Aluminum Recycling – Challenges & Opportunities

advertisement

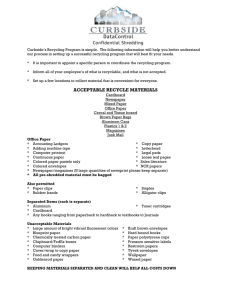

Dr. Subodh K. Das President & CEO Secat, Inc. Aluminum Recycling – Challenges & Opportunities Presented To: Can Manufacturing Institute Aluminum Association Aluminum Can Council May 17, 2006 Washington, DC Items to be discussed • Enhancing UBC Recycling – Sloan Center for a Sustainable Aluminum Industry – Fayette County Recycling Laboratory – Six Sigma Studies ( Published in Light Metal Age, June 2006 – Economics of Recycling ( To be Published in Journal of Metals or Aluminum Now ? ) – Consumer Behavior Studies ( To be Published in Aluminum Now ?) – Future Studies • Emerging Trends in Aluminum Recycling Center for a Sustainable Aluminum Industry (CSAI) • Founded in Jan. 2005 • Funded by several sources: – Sloan Foundation Industry Centers Program – Arco Aluminum, Aleris International, Wise Alloys, Nichols Aluminum, Logan Aluminum, Ormet, Hydro Aluminum, Century Aluminum – The Commonwealth of Kentucky – The University of Kentucky Sloan Industry CenterSynergy of Partnership Clark Distributing Co. Commodities Shipped from LFUCG Recycling Center 06/01/04 to 06/30/05, 12 months Recyclable Commodities Weight Shipped (lbs) Price for April 2005 ($) Composition by Weight of Total Commodities Shipped (%) Revenues Generated ($) Composition of Total Revenue Generated (%) Ratio of Revenues Generated to Weight Shipped 15,151,025 82.50 per ton 624,980 50.0% 36.68% 0.73 4,940,336 77.50 per ton 191,438 16.3% 11.23% 0.69 Mixed Plastic 240,400 0.04 per lb 9,616 0.8% 0.56% 0.71 High Density Polyethylene (HDPE) 461,800 0.29 per lb 133,922 1.5% 7.86% 5.16 3,238,982 4.80 per ton 7,774 10.7% 0.46% 0.04 Fiberboard 951,160 44.10 per ton 20,973 3.1% 1.23% 0.39 Aluminum Cans 579,252 0.63 364,929 1.9% 21.42% 11.20 Steel Cans 638,920 200.00 per ton 63,892 2.1% 3.75% 1.78 2,101,710 105.00 per ton 110,340 6.9% 6.48% 0.93 Phone Books 588,600 49.70 per ton 14,627 1.9% 0.86% 0.44 PET-2 liters 659,480 0.20 131,896 2.2% 7.74% 3.56 Magazines 740,880 80.00 29,635 2.4% 1.74% 0.71 Old Newspapers (ONP) Old Corrugated Containers (OCC) Glass Sorted Office Papers (SOP) Source: James Carter, Manager LFUCG Recycling Center per lb per lb per ton Ratio of Revenues Generated to Weight for Commodities Shipped From LFUCG Recycling Magazines, 0.71 Old Corrugated Containers (OCC), Old New spapers 0.69 Center (06/01/04 to 04/15/05) Mixed Plastic, 0.71 (ONP), 0.73 PET-2 liters, 3.56 High Density Polyethylene (HDPE), 5.16 Phone Books, 0.44 Sorted Office Papers (SOP), 0.93 Steel Cans, 1.78 Glass, 0.04 Fiberboard, 0.39 Aluminum Cans, 11.20 Beverage Can Recycling Update Fayette County Program Update • “Green” Proclamation – August 24 • • • • • – Mayor Isaacs, President Todd, Superintendent Silberman Calculating “True” Recycling Rate – Data available from recyclers (MRF, Wise, Baker) – Data available from distributors (AB) – Information needed from distributors (Coke, Pepsi, Coors, Miller) Collecting “Real” Data – Supermarkets – Waste Composition Analysis Six Sigma Methodology Initiated – Define Causes and Cures Find Ways to Measure and Implement Higher Recycling Rates Strategies Enhancing Aluminum Recycling in Fayette County: A Six Sigma Study Dr. Subodh K. Das, President SECAT, Inc. Dr. Pradeep Deshpande, President Six Sigma & Advanced Controls, Inc. Margaret Hughes, Doctoral Candidate, Gatton College of Business and Economics, University of Kentucky Why Six Sigma for Aluminum Recycling? • Every “aluminum can” not recycled is considered a “defect”. • Finding causes of these defects and recommending strategies to enhance recycling rate. Six Sigma Application to Aluminum Recycling Steps: 1. Find “true” recycling rate (first iteration 39%). 2. Draw process map to show recycling loop. 3. Find “gaps” or areas of improvement in the recycling loop. (i.e. Rosies delivered/vending machines/businesses/apartments) 4. Alter the process map to plug gaps. Revised Process Map Supplier No Rosie Delivered Calls MRF Retailer Yes Dispensing Machines Businesses Recycling Bins\ At Schools Dormatories Redeem for Money University Of Kentucky Houses Trash Rosie Rosie Picked Up Baker Wise Alloys Landfill MRF No Going Forward…. 1. Implement Changes in Fayette County 2. Replicate Warren County project 3. Re-measure recycling rate to calculate improvement 4. Formulate plan for sustainability and replicability 5. Results will be published in August 2006 issue of Journal of Metals The Economics of Aluminum Recycling: A White Paper Glenn Blomquist, Professor Brandon Koford, Research Assistant Department of Economics Gatton College of Business and Economics University of Kentucky CSAI Steering Committee Presentation January 2006 Review Economics Literature – Large! • • • • • • Aluminum: U.S. and International Markets Solid Waste Disposal and Recycling Pricing of Garbage Deposit/Bottle Bills Curbside Recycling Municipal Recycling Facilities Determinants of Recycling International Experience US Disposal Trends 1989-2002 90 80 70 60 50 40 30 20 10 0 1989 1990 1991 1992 1993 1994 MSW Landfilled (%) 1995 1996 1997 MSW Recycled (%) 1998 1999 2000 MSW Incinerated (%) 2001 2002 Why the Decline in Recycling? • T.Kinnaman and D. Fullerton “The Economics of Residential Waste Management” (1999, 2000) Curbside recycling factors: – – – – – Tipping fee higher, landfill savings Population density greater, collection cost Convenience and household’s time cost Education, college degree Membership in environmental group Price of Recyclable Material – Factor? • Price of recyclable materials falls → incentive to recycle is weaker • REAL Price of used aluminum cans: – Price RELATIVE to prices of other things – US Bureau of Labor Statistics • Real Price Index Value for Used Aluminum Cans = (Price Index Value for Used Aluminum Cans/CPI) (100) Real Can Price & Aluminum Can Recycling Rate 1.4 80 70 1.2 Real Can Price Index 50 0.8 40 0.6 30 0.4 20 0.2 10 0 0 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 Year Real Can Price Aluminum Can Recycling Rate Aluminum Can Recycling Rate 60 1 Socially Optimal Recycling • Average net benefit of curbside recycling for society as a whole is zero! (Aadland & Caplan, 2005) • Recycling that leads to an 8% reduction of waste is best for society (Palmer, Sigman, and Walls,1997) • Costs: $50 - $100 per ton more than landfill. Consumer time is a factor. • Benefits: less of - litter, raw material use, and garbage. Willingness to Pay surveys. Next Steps • Results to date will be published in August issue of Light Metal Age • Funding will be awarded to collect new data for one of the following two proposals to be selected for future study Proposal 1: Price and Time • Part of study of recycling behavior and marketing (Lexington) • Investigate the role of real price of used aluminum cans on recycling rate - statistical • Redemption rate experiments – individual, group • Convenience & time cost experiments • Reverse vending machines experiments Proposal 2: Ripe Cities • Identify cities with (estimated) positive social net benefits of more recycling and target efforts • Cost and Benefit information from Aadland and Caplan (2005) • Adjust to Midwest, Southeast, and East • Compare to current recycling rates • Cities with positive net benefits and low recycling rates are ripe for more recycling Understanding Recycling Behavior: Who Recycles and What Motivates Them Dr. Fred Morgan and Margaret Hughes School of Management University of Kentucky January 19, 2006 Recyclers Relative To The U.S. Population: Older Larger incomes Live in households with fewer members More liberal in political orientation So on balance, Kentuckians will be harder to motivate to recycle because they are younger, with less wealth, larger households, and more conservative politically Research indicates that the benefits of recycling (and most voluntary programs) are easy to understand by nearly everyone if the facts are presented clearly What people need is to feel “connected” to the reasons for recycling so that they will participate without dropping out Explaining Recycling Behavior Theory of Planned Behavior - Theory of Reasoned Action - Residual Effect of Past on Recent Behavior - Taken together, these theories suggest that people act in ways that take into account: • consequences of their behavior, • ways others are likely to view their behavior, • factors that help or hinder their behavior. What These Theories Tell Us • Behavioral Beliefs (How will I feel or what will happen to me if I act in a certain way?) • Normative Beliefs (How will people I know expect me to behave and what will they think of me?) • Control Beliefs (What events or results or people could hinder my acting in a certain way?) These lead to behavioral intention. Then to actions. Perceived Consumer Benefits of Recycling from Empirical Research • Environmental – saving natural resources – saving energy • Economic – – – – savings of using recycled aluminum local jobs supported by recycling community funds from recycling programs Personal funds through compensation • Personal – participation in environmentally helpful activities – sense of individual importance in a global program – being recognized by others as being responsible Research Model to Be Tested Reasons for Acting Desire Intentions Overt Signal of Intentions Actions Future Research • Investigate impact of economic benefit programs (ie couponing) on recycling for lower income households. • Investigate education programs to translate planned behavior into action. • Investigate effect of feedback processes. • Action steps: test programs – economic and educational cross-sectional interviews data collection Emerging Trends in Aluminum Recycling – Reasons & Responses Dr. Subodh K. Das, President & CEO Secat, Inc. Presented to: TMS 2006 San Antonio, TX March 15, 2006 Number of Primary Smelting Plants in the U.S. 35 2003: Fourteen (14) 30 Smelters Operating 25 20 15 SMELTERS OPERATING - 2003 • 8 Alcoa • 2 Century ? • 1 Alcan 10 5 • 1 Norandal • 1 Ormet • 1 Columbia Falls 0 1980 1990 2000 SOURCE: LIGHT METAL AGE 2003 2010 U.S. Trends Of Re-Melting vs. Smelting (000 Metric Tons) 20,000 18,000 16,000 14,000 12,000 10,000 8,000 6,000 4,000 2,000 0 1980 1990 2000 RE-MELTING SOURCE: SECAT, INC. 2010 (e) 2020 (e) SMELTING 2030 (e) Why Recycling? The Aluminum Can Recycling Rate, 1992-2004 70 65 1% change in recycling rate has an economic impact of approximately $12 million 60 % 55 50 45 Trashed cans contribute about $600 million to the nation’s trade deficit each year 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 Year National Aluminum Beverage Can Recycling Rate Trends. Impact of Recycled Automotive Aluminum • Two largest areas are cans and autos • Can recovery reached ~67% in early 1990’s – now at ~50%; cultural, societal and technical issues • Auto metal recovery >90%; aided by regulations, shredders and lack of individual choice. • Recovery of Al from autos has exceeded all other scrap sources since 2005 • We have to learn to make as much new aluminum products as technically possible from recycled automotive aluminum in the US