The Effects of Directional Drilling Fluids on the Environment

The Effects of Directional

Drilling Fluids on the

Environment

Shannan Casteel

Undergraduate Student (Professional Communication

Concentration)

Department of English

Tennessee Technological University

Cookeville, TN 38505

Project Summary

Problem: Directional Drilling Fluids may be damaging to the environment

Objective: To determine the effects of various Directional Drilling Fluids on the environment

Hypothesis: Directional Drilling Fluids have relatively no effect on the environment

Project Summary (cont.)

Null Hypothesis: Directional Drilling Fluids have a significant effect on the surrounding environment

Goals: To determine the effects of Directional

Drilling Fluids on the surrounding environment

Project Summary (cont.)

Plan: Visit several drill sites with multiple recordable variables and make “Before &

After” observations to determine the effects of

Directional Drilling Fluids on the surrounding environment

Expected Results: Relatively little or no environmental damage will occur

Introduction

Problem: Directional Drilling Fluids may be damaging to the environment

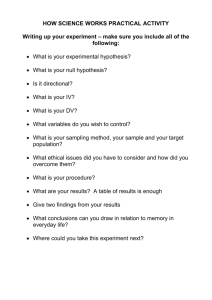

Pictures

Literature Review

Literature Summary:

Types of Drilling Fluids

Toxicity of Drilling Fluids

Water Based

Oil Based

Erosion Control

Possible benefit of drilling waste

Government Regulations

Literature Review

Black, A.J., L.H. Evans, Y.B. Tsvetnenko. 2000. Development of

Marine Sediment Reworker Tests with Western Australian

Species for Toxicity Assement of Drilling Mud. Toxicol 15 : 540-

548

Choi, Woo-Jung, Scott X. Chang, Ziying Hao. 2005. White

Spruce Response to Co-Composted Hydrocarbon-Contaminated

Drillng Waste: Effects of cmpost Age and Nitrogen Fertilization.

J. Environ. Qual. 34: 1319-1328.

Eide, I. 1990. A Review of Exposure Conditions and Possible

Health Effects Associated With Aerosol and Vapour From Low-

Aromatic Oil-Based Drilling Fluids. Annal Occupational Hygiene

34 : 149-157.

Fifield, Jerald S. 2005. Designing for Effective Sediment and

Erosion Control on Construction Sites. Environmental &

Engineering Geoscience. 11 : 177-190.

Literature Review (cont.)

Snyder, Robert E. “Environmentally safe dirll wastes.” World Oil. Jan. 2002.

Upton, D. P. 2000. Optimization of cutting fluid performance. International Journal of Production

Research 38 : 1219-1223.

Urquhart, John C. “Back to the Future in Silicate

Drilling Fluids.” World Oil. Oct. 1998.

Wassenborg, Marc. “Fluids Management and Batch

Drilling Minimize Waste and Cut Overall Costs.”

World Oil. Oct. 2000.

Literature Review (cont.)

Young, Steve. “High-performance waterbased mud improves results: Five component system matches invert emulsion mud.” World Oil. Apr. 2006.

Background

Drill Fluid Uses:

Drill head lubrication

Cutting

Transport waste to surface

Problems stem from:

Erosion

Groundwater contaminants

Miscellaneous

Some drilling fluids may aid tree-growth

Objectives & Hypotheses

Objective: To determine the effects of directional drilling fluid on its environmental surroundings.

Hypothesis: Fluid used for directional drilling has a minimal effect on its environmental surroundings.

Null Hypothesis: Directional drilling fluid has an adverse effect on its environmental surroundings.

Methods and Materials

1.

2.

3.

6.

7.

4.

5.

Visit several Directional Drill sites pre-bore

Attend several DD-3238 Directional Drill work sites

Collect various information about the bore (i.e. length, diameter, obstacles, surroundings)

Note the differences between the sites

Make observations about the surroundings

Note any changes that have occurred post-bore

Draw conclusions concerning the effects of the

Directional Drilling Fluids on the surroundings

Methods and Materials (cont.)

3

4

1

2

Data Form

1 2 3

Data Unit #

4 5

Operator Mud Type Mud

Liters

Used

6 7 8 9 10

Mud

Liters

Recovered

Bore

Length

Drill Rod

Size

Duration of Bore

Location

Expected Results and Benefits

Research will allow contractors, operators,

EPA regulators, and anyone who is concerned to determine the best type of

Drilling Fluids to use for the least impact on the surrounding environment

Project Timeline

Develop problem statement, hypothesis statement

Develop data form and experimental design

Visit drill sites and make observations

Analyze data

Draw conclusions

Week 1 Week 2 Week 3 Week 4 Week 5 Week 6 Week 7 Week 8

Budget

Personnel

Principal Investigator

Project Associate

Graduate Research Assistant

Subtotal

Staff Benefits

Subtotal

Equipment

Digital Camera

Gloves

Subtotal

Budget

Personal

Expenses Staff

$10,000.00

$0.00

$1,000.00

$0.00

$2,000.00

$0.00

$14,000.00

$0.00

$4,200.00

$0.00

$32,200.00

$0.00

$300.00

$0.00

$25.00

$0.00

$325.00

$0.00

Budget (cont.)

Travel

Air Fare

Per Diem @ $100/day

Local Transportation

Subtotal

Total Direct Costs

Indirect Costs

Grand Total

$900.00

$900.00

$100.00

$400.00

$32,925.00

$900.00

$33,825.00

$0.00

$0.00

$0.00

$0.00

End Presentation

Questions?