Executive Master's in International Logistics

advertisement

Review of Part I

Preparation for Exam

John H. Vande Vate

Fall 2009

1

1

Review

• Transportation costs are generally concave

– Economies of scale

– Consolidation reduces transport costs

• But there are other financial/operational issues to

balance

– Operating Expense

• We focus on transport, but handling, labor, …

– Capital

• We focus on working capital in inventory

– Time

• We focus on OTD

2

2

Review

• Illustrated (some of) these trade-offs in our

“Case Study”

– Estimating inventory costs

• “cycle” inventory driven by mode

• Pipeline inventory driven by time and total demand

– The impact of crossdocking/consolidation on

inventory

– Trading off inventory vs transportation

• EOQ for 1-to-1

• EPQ for 1-to-many

3

3

Review

• After that we have to work harder …

• Review of network models and useful extensions

– Modeling!

• Pool points – Consolidating for speed

– Load driven systems

• Zone skipping – Consolidating for cost (and

speed)

– Service or schedule driven systems

4

4

Review

• Multi-Stop routes & Milk runs

– Digression into column generation

– Application to multi-stop routes

• Location

– Where to put consolidation/distribution

facilities

• Landed cost models

– Incremental vs systems views

5

5

Exam Overview

•

•

•

•

•

•

•

Typically 4-5 questions

There will be modeling!

Open books, open notes

Calculator ok

No computers

No internet

No collaboration

6

6

There will be modeling

• /* The objective: Minimize Transportation Cost in

$/year */

• Minimize TransportCost:

• Sum{(orig, dest) in LANES}TruckCosts[orig,

dest]*Trucks[orig, dest];

• Minimize

TruckCost[i, j ] * Trucks[i, j ]

( i , j ) inLANES

• You may provide answers using either notation.

• Be sure your answers are clear and unambiguous.

–

–

–

–

Define your variables – what are they?

Set out the units (e.g., $/mile, lbs/Truckload, …)

Be specific about indices of summation

Comment on what a constraint is designed to do

7

7

Last Year’s Exam

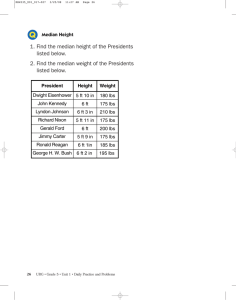

• Question 1 (25 points) Basic

understanding. Can you perform the

kind of simple analysis we did for our

case study company

• Question 2 (25 points) Elaboration of

basic concepts. Apply the EPQ idea

when costs include weight breaks and

freight includes a mix of products

8

8

Last Year’s Exam

• Question 3: Extending a basic model.

Expand our basic consolidation model to

address different products with different

weights and dimensions

• Question 4: Theory through example.

Did you understand the basic tenets of

location?

9

9

Last Year’s Exam

• Consider the operations of a company, similar to the one we

discussed in the lecture of August 25th, that sells computers and

TVs through 100 stores across the country.

• Assume the average distance to a store (from Indianapolis) is

1,000 miles and that a truck can travel 500 miles per day.

• As consumers adopted the new flat panel televisions, the business

of the company has changed so that its stores sell 20 TVs and 10

computers (consisting of a CPU and a monitor) each day. (Assume

250 days in the year).

• The company closed down the operations in Denver and now

produces

– CPUs weighing 5 lbs and costing $300 each in Green Bay and

– Flat Panel TVs and Monitors weighing 10 lbs and costing $400 each

in Indianapolis.

• The distance from Green Bay to Indianapolis is 500 miles.

• The company uses all full truck load shipments (a truck holds

35,000 lbs.) to ship everything to Indianapolis where it is

consolidated and shipped in full truckload shipments to the stores.

10

10

Units/Truck = 35000 lbs per truck

5 lbs per unit

= 7000 units

Value of TL = $300*7000

= $2.1million

• Assuming an inventory holding cost

of 15% and a

Inventory in Green Bay $1.05million

Question 1

•

•

•

•

•

transportation cost of $1.50/mile compute:

The capital required to run theUnits/day

system =including

100 storesthe

* 10capital:

cpus/day

= 1000 cpus

at Green Bay: __$1,050,000 _____________

Worth $300,000

at the cross dock in

Time units spend in transit is 1 days

Indianapolis:__$1,800,000_____________

So pipeline inventory $300,000

at each store:__$750,000______________

in-transit between

– Green Bay and Indianapolis: __$300,000 (or $240,000 is more

accurate)___________

– Indianapolis and each store: __$30,000____________

11

11

What’s in truck to store?

20 TVs weigh

10 Computers weigh

So this "basket" weighs

Since a truck holds

200lbs and cost

150lbs and cost

350lbs and costs

35,000 lbs, it can hold

$

$

$

8,000

7,000

15,000

100

• Value on a truck to a store

– 100*$15,000 = $1.5 million

• Capital at a store: $750,000

• Capital at Indianapolis cross dock

– $1.05 million from Green Bay

– $0.75 million staged for store

– $1.8 million total

12

12

Question 1

• Assuming an inventory holding cost of 15% and a

1 Store sells $15,000/day

transportation cost of $1.50/mile

compute:

Time units spend in transit is 2 days

• The capital required toSorun

the system

the

capital:

pipeline

inventoryincluding

$30,000 per

store

• at Green Bay: __$1,050,000 _____________

• at the cross dock in

Indianapolis:__$1,800,000_____________

• at each store:__$750,000______________

• in-transit between

– Green Bay and Indianapolis: __$300,000_________

– Indianapolis and each store: __$30,000____________

13

13

Capital

At Green Bay: $1.05 million

At Indianapolis: $1.8 million

At each Store: $0.75 million

Between GB and Indianapolis: $0.3 million

Between Indianapolis and Stores: $3 million

Total: $81.15 million

Question 1 Cont’d

•

The total cost of operating the system

including:

Holding cost: $12.2 million

–

Annual transportation costs: __$402,000

(401,786)_ and

From Green Bay to Indianapolis:

– Units

Annual

costs:

per yearinventory

= 100 stores holding

* 10 units per

day *250 days = 250,000

units/year

_$12,172,500 (or $12,163,500)_

Trucks/year = 250,000/7000 = 35.7

$/year = 35.7*$1.50/mile*500miles

= $26,800

From Indianapolis to Store

A truck holds 100 days of sales

We visit each store 2.5 times per year

100 stores * $1500/visit *2.5 visits/year

= $375,000

14

14

Question 2

•

•

•

•

•

•

•

•

Consider the company described in Question 1. The company is exploring

the option of replacing truck load shipments from Indianapolis to its stores

with LTL shipments.

As a first approximation to the magnitude of the opportunity, the company

has assembled an estimate of average LTL rates for shipments to customers

1,000 miles away. For simplicity, they have averaged out geographic

aspects (e.g., shipping to customers in Florida is more expensive) and come

out with average costs based only on the weight of the shipment:

Weight

Cost per CWT ($/100lbs)

500 – 1000 lbs

$14

1000 – 5000 lbs

$12

5000 – 20000 lbs

$ 9

> 20000 lbs

$ 7.25

The minimum charge for any shipment is $100. So for example, a 500 lb

shipment nominally costs $70 = $14/CWT*5 CWT, but the carrier won’t

accept less than $100 for any shipment so the actual cost is $100.

15

15

Thinking

• What are the options?

• Claim: Ship either

–

–

–

–

–

$100 shipping cost

500 lbs

1,000 lbs

5,000 lbs or

20,000 lbs

• Why?

If you ship 800 lbs,

transport costs are

the same as if you

ship 500 lbs but

inventory costs are

higher!

16

16

Calculations

• What are we shipping? Basket of

products

–

–

–

–

weighs 3.5 CWT

Worth $15,000

Holding cost/year: $2,250

Annual demand at a store: 250

• Minimum Charge:

• $100/14 = 7.14 CWT

17

17

The Numbers

With shipments of

Total Transport to the

stores is

Unit Costs are

Shipment Size in

Baskets is

Store Inventory is

Total Cost

500 lbs

14 $

1,225,000

1.43

1,071,429

1,385,714

1000 lbs

12 $

1,050,000

2.86

2,142,857

1,371,429

5000 lbs

9$

787,500

14.29

10,714,286

2,394,643

7.25 $

634,375

57.14

42,857,143

7,062,946

20000 lbs

Should we use

LTL? Yes!

What constitutes a shipment?

2.86 baskets

2.86*20 = 57 TVs

2.86*10 = 29 computers18

18

Minimum Charge

• We exceeded it. No additional

calculation needed.

• If we hadn’t?

EPQ with fixed

transport cost of $100

19

19

Question 3

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

In class, we outlined a model to help identify which candidate consolidation points to use and to assign

customers to those consolidation points to minimize the costs of transportation while meeting a “service

constraint” imposed in terms of a minimum number or frequency of trucks to each opened consolidation point.

This question asks you to flesh out that formulation for a setting in which we sell several different products. Let

PRODS denote the set of products we sell.

Each customer has a projected demand for each product given in the parameter Demand. Let CUSTS denote the

set of customers and, for each customer c and product p, let Demand[c, p] be the customers demand for that

product in units per year.

Each product has a cubic ft. per unit given in the parameter Cubes, i.e., Cubes[p] is the cubic feet occupied by

one unit of product p.

Each product has a unit weight given in the parameter Weight, i.e., Weight[p] is the weight in pounds of one unit

of product p.

Let CONSOLS denote the set of candidate consolidation points and suppose the

LTL (less-than-truckload) costs for shipping each customer’s annual demand for

each product from each candidate consolidation point are given in the parameter

LTL, i.e., LTL[c, p, k] is the LTL cost for shipping all of customer c’s annual

demand for product p to the customer from consolidation point k.

The LTL costs for direct shipments for the annual demand of each product from our plant to each customer are

given in the parameter Direct, i.e., Direct[c, p] is the LTL cost for shipping all of customer c’s annual demand

for product p directly to the customer from the plant.

The cost to send a truck from our plant to each candidate consolidation point are given in a parameter

TruckCost, i.e., TruckCost[k] is the cost to send one truck from the plant to consolidation point k.

A truck can hold (with the load factor calculated in) up to 30,000 lbs and up to 3,000 cubic feet (again this

number incorporates the load factor).

Our service requirement stipulates that we send at least 112 trucks a year to each open consolidation point.

Formulate a linear, mixed integer program to model the problem of minimizing the total cost of

transportation while meeting the service requirement. Do NOT consider multi-stop routes in your answer.

Be sure to use the parameters described above. Be sure to clearly define your variables and their units

(e.g., lbs, $, hours).

20

20

AMPL Model

Set PRODS; /* The set of Products */

Set CUSTS; /* The set of customers */

Set CONSOLS; /* The set of candidate

consolidation points */

Param Demand{CUSTS, PRODS}; /*

customer’s demand for each product in

units per year. */

Param Cubes{PRODS}; /* the cubic feet

occupied by one unit of each product */

21

21

AMPL Model

Param Weight{PRODS}; /* the weight in

pounds of one unit of each product */

Param LTL{CUSTS, PRODS,

CONSOLS}; /* the LTL cost for

shipping all of a customer annual

demand for product p to the customer

from consolidation point k. */

22

22

AMPL Model

Param Direct{CUSTS, PRODS}; /* the

LTL cost for shipping all of a

customer’s annual demand for each

product directly to the customer from

the plant. */

Param TruckCost{CONSOLS}; /* the

cost to send one truck from the plant to

consolidation point */.

23

23

AMPL Model

Var Open{CONSOLS} binary; /*

Whether each consol is open or not */

Var Trucks{CONSOLS} integer >= 0; /*

How many trucks we send to each

consol */

Var Assign{CUSTS, PRODS,

CONSOLS} >= 0; /* Fraction of

demand for each product to each

customer we ship via each consol –

24

note we allow fractions */

24

AMPL Model

Var DirectShip{CUSTS, PRODS} >= 0;

/* Fraction of demand for each product

to each customer we ship direct from

the plant */

25

25

AMPL Model

Minimize Transport Cost:

Sum{c in CUSTS, p in PRODS,

k in CONSOLS}

LTL[c, p, k]*Assign[c, p, k] +

Sum{k in CONSOLS}

TruckCost[c]*Trucks[c] +

Sum{c in CUSTS, p in PRODS}

Direct[c, p]*DirectShip[c, p];

26

26

AMPL Model

s.t. MeetAllDemandForEachProductAtEachCustomer

{c in CUSTS, p in PRODS}:

sum{k in CONSOLS}Assign[c, p, k] + DirectShip[c, p] =

1;

s.t. DontAssignCustomersToClosedConsols

{c in CUSTS, p in PRODS, k in CONSOLS}:

Assign[c, p, k] <= Open[k];

27

27

AMPL Model

s.t. MeetAllDemandForEachProductAtEachCustomer

{c in CUSTS, p in PRODS}:

sum{k in CONSOLS}Assign[c, p, k] + DirectShip[c, p] =

1;

s.t. DontAssignCustomersToClosedConsols

{c in CUSTS, p in PRODS, k in CONSOLS}:

Assign[c, p, k] <= Open[k];

28

28

AMPL Model

s.t. SendEnoughTrucksToEachConsolToCarryCube

{k in CONSOLS}:

3000*Trucks[k] >=

sum{c in CUSTS, p in PRODS}

Cubes[p]*Demand[c, p]*Assign[c, p, k];

s.t. SendEnoughTrucksToEachConsolToCarryWeight

{k in CONSOLS}:

30000*Trucks[k] >=

sum{c in CUSTS, p in PRODS}

Weight[p]*Demand[c, p]*Assign[c, p, k];

29

29

AMPL Model

s.t. MeetServiceRequirementAtOpenConsols

{k in CONSOLS}:

Trucks[k] >= 112*Open[k];

30

30

Question 4

• In our discussions on Location problems, we

observed that locating a facility at the “center of

gravity” of a set of customers (average the x and y

coordinates of the customers) does NOT minimize

the sum of the Euclidean Distances to those

customers.

• Does locating a facility at the “center of gravity” of

a set of customers minimize the sum of the

distances to those customers under the Manhattan

Metric, where the distance between two points (x,

y) and (x’, y’) is

|x – x’| + |y – y’|?

No!

31

31

Question 4

• If you answered “Yes” to part A, provide a brief

argument supporting your conclusion. If you

answered “No” to part A, provide an example

showing the center of gravity is not the best

location.

• Counterexample?

32

32

Questions?

Good Luck!

33

33