Document

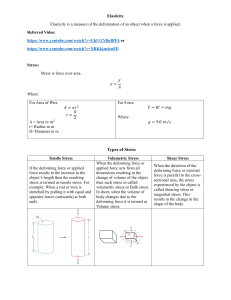

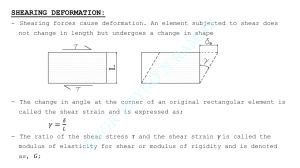

advertisement

Strengths Chapter 10 Strains 1-1 Intro • Structural materials deform under the action of forces • Three kinds of deformation • Increase in length called an elongation • A decrease in length called a contraction • Change in shape called an angular distortion • Deformation per unit length is called linear strain 10-2 Linear Strain • Axial forces applied to a member tend to elongate or compress the member • Original length L of the member is elongated to a length l+ @ after the tensile load P is applied. The total deformation is @ Greek lowercase letter delta • Linear strain defined as deformation per unit of original length of the unstressed member • Formula 10-1 page 357 and page 358 10-3 Hooke’s Law • Linear relationship exists between stress and strain – to a point – stress is proportional to the strain – beyond this limit stress will no longer be proportional to strain – limiting value is called the proportional limit of the material – this relationship is called hooke’s law formula 10-2a page 358 • Modulus of elasticity expressed usually as psi or ksi or GPa or Mpa • Modulus of elasticity indicates its stiffness or ability of material to resist deformation • 210gpa for steel and 70gpa for aluminum – aluminum will stretch three times more than steel of the same length when subjected to the same stress. 10-4 Axial Deformation • Axial loaded member elongates under a tensile load and contracts under compressive load – can be computed as long as it does not exceed proportional limit • Figure 10-2 and formulas 10-4 10-5 page 359 • For structural materials the moduli of elasticity for tension and for compression are the same, so they will work for compression or tension – tension forces are positive – compression forces negative. • Example 10-1 page 360 • Example 10-2 page 360 • Example 10-3 page 362 10-5 Statically Indeterminate problems • When unknown forces in structural members cannot be determined by the equilibrium equations alone – structure is said to be statically indeterminate – statically indeterminate problems – involve axially loaded members to be analyzed by introducing the conditions of axial deformations • Example 10-4 page 363 • Example 10-5 page 364 • Example 10-6 page 365 10-6 Thermal Stresses • Homogeneous materials deformation due to temperature change can be calculated using formula page 367 10-6 • Stresses produced by a temperature rise or drop are called thermal stresses • Example 10-7 page 368 • Example 10-8 page 368 • Example 10-9 page 369 10-7 Poisson’s ratio • When a bar is subjected to an axial tensile load, it is elongated in the direction of the applied load at the same time its transverse dimension decreases • Axial compressive load is applied to the bar the bar contracts along the axial direction while its transverse dimension increases • Formula 10-7 page 371 • Examples 10-10 page 371 10-8 shear strain • A shear force causes shape distortion of a body • Total deformation occurs over a length • Shear strain is thus the change in radians in a right angle between tow perpendicular lines. • Use of hookes law • Formula 10-10 page 373 • G is a constant of proportionality called the shear modulus of elasticity or the modulus of rigidity. • Example 10-11 page 373