SCADA System, Hardware & Firmware

advertisement

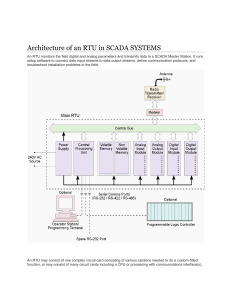

SCADA SYSTEM, HARDWARE & FIRMWARE SCADA SYSTEM A system consisting of a number of remote terminal units (or RTUs) collecting field data connected back to a master station via a communications system. The master station displays the acquired data and also allows the operator to perform remote control tasks. On a more complex SCADA system there are essentially five levels or hierarchies: • Field level instrumentation and control devices • Marshalling terminals and RTUs • Communications system • The master station(s) • The commercial data processing department computer system DISTRIBUTED CONTROL SYSTEM (DCS) The data acquisition and control functions are performed by a number of distributed microprocessor-based units situated near to the devices being controlled or the instrument from which data is being gathered. PROGRAMMABLE LOGIC CONTROLLER (PLC) PLCs have replaced hardwired relays with a combination of ladder–logic software and solid state electronic input and output modules. SMART INSTRUMENT Typically means an intelligent (microprocessor based) digital measuring sensor (such as a flow meter) with digital data communications provided to some diagnostic panel or computer based system. REMOTE TERMINAL UNITS a standalone data acquisition and control unit, generally microprocessor based, which monitors and controls equipment at some remote location from the central station. Its primary task is to control and acquire data from process equipment at the remote location and to transfer this data back to a central station The RTU can also act as a relay station (sometimes referred to as a store and forward station) to another RTU, which may not be accessible from the central station. Small sized RTUs generally have less than 10 to 20 analog and digital signals, medium sized RTUs have 100 digital and 30 to 40 analog inputs. Typical RTU hardware modules include: Control processor (or CPU) This is generally microprocessor based (16 or 32 bit) e.g. 68302 or 80386. Total memory capacity of 256 kByte (expandable to 4 Mbytes) Analog input modules There are five main components making up an analog input module. They are: • The input multiplexer • The input signal amplifier • The sample and hold circuit • The A/D converter • The bus interface and board timing system ANALOG I/O MODUL DIGITAL INPUTS These are used to indicate items such as status and alarm signals. Digital output module A digital output module drives an output voltage at each of the appropriate output channels with three approaches possible: • Triac switching • Reed relay switching • TTL voltage outputs COMMUNICATION INTERFACES The modern RTU should be flexible enough to handle multiple communication media such as: • RS-232/RS-442/RS-485 • Dialup telephone lines/dedicated landlines • Microwave/MUX • Satellite • X.25 packet protocols • Radio via trunked/VHF/UHF/900 MHz PLCS USED AS RTUS The advantage of a PLC over the RTU offerings from various manufacturers is that it can be used in a general-purpose role and can easily be set up for a variety of different functions. PLCs are popular for the following reasons: Economic solution Versatility and flexibility Ease of design and insta More reliable Sophisticated control Physically compact Easier troubleshooting and diagno THE MASTER STATION The central site/master station can be pictured as having one or more operator stations connected to a communication system consisting of modem and radio receiver/transmitter. The features that should be available are: • Operator interface to display status of the RTUs and enable operator control • Logging of the data from the RTUs • Alarming of data from the RTU master station has two main functions: • Obtain field data periodically from RTUs and submaster stations • Control remote devices through the operator station The master station has the following typical functions: Establishment of communications Operation of the communications link • Configure each RTU • Initialize each RTU with input/output parameters • Download control and data acquisition programs to the RTU • If a master slave arrangement, poll each RTU for data and write to RTU • Log alarms and events to hard disk (and operator display if necessary) • Link inputs and outputs at different RTUs automatically Diagnostics • Provide accurate diagnostic information on failure of RTU and possible problems • Predict potential problems such as data overloads VARIOUS APPROACHES POSSIBLE FOR THE MASTER STATION It may also be necessary to set up a submaster station. This is to control sites within a specific region. The submaster station has the following functions: • Acquire data from RTUs within the region • Log and display this data on a local operator station • Pass data back to the master station • Pass on control requests from the master station to the RTUs in its region COMMUNICATION ARCHITECTURES Point-to-point (two stations) Multipoint (or multiple stations) Relay Stations Communication philosophies There are two main communication philosophies possible. These are; polled (or masterslave) and carrier sense multiple access/collision detection (CSMA/CD).