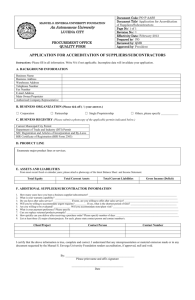

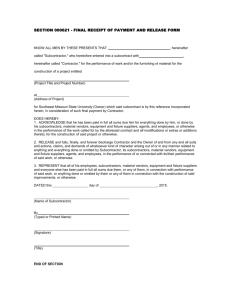

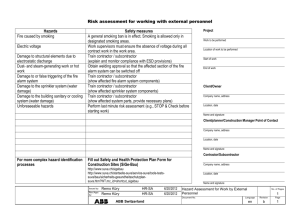

6. Legal and Other Requirements

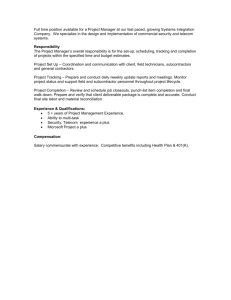

advertisement