs Theta 1200 70 Shear Stress Compressive Stress 60 1000 50 Stress (psi) Strength (psi) 800 600 40 30 400 20 200 0 10 0 50 Theta (Degrees) 100 0 0 50 Theta (Degrees) 100 Feasibility of Molds • • • • • Wood – Plastic sheets (release agent) – Reusable – Not as precise Metal Plastic Plastic injection methods Foam – Expensive (concrete canoe~$800) – Very accurate – Trying to figure out the release agent Composition • • Aggregates • Bind properly • Provide strength • Reduce cost Cement Replacements Mixtures • 6 different mixtures (each contained cement, course aggregates, fine aggregates, and water) • Cement (ternary mix) – Portland, slag, fly ash (improves strength, workability, and requires less water) • Aggregates (all mixtures contained sand) – Course • Coconut shells • Rubber • Limestone – Fine • Sand • Plastic Beads • Styrofoam Why? • Slag and fly ash improve strength of concrete when combined with Portland • Aggregates can be found in Haiti • Coconut shells – considered trash/ in abundance • Rubber – Need to figure out a way to grind up tires • Limestone/Sand – In abundance in Haiti • Plastic Beads/Styrofoam – Could grind up plastic water bottles Cylinder Testing Procedure • Slump test: General idea on mold capability as well as the proper amount of water • After 7 days/28 days of curing – ASTM C39: radius= 4” height= 8” Cylinder is loaded axially. Determines maximum compressive strength (psi) Test Mixtures (lbs.) Units (lbs) Mix 1 Mix 2 Mix 3 Mix 4 Mix 5 Mix 6 Mix 7 Mix 8 Mix 9 Cement 12.49 12.49 12.49 12.49 12.49 12.49 2.35 4.83 2.96 Slag 5.85 5.85 5.85 5.85 5.85 5.85 0.83 X 1.05 Flyash 4.82 4.82 4.82 4.82 4.82 4.82 0.65 X 0.82 Sand 1.50 1.50 1.50 1.50 1.50 1.50 6.95 8.87 8.87 Rubber 1.20 X X 1.20 X X 2.21 X X Styrofoam 0.01 0.01 X X 0.01 X 0.04 X X Plastic X X 0.68 0.68 X 0.68 X X X Coconut X 1.20 1.20 X X X X 4.14 4.14 Limestone X X X X 1.77 1.77 X X X Water 7.75 7.75 8.26 7.5 8 8.26 1.72 2.18 2.18 Glenium X X X X X X 10mL 8mL 8mL 6.77 6.70 6.73 6.88 7.08 4.53* 7.16* 7.32* Weight/cyl 6.45 *weight measured before curing Cylinder Plan • 70% Strength at 7 days • 28 day Accepted Standard • Fibers add mild Compression Strength • Limestone/Rubber/ Coconut/Shells/Sand/ Stryofoam/Plastic Results from 7 Day Cylinders Trial 1 (7 days) 2 (28) 3 Trial 1 (7 days) 2 (28) 3 Max Compressive Force For Mix (Kips) 1 2 3 4 5 22.64 37.67 34.67 21.35 47.07 6 58.58 Area of Test cylinder= Recorded Max Compressive Strength (psi) 1 2 3 4 5 6 1801.634 2997.683 2758.95 1698.98 3745.71 4661.65 0 0 0 0 0 0 0 0 0 0 0 0 Mix Tensile Strength (psi, assume 15% compression) Trial 1 2 3 4 5 6 1 (7 days) 270.24509 449.6525 413.843 254.847 561.857 699.247 2 (28) 0 0 0 0 0 0 3 0 0 0 0 0 0 A= π*r2 σ=F[lbf]/A[in2] 12.56637 Mix performance Mixture lb/ft^3 Mixture Compressive Strength 5000 122 4500 120 4000 118 3500 Compressive Stress (psi) 124 lb/ft^3 116 114 112 110 3000 2500 2000 1500 108 1000 106 500 104 0 Mix 1 Mix 2 Mix 3 Mix 4 Mix 5 Mix 6 Mix 1 Mix 2 Mix 3 Mix 4 Mix 5 Mix 6 Improvements Moving Forward • Add more aggregates – Used too much cement in first round of testing – Will reduce weight • Make more viscous (less water) – Styrofoam floated to the top of cylinders – Use Glenium • Use of finer aggregates – Sand is more dense than concrete – Higher strength with less voids Features • Modular upgrades for additional cost • Prepare basic design to allow for add-ins • Handles • Textures • Shelter connection points Transportability • Handles • Wheels • Rope Attachments $5.98 All require holes and screws • Terrain is too rough for wheels • Anchor bolts require $ and drill • Mold holes in sides for handles/hooks – Can this be done? • Multi-functional attributes simplicity $2.80 $4.12 $0.48 Shelter Interface • Holes? – Consistent with transportability features – Pole connection • Grooves? – Sheet metal connection • Small size? • Also reduces material and weight • Depends on ground hole Odor/Pest Reduction • Cheap, simple cover • What can be reused? • Simple hinge? • Additional holes for toilet seat cover? • Recommendation for household materials to use – Five gallon bucket How to make it visually appealing and simple at the same time: Material Costs Materials Rubber Mulch Coconut* Limestone Sand* Styrofoam Plastic Cement* Slag Fly Ash Cost Weight (lb) Cost/lb $ 10.98 19.8 $ 0.55 $ $ $ 10.00 2000 $ 0.01 $ $ $ 14.99 2 $ 7.50 $ 7.99 2 $ 4.00 $ 6.28 94 $ 0.07 $ 90.00 2000 $ 0.05 $ 70.00 2000 $ 0.04 *Reflects Cost in Haiti Fly Ash/Slag? • Need to evaluate cost/strength trade-off – Fly ash and slag are not produced in Haiti – Shipping costs are unknown – Currently testing mixes with and without flyash and slag Cost Breakdown Cement Fly Ash Slag Rubber Coconut Shells Weight Cost/lb Weight Cost Weight Cost Weight Cost Weight Cost 1 Cylinder 4.2 $ 0.28 1.6 $ 0.06 2.0 $ 0.09 0.2 $ 0.11 0.2 $ Arborloo 117.0 $ 7.82 45.3 $ 1.58 54.8 $ 2.47 5.6 $ 3.12 5.6 $ Limestone Sand Weight Cost Weight Cost 1 Cylinder 0.6 $ 0.00 0.5 $ Arborloo 16.6 $ 0.08 14.1 $ - Styrofoam Plastic Pellets Weight Cost Weight Cost 0.003 $ 0.02 0.2 $ 0.92 0.079 $ 0.59 6.5 $ 25.84 Summary of Results Mixtures Coarse Ag Fine Ag PM Arborloo Cylinder Strength (psi) Total Cost Weight Compressive Tensile* Mix 1 Rubber Styrofoam $ 15.58 Mix 2 Coconut Styrofoam $ 12.46 Mix 3 Coconut Plastic $ 37.71 Mix 4 Rubber Plastic $ 40.83 Mix 5 Limestone Styrofoam $ 12.54 Mix 6 Limestone Plastic $ 37.80 * Assume 20% of compression strength 181.41 190.41 188.44 189.28 193.50 199.13 1801.63 2997.68 2758.95 1698.98 3745.71 4661.65 360.33 599.54 551.79 339.80 749.14 932.33 Ranking Total Cost Weight Strength 4 6 2 6 4 4 3 5 3 1 3 1 5 2 5 2 1 6 Score Total 12 14 11 5 12 9 Engineering Requirements – Purchase Cost • Plastic expensive • Ranges from $12-$40 • Target <$25 – Load it can support • Compression Results • Only 70% strength • Ranges from 1500 psi to 4600 psi • Target >2500 psi – Ground Hole size Over design – Weight • Average weight per/cylinder = 6.832 lbs. • Per/arborloo= 190.36 lbs. Project Schedule: Past/Current Project Schedule: Future Budget Tracker Item Store Price 94 lb Portland Cement Home Depot $10.47 40" PVC Fencing Home Depot $9.97 48"x.25" Round Steel Rod Home Depot $9.26 Bird Netting Home Depot $14.47 .8 cu ft Rubber Mulch Home Depot $5.97 Plastic Sheeting Home Depot $10.98 Hardware Cloth Home Depot $9.22 Chicken Wire Home Depot $7.97 Bean Bag Filler Bed Bath and Beyond $14.99 Cement Mixer Lowes $8.54 Platic Beads Jo-Ann Fabrics $14.99 2 gallon Bags Target $8.18 Styrofoam Michael's $8.99 4”x8” Test Cylinders Forney LP $57.06 Total: $191.06 Updated Risk Assessment Moving Forward • Refining concrete mixtures – Aggregates for low cost compressive strength • Flexural testing – Mold for test block – Finalize reinforcements • Cost estimates – Availability in Haiti – Shipping costs • Finalizing features – Continue to assess feasibility • Divide team between mold and mixtures