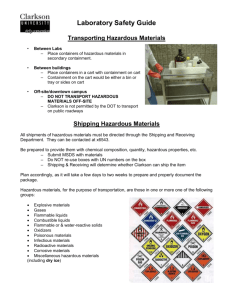

Hazardous Material Management plan

advertisement

HAZARDOUS MATERIAL MANAGEMENT PLAN Office of the Fire Marshal Glendale Fire Department December 2005 The City of Glendale Arizona has adopted the International Fire Code (IFC), including appendix chapter B, 2003 Edition. If your business uses, stores or handles hazardous materials and quantities exceeding the Permit Level Amounts of Hazardous Materials stated in the International Fire Code, you are required to obtain an annual Hazardous Materials Permit from the Glendale Fire Department. The permit constitutes permission to maintain, store, use or handle materials, or to conduct processes that produce conditions hazardous to life or property, or to install equipment used in connection with such activities. Information contained in this file will provide instruction on how to complete the General Occupancy Information Form, the Hazardous Materials Management Plan, and the Hazardous Materials Inventory Statement as required by the fire code. Renewals shall be submitted 60 days prior to expiration of permit. Please complete all forms and return them within 10 business days. These forms must be submitted on a CD in Excel format. If you have any questions or comments regarding the forms, please contact the Fire Marshal’s office at (623) 930-3401. 2 PENALTIES Failure to comply with the fire code, false statements or misrepresentations of information provided in the submittal may result in a criminal complaint being issued for violation of Section 109.3 of the fire code which is a class one misdemeanor punishable by a fine of not more than $2,500 or imprisonment not exceeding one year, or both such fine and imprisonment. The permit may be suspended or revoked when it is determined that the permit was issued in error or in violation of an ordinance, regulation or code. 3 PLEASE NOTE The person responsible for completing these reporting forms should have a good understanding of the chemicals and processes used in each operation, should know how to use material safety data sheets, and possess a basic understanding of building construction. Our goal has been to make this reporting process as user-friendly as possible, but the complexity of certain operations may involve a high degree of knowledge and technical skills that can make this reporting process very difficult to complete for the average person. We suggest that you purchase a copy of the 2003 International Fire Code for reference. We recommend that a third party reporting agency be consulted to complete these forms if you have difficulty in their preparation. 4 RESOURCES This CD also contains the following resources: Occupancy Information Form Hazardous Material Inventory Statement Form (HMIS) List of Definitions Key symbols for Facility Map Reference Tables: IBC table 414.2.2, IFC 105.6.11, IFC 105.6.17, IFC 105.6.21, IFC 2703.11.1 5 INTENT To provide instruction on the preparation and submittal of the General Occupancy Information Form, Hazardous Material Management plan (HMMP) and the Hazardous Materials Inventory Statement (HMIS) in order to meet compliance with the requirements of the City of Glendale Fire Code. 6 RESPONSIBILITY Persons responsible for the operation of areas in which hazardous materials are stored, dispensed, handled or used, shall be familiar with the chemical nature of the materials and the appropriate mitigating actions necessary in the event of fire, leak, or spill. 7 WHEN IS A HAZARDOUS MATERIALS PERMIT REQUIRED? A City of Glendale Hazardous Materials Permit is required to store, transport on site, dispense, use, or handle hazardous materials that equal or exceed amounts listed in Table 105.6.21. of the International Fire Code. Table 105.6.21 is included in the attached tables folder. 8 WHEN IS A OCCUPANCY INFORMATION FORM AND A HMIS REQUIRED TO BE FILLED OUT AND SUBMITTED? Whenever a Fire Department Permit is required to store hazardous materials. 9 WHEN IS A HAZARDOUS MATERIAL MANAGEMENT PLAN (HMMP) REQUIRED TO BE FILLED OUT AND SUBMITTED? When: Hazardous materials exceed EXEMPT amounts specified in the Fire Code; Fire Code requires exterior or detached storage of hazardous materials; If any part of the structure is rated as a “hazardous occupancy” SARA Title III extremely hazardous substance is used, handled or stored on site in quantities requiring a Fire Code permit and which are above threshold planning quantities; When otherwise determined necessary by the Fire Marshal because of unique circumstances. 10 WHAT IS INCLUDED IN A HAZARDOUS MATERIAL INVENTORY STATEMENT? An HMIS consists of a spreadsheet listing the following information for each individual control area: Product name or chemical name Hazard classification Chemical state and quantities stored or dispensed Storage conditions. 11 WHAT IS INCLUDED IN A HAZARDOUS MATERIAL MANAGEMENT PLAN? An HMMP is a site-plan indicating the following information: Storage and use areas (control areas) Location of emergency isolation and mitigation valves and devices. Product conveying piping containing liquids or gases, other than utility-owned fuel gas lines On and off positions of valves for valves that are of the self indicating type Storage plan showing the intended storage arrangement, including the location and dimensions of aisles The location and type of emergency equipment. The plans shall be legible and drawn approximately to scale. Separate distribution systems are allowed to be shown on separate pages. 12 WHAT IS A “CONTROL AREA” Control areas are spaces in a building or outside, where hazardous materials (not exceeding the maximum quantities allowed by the international fire Code) are stored dispensed, used, or handled. A building may have multiple control areas, provided the maximum allowable quantities within a single control area are not exceeded. Control areas shall be separated from each other by not less than a 1-hour fire barrier. Floor areas shall be separated by not less than a minimum rating of 2 hours. The maximum number of control areas in a building shall be in accordance with IBC table 414.2.2 . A copy of table 414.2.2 is provided in the tables folder. 13 What are the advantages of Control Areas? They provide an alternative method to a Group H occupancy classification. A high-hazard occupancy classification can be avoided, provided there are no control areas that contain in excess of the maximum allowable quantities indicated in IBC table 414.2.2 . They regulate quantities of hazardous materials per control area rather than per building area. Control areas, in conjunction with the maximum allowable quantity tables in 2703.1, utilize a density concept for hazardous materials. Without control areas, the maximum allowable quantities for a hazardous material would be limited to a single building area regardless of the overall size or height of the building. 14 IBC TABLE 414.2.2 ALSO KNOWN AS IFC TABLE 2703.8.3.2 15 16 17 PLEASE FOLLOW EACH OF THE FOLLOWING STEPS TO COMPLETE THE GENERAL OCCUPANCY INFORMATION FORM AND THE HAZARDOUS MATERIAL INVENTORY STATEMENT 18 STEP 1 Refer to IFC table 105.6.21 for each type and quantity of hazardous material that is stored on your property. A material safety data sheet (MSDS) should be used to obtain the correct information for each chemical. The retailer or manufacturer can provide this data sheet to you. 19 An MSDS sheet is required to be submitted with each separate hazardous chemical listed on the HMIS that does not have a CAS number. MSDS sheets can be submitted in hardcopy format or preferably copied to the CD with the HMIS. 20 Referring to table 105.6.21. Determine if any one chemical contained at your site equals or exceeds the amounts listed, or the total aggregate amount of the hazardous materials in the same classification exceed the amounts listed next to each classification. If so, a permit is required. NOTE: For retail and wholesale storage and display in Group M occupancies and Group S storage, see also IFC Table 2703.11.1 21 PERMIT AMOUNTS FOR HAZARDOUS MATERIALS PERMIT AMOUNTS FOR HAZARDOUS MATERIALS Table 105.6.21 Table 105.6.21 (cont) Combustible liquids Corrosive materials Gases Liquids Solids Explosive materials Flammable materials Gases Liquids Solids Highly toxic materials Gases Liquids Solids Oxidizing materials Gases Liquids o Class 4 o Class 3 o Class 2 o Class 1 Solids o Class 4 o Class 3 o Class 2 o Class 1 Organic peroxides Liquids o Class I o Class II o Class III o Class IV o Class V Solids o Class I o Class II o Class III o Class IV o Class V See section 105.6.17 below 200 cubic ft at NTB 55 gallons 1,000 pounds Manufacturing, storage, handling, sale or use of any quantity of explosive material, fireworks, or pyrotechnic special effects within the scope of chapter 33. (Except cryogenic fluids and liquefied petroleum gases) 200 cubic ft at NTB. See section 105.6.17 below 100 pounds Any amount Any amount Any amount (including oxygen) 504 cubic ft at NTB Any amount 1 gallons 10 gallons 55 gallons Any amount 10 pounds 100 pounds 500 pounds Any amount Any amount 1 gallon 2 gallons No permit required Any amount Any amount 10 pounds 20 pounds No permit required Pyrophoric materials Gases Liquids Solids Toxic materials Gases Liquids Solids Unstable (reactive) materials Liquids o Class 4 o Class 3 o Class 2 o Class 1 Solids o Class 4 o Class 3 o Class 2 o Class 1 Water reactive Materials Liquids o Class 3 o Class 2 o Class 1 Solids o Class 3 o Class 2 o Class 1 Any amount Any amount Any amount 10 gallons 100 pounds Any amount Any amount 5 gallons 10 gallons Any amount Any amount 50 pounds 100 pounds Any amount 5 gallons 55 gallons Any amount 50 pounds 500 pounds PERMIT AMOUNTS FOR CRYOGENIC FLUIDS Table 105.6.11 TABLE OF CRYOGENIC FLUID Flammable Inert Oxidizing (includes O2) Physical or health hazard not indicated above. INSIDE BUILDING (GALLON) More than 1 60 10 Any amount OUTSIDE BUILDING (GALLON) 60 500 50 Any amount 22 • ----------------------------------------------------------------------------_________________________ _________________________ _________________________ _________________________ _________________________ _________________________ _________________________ _________________________ _________________________ _________________________ _________________________ ______ PERMIT AMOUNTS FOR HAZARDOUS MATERIALS 105.6.17 Flammable and combustible liquids: 1. To use or operate a pipeline for the transportation within facilities of flammable or combustible liquids. This requirement shall not apply to the off-site transportation in pipelines regulated by the Department of Transportation (DOTn) nor does it apply to piping systems. 2. To store, handle or use Class I liquids in excess of 5 gallons in a building or in excess of 10 gallons outside of a building, except that a permit is not required for the following: 2.1 The storage or use of Class I liquids in the fuel tank or a motor vehicle, aircraft, motorboat, mobile power plant or mobile heating plant, unless such storage, in the opinion of the code official, would cause and unsafe condition. 2.2 The storage or use of paints, oils, varnishes or similar flammable mixtures when such liquids are stored for maintenance, painting or similar purposes for a period of not more than 30 days. 3. To store, handle or use Class II or IIIA liquids in excess of 25 gallons in a building or in excess of 60 gallons outside a building, except for fuel oil used in connection with oil burning equipment. 4. To remove Class 1 or Class II liquids from an underground storage tank used for fueling motor vehicles by any means other than the approved, stationary on-site pumps normally used for dispensing purposes. 5. To operate tank vehicles, equipment, tank plants, terminals, wells, fuel dispensing stations, refineries, distilleries and similar facilities where flammable and combustible liquids are produced, processed, transported, stored, dispensed or used. 6. To place temporarily out of service (for more than 90 days) an underground, protected above-ground or above ground flammable or combustible liquid tank. 7. To change the type of contents stored in a flammable or combustible liquid tank to a material which poses a greater hazard than that for which the tank was designed and constructed. 8. To manufacture, process, blend or refine flammable or combustible liquids. 9. To engage in the dispensing of liquid fuels into the fuel tanks of motor vehicles at commercial, industrial, governmental or manufacturing establishments. 10. To utilize a site for the dispensing of liquid fuels from tank vehicles, into the fuel tanks of motor vehicles at commercial, industrial, governmental or manufacturing establishments. 23 STEP 2 Determine the accurate “Occupancy Classification” for your building and each specific area where hazardous materials are stored. This information should be obtained from either the building or fire departments. It is possible to have multiple classifications. Examples: Assembly Group A Business Group B Educational Group E Factory Group F High Hazard Group H Institutional Group I Mercantile Group M Residential Group R Storage Group S Utility and Misc. Group U 24 STEP 3 Determine how many inside and outside control areas are located at your site. ( See IBC table 414.2.2 ). 25 STEP 4 Complete the General Occupancy Information Report The General Occupancy Information Report form is located on the CD in Excel 2000 format. The form is self-explanatory. Accurate occupancy classification and type of construction are important. This information can be obtained from the Glendale Building Safety Department at (623) 930-2800 if you are not sure. It is required that you submit this report on a CD along with the HMIS (and HMMP if required). A signed copy of the Occupancy Information report is required to also be submitted on hardcopy 26 General Occupancy Information Form GLENDALE FIRE DEPARTMENT Hazardous Materials Inventory Statement General Occupancy Information PART 1-Contact Information Example: Facility Information Business Name: Street Address: Telephone Number: FAX Number: E-mail Address: Owner Information Name: Address: City/State/Zip: Phone: 24 Hour Emergency Contacts Name: Home Phone: Work Phone: Cell Phone: Pager: 1 2 3 4 Fire Alarm (Y/N) Inside/Outside Part II-Building Information Occupancy Classification: Type of Construction: Roof Structure Type: Year Structure was Built: Total Square Footage: Number of Stories: Basements: Control Areas Occupancy Classification Square Footage AFES (Y/N) 1 2 3 4 5 6 Describe principle business activities involving hazardous materials: ANNUAL RENEWALS ONLY: I declare that there have been no changes to last years Hazardous Material Management Plan or the Hazardous Material Inventory Statements. Last submittal date: MM/DD/YY Declaration must be signed by owner/operator or authorized representative. I certify that the information as part of this Hazardous Materials Inventory Statement and/or Hazardous Materials Management Plan is true and correct to the best of my knowledge. Print Name: Signature: Date: 27 MM/DD/YY FMO 12/7/2005 If you submitted either an HMMP or a HMIS last year and “no” changes have taken place on either form, you do not have to resubmit another copy. Complete an updated General Occupancy Information Form and enter the date of last year’s submittal in the block provided. 28 STEP 5 A separate Hazardous Materials Inventory Statement (HMIS) is required for each separate control area. A copy of the HMIS is contained on this disk in Excel format. Additional copies of the HMIS can be made from disk for each control area. 29 STEP 6 Fill in the company name, control area, address, and date at the top of the page. If the control area is protected by an approved automatic fire extinguishing system, please mark “yes” in the space provided. COMPANY NAME: ADDRESS: Item # Product or Chemical Name Material Classification Class Comb. Liq. / Cryogenic / I / II / etc CAS # Explosive / Flam. Liq. / Oxidizer / etc. Solid STORAGE Liquid Gas Pounds Gallon cubic ft (cubic feet) (pounds) at NTB CONTROL AREA: DATE: SPRINKLERED Y/N USE-CLOSED SYSTEM Solid Liquid Gas Pounds Gallon cubic ft USE-OPEN SYSTEM NFPA 704 Solid Liquid Health Flamm React Pounds Gallon (Blue) (Red) Spec (Yellow ) (White) 30 Column descriptions: Item # Use this space to indicate each separate item that you are logging. The correct format is 1,2,3,4, etc. Product or Chemical Name The official name of the product. Material Classification What is the common classification of the product (Combustible, flammable liquid, explosive, oxidizer, organic peroxide, flammable solid, etc.) Class For products that break down into different classifications (example: Class 4 oxidizer, or Class III organic peroxide). COMPANY NAME: ADDRESS: Item # Product or Chemical Name Material Classification Class Comb. Liq. / Cryogenic / I / II / etc Explosive / Flam. Liq. / CAS # STORAGE Solid Liquid Pounds Gallon Gas 31 cubic ft Quantities in brackets indicate quantity units in brackets at the head of each column. STORAGE Solid Liquid Gas USE-CLOSED SYSTEM Solid Liquid Gas USE-OPEN SYSTEM Solid Liquid Pounds Gallon cubic ft Pounds Gallon cubic ft Pounds Gallon [cubic feet] [pounds] at NTB [cubic feet] [pounds] at NTB [cubic feet] [pounds] 10 [1] [1] Pound 10 Gallons 32 REPORTING GUIDELINES Mixtures shall be classified in accordance with hazards of the mixture as a whole. When a material has multiple hazards, all hazards shall be addressed. If the aggregate total for any product/chemical meets or exceeds the permit levels in any classification then they shall be reported. If the products/chemicals to be bulked are stored/used in different control areas in your facility, each location will require a separate entry on the HMIS. Products/chemicals that are in temporary locations (awaiting transport on shipping dock, etc.) shall be reported from their primary or permanent location. 33 CONVERSION Where quantities are indicated in pounds and when the weight per gallon of the liquid is not provided to the fire code official, a conversion of 10 pounds per gallon shall be used. 34 CAS# CAS Registry Numbers, (often referred to as CAS RNs or CAS Numbers) These are unique identifiers for chemical substances. A registry number itself has no inherent chemical significance but provides an unambiguous way to identify a chemical substance or molecular structure when there are many possible systematic, generic, proprietary, or trivial names. A CAS (Chemical Abstracts Service) Registry Number is a unique identifier that tells you, for example, that acetone and dimethyl ketone are actually the same substance. From a safety and inventory perspective, CAS numbers uniquely identify a chemical, but not necessarily the manufacturer or concentration. Storage The keeping, retention, or leaving of hazardous materials in closed containers, tanks, cylinders, or similar vessels or vessels supplying operations through closed connections to the vessel. Storage is divided into that of solids, liquids and gases. COMPANY NAME: ADDRESS: Item # Product or Chemical Name Material Classification Class Comb. Liq. / Cryogenic / I / II / etc Explosive / Flam. Liq. / CAS # STORAGE Solid Liquid Pounds Gallon Gas cubic ft 35 Use-Closed System Use of a solid or liquid hazardous material involving a closed vessel or system that remains closed during normal operations where vapors emitted by the product are not liberated outside of the vessel or system and the product is not exposed to the atmosphere during normal operations; and all uses of compressed gases. Examples of closed systems for solids and liquids include product conveyed through a piping system, into a closed vessel, system or piece of equipment. Storage is divided into that of solids, liquids and gases. CONTROL AREA: DATE: USE-CLOSED SYSTEM Solid Liquid Gas SPRINKLERED Y/N USE-OPEN SYSTEM NFPA 704 Solid Liquid Health Flamm React Spec 36 Use-open system The use of a solid or liquid hazardous material involving a vessel or system that is continuously open to the atmosphere during normal operations and where vapors are liberated, or the product is exposed to the atmosphere during normal operations. Examples of open systems for solids and liquids include dispensing from or into open beakers or containers, dip tank and plating tank,operations. Storage is divided into that of solids and liquids. NFPA 704 Hazard Identification ratings system (the familiar NFPA "hazard diamond" shown on the right) for health, flammability, and instability. These numbers can be obtained from the MSDS or The NFPA's Fire Protection Guide to Hazardous Materials. 37 Cabinets If this chemical is stored in an approved hazardous material cabinet, check “yes”. Or “no,” if it is not. Safety Cans If this chemical is stored in an approved safety can, check “yes.” Or “no,” if it is not. 38 15 PSI SPRINKLERED Y/N USE-CLOSED SYSTEM Solid Liquid Gas Pounds Gallon (cubic feet) (pounds) USE-OPEN SYSTEM NFPA 704 Solid Liquid Health Flamm React cubic ft Pounds Gallon at NTB (cubic feet) (pounds) (Blue) (Red) Spec (Yellow ) (White) 15 PS1 Y/N DATE: CABINETS Y/N . CONTROL AREA: SAFETY CANS Y/N This only applies if the chemical is a flammable or combustible liquid. If it is flammable or combustible, and it is stored or used at pressures greater than 15 psi, enter “Y” for yes. Otherwise enter “N” for no. 39 STEP 7 Prepare a Hazardous Material Management Plan (if required). A basic drawing of the facility site is required. The following items need to be included: Storage and use areas (control areas) Location of emergency isolation and mitigation valves and devices Product conveying piping containing liquids or gases, other than utility-owned fuel gas lines On and off positions of valves for valves that are of the selfindicating type Storage plan showing the intended storage arrangement including the location and dimensions of aisles. Location and type of emergency equipment. Plans shall be legible and drawn approximately to scale. Separate distribution systems are allowed to be shown on separate pages. Business name, address, person who drew the plan, and their phone number with area code. 40 The Hazardous Materials Management Plan needs to be drawn and transferred to a CD. It is required to be submitted with the Hazardous Materials Inventory Statement. 41 Included on this CD is a reference sheet which provide key symbols to be used for drawing the Facility Map. Key Symbols for Facility Map FDC Fire Department Connection ^^^^^ E OSY PIV E O S and Y Valve Evacuation Route Power Lines Post Indicator Valve Railroad Track Wire Fence 4th St. FH FCP (indicate by name) CG CG Compressed Gas Cylinders CG CG Compressed Gas Cabinet Risers for Sprinklers Fire Alarm Control Panel Hose Cabinet/Connection E Hazardous Material Drum Fire Extinguisher Fire Pump Hazardous Material Storage Cabinet Roof Fan GD HD Underground Storage Tank In Vault Insulated Tank IT WT Haz. Mat. FP UHT Pressurized Tank Water Tank Cryogenic Dewar HMD FX Above Ground Vertical Tank Above Ground Horizontal Tank HT PT CRY HC VT Streets and Alleys Fire Hydrant (indicate type and size) R Berms and Dikes Gas Detector ESD G HVAC Electrical Panel Electrical Shut Down Gas Shutdown HVAC Shut Down W (specify type) Heat Detector Wall Fan Key Water Shut-Off Fire Dept Key Box Visual Alarm SD Smoke Detector Audible alarm Storm Drain Floor Drain SPILL Roof Access Roof 1 4 Trash Material Safety Data Sheets INFO Emergency Info., Business Plan, Chemical Inventory, and Maps ECS Elevator E Spill Control Equipment Secondary Containment Attic Access Attic MSDS Emergency Control Station Evacuation Staging Area GS Guard Station HMS HAZARDOUS MATERIAL STORAGE HMH HAZARDOUS MATERIAL HANDLING Stairway (low to high) Trash/Refuse HMW HAZARDOUS MATERIAL WASTE 42 HMMP EXAMPLE 43 PHOTOGRAPHS Digital photographs are a tremendous asset to firefighters if they are dispatched to your business for an emergency. Photographs take some of the guesswork out of the lay of the building, which can improve firefighter safety. Digital photographs of the control areas, storage areas, mixing areas, and any other process or area that will help illustrate your operation are encouraged. 44 FREQUENTLY ASKED QUESTIONS How will this information be used? It will benefit the Fire Department in the prevention, control a mitigation of dangerous conditions related to storage, dispensing, use, and handling of hazardous materials; and when responding to emergency calls to your facility. Is it necessary for me to report each chemical in the facility? Yes Exceptions: 1. The quantities of alcoholic beverages, medicines, foodstuffs and cosmetics, containing not more than 50% by volume of water-miscible liquids and with the remainder of the solutions not being flammable, in retail sales, occupancies are unlimited when packaged in individual containers not exceeding 4 liters. 2. Application and release of pesticide products and materials intended for use in weed abatement, erosion control, soil amendment, or similar applications. Do I have to use the forms provided? Yes. It is important that we maintain uniformity in our records for all facilities reporting information. 45 How often must I complete a Hazardous Materials Inventory Statement? Annually, when you renew your permit. Also, an amended HMIS shall be provided within 30 days of the storage of any hazardous materials which changes or adds a hazard class or which is sufficient in quantity to cause an increase in the quantity which exceeds 5% for any hazard class. Is it important that I submit copies of the Hazardous Materials Inventory Statement? Yes. This will assist you in preparing the forms the following year. Do I need to submit the Material Safety Data Sheet (MSDS) with this form? Yes, for all chemicals that do not have a CAS number. Preferably copied to CD. 46 INFORMATION SUBMITTAL FOR RENEWAL OF HAZARDOUS MATERIALS PERMIT ONLY Submit CD with completed General Information Form, Hazardous Material Inventory Statement (HMIS) and (if required) the Hazardous Material Management Plan (HMMP), along with a signed hardcopy of the General Information Form to: Glendale Fire Marshal Hazardous Materials Unit 6835 N. 57th Drive Glendale, AZ 85301 FOR NEW CONSTRUCTION, TENANT IMPROVEMENTS AND ANY RELOCATION Submit CD with completed General Information Form, Hazardous Material Inventory Statement (HMIS) and (if required) the Hazardous Material Management Plan (HMMP), along with a signed hardcopy of the General Information Form to: Glendale City Hall 2nd Floor, Suite 263 Fire Department Plans Review 5850 W. Glendale Avenue Glendale, AZ 85301 47 WHAT HAPPENS WITH THIS INFORMATION? The information you submit will be examined to insure that the quantities listed do not exceed the maximum allowable quantities. Storage locations will be examined to insure that each hazardous material is safely separated from other incompatible materials. A copy will also be sent to the Glendale Fire Department Hazmat Unit in the event they are dispatched to your business. 48 We appreciate your efforts in completing this report. The information you provided is vital in helping us provide for the safety of the citizens of Glendale, the firefighters who serve this community, and your property. THANK YOU. 49