IENG 4020

advertisement

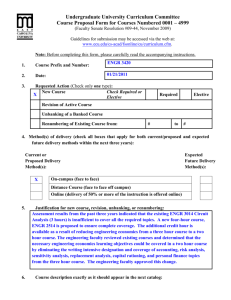

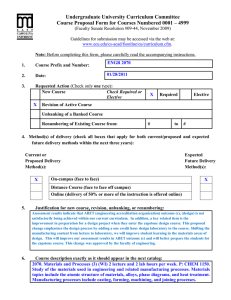

Undergraduate University Curriculum Committee Course Proposal Form for Courses Numbered 0001 – 4999 (Faculty Senate Resolution #8-16, March 2008) Guidelines for submission may be accessed via the web at: www.ecu.edu/cs-acad/fsonline/cu/curriculum.cfm. Note: Before completing this form, please carefully read the accompanying instructions. 1. Course Prefix and Number: IENG 4020 2. Date: February 16th 2011 3. Requested Action (Check only one type): New Course X Check Required or Elective Required Elective Revision of Active Course Unbanking of a Banked Course Renumbering of Existing Course from: # to # 4. Method(s) of delivery (check all boxes that apply for both current/proposed and expected future delivery methods within the next three years): Current or Proposed Delivery Method(s): X Expected Future Delivery Method(s): On-campus (face to face) X Distance Course (face to face off campus) X 5. Online (delivery of 50% or more of the instruction is offered online) X Justification for new course, revision, unbanking, or renumbering: The course title and the catalog description of the course are proposed to be updated to accommodate the latest body of knowledge based on input from faculty, alumni, the advisory board, and students. 6. Course description exactly as it should appear in the next catalog: Editorially revised 04-22-10 4020. Process and Systems Planning (3) (F) P/C: ITEC 3200 or MATH 2283. Strategy, product design, learning curves, forecasting, aggregate planning, stochastic inventory control, reliability models, linear programming, and scheduling for process and systems planning. 7. If this is a course revision, briefly describe the requested change: The faculty associated with this course in the Department of Technology Systems have met and recommended changes to the title and the catalog description of the course to accommodate an updated body of knowledge. 8. 9. 10. If writing intensive (WI) credit is requested, the Writing Across the Curriculum Committee must approve WI credit prior to consideration by the UCC. Has this course been approved for WI credit (yes/no/NA)? NA If Yes, will all sections be WI (yes/no/NA)? NA If service-learning (SL) credit is requested, the Service-Learning Advisory Committee must approve SL credit prior to consideration by the UCC. Has this course been approved for SL credit (yes/no/NA)? NA If Yes, will all sections be SL (yes/no/NA)? NA If foundations curriculum (FC) credit is requested, the Academic Standards Committee (ASC) must approve FC credit prior to consideration by the UCC. If FC credit has been approved by the ASC, then check the appropriate box (check at most one): English (EN) Science (SC) Humanities (HU) Social Science (SO) Fine Arts (FA) Mathematics (MA) Health (HL) Exercise (EX) 11. Course Credit: Weekly or Per Term = Credit Hours Lab Weekly or Per Term = Credit Hours s.h. Studio Weekly or Per Term = Credit Hours s.h. Practicum Weekly or Per Term = Credit Hours s.h. Lecture Hours 3 3 s.h. Editorially revised 04-22-10 Internship Weekly = Per Term or Credit Hours s.h. s.h. Other (e.g., independent study): Total Credit Hours 12. Anticipated yearly student enrollment: 13. Affected Degrees or Academic Programs: Degree(s)/Course(s) BS in Industrial Engineering Technology, BS in Industrial Technology 14. 3 s.h. 60 PDF Catalog Page 304 Change in Degree Hours None Overlapping or Duplication with Affected Units or Programs: NA Not Applicable Applicable (Notification and/or Response from Units Attached) 15. Approval by the Council for Teacher Education (required for courses affecting teacher education programs): NA Not Applicable Applicable (CTE has given their approval) 16. Instructional Format: please identify the appropriate instructional format(s): X Lecture Technology-mediated Lab Seminar Studio Clinical Practicum Colloquium Internship Other (describe below): Student Teaching 17. Statements of Support: (Please attach a memorandum, signed by the unit administrator, which addresses the budgetary and staff impact of this proposal.) X Current staff is adequate Additional staff is needed (describe needs below): Editorially revised 04-22-10 X Current facilities are adequate Additional facilities are needed (describe needs below): X Initial library resources are adequate Initial resources are needed (give a brief explanation and estimate for cost of acquisition of required resources below): X Unit computer resources are adequate Additional unit computer resources are needed (give a brief explanation and an estimate for the cost of acquisition below): X ITCS Resources are not needed Following ITCS resources are needed (put a check beside each need): Mainframe computer system Statistical services Network connections Computer lab for students Describe any computer or networking requirements of this program that are not currently fully supported for existing programs (Includes use of classroom, laboratory, or other facilities that are not currently used in the capacity being requested). Approval from the Director of ITCS attached 18. Syllabus – please insert course syllabus below. Do not submit course syllabus as a separate file. Do not include instructor- or semester-specific information in the syllabus. Strategy, product design, learning curves, forecasting, aggregate planning, stochastic inventory control, reliability models, linear programming, and scheduling for process and systems planning. (a) Citation of the textbook chosen for the course: Stevenson, W. J. (2009). Operations Management, 10th Edition with CD. McGraw-Hill Irwin, USA. ISBN: 0-07-337784-1. (b) Course objectives: Upon completion of the course, students will be able to: (a) Analyze the function of manufacturing management and its impact on strategy and competition (b) Create strategies for competitiveness and productivity (c) Apply forecasting tools in manufacturing system planning Editorially revised 04-22-10 (d) Analyze the impact of product design decisions on manufacturing system planning and effectiveness. (e) Apply principles of product and service design, including design for manufacturing, design for assembly (f) Apply world class manufacturing principles to enhance equipment and resource reliability (g) Create strategic capacity plans for products and services (h) Apply principles of inventory management for superior performance (i) Conduct hierarchical aggregate planning for manufacturing systems (j) Implementation of MRP and ERP systems in manufacturing and service setups (k) Apply and analyze scheduling algorithms. (c) Course content outline (a) Introduction to Operations Management (b) Competitiveness, Strategy, and Productivity (c) Learning Curves (d) Forecasting (e) Product and Service Design (f) Reliability Consideration in Designing Systems and Facilities (g) Strategic Capacity Planning for Products and Services (h) Location Theory and Analysis (i) Decision Theory in Capacity Planning (j) Inventory Management (k) Aggregate Planning (l) MRP and ERP (m) Scheduling (d) Course assignments and grading plan. Grade A B C D F Percentages 90-100 80-89.9 70-79.9 60-69.9 0-59.9 Assessment Assignments and quizzes Tests Class paper Total Percentages 20 60 20 100 Editorially revised 04-22-10