LECTURE 30

advertisement

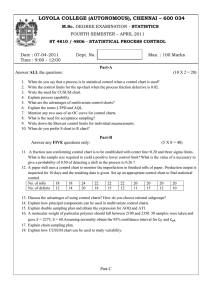

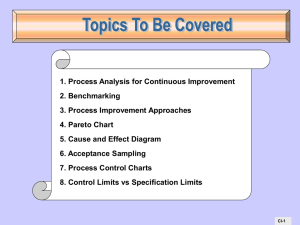

Quick Recap Monitoring and Controlling Performance Management Objectives In this training you will learn the most effective methods to create constructive performance evaluations and how to communicate with employees during the performance process. • To learn the basics of Performance Management • To understand the purpose and strategies behind Performance Appraisals • To gain knowledge of the performance management forms and tools • To gain an understanding of the merit/awards process 2 Lesson 13: Monitoring and Controlling Project Performance and Quality Topic 13A: Perform Quality Control Topic 13B: Report on Project Performance Quality Control • Quality control is a process that measures output relative to standard, and acts when output doesn't meet standards. • The purpose of quality control is to assure that processes are performing in an acceptable manner. • Companies accomplish quality control by monitoring process output using statistical techniques. Phases of Quality Assurance Figure 10.1 Inspection before/after production Acceptance sampling The least progressive Inspection and corrective action during production Process control Quality built into the process Continuous improvement The most progressive Inspection • Inspection is an appraisal activity that compares goods or services to a standard. • Inspection can occur at three points: - before production: is to make sure that inputs are acceptable. - during production: to make sure that the conversion of inputs into outputs is proceeding in an acceptable manner. - after production: to make a final verification of conformance before passing goods to customers Inspection • Inspection before and after production involves acceptance sampling procedure. • Monitoring during the production process is referred as process control Inputs Acceptance sampling Transformation Process control Outputs Acceptance sampling Inspection • The purpose of inspection is to provide information on the degree to which items conform to a standard. • The basic issues of inspection are: 1 - how much to inspect and how often 2- At what points in the process inspection should occur. 3 - whether to inspect in a centralized or on-site location. 4- whether to inspect attributes (counts) or variables (measures) How much to inspect and how often • The amount of inspection can range from no inspection to inspection of each item many times. • Low-cost, high volume items such as paper clips and pencils often require little inspection because: 1. the cost associated with passing defective items is quite low. 2. the process that produce these items are usually highly reliable, so that defects are rare. • High-cost, low volume items that have large cost associated with passing defective items often require more intensive inspection such as airplanes and spaceships. • The majority of quality control applications ranges between these two extremes. • The amount of inspection needed is governed by the cost of inspection and the expected cost of passing defective items. Inspection Costs Cost Figure 10.3 Total Cost Cost of inspection Cost of passing defectives Optimal Amount of Inspection Where to Inspect in the Process Inspection always adds to the cost of the product; therefore, it is important to restrict inspection efforts to the points where they can do the most good. In manufacturing, some of the typical inspection points are: • Raw materials and purchased parts • Finished products • Before a costly operation • Before an irreversible process • Before a covering process Examples of Inspection Points Table 10.1 Type of business Fast Food Inspection points Cashier Counter area Eating area Building Kitchen Hotel/motel Parking lot Accounting Building Main desk Supermarket Cashiers Deliveries Characteristics Accuracy Appearance, productivity Cleanliness Appearance Health regulations Safe, well lighted Accuracy, timeliness Appearance, safety Waiting times Accuracy, courtesy Quality, quantity Centralized versus on-site inspection • Some situations require that inspections be performed on site such as inspecting the hull of a ship for cracks. • Some situations require specialized tests to be performed in a lab such as medical tests, analyzing food samples, testing metals for hardness, running viscosity tests on lubricants. Statistical process control • Quality control is concerned with the quality of conformance of a process: Does the output of a process conform to the intent of design? • Managers use Statistical Process Control (SPC) to evaluate the output of a process to determine if it is statistically acceptable. • Statistical Process Control: Statistical evaluation of the output of a process during production • Quality of Conformance: A product or service conforms to specifications Control Chart • Control Chart: an important tool in SPC – Purpose: to monitor process output to see if it is random (in control) or not (out of control). – A time ordered plot representative sample statistics obtained from an on going process (e.g. sample means). – Upper and lower control limits define the range of acceptable variation. Control Chart Figure 10.4 Abnormal variation due to assignable sources Out of control UCL Mean Normal variation due to chance LCL Abnormal variation due to assignable sources 0 1 2 3 4 5 6 7 8 9 Sample number 10 11 12 13 14 15 Statistical Process Control • The essence of statistical process control is to assure that the output of a process is random so that future output will be random. Statistical Process Control • The Control Process include – Define what is to be controlled. – Measure the attribute or the variable to be controlled – Compare with the standard – Evaluate if the process in control or out of control – Correct when a process is judged out of control – Monitor results to ensure that corrective action is effective. Statistical Process Control • Variations and Control – Random variation: Common natural variations in the output of a process, created by countless minor factors. It would be negligible. – Assignable variation: A special variation whose source can be identified (it can be assigned to a specific cause) Sampling Distribution • The variability of a sample statistic can be described by its sampling distribution. • The sampling distribution is a theoretical distribution that describe the random variability of a sample statistic. • The goal of the sampling distribution is to determine whether nonrandom-and thus, correctable-source of variation are present in the output of a process. How? Sampling distribution • Suppose there is a process for filling bottles with soft drink. If the amount of soft drink in a large number of bottles (e.g., 100) is measured accurately, we would discover slight differences among the bottles. • If these amounts were arranged in a graph, the frequency distribution would reflect the process variability. • The values would be clustered close to the process average, but some values would vary somewhat from the mean. Sampling distribution (cont.) • If we return back to the process and take samples of 10 bottles each and compute the mean amount of soft drink in each sample, we would discover that these values also vary, just as the individual values varied. They, too, would have a distribution of values. • The following figure shows the process and the sampling distribution. Sampling Distribution Figure 10.5 Sampling distribution Process distribution Mean Sampling distribution Properties • The sampling distribution exhibits much less variability than the process distribution. • The sampling distribution has the same mean as the process distribution. • The sampling distribution is a normal distribution regardless of the shape of the process distribution. (central limit theorem). Process and sampling distribution Process distribution Mean = Variance = 2 Standard deviation = Where: n = sample size Sampling distribution Mean = Variance = 2 n Standard deviation = n Normal Distribution Figure 10.6 Standard deviation Mean 95.44% 99.74% Control limits • Control charts have two limits that separate random variation and nonrandom variation. • Control limits are based on sampling distribution • Theoretically, the normal distribution extends in either direction to infinity. Therefore, any value is theoretically possible. • As a practical matter, we know that 99.7% of the values will be within ±3 standard deviation of the mean of the distribution. • Therefore, we could decide to set the control limit at the values that represent ±3 standard deviation from the mean Control Limits Figure 10.7 Sampling distribution Process distribution Mean Lower control limit Upper control limit SPC hypotheses Null hypothesis H0: the process is in control Alternative hypothesis H1: the process is out of control Actual situation Decision Reject H0 Don’t reject H0 H0 is true Type I error H0 is false Correct Correct Type II error SPC Errors • Type I error – Concluding a process is not in control when it actually is. The probability of rejecting H0 when it is actually true. • Type II error – Concluding a process is in control when it is not. The probability of accepting H0 when it is actually not true. Type I Error Figure 10.8 /2 /2 Mean Probability of Type I error LCL UCL Using wider limits (e.g., ± 3 sigma limits) reduces the probability of Type I error Observations from Sample Distribution Figure 10.9 UCL LCL 1 2 Sample number 3 4 Types of control charts • There are four types of control charts; two for variables, and two for attributes • Attribute: counted data (e.g., number of defective items in a sample, the number of calls per day) • Variable: measured data, usually on a continuous scale (e.g., amount of time needed to complete a task, length, width, weight, diameter of a part). Variables Control Charts • Mean control charts – Used to monitor the central tendency of a process. – X-bar charts • Range control charts – Used to monitor the process dispersion – R charts Mean Chart (X-bar chart) • The control limits of the mean chart is calculated as follows: (first approach) • Upper Control Limit (UCL) = x z x • Lower Control Limit (LCL) = x z x Where: n = sample size z = standard normal deviation (1,2 and 3; 3 is recommended) = process standard deviation x = standard deviation of the sampling distribution of the means x = average of sample means x n Mean Chart (X-bar chart) • Example A quality inspector took five samples, each with four observations, of the length of time for glue to dry. The analyst computed the mean of each sample and then computed the grand mean. All values are in minutes. Use this information to obtain three-sigma (i.e., z = 3) control limits for the means of future time. It is known from previous experience that the standard deviation of the process is 0.02 minute. Mean chart Sample 1 Observation 2 3 4 5 1 12.11 12.15 12.09 12.12 12.09 2 12.10 12.12 12.09 12.10 12.14 3 12.11 12.10 12.11 12.08 12.13 4 12.08 12.11 12.15 12.10 12.12 x 12.10 12.12 12.11 12.10 12.12 Solution • n=4 • z=3 • = 0.02 12.10 12.12 12.11 12.10 12.12 x 12.11 5 0.02 UCL : 12.11 3 12.14 4 0.02 LCL : 12.11 3 12.08 4 Control chart UCL 12.14 x 12.11 LCL 12.08 1 2 3 Sample 4 5 Mean chart • A second approach to calculate the control limits: • This approach assumes that the range is in control UCL x A2 R LCL x A2 R Where: A2 = A factor from table 10.2 Page 441 R = Average of sample ranges This approach is recommended when the process standard deviation is not known Example • Twenty samples of n = 8 have been taken from a cleaning operations. The average sample range for the 20 samples was 0.016 minute, and the average mean was 3 minutes. Determine threesigma control limits for this process. • Solution x = 3 min.R, = 0.016, A2 = 0.37 for n = 8 (table 10.2) UCL x A2 R 3 0.37(0.016) 3.006 LCL x A2 R 3 0.37(0.016) 2.994 Range Control Chart (R-chart) • The R-charts are used to monitor process dispersion; they are sensitive to changes in process dispersion. Although the underlying sampling distribution of the range is not normal, the concept for use of range charts are much the same as those for use of mean chart. • Control limits: UCL D4 R LCL D3 R Where values of D3 and D4 are obtained from table 10.2 page 441 R-chart • Example Twenty-five samples of n = 10 observations have been taken from a milling process. The average sample range was 0.01 centimeter. Determine upper and lower control limits for sample ranges. • Solution R = 0.01 cm, n = 10 From table 10.2, for n = 10, D4 = 1.78 and D3 = 0.22 UCL = 1.78(0.01) = 0.0178 or 0.018 LCL = 0.22(0.01) = 0.0022 or 0.002 R-Chart • Example Small boxes of cereal are labeled “net weight 10 ounces.” Each hour, a random sample of size n = 4 boxes are weighted to check process control. Five hours of observation yielded the following: Time 9 A.M. 10 A.M 11 A.M Noon 1 P.M Box 1 9.8 10.1 9.9 9.7 9.7 Box 2 10.4 10.2 10.5 9.8 10.1 Box 3 9.9 9.9 10.3 10.3 9.9 Box 4 10.3 9.8 10.1 10.2 9.9 Range 0.6 0.4 0.6 0.6 0.4 R-Chart • Solution n=4 For n = 4 , D3 = 0 and D4 = 2.28 0.6 0.4 0.6 0.6 0.4 0.52 5 UCL D4 R 2.28(0.52) 1.1865 R LCL D3 R 0(0.52) 0 Since all ranges are between the upper and lower limits, we conclude that the process is in control Using Mean and Range Charts • Mean control charts and range control charts provide different perspectives on a process. • The mean charts are sensitive to shifts in process mean, whereas range charts are sensitive to changes in process dispersion. • Because of this difference in perspective, both types of charts might be used to monitor the same process. Mean and Range Charts Figure 10.10A (process mean is shifting upward) Sampling Distribution UCL Detects shift x-Chart LCL UCL R-chart LCL Does not detect shift Mean and Range Charts Figure 10.10B Sampling Distribution (process variability is increasing) UCL x-Chart LCL Does not reveal increase UCL R-chart Reveals increase LCL Using the Mean and Range Chart To use the Mean and Range control chart, apply the following procedure: 1. 2. 3. 4. 5. Obtain 20 to 25 samples. Compute the appropriate sample statistics (mean and range) for each sample. Establish preliminary control limits using the formulas. Determine if any points fall outside the control limits. If you find no out-of-control signals, assume that the process is in control. If not, investigate and correct assignable cause of variation. Then resume the process and collect another set of observations upon which control limits can be based. Plot the data on a control chart and check for out-of-control signals. Control Chart for Attributes • Control charts for attributes are used when the process characteristic is counted rather than measured. Two types are available: • P-Chart - Control chart used to monitor the proportion of defectives in a process • C-Chart - Control chart used to monitor the number of defects per unit Attributes generate data that are counted. Use of p-Charts Table 10.3 • When observations can be placed into two categories. – Good or bad – Pass or fail – Operate or don’t operate • When the data consists of multiple samples of several observations each P-Charts • The theoretical basis for the P-chart is the binomial distribution, although for large sample sizes, the normal distribution provides a good approximation to it. • A P-chart is constructed and used in much the same way as a mean chart. • The center line on a P-chart is the average fraction defective in the population, P. • The standard deviation of the sampling distribution when P is known is: p(1 p) p n P-Chart • The Control limits UCL p z p LCL p z p If p is unknown, it can be estimated from the samples. That estimates p, replaces p in the preceding formulas, and ^ p replaces p. p Total number of defectives Total number of observations P-Chart • Example An inspector counted the number of defective monthly billing statements of a company telephone in each of 20 samples. Using the following information, construct a control chart that will describe 99.74 percent of the chance variation in the process when the process is in control. Each sample counted 100 statements. P-Chart • Example (cont.) Sample # of defective Sample # of defective 1 4 11 8 2 10 12 12 3 12 13 9 4 3 14 10 5 9 15 21 6 11 16 10 7 10 17 8 8 22 18 12 9 13 19 10 10 10 20 16 Total 220 P-Chart • Solution Z for 99.74 percent is 3 p ^ p 220 0.11 20(100) p (1 p ) n 0.11(1 0.11) 0.03 100 Control limits are ^ UCL p z p 0.11 3(0.03) 0.20 p 0.11 3(0.03) 0.02 ^ LCL p z P-Chart • Solution (cont.) Fraction defective 0.20 UCL 0.11 p 0.02 LCL 1 10 Sample number 20 Use of c-Charts Table 10.3 • Use only when the number of occurrences per unit of measure can be counted; non-occurrences cannot be counted. – Scratches, chips, dents, or errors per item – Cracks or faults per unit of distance – Breaks or Tears per unit of area – Bacteria or pollutants per unit of volume – Calls, complaints, failures per unit of time C-Chart • When the goal is to control the number of occurrences (e.g., defects) per unit, a C-chart is used. • Units might be automobiles, hotel rooms, typed papers, or rolls of carpet. • The underlying sampling distribution is the Poisson distribution. • Use of Poisson distribution assumes that defects occur over some continuous region and that the probability of more than one defect at any particular point is negligible. • The mean number of defects per unit is c and the standard deviation is: c C-Chart • Control Limits UCL c z c LCL c z c If the value of c is unknown, as is generally the case, the sample estimate, c , is used in place of c. where: c = Number of defects ÷ Number of samples C-Chart • Example Rolls of coiled wire are monitored using cchart. Eighteen rolls have been examined, and the number of defects per roll has been recorded in the following table. Is the process in control? Plot the values on a control chart using three standard deviation control limit. sample # of Sample # of defects defects 1 2 3 4 5 6 7 8 9 3 2 4 5 1 2 4 1 2 10 11 12 13 14 15 16 17 18 1 3 4 2 4 2 1 3 1 45 C-Chart • Solution Average number of defects per coil = c = 45/18 =2.5 UCL c 3 c 2.5 3 2.5 7.24 LCL c 3 c 2.5 3 2.5 2.24 0 When the computed lower control limit is negative, the effective lower limit is zero. The calculation sometimes produces a negative lower limit due to the use of normal distribution as an approximation to the Poisson distribution. The control chart is left for the student as a homework Managerial consideration concerning control charts • At what point in the process to use control charts: at the part of the process that (1) have tendency to go out of control, (2) are critical to the successful operation of the product or service. • What size samples to take: there is a positive relation between sample size and the cost of sampling. • What type of control chart to use: – Variables: gives more information than attributes – Attributes: less cost and time than variables Run Tests • Run test – a test for randomness • Control charts test for points that are too extreme to be considered random. • However, even if all points are within the control limits, the data may still not reflect a random process. • Any sort of pattern in the data would suggest a nonrandom process. • The presence of patterns, such as trends, cycles, or bias in the output indicates that assignable, or nonrandom, cause of variation exist. • Analyst often supplement control charts with a run test, which is another kind of test for randomness. Nonrandom Patterns in Control charts Figure 10.11 • Trend: sustained upward or downward movement. • Cycles: a wave pattern • Bias: too many observations on one side of the center line • Mean shift: A shift in the average • Too much dispersion: the values are too spread out Run Test • A run is defined as a sequence of observations with a certain characteristic, followed by one or more observations with a different characteristic. • The characteristic can be anything that is observable. • For example, in a series AAAB, there are two runs; a run of three A’s followed by a run of one B. • The series AABBBA , indicates three runs; a run of two A’s followed by a run of three B’s, followed by a run of one A. Counting Runs Figure 10.12 Counting Above/Below Median Runs B A Figure 10.13 A B A B B B A Counting Up/Down Runs U U D U (7 runs) A B (8 runs) D U D U U D Run test procedure • 1. 2. To determine whether any patterns are present in control charts, one must do the following: Transform the data into both A’s and B’s and U’s and D’s, and then count the number of runs in each case. Compare the number of runs with the expected number of runs in a completely random series, which is calculated as follows: N E ( r ) med E (r ) u / d 1 2 2N 1 3 Where: N is the number of observations or data points, and E(r) is the expected number of runs Run test procedure (cont.) 3. Calculate the standard deviations of the runs as: med N 1 4 u/d 16 N 29 90 4. Calculate the test statistic (Ztest) as following: Z test observed number of runs – expected number of runs standard deviation of number of runs N 1) 2 N 1 4 2N 1 r ( ) 3 16 N 29 90 r ( Z t est Z t est For the median Up and down If the Ztest is within ± 2 or ± 3; then the process is random; otherwise, it is not random Run test • Example sample mean sample Mean Twenty sample means have 1 10 11 10.7 been taken from a process. The means are shown in 2 10.4 12 11.3 the following table. Use 3 10.2 13 10.8 median and up/down run test with 4 11.5 14 11.8 z = 2 to determine if 5 10.8 15 11.2 assignable causes of variation are present. 6 11.6 16 11.6 Assume the median is 11. 7 8 9 10 11.1 11.2 10.6 10.9 17 18 19 20 11.2 10.6 10.7 11.9 Run test • Solution sample mean A/B U/D Sample Mean A/B U/D 1 10 B - 11 10.7 B D 2 10.4 B U 12 11.3 A U 3 10.2 B D 13 10.8 B D 4 11.5 A U 14 11.8 A U 5 10.8 B D 15 11.2 A D 6 11.6 A U 16 11.6 A U 7 11.1 A D 17 11.2 A D 8 11.2 A U 18 10.6 B D 9 10.6 B D 19 10.7 B U 10 10.9 B U 20 11.9 A U Run test Solution (cont.) 1. A/B: 10 runs and U/D: 17 runs 2. Expected number of runs for each test is: N 20 1 1 11 2 2 2 N 1 2(20) 1 13 3 3 E (r ) med E (r ) u / d 3. The standard deviations are: med N 1 4 20 1 2.18 4 u/d 16 N 29 90 16( 20) 29 1.8 90 4. The ztest values are: 10 11 0.46 2.18 17 13 2.22 1 .8 Z med Zu / d Although the median test doesn’t reveal any pattern, because its Ztest value is within ±2, the up/down test does; its value exceed +2. consequently, nonrandom variations are probably present in the data and, hence, the process is not in control Process Capability • Tolerances or specifications – Range of acceptable values established by engineering design or customer requirements • Process variability – Natural variability in a process • Process capability – Process variability relative to specification Capability analysis • Capability analysis is the determination of whether the variability inherent in the output of a process falls within the acceptable range of variability allowed by the design specification for the process output. • If it is within the specifications, the process is said to be “capable.” if it is not, the manager must decide how to correct the situation. • We cannot automatically assume that a process that is in control will provide desired output. Instead, we must specifically check whether a process is capable of meeting specifications and not simply set up a control chart to monitor it. • A process should be both in control and within specifications before production begins. Process Capability Figure 10.15 Lower Specification Upper Specification A. Process variability matches specifications Lower Specification Upper Specification B. Process variability Lower Upper well within specifications Specification Specification C. Process variability exceeds specifications Capability analysis • If the product doesn’t meet specifications (not capable) a manager might consider a range of possible solutions such as: 1. Redesign the process. 2. Use an alternative process. 3. Retain the current process but attempt to eliminate unacceptable output using 100% inspection. 4. Examine the specifications to see whether they are necessary or could be relaxed without adversely affecting customer satisfaction. Process Capability Ratio Calculate the capability and compare it to specification width. If the capability is less than the specification width, the process is capable. Where: Capability = 6; where is the process SD Or calculate Process capability ratio, Cp = Cp = specification width process width Upper specification – lower specification 6 The process is capable if Cp is at least 1.33, this ratio implies only about 30 parts per million can be expected to not be within the specification Capability analysis • Example A manager has the option of using any one of three machines for a job. The machines and their standard deviations are listed below. Determine which machines are capable if the specifications are 10 mm and 10.8 mm. Machine A Standard deviation (mm) 0.13 B 0.08 C 0.16 Capability analysis • Solution Capability = 6 Machine A B C Standard deviation (mm) 0.13 0.08 0.16 Machine capability 0.78 0.48 0.96 Capable Yes Yes No It is clear that machine A and machine B are capable, since the capability is less than the specification width (10.8 – 10 = 0.8) Capability ratio Example Compute the process capability ratio for each machine in the previous example Solution Machine Standard Machine deviation capability (mm) 6 A 0.13 0.78 B C 0.08 0.16 0.48 0.96 Cp Capable 0.8/0.78= 1.03 No 0.8/0.48 = 1.67 0.8/0.96 = 0.83 Yes No Only machine B is capable because its ratio exceed 1.33 3 Sigma and 6 Sigma Quality Upper specification Lower specification 1.350 ppm 1.350 ppm 1.7 ppm 1.7 ppm Process mean +/- 3 Sigma +/- 6 Sigma Cpk ratio • If a process is not centered (the mean of the process is not in the center of the specification), a more appropriate measure of process capability is the Cpk ratio, because it does take the process mean into account. • The Cpk is equal the smaller of Upper specification – process mean 3 And Process mean – lower specification 3 Cpk Ratio • Example A process has a mean of 9.2 grams and a standard deviation 0f 0.3 grams. The lower specification limit is 7.5 grams and upper specification limit is 10.5 grams. Compute Cpk Solution 1. Compute the ratio for the lower specification: 9.2 7.5 1.7 1.89 3(.3) 0.9 2. Compute the ratio for the upper specification: 10.5 9.2 1.3 1.44 3(0.3) .9 The smaller of the two ratios is 1.44 (greater than 1.33), so this is the Cpk . Therefore, the process is capable Improving Process Capability • • • • • Simplify the process Standardize the process Mistake-proof Upgrade equipment Automate Method Examples Process Capability Improving Simplify Eliminate steps, reduce number of parts Standardize use standard parts, standard procedure Make mistake-proof Design parts that can only be assembled the correct way; have simple checks to verify a procedure has been performed correctly Upgrade equipment Replace worn-out equipment; take advantage of technological improvements Automate Substitute processing for manual processing Taguchi Loss Function Figure 10.17 Traditional cost function Cost Taguchi cost function Lower spec Target Upper spec Limitations of Capability Indexes 1. Process may not be stable 2. Process output may not be normally distributed 3. Process not centered but Cp is used