Presentation mark scheme

advertisement

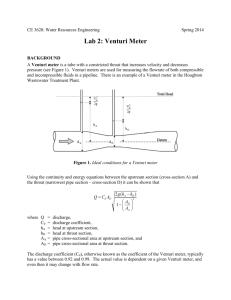

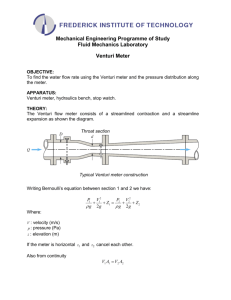

Insert title of the document here Sheffield Hallam University Department of Engineering and Maths Faculty of Arts, Computing, Engineering and Science For the attention of: Insert name of tutor here Report author: Insert your name here Report author ID: Insert student ID here Module name & code: Insert the name of the module and code here Course name: Insert the name of the course you are on here Date: Insert date here Executive Summary Use this space to complete the executive summary, or abstract, for the piece of work you have conducted. A summary of the essential aspects of the report. An abstract should be brief, i.e. contain 100-200 words. It should summarize all the information presented in the report, including the aim, background to the subject, introduction, procedure, results, key findings, discussion and conclusions. Abstracts are hard to write. ii Contents Executive Summary ....................................................................................................ii Nomenclature .............................................................................................................iv 1 Introduction ......................................................................................................... 1 2 Background Theory ............................................................................................. 5 3 4 2.1 Conservation of Mass ................................................................................... 5 2.2 Conservation of Energy ................................................................................. 6 2.3 Flow measurement ........................................................................................ 6 2.4 Coefficient of discharge ................................................................................. 7 Experimental Procedure ...................................................................................... 8 3.1 Equipment ..................................................................................................... 8 3.2 Procedure...................................................................................................... 9 3.3 Your reflection ............................................................................................. 11 3.4 Procedure Mark Scheme ............................................................................ 11 Results .............................................................................................................. 12 4.1 Your reflection ............................................................................................. 12 4.2 Results Mark Scheme ................................................................................. 12 5 Discussion ......................................................................................................... 13 6 Conclusions ...................................................................................................... 13 6.1 Your reflection ............................................................................................. 14 6.2 Discussion Mark Scheme ............................................................................ 14 7 Further Work ..................................................................................................... 14 8 References ........................................................................................................ 15 iii Nomenclature Area of the pipe Area of the constriction Discharge Coefficient Diameter of the pipe Diameter of the constriction Mass Mass flow rate Pressure Average velocity Time Ratio of diameters Density iv 1 Introduction The aim of the investigation is to experimentally determine the coefficient of discharge of a specific Venturi meter and compare the result to previously obtained empirical results. A Venturi meter is an invasive, full bore flow measurement device that employs a combination of the conservation of mass and energy to determine the flowrate of internal flows in within pipes. The device was invented by Clemens Herschel in 1819 and is named in honour of Italian physicist Giovanni Venturi (1746-1822). The principle design consists of a Venturi meter is to introduce a constriction into a pipe and measure the drop in pressure of fluid in the pipe of original diameter and that in the constriction, as shown in figure 5.1, where A1represents the area of the original pipe and A2 represents the area of the constriction, known as the "throat". Figure 1.1 The control volume used in the conservation analysis of the Venturi meter The pressure difference measurement in figure 1.1 is illustrated using a U tube manometer, where the difference in height difference, h, in the manometer fluid can be measured and converted into a pressure difference using Pascal's Law. Other pressure measuring devices, such as digital pressure gauges or piezometers, can also be used to recorder the pressure difference in the fluid in the pipe and the constriction. Venturi meters are used in a wide variety of industrial engineering applications over a range of size scales. One such installation of is shown in figure 1.2. Advantages over other flow meters, for example an orifice plate, include their robust operation 1 due to simple design and lack of moving parts, and, once installed, they do not require interruption of the flow to measure the flow rate. Figure 1.2 Industrial Venturi meter with digital readout [1] If the gradient of the contracting (nozzle) and diverging (diffuser) section of the Venturi meter is shallow, the pressure loss due to friction is minimal and the relationship between measure pressure drop and flow rate can be determined using analytical means. Regardless of the design of a Venturi meter, friction will reduce recoverable pressure within the fluid and create a discrepancy between the theoretical and actual flow rate recorded. This discrepancy is characterised by the quantity referred to as the coefficient of discharge, , which can only be determined though empirical means. In the theoretical idealized example of no friction existing and all pressure being recoverable, the coefficient of discharge for a flow meter would be unity. The coefficient of discharge of Venturi meters is typically higher than other full bore flow measurement devices, resulting in less running cost from pumping systems required to overcome the non-recoverable pressure loss. However, the capital cost of Venturi meters is typically higher than simpler flower measurement devices. The original Herschel Venturi meter, as illustrated in figure 1.3,consisted of a 21oconical contraction,constant diameter throat of length equal to diameter and a conical expansion of 7 to 15o. The coefficient of discharge of the Herschel Venturi meter varies is independent of the ratio of throat to pipe diameter ( ), but varies with Reynolds number, as shown in figure 1.4. 2 Figure 1.3 Herschel Venturi meter Figure 1.4Variation of coefficient of discharge with Reynolds for Herschel type Venturi meters (In this image, Red and ReD refer to the Reynolds number in the throat and pipe, respectively) [2] The modern standard for measurement of fluid flow by means of orifice plates, nozzles, and Venturi meters is given byISO 5167-3 2003 [3]. These standards dictate a Venturi meter should contain an ISA 1932 nozzle entrance and conical expansion of no more than 15o, as illustrated in figure 1.5. When operated within a Reynolds number range of between 1.5×105 and 2×106, based on the pipe rather than throat diameter, the coefficient of discharge for the Venturi meter should be given by equation 2.0.1. 3 (1.0.1) The empirical correlation in equation 1.0.1 is valid for value of 0.775 and is independent of Reynolds number. between 0.316 and Figure 1.5 International standard (ISO 5167-3 3003) shapes for Venturi meter [3] 4 2 Background Theory The physical principles underlying the operation of a Venturi meter are those of the conservation of mass, also referred to as the continuity, and the conservation of energy though the Bernoulli equation. When analysing conservation in engineering systems a theoretical boundary in physical space, referred to as a control volume, is utilised to balance the flows of the conserved property. The control volume use in the conservation analysis of the Venturi meter is illustrated in figure 2.1. Figure 2.1The control volume used in the conservation analysis of the Venturi meter 2.1 Conservation of Mass Conservation of mass dictates that, with the exception of the existence of nuclear reactions, the difference between the mass entering a control volume and the mass leaving a control volume must equal the accumulation of mass within the control volume. This relationship, in rate quantities, is given in equation 2.1.1, (2.1.1) where subscript and represent the quantity into and out of the control volume, respectively. It is assumed that, as the flow is incompressible and running for a significant period of time that the operation of the Venturi meter will be steady state and the transient term in equation 2.1.1 ( ) will become zero, leading to the mass flow rate out being equal to the mass flow rate in. The velocity of the fluid within the pipe will vary across the cross section due to the no slip boundary condition at the wall. However, for the purposes of analysis, an 5 average velocity, , can be defined based on the mass flow rate using the relationship shown in equation 2.1.2. (2.1.2) In steady state the mass flow rate into and out of the control volume shown in figure 2.1 must be equal and for incompressible flow the density will remain constant, giving rise to equation 2.1.3. (2.1.3) The physical manifestation of continuity equation 2.1.3 is that the fluid must accelerate as the area of the pipe decrease. 2.2 Conservation of Energy The conservation of energy, also referred to as the first law of thermodynamics, dictates that the difference between the energy entering a control volume and the energy leaving a control volume must equal the accumulation of energy within the control volume, as energy can neither be created nor destroyed. Under the same assumption that the Venturi meter is operating in steady state, the energy that is transported by the fluid into the control volume must also leave the control volume. Bernoulli's equation describes the conservation of energy within a fluid stream and assumes that all the energy is accounted for by a combination of static ( ) and dynamic ( ) pressure, and that there is no change in the fluid's internal energy, no change in elevation and no energy is lost due to friction. If it is assumed that all the energy that leaves the control volume is transported out by the fluid leaving the control volume, Bernoulli's equation can be applied to the control volume in figure 6.1 as shown in equation 2.2.1. (2.2.1) 2.3 Flow measurement Substituting equation 2.1.3 into 2.2.1 and rearranging yieldthe result shown in equation 2.3.1 (2.3.1) Rearranging equation 2.3.1 and substituting in equation 2.1.3 produces a relationship for the mass flow rate though the control volume based on the pressure drop between the inlet and outlet, as shown in equation 2.3.2, 6 (2.3.2) where is the ratio of outlet and inlet pipe diameters. Therefore by measuring the pressure drop across any section of a converging or diverging section of a Venturi meter where the area is known, the theoretical mass flow rate can be determined, under the following assumptions 1. The Venturi meter is operating in steady state 2. There is no change in elevation 3. There is no change in temperature of the fluid and hence no change in internal energy 4. The fluid is incompressible 5. There is no recoverable pressure loss due to friction. 2.4 Coefficient of discharge The theoretical relationship between mass flow rate and pressure drop across a control volume of a Ventrui meter will not be achieved in practices due to the presence of friction. In order to account for this discrepancy, the coefficient of discharge, , is defined for Venturi meters using equation 2.4.1, (2.4.1) where the subscript is the predicted mass flow rate determined by analytical means, though measurement of the pressure drop, , and applying it toequation 2.3.2.The subscript is the actual mass flow rate passing though the control volume of the Venturi meter, which can be measure directly. Coefficients of discharge can only be established though experimental methods. An empirical relationship for Herschel type Venturi meters is given in figure 1.4 and for an ISO 5167-3 standard [3] Venturi meter in equation 1.0.1. 7 3 Experimental Procedure 3.1 Equipment Venturimeter fitted across a pipeline leading to a collecting tank Stop Watch U-Tube manometer connected across 8 entry and throat sections 3.2 Procedure Close the valve on the outlet side of the venturi, then switch the pump on, making sure that the valve on the inlet side of the venturi is fully open. Slowly open the outlet side valve until the air is cleared from the connecting pipes and tubes. Then reclose the outlet side valve. This may have already been done. As the pressure level observed from the manometer tubes can be seen to be lower when the outlet valve is open, i.e. water is flowing, then we have to adjust the static pressure such that we can get maximum use from the manometer range. With the outlet side valve closed, very carefully release air pressure from the manometer system by means of pressing in the valve located on the top RHS of the arrangement. By means of this valve adjust the static level in the manometer tubes until it is 90% of full scale (reading about 21-22cm). Again this will probably have been done. Note the levels in the individual tubes in the chart given with this instruction sheet. Now, open the outlet side valve and adjust the flow so that the lowest pressure in the manometer tubes is as near to zero as you can obtain (without going lower than zero). Note all the manometer readings on the chart provided. Next measure the actual mass flow rate of water. Close the drain on the weighing tank underneath the apparatus by turning the handle on the front. Water will now start to fill the tank until it causes the balance to tip. At this instance start timing with the stop watch provided and place on the end of the balance arm a weight representing 15Kg (or weights) which will tip the balance back. As the tank fills up further the balance will again tip over. At this instance stop the watch and note down the time. The actual mass flow rate is this weight divided by the time recorded. Record this value on the sheet provided. Repeat for 2 other lower mass flow rates, one of which should be when the pressure difference between the inlet and throat is approximately 2cm. Calculate the theoretical mass flow rate for the three sets of measurements and determine the value of C_D. 9 OR Note the pipe diameter (d1) and throat diameter (d2) of Venturimeter. Note the density of manometric liquid i.e. mercury (ρm) and that of fluid flowing through pipeline i.e. water (ρw ). Check all the clamps for tightness. Check whether the water level in the tank is sufficient such that the suction pipe of pump is completely immersed. For measurement through venturi, open the outlet valve of the venturi meter and For a good amount of variation in discharge also close the by-pass valve of pump. Now switch on the pump. Open the gate valve and start the flow. If any air bubbles exist in U-tube manometer remove them through air cock valve. Operate the air cock valve slowly and cautiously to avoid mercury run away through water. Wait for a while for stabilization of flow. Close the gate valve of measuring tank and measure the time for discharge of five liters of water and the manometer difference. Before taking any measurements, make sure the flow is stable. Repeat the procedure by changing the discharge by slowly opening the bypass valve and take the five readings. Determine the coefficient of discharge (Cd) for each flow rate and find the mean value of coefficient of discharge (Cd) mean. SAFETY NOTES 1. Safety Glasses with side shields shall be worn during the running of this experiment. 2.Tap water is used in this experiment. As stated, it is possible for hoses or tubing to pop off and spray water. 3. Be careful of the outlet hose position and the position of the bench and flow control valves when starting the pump. It is easy for the outlet hose to spray water. It is also possible to blow off the pressure tap hoses and spray water all over. 10 3.3 Your reflection The images for each equipment was provided so that all the equipments may be easily identified. Further the procedure was written carefully and in detail so that anyone would be able to replicate the process. Marks: 14/20 3.4 Procedure Mark Scheme 20-14 14-12 12-10 10-8 8-0 Procedure is written in prose and contains enough information to be repeatable by anybody else at a later date, without including superfluous information. Use of images enhances the readers understanding of the experiment. Equipment is fully described (such as including model numbers) and the precision and/or accuracy is detailed.Reflection is mature and professional, illustrating both strengths and weakness. The procedure is written in prose and contains enough information to make the experiment repeatable by a anybody else at a later date. Images have been included to aid understanding of the procedure adopted. Equipment is well described (such as including model numbers). The procedure is written in prose, but misses information to fully describe the procedure undertaken during the laboratory. Images are not included or are not sufficiently labelled or discussed to make them helpful for the reader. Equipment used during the experiment is listed. Procedure consists of bullet points with of tasks that were completed. Information is missing that would prevent a reader from being able to repeat the experiment. The equipment used is not listed. None or very little procedure given. Procedure may be written in such a way that it makes it impossible for the reader to understand what happened during the experiment. The equipment used is not listed. Appropriate mark awarded and reasonable supporting comments given. Reflection contains unjustified mark and some relevant comments. 11 Reflection consists only of an unjustified mark. No reflection has taken place 4 Results Table 1: Observations m (Kg) Time (sec) mass flow rate 𝑚̇ (Kg/sec) 𝑃1 𝑃4 𝑃11 Pressure Loss 100(𝑃1 − 𝑃11 ) 𝑃1 (%) 15 15 15 15 15 35 53 65 115 45 0.429 0.283 0.231 0.130 0.333 0.245 0.216 0.216 0.250 0.089 0.004 0.122 0.155 0.230 0.089 0.201 0.200 0.205 0.246 0.197 17.95 7.47 5.09 1.60 10.45 Table 2: Calculations 4.1 m (Kg) Time (sec) mass flow rate 𝑚̇ (Kg/sec) K2 ∆p Theoretical Mass Flow Rate (Kg/sec) Cd 15 15 15 15 15 35 53 65 115 45 0.429 0.283 0.231 0.130 0.333 0.143 0.143 0.143 0.143 0.143 2364 922 598 196 1285 0.47 0.30 0.24 0.14 0.35 0.907 0.959 0.971 0.958 0.957 Your reflection The results are as expected for the experiment. The coefficient of discharge values are in line with expected values for a Venturi meter. Marks Obtained: 16/20 4.2 Results Mark Scheme 20-14 14-12 12-10 10-8 8-0 Data presented in alogical manner usingthe most appropriate methods. Data ispresented in a stylethat clearly displaysthe points beingreferred to in the text. Any raw or superfluous Data is presented in a suitable manner. It may be displayed so it cannot be compared to other results or so trends cannot be seen. Discussion of results is presented but displays limited understanding of the experiment. The method of data presentation is not appropriate. Raw data may not be processed or not properly processed or there is limited discussion of how raw data has been converted into experimental results. Raw data is presented without processing or calculations being shown. Very little discussion of results or the discussion of results is limited to basic description with little context. Little or no data has been presented. The data presented may consist of a table of raw data or a graph that is not discussed. No points are raised in the text to illustrate why data is displayed. 12 data in appendix. Reflection is mature and professional, illustrating both strengths and weakness. Appropriate mark awarded and reasonable supporting comments given. Reflection contains unjustified mark and some relevant comments. Reflection consists only of an unjustified mark. No reflection has taken place 5 Discussion In the calculation table, the Cd for was calculated for each time the experiment was repeated. The average value from the 5 readings give the coefficient of discharge as 0.950. The expected value of coefficient of discharge for an venturi meter is between 0.95 - 0.98. There were sources of error in this experiment. One source of error was due to the measurement of the head loss, Δh, from the manometer board. Due to nonsteady flow in the testing apparatus, the air over water manometer did not give a steady reading. Inorder to compensate for this discrepancy, the lowest value the fluctuating fluid took wasthe recorded value. Another source of error was present due to the neglecting of frictionin the theoretical flow rate calculation. This discrepancy explains the difference of values plotted in Because friction was neglected, the theoretical values of the flow rateappear to be higher than the experimental values. In reality, the viscous forces of the fluid and the pipe cause the flow rate to be lower than the calculated values. 6 Conclusions The actual flow rate will be different from the theoretical flow rate due to frictional and turbulence effects. In order to take this into account the coefficient of discharge is introduced into the equations. The coefficient of discharge Cd is the ratio of the actual mass flow rate to the theoretical mass flow rate. The actual mass flow rate of water was measured by dividing the mass of the balance by the time taken for the tank to fill before it tipped over. On the other hand the theoretical mass flow rate was calculated using this formula 𝑚̇ = 𝐴2 √ 2∆𝑝𝜌 [1− 𝜅2 ] Thus dividing the actual mass flow rate by the theoretical value one calculated the C d. In this experiment, the value of Cd (0.95) was along the expected value of a Venturi meter. Hence the experiment was a success. 13 6.1 Your reflection Marks: 25/30 6.2 Discussion Mark Scheme Use this marking grid to assign yourself the mark you think you deserve for the discussion and conclusion section. 30-21 21-18 18-15 15-12 12-0 Discussion displays solid understanding of the physics of the experiment. Points raised about results relate back to the introduction section. Error in the experiment have been identified and an attempt has been made to quantify. Repeatability is discussed. Conclusions contain brief summary of points raised in discussion. Discussion displays good understanding of the physics of the experiment. Points raised about results relate back to the introduction section. Errors in the experiment have been identified and an attempt has been made to indicate their impact on the results. Conclusions contain brief summary of points raised in discussion. Discussion displays some understanding of the physics of the experiment. The points raised in the discussion do not relate to the aims and objectives set out in the introduction. Errors are listed and qualitatively discussed. Conclusions are given, but either do not correctly summarise points in the discussion or includes new information. Discussion displays limited understanding of the physics of theexperiment. Results are not discussed or with little understanding or reference to why experiment was conducted. Errors are listed only, without attempt to suggest importance. Conclusions are not attempted. The discussion illustrates that student has no or little understanding of the experiment or the physic of the system. Presented results not discussed, or discussion is a reiteration of the results presented. There is little indication that experimental errors have been considered. Reflection consists only of an unjustified mark. No reflection has taken place Reflection is mature and professional, illustrating both strengths and weakness. Appropriate mark awarded and reasonable supporting comments given. Reflection contains unjustified mark and some relevant comments. 7 Further Work You may attempt to complete this section, about what further work you would do if you have the resources, to improve the experiment you have conducted. 14 8 References 1. Paras Engineers, Company Product Catauouge 24th January 2012. http://52168.in.all.biz/goods_venturi-meter_383220 (last accessed 7th August 2012) 2. White, F. M., Fluid Mechanics. Sixth Edition, McGraw Hill, 2008. 3. Int. Organ. Stand. “Measurement of Fluid Flow by Means of Orifice Plates, Nozzles, and Venturi Tubes Inserted in Circular Cross Section Conduits Running Full,” Rep. DIS-5167, Geneva, April 1976. 15 Presentation mark scheme Use this marking grid to assign yourself the mark you think you deserve for the presentation of your report 20-14 14-12 12-10 10-8 8-0 Professionally presented. All standards in marking proforma adhered to. Use of English is concise, technically correct and precise. Clear and consistent referencing is used. Document is well presented. One or two standards in marking proforma not adhered to. Use of English is technically correct. Clear and consistent referencing is used. Document is well presented but a few minor standards in the marking proforma not adhered to. The standard of English is reasonable, but the use of colloquial terms or journalistic styles is present. Document is visually well presented, but fails to conform to many standards in the marking proforma. Poor use of English. Sourced material is referencing, but style not consistent or lacks enough detail. Document is poorly presented or hand written. Many of the important standards in the proforma not adhered to. Standard of English is poor. Sourced material is not cited. Appropriate marking has been awarded by student. Mark not appropriate for work submitted. Appropriate marking has been awarded by student. Appropriate marking has been awarded by student. Mark not appropriate for work submitted Laboratory Mark Breakdown Record of work in during lab time /10 Procedure /20 Presentation of results /20 Discussion and conclusions /30 Presentation of document /20 Total /100 16