Document

advertisement

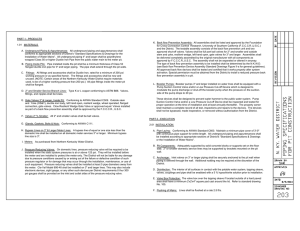

2. FLUID FRICTION IN PIPES, VALVES AND FITTINGS A variety of studies will be conducted with this equipment, including the determination of: a) the friction factor - Reynolds number relationship for pipe flow, b) valve coefficients (Cv values) and characteristics (f(x) vs x) for gate valves, and globe valves, c) friction losses for various fittings. Since the piping systems used for a, b, and c contain substantial lengths of pipe, it will be necessary to correct the measured pressure drops for the lengths of straight piping between the fittings. These corrections should be calculated assuming the pipe is smooth. The main apparatus is a flow loop with ten (10) separate lines, each incorporating different types of fittings. The pressure differences across the piping and from the venturi meter are measured with variable reluctance differential pressure transducers. The transducer output is a voltage signal that is collected by Voltage Meters and Demodulators, which are connected to a SCB-68 National Instruments Shielded I/O Connector Block for DAQ Devices with 68-pin connectors. The Connector Block is then used to send voltage signals to a NI PCI-MIO-16E-4 I/O Terminal installed in an IBM Intel computer. The resulting signals are then picked up by LabVIEW 8.2 and displayed in “Fluid Friction.vi” in a series of graphs and indicators. A cold junction-compensated (CJC) thermocouple is used to measure the temperature of the fluid. The CJC occupies channel ai0 and the thermocouple is attached to channel ai1 and ai9 of the connector block. Each transducer is calibrated individually. The Demodulators are set to zero by allowing the individual transducers to be open to atmospheric pressure (with both bleed screws open). Once stabilized, the spans of the Demodulators are set at 10V with the bleed screws closed and air applied at the appropriate pressure. The exact procedure will be discussed by the TA. To measure the flow rate for comparison with the Venturi meter, a bucket, stopwatch, and scale are required. A 3/32” Allen wrench is also necessary for adjusting the pressure transducer bleed screws. The inside diameter of the tubing is 0.527 inches. The equipment is fairly complex and you will have to spend some time tracing the flow lines and thinking about what you are going to do. Don’t turn anything on until the demonstrator has given his/her approval. From your experimental measurements on the Venturi meter, calculate the coefficient of discharge, C, in the relation: w CA 2 2 ( p )1 1 4 where W is the mass rate of flow, A2 is the cross-sectional area of the throat of the Venturi, 1 is the density of the fluid just upstream of the throat, (-) is the pressure difference across the Venturi, is the ratio of throat diameter to inside pipe diameter (14.3 mm and 25.3 mm respectively) The valve coefficient and valve stem function are defined as: Q Cv f ( x) where Q Cv f(x) S Pv x Pv S = flowrate (US gallon/minute) = valve coefficient (usgpm/psi0.5) = dimensionless stem function (0, closed; 1, fully open) = fluid density/water density = pressure drop over valve (psi) = stem position (fraction open) A possible f(x) vs x relationship is of the form f(x) = xm. In examining the valve performances the data should be used to find the best-fit values of Cv and m. References 2.1 Anon, “Flow of Fluid Through Valves, Fittings and Pipe”, Technical Paper No. M409, Crane Ltd., 1950. 2.2 Perry’s Chemical Engineers’ Handbook, 6th Edition, 1984.