Occupational Health and Safety Management Systems

advertisement

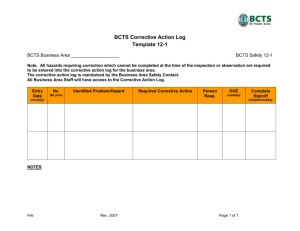

Occupational Health and Safety Management Systems (OHSMS) ANSI Z10 History of a Standard or…. Why do we need another standard? • • • • • • Roots are with ISO ISO 14000 TAG formed- 1993 Rosemont Meetings- May 6-7, 1996 ISO declines S & H Standard 1995 BSI 8800 gives birth to “18000” Std. ISO re-visits S&H standard, narrowly rejected-2000 • ILO develops guideline 2001 • OSHA still pushing VPP and “Program Standard” History of a Standard • AIHA approved as Secretariat- 1999 • ASSE Fights Need- Mid 1999 • AIHA Wins-Dec. 2000 • Committee formed mid 2000 • Committee Starts to MeetFeb. 2001 Rationale-Per AIHA • Harmonization will help US Business • Improve protection of worker safety and health • Help integrate quality, environmental and S&H Systems • Provide tools for future OSHA std. • Enhance US influence internationally • ANSI process best for stakeholders Rationale-For Some Members • Influence look of potentially far reaching standard • Influence look of standard that could be model for OSHA standard • Influence potential ISO standard • Be part of glamorous standards development process Intended Scope of Standard • Standard for S&H management principles and systems • Continuous improvement of system • Integration of S&H into business systems • Applicable to all size businesses • Compatible with existing international standards Interest Sectors on Committee • • • • • • Industry Labor Government Professional Associations General Interest Liaisons to relevant standards Early Meetings • Selection of composition of committee was in depth • Representation of all sectors was paramount • Argument for need was extensive • First meeting voted to exist!!!! • Struggled with what product should be Early Meetings • Salvos were fired • Acrimonious at best • First two meetings were “theory” • Decided on outline • Settled into routine • Trust developed Early Direction • Make something everyone could use • Performance standard • The “What’s” not “How To’s” • Not contradict existing international standards • Write “systems” oriented standard OSHMS Model Let the Games Begin! • • • • • Wrote Scope Argued Scope Identified “Sections” of Standard Argued “Sections” of Standard Formed subcommittees for drafting language for each of the sub-parts • Began drafting process • Insulted each others work • Formed editing committee Standard Outline • • • • • • • • 1. Scope, Purpose & Applications 2. Definitions 3. References 4. Management Leadership & Employee Participation 5. Planning 6. Implementation & Operation of OHSMS 7. Checking & Corrective Action 8. Management Review Scope, Purpose & Application • • • • • • • Performance Requirements Voluntary Req’s for Management Systems Not for OSHA Compliance All Size Employers Fits in with Other Standards MEANT TO REDUCE RISKS! Management Leadership & Employee Participation • Requires Management Develop OHSMS • Policy– Continually improve by reducing risk – Ensure employee participation – Conform with Orgs Requirements – Comply with laws and regulations Management Leadership & Employee Participation • Assign Responsibility & Authority for: →Implement./maint./perf. of OHSMS →Roles & Responsibilities →Resources • Employee Participation by Providing: →Provide with time and resources →Timely access to information →Remove obstacles to participation Planning • • • • • Conduct Initial Review Identify Hazards and Risks Assess & Prioritize Issues Set Objectives Develop Implementation Plans Planning- Initial Review • • • • • • The Organization shall gather and review information regarding: Relevant business management systems Hazards, risks and controls Resources Relevant Regs, Stds, Internal Requirements Assessments Other relevant activities Planning-Ongoing Review Org shall establish ongoing review process based on: • Implementation and operations • Evaluations and corrective actions • Management review PlanningAssessment & Prioritization The Process Shall: • Assess level of risk • Establish priorities • Identify casual factors • Set Objectives • Focus on system improvement • Document implementation plans • Assign resources Implementation & Operation • • • • • • • • Identify Operational Elements of Plan Identify Risk Controls Hierarchy of Controls Design Review/Management of Change Procurement Contractors Emergency Preparedness Education and Training Implementation and Operation • Communication • Document Control • Records Control Implementation-Operational Elements • Identify required elements for system • Integrate into management plan ImplementationHierarchy of Controls • • • • • Elimination Substitution Engineering Administrative Personal Protective Equipment Implementation-Design Review & Management of Change • New Processes or Operations • Changes to existing operations, suppliers, services etc. Implementation-Procurement • Identify risks associated with purchased products, raw materials • Establish requirements for supplies, equipment, raw materials • Ensure purchased products conform to requirements Implementation-Contractors • Evaluate contractor activities • Contractor selection criteria • Coordination of OHSMS activities ImplementationEmergency Preparedness • Develop plans based on potential scenarios • Periodic testing of plans Implementation Education, Training & Awareness • Assess and define competence needed • Ensure appropriate training • Remove barriers to participation • Provide in language employees understand • Ensure trainers are competent Implementation-Communication • Communicate information regarding OHSMS to all levels of employees • Prompt reporting of incidents • Remove barriers to reporting • Encourage employees to make recommendations for corrective actions ImplementationDocument & Record Control • Have process to create and maintain documents • Have document revision process • Have retention process Checking & Corrective Action • • • • Monitoring & Measurement Audits Incident Investigation Corrective & Preventative Actions • Responsibilities and Authorities • Checking & Corrective Action Continual Improvement Evaluation & Corrective Action Monitoring & Meaurement • • • • • Physical inspections Exposure assessment Injury/Illness tracking Employee input Occupational health assessment Evaluation & Corrective ActionAudits • Establish protocols • Determine frequency and scope of audits • Select expertise • Document results Evaluation & Corrective ActionIncident Investigation • Develop process to investigate incidents • Have corrective and preventative action system • Feed back into process Management Review • Periodic Assessment • Done by Top Management • Create & Track Recommendations • Document and Report Difference twixt Audit’s, Inspections and Reviews • • • • Inspection/Tests…….. Snapshot of the moment Audits…….. Measure against pre-agreed benchmark, protocol driven • Reviews……. • “State of the Union” • Risks vs. the System Timeline • Dec 03- Review of Final Draft • Jan 04- 60 Day Peer Review • April 04- Post Peer Review Final Draft for vote • July 04- Public Review • Second Half ’04- Respond to Comments • 2005- Standard Vote • Standard Approved July 25th, 2005 In Summary • • • • Performance Standard Fairly Brief-No “Sub-standards” Management Systems Standard Blends with ISO and other OSH Standards • Limits Documentation • Fits All Business Sizes • Continuous Improvement Questions?