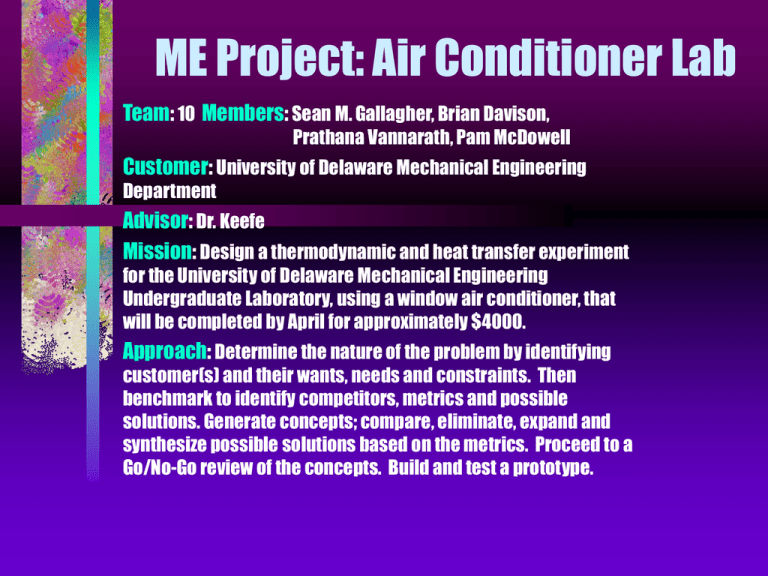

GROUP #10: ME Project - Air Conditioner

advertisement

ME Project: Air Conditioner Lab Team: 10 Members: Sean M. Gallagher, Brian Davison, Prathana Vannarath, Pam McDowell Customer: University of Delaware Mechanical Engineering Department Advisor: Dr. Keefe Mission: Design a thermodynamic and heat transfer experiment for the University of Delaware Mechanical Engineering Undergraduate Laboratory, using a window air conditioner, that will be completed by April for approximately $4000. Approach: Determine the nature of the problem by identifying customer(s) and their wants, needs and constraints. Then benchmark to identify competitors, metrics and possible solutions. Generate concepts; compare, eliminate, expand and synthesize possible solutions based on the metrics. Proceed to a Go/No-Go review of the concepts. Build and test a prototype. Project Background • ME 2000 Curriculum – Joint Laboratory Classes – Combined Thermodynamics II and Heat Transfer Lab • Single lab apparatus for multiple labs • Increased understanding of Thermodynamic and Heat Transfer fundamentals Lab Setup Schematic Expansion valve Mass flow fluid T, P T, P X M air T1 P P T2 M air T3 RH T, P T4 Relative Humidity T, P Compressor M water Outside Coil Inside Coil Mission Statement Customers • Dr. Tony Wexler • Dr. Suresh Advani • Undergraduate students who perform the laboratory experiment • Graduate students who supervise the experiment • Dr. Sun as a representative laboratory professor • George Sestak from ASHRAE • Manufacturers who would fabricate our device • Other schools who would be interested in a similar experiment • Dr. Michael Keefe for Senior Design requirements Wants (Prioritized) • • • • • • • • • • • • Effective learning tool Easy to Use Self Evident Easy to set up Low manufacturing cost Easy fabrication LabView compatible data acquisition Forgiving of incompetence Quiet Quick Accessible parts Durable Constraints (Prioritized) • Safety regulations set by U of D • Portable • Schedule dictated by NCDA • Budget Benchmarking: Areas under investigation • Lab supply companies • Educational methods • Safety issues Detailed Two Week Schedule (Division of Labor) • Week of 9/28 – Continue to contact & interview customers (group) – Refine customer wants (group) – Benchmark lab supply companies (Brian) – Benchmark educational methods (Prathana) – Benchmark safety issues (Pam) • Week of 10/5 – Developing the fundamentals of the lab • What key lessons to include (Sean) • Best way to demonstrate lessons (group) • Required equipment (Brian) Schedule Overview • Preliminary Lab Layout by 10/16 – Multiple lab lessons developed – Best educational format used • Preliminary Equipment Design by 10/29 – Hardware components selected – Design of component installation on AC unit • Develop detailed lab layout and design for Preliminary Design Report on 11/24 Preliminary Budget Preliminary Budget: Project 99.10, ME Air Conditioning Experiment Fully Instrumented Version Component Est. Price Quantity Subtotal Total Air Conditioning Unit $ 250.00 1 $ 250.00 Lab Cart $ 100.00 1 $ 100.00 Rel. Humidity/Temp Sensor $ 225.00 4 $ 900.00 Mass Flowmeter $ 1,000.00 1 $ 1,000.00 Thermocouple $ 25.00 4 $ 100.00 Pressure Transducer $ 255.00 10 $ 2,550.00 Air Flowmeter $ 400.00 2 $ 800.00 Assorted Fittings $ 100.00 1 $ 100.00 Wiring, Connectors $ 75.00 1 $ 75.00 Refrigerant Recharge $ 25.00 1 $ 25.00 $ $ Total: $ 5,900.00