PACC440 LeanProducti..

advertisement

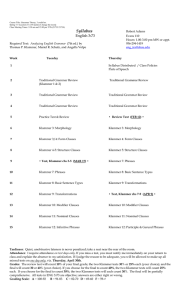

Production Methods Craft Mass Lean Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Mass versus Lean -- Process Differences 1 2 3 4 Mass Top down control of employees Supplier relationships arms length Limited relationships with customers Linear design process 1 2 3 4 Lean Empowered workers Cooperative relationship with suppliers Customer focused organization Concurrent design of product and process Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Mass versus Lean -- Structure Differences Mass 1 Inflexible single purpose equipment 2 High setup time for equipment 3 Simple tasks and low skilled labor Lean 1 Flexible multi-use equipment 2 Low setup time for equipment 3 Complex tasks and skilled labor Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Mass Production Assumptions Volume decreases cost Product variety increases cost Quality equals higher costs Time to market increases costs Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Mass Production Environment Stable Environment - Cost accumulation Large inventory - Inventory focus Labor specialization - Labor reporting Top down control - Budget and standard costing Manufacturing - Cost assignment issues Single entity Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Lean Production Assumptions Free product variety Quality reduces costs Time to market equals profitability Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Lean Production World Competitive Environment - information share Small inventory - availability Flexible workers - decision data Actual cost - timely data Process Value chain - life cycle Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Mass versus Lean -Management Accounting Systems 1 2 3 4 Mass Relationship of volume to cost Responsibility accounting - Unit focus Inventory driven reporting & control Labor reporting 1 2 3 4 Lean Relating “drivers” to cost Process accounting Value Chain Focus No inventory reporting Indirect cost reporting Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Mass versus Lean -Cost Strategy of a Mass Producer Mass to: producers rely on economies of scale – Spread set up costs over larger number of units – Spread indivisible capital costs over larger number of units – Create learning effects to bring costs down – Lower their process complexity costs (Procurement, scheduling, deliveries) Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Mass versus Lean -Cost Strategy of a Lean Producer Design costs out before production Reduce set-up costs by: – Mechanical redesign – Software based Numerically Controlled Machines Invest in “divisible” capital equipment Increase rate of learning by using: – Robotics – Skilled & trained work force Manage complexity costs through: – Process redesign – Supplier partnerships – Cross-functional teams Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Technical Attributes 1 2 3 1 Mass Decision Relevance Short run decisions Internal efficiency Single responsibility unit focus Process Understanding Not emphasized 1 2 3 1 Lean Decision Relevance Long run cost structures External environment focus Cross functional and value chain focus Process Understanding Primary emphasis Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Behavioral Attributes Mass Lean Assumptions Assumptions 1 Strong control of workers, 1 Empowered responsible suppliers workers, suppliers 2 Individual accountability 2 Team responsibility 3 Monetary motivation 3 Multiple motivational factors 4 Accountant as team player 4 Accountant as control agent Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999. Mass versus Lean -Cultural Attributes 1 2 3 4 Mass Beliefs and Values Individual responsibility Competition and market efficiency Pro-capital and management Managerial power 1 2 3 4 Lean Beliefs and Values Team responsibility Cooperation Work for common good Knowledge based power Copyright, Ansari, Bell, Klammer and Lawrence, Management Accounting: A Strategic Focus, Irwin-McGraw-Hill, 1999.