provide for the current PEM rules

advertisement

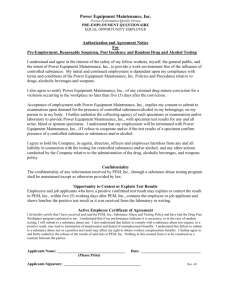

TEXTILES AND CLOTHING IN THE REVISION OF THE LIST RULES OF ORIGIN OF THE PEM CONVENTION April 2013 Albert HENDRIKS DG TAXUD – Unit B3 Rules of origin Content • • • • • • • • • 1) 2) 3) 4) 5) 6) 7) 8) 9) Introduction Origin rules for Textiles and Clothing Modernisation Tolerances The Printing rule What about dyeing EU perspective Position of other PEM partners Way forward 1) Introduction Present policy orientations for textiles and clothing for the revision of the Convention Perspective is the need to modernise the PEM rules to reflect current –and future- market realities. Reflections on the printing rule and further orientations on dyeing as an origin conferring operation. 3 2) Origin rules for Textiles and Clothing • For a preferential arrangement to be applicable to a given product, the latter should have originating status. • Products have originating status if they are either 'wholly obtained' or 'sufficiently worked or processed'. • • 'Wholly obtained' refers mainly to natural products grown, harvested etc., in a Party (country or territory) and to products made entirely from them. • Example: Fibres: • (Silk, Horse hair, Wool, Cotton, other vegetable fibres) • Although such products could normally qualify under a wholly obtained rule their origin is also defined in a Product Specific Rule of Origin (PSRO): • Manufacture from materials of any heading except that of the product. • The effect of this rule is twofold: - all the fibres (beyond the tolerance threshold) should be wholly obtained (as one cannot make wool from a product classified in a (4-digit) heading different from wool itself) - other materials used in the production of a product which is classified as silk, wool etc. may be non-originating • 'Sufficiently worked or processed' means that the nonoriginating materials or components must be sufficiently worked in order for the final product to obtain origin. • Sufficiently worked means sufficiently worked according to the specifications of the list rules. • criteria: • - the sufficient transformation/ change of heading criterion • - the maximum non-originating material value threshold criterion • - the specific process criterion • Example: Wovens • (example from EU GSP reformed RoO) • • Spinning of natural and/or man- made staple fibres or extrusion of man-made filament yarn or twisting, in each case accompanied by weaving • or • Weaving accompanied by dyeing • or • Yarn dyeing accompanied by weaving • or Printing accompanied by at least two preparatory or finishing operations (such as scouring, bleaching, mercerising, heat setting, raising, calendering, shrink resistance processing, permanent finishing, decatising, impregnating, mending and burling), provided that the value of the unprinted fabric used does not exceed 47,5 % of the ex-works price of the product. 3) Modernisation • The current standard PEM rule defines the origin of the final product by taking into account the manufacturing process in relation to the non-originating materials used at the start of the processing. • The manufacturing process changes the characteristics of materials used in the production resulting in a new or different product. 9 • Current PEM rule for yarn: • Manufacture from: • - raw silk or silk waste, carded or combed or otherwise prepared for spinning, • - other natural fibres, not carded or combed or otherwise prepared for spinning, • - chemical materials or textile pulp, or • - paper-making materials • New approach has been used for the reform of EU GSP RoO • Identification of key manufacturing processes carried out in relation to the final product • The origin of the materials used in these manufacturing processes should not be taken into account. • • • • GSP rule for yarn: Spinning of natural fibres or extrusion of man-made fibres accompanied by spinning or twisting • The EU proposal for PEM adds additional process as compared to EU GSP reformed RoO. • EU proposal for PEM rule for yarns: • Spinning of natural fibres • or • Extrusion of man-made fibres combined with spinning • or • Twisting combined with gimping 4) Tolerances • The tolerance rule permits manufacturers to use non-originating materials up to a specific limit. • For textiles and clothing specific tolerance rules apply which are included in the introductory notes to the list rules. 14 • The standard PEM tolerance rules for Chapters 50-63: • when referring to the Explanatory Note 5: Allows for a tolerance up to 10% in weight of all the basic textile materials used, provided that the product is made from two or more basic textile materials. • when referring to the Explanatory Note 6: Allows a tolerance for materials, with the exception of linings and interlinings (of 8% in value and provided that the materials have undergone a change of tariff heading). 5) The Printing rule • The printing of fabrics or clothing articles represents an important manufacturing process and has been recognised as origin conferring when combined with specific additional processes and fulfils a value added criterion. 16 • The modernisation of the printing rule is one of the cornerstones of the EU proposal for the revision of the origin rules for the PEM. • The modernisation concerns the following elements: • 1: the creation of a simple printing rule which needs to be combined with another process • Printing (when combined with Weaving, Knitting/ Crocheting, Tufting or Flocking) is defined as: • a technique by which an objectively assessed function, like colour, design, technical performance, is given to a textile substrate with a permanent character, using screen, roller, digital or transfer techniques. 2: the creation of a standalone printing rule Printing (as standalone operation) is defined as a technique by which an objectively assessed function, like colour, design, technical performance, is given to a textile substrate with a permanent character, using screen, roller, digital or transfer techniques combined with at least two preparatory/finishing operations (such as scouring, bleaching, mercerizing, heat setting, raising, calendaring, shrink resistance processing, permanent finishing, decatising, impregnating, mending and burling), provided that the value of all the materials used does not exceed 50% of the ex-works price of the product. • The following operations do not qualify under this rule: • The adding of fugitive/non-permanent functionalities (including colour, design, technical performance) • The adding of logos whenever they are not integral part of the design • Printing on the selvedge in case this is the origin qualifying characteristic • The following operations: washing or dressing 6) WHAT ABOUT DYEING? • Similarities and differences as compared to the printing rule.. 21 7) EU PERSPECTIVE ON RULES OF ORIGIN FOR TEXTILES AND CLOTHING • - 'double transformation' ! • - strike the balance between the needs of more traditional and more innovative textile industries. • - allows more flexibility; allows more qualifying processes and processes at a higher transformation level; provides simplification; increases legal certainty. 22 8) POSITION OF OTHER PEM PARTNERS • - provide for a full relaxation, by allowing the manufacture from materials of any heading; • - provide for manufacture from materials of any heading except that of the product; • - provide for the current PEM rules; • - provide for the current PEM rules, while introducing a dyeing rule for a wide range of products. 23 9) The way forward • Given the divergent views which have been presented during consultations, no Party can escape making concessions or face the consequences of a status quo. • Revision of PEM rules without an agreement on new list rules for Chapters 50-63 would seriously diminish the significance of the exercise as a whole. 24 • Unit B3 – Origin of goods • European Commission DG Taxation and Customs Union • TAXUD-UNIT-B3@ec.europa.eu • http://ec.europa.eu/taxation_customs/customs/customs_duti es/rules_origin/preferential/index_en.htm