Strategies and Activities Utilized for D&D in the

U.S. and Other Countries

AtomEco Intrernational Conference, Moscow

October 2012

© 2012 Fluor. All Rights Reserved.

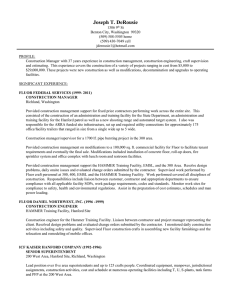

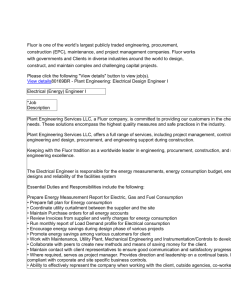

Fluor Corporation Overview

Fluor is one of the world’s leading publicly

traded engineering, procurement, construction,

maintenance, and project management

companies

2011 Revenue: $23.4 billion

2011 New Awards: $26.9 billion

Current Backlog: $39.5 billion

International: 75%

Energy &

Chemicals

Power

Global

Services

Government

#124 in the FORTUNE 500 in 2011

Industrial &

Infrastructure

Over 1,000 projects annually, serving more

than 600 clients in 66 different countries

Offices in 28 countries on 6 continents

Revenue by Business Segment

Celebrating 100 years in 2012

Workforce of over 42,000 men and women executing projects globally

1

Fluor’s Diversified Businesses

Energy & Chemicals

Chemicals

Downstream

Industrial &

Infrastructure

Government

Alternative Power Nuclear

Decommissioning

Commercial &

Institutional

Offshore

Solutions

Healthcare

Upstream

Life Sciences

ICA Fluor

Manufacturing

Mining & Metals

Telecom

Transportation

Water

Power

Solid-Fueled

Gas-Fueled/IGCC

Logistics &

Construction

Renewable

Energy

Contingency

Operations

Commercial

Nuclear

Services

Environmental

Compliance

Clients:

DOD

Power Services

DOE

DHS

DOL

NASA

UK Nuclear

Decommissioning

Authority

Global Services

Operations &

Maintenance

Construction

Equipment &

Tools

Staffing

2

Fluor’s Safety Performance

Total Case Incident Rate (TRIR) based on

more that 250 million hours worked

3

Nuclear Decommissioning

5 sample projects:

K Basin Spent Nuclear Fuel & Sludge Removal Project –

U.S. DOE, Hanford 1996-2006

Portsmouth Decommissioning Project – U.S. DOE, Ohio

2011-Present

Fernald Environmental Remediation Project – U.S. DOE

Ohio 1998-2007

Savannah River Nuclear Site (SRS) – U.S. DOE, South

Carolina 2008-Present

International Remediation Projects – U.K. and Russia,

2004-2008

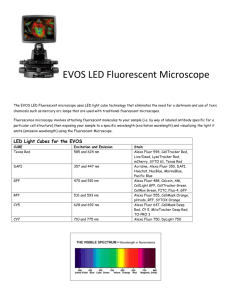

Workers using video equipment at

K-Basins, DOE

Hanford, Washington

4

Hanford K-Basins – High Hazard Project

95 percent of the radioactivity in Hanford’s reactor area Over 2.11 million kilograms of deteriorated and

damaged fuel removed, washed, dried, containerized,

and stored - Approximately 2.0 x 106 TBq

Hanford Site - 1517 km2

5

Hanford Project - K Reactor Fuel Basins

Highly radioactive fuel and

debris handling tool

Highly corroded metal

uranium fuels in a canister

Disintegrated fuel in

containers

105,000 fuel assemblies covered with

miscellaneous contaminated debris

6

Hanford Project - K Basin – Challenges Met

K-Basins as

it appeared

in 2000

2000

2007

Six engineered containers of sludge (46 m3) in

K-Basins while awaiting transfer & treatment

135.4 metric tons of debris, racks and

canisters removed from K-Basin

7

Hanford Project Management - Sludge Transfer

Booster Station and Hose

Transferred approximately 38 m3 of highly radioactive sludge from engineered containers in K

East to engineered containers in K West via approximately 0.8 km long hose-in-hose system

with 4 booster pump stations

8

Portsmouth Gaseous Diffusion Plant D&D

D&D of 415 buildings at Portsmouth Gas Diffusion

Plant formally used to enrich uranium

hexafluoride (UF6)

Fluor is responsible for performing the

decontamination and demolition (D&D) of three

massive uranium enrichment process buildings

– each covering more than 12-hectares

10-year, $2.1 billion contract awarded in 2011

1,600+ employees

1,500-hectare site

Fluor is providing economic development

advisors to bring new industry to the depressed

Portsmouth region

9

Fernald Environmental Remediation Project

Converted a 425-hectare U.S. DOE Fernald Uranium

Processing Complex to a Nature Reserve

Reduced original clean-up schedule by 12 years

and project cost by US $7.8 billion (original

schedule was 27 years and $12.2 billion).

Dismantled over 300 buildings, including 250

radiologically-contaminated buildings and

structures.

Excavated and shipped 1 million tons of waste

from 6 waste pits.

Removed 31 million pounds of uranium product

Disposed of 2.0 million cubic meters of

contaminated soil, including shipping 1.4 million

cubic meters off site.

Remediated a 90-hectare uranium-contaminated

groundwater plume.

DOE Fernald site, Ohio United States

Two silos and processing facilities

10

Sellafield – Resource Enhancement Contract

Resource Enhancement contract to improve cleanup and decommissioning

performance

Contract with British Nuclear Group

(BNG)

2-year contract focused on improving

cleanup and decommissioning.

Scope approx. $400 million/year out

of $1.2 billion Site budget.

Seconded 24 Senior Fluor employees

into site management team

Head of B30 ponds

Head of low-level disposal facility

Head of project controls

Reduced Site Lifetime Plan costs by

several hundred million dollars and

accelerated baseline schedules

Sellafield Site

11

Sellafield - B30 Sludge Inventory

350 tons of degraded fuel

1,204m3 sludge inventory

1,234 containers in the pond

12

Northern Dimension Environmental Partnership,

Russia

Provided Russia with program

management expertise and lessons

learned from U.S. nuclear

decommissioning projects

Project funded by European Bank for

Reconstruction and Development

(EBRD) and managed by Russian

Academy of Sciences, Nuclear Safety

Institute.

Fluor specialists were fully integrated

into project teams and worked hand in

hand with Russian experts.

Multi-purpose Submarine being dismantled

Introduced best practice processes used

for strategic planning.

Andreeva Bay, Murmansk Region

13

Management Objectives for Decommissioning

Four critical project management elements

assure that project objectives are SAFELY met

Technical Scope — Ensuring defined technical objectives are

achieved

Accelerating Schedule — Ensuring work is constantly brought

forward

Reducing Costs — Ensuring non-project costs are driven down

or eliminated

Risk Management — Ensuring project risks are identified and

managed

Fluor Confidential for Battelle &

BWXT