Chapter 13

Merchandise Planning

McGraw-Hill/Irwin

Retailing Management, 6/e

Copyright © 2007 by The McGraw-Hill Companies, Inc. All rights reserved.

13-2

Merchandise Management

Planning

Merchandise

Assortments

Retail

Communication

Mix

Merchandise

Planning

Systems

Buying

Merchandise

Pricing

13-3

Types of Buying Systems

The McGraw-Hill Companies Inc./Ken Cavanagh Photographer

Fashion Merchandise

Unpredictable Demand

Limited Sales History

Difficult to Forecast Sales

The McGraw-Hill Companies, Inc./Lars A. Niki,

photographer

Staple Merchandise

Predictable Demand

History of Past Sales

Relatively Accurate

Forecasts

13-4

Staple Merchandise Planning

Staple merchandise planning systems provide information

needed to assist buyers by performing three functions:

•Monitoring and measuring current sales for items at the

SKU level

•Forecasting future SKU demand with allowances made for

seasonal variations and changes in trend

•Developing ordering decision rules for optimum restocking

13-5

Staple Merchandise Planning

Most merchandise

at home

improvement

centers are

staples.

Ryan McVay/Getty Images

13-6

Inventory Levels for Staple Merchandise

13-7

Factors Determining Backup Stock

• Level of backup depends on product availability retailer

wishes to provide

• The greater the fluctuation in demand, the more backup

stock is needed

• The amount of backup stock needed is also affected by

the lead time from the vendor

• Fluctuations in lead time affect the amount of backup

stock

• Vendor’s product availability affects retailers’ backup

stock requirements

Relationship between Inventory

Investment and Product Availability

600

500

400

300

200

100

0

80

85

90

95

Product Availability (Percent)

100

13-8

13-9

Cycle and Backup Stock

Units Available

150 -

Order 96

Cycle

Stock

100 Buffer

Stock

50 -

0-

1

2

3

Weeks

4

13-10

Basic Stock List

•

Indicates the Desired Inventory Level for

Each SKU

– Amount of Stock Desired

Lost Sale Due

to Stockout

Cost of Carrying

Inventory

Inventory Management Report for

Rubbermaid Merchandise

13-11

13-12

Order Point

• Order point = the point at which inventory

available should not go below or else we will

run out of stock before the next order arrives.

• Assume Lead time = 0, Order point = 0

• Assume Lead time = 3 weeks, review time =

1 week, demand = 100 units per week

• Order point = demand (lead time + review

time) + buffer stock

• Order point = 100 (3+1) = 400

13-13

Order Point continued

• Assume Buffer stock = 50 units, then

• Order point = 100 (3+1) + 50 = 450

• We will order something when order point

gets below 450 units.

13-14

Calculating the Order Point

Order Point = (Demand/Day) x (Lead Time

+Review Time) + Backup Stock

167 units = (7 units x (14 + 7 days) + 20 units

So Buyer Places Order When Inventory in Stock

Drops Below 167 units

Merchandise Planning for

Fashionable Merchandise

• Steps in Developing a Merchandise Budget

Plan

• Set margin and inventory turn goals

• Seasonal sales forecast for category

• Breakdown sales forecast by month

• Plan reductions – markdowns, inventory loss

• Determine stock needed to support forecasted

sales

• Determine “open to buy” for each money

13-15

13-16

Merchandise Budget Plan

• Plan for the financial

aspects of a merchandise

category

• Specifies how much money

can be spent each month to

achieve the sales, margin,

inventory turnover, and

GMROI objectives.

• Not a complete buying

plan--doesn’t indicate what

specific SKUs to buy or in

what quantities.

Royalty-Free/CORBIS

Six Month Merchandise Plan for

Women’s Casual Slacks

13-17

13-18

Monthly sales percent Distribution to Season

(Line 1)

Sales % Dist. to

1. Month

6 mo. data

100.00%

April

21.00%

May

12.00%

June

12.00%

July

19.00%

Aug

21.00%

Sept

15.00%

13-19

Monthly sales (Line 2)

Sales % Dist. to

1. Month

6 mo. data

April

May

100.00%

21.00% 12.00%

2. Mo. Sales $130,000

$27,300 $15,600

June

July

Aug

12.00% 19.00% 21.00%

$15,600 $24,700 $27,300

Sept

15.00%

$19,500

13-20

Monthly Reductions Percent Distribution

(Line 3)

Reduction % Distribution to

3. Month

6 mo. data

100.00%

April

40.00%

May

14.00%

June

16.00%

July

12.00%

Aug

10.00%

Sept

8.00%

13-21

Shrinkage

Inventory loss caused by shoplifting, employee

theft, merchandise being misplaced or damaged

and poor bookkeeping.

Retailers measure shrinkage by taking the

difference between

1. The inventory recorded value based on

merchandise bought and received

2. The physical inventory actually in stores and

distribution centers

13-22

Monthly Reductions

Reduction % Distribution to

3. Month

6 mo. data

April

100.00%

40.00%

4. mo.

reductions $16,500

$6,600

May

14.00%

$2,310

June

16.00%

$2,640

July

12.00%

$1,980

Aug

10.00%

$1,650

Sept

8.00%

$1,320

Beginning of Month Stock to sales ratio

(Line 5)

5. BOM Stock to Sales Ratio

6 mo. data

April

4.0

3.6

May

4.4

June

4.4

July

4.0

Aug

3.6

Sept

4.0

13-23

13-24

BOM Stock (Line 6)

6. BOM Inventory

6 mo. data

98280

April

98280

May

68460

June

68640

July

98800

Aug

98280

Sept

78000

13-25

EOM Stock (Line 7)

7. EOM Inventory

6 mo. data

85600

April

68640

May

68460

June

275080

July

98280

Aug

78000

Sept

65600

13-26

Monthly Additions to Stock (Line 8)

8. Monthly additions to stock

6 mo. data April

113820

4260

May

17910

June

48406

July

26180

Aug

8670

Sept

8420

13-27

Open to Buy

Monitors Merchandise Flow

Determines How Much Was Spent and

How Much is Left to Spend

PhotoLink/Getty Images

PhotoLink/Getty Images

13-28

Six Month Open to Buy

13-29

Allocating Merchandise to Stores

Allocating merchandise to stores involves three decisions:

• how much merchandise to allocate to each store

• what type of merchandise to allocate

• when to allocate the merchandise to different stores

13-30

Allocation Based on Sales Volume

13-31

Different Geodemographic Segments

13-32

Apparel Size Difference Across Stores

13-33

Sales of Capri Pants by Region

13-34

Analyzing Merchandise Management

Performance

Three types of analyses related to the

monitoring and adjustment step are:

• Sell through analysis

• ABC analysis

• Multiattribute analysis of vendors

13-35

Sell Through Analysis Evaluating Merchandise Plan

A sell-through analysis compares actual and planned sales to

determine whether more merchandise is needed to satisfy demand or

whether price reductions are required.

13-36

ABC Analysis

An ABC analysis identifies the performance of individual

SKUs in the assortment plan.

Rank - orders merchandise by some performance

measure determine which items:

– should never be out of stock.

– should be allowed to be out of stock

occasionally.

– should be deleted from the stock selection.

ABC Analysis Rank Merchandise

By Performance Measures

13-37

Contribution Margin

Sales Dollars

Sales in Units

Gross Margin

GMROI

Use more than one criteria

Ryan McVay/Getty Images

13-38

Multiattribute Method for Evaluating Vendors

The multiattribute method for

evaluating vendors uses a

weighted average score for

each vendor. The score is

based on the importance of

various issues and the vendor’s

performance on those issues.

C Squared Studios/Getty Images

13-39

Multiattribute Method for Evaluating Vendors

Performance Evaluation of Individual

Brands Across Issues

Issues

Importance

Evaluation

of Issues (I)

(1)

Vendor reputation

Service

Meets delivery dates

Merchandise quality

Markup opportunity

Country of origin

Product fashionability

Selling history

Promotional assistance

n

Overall evaluation =

(2)

9

8

6

5

5

6

7

3

4

I *P

j

i 1

ij

Brand A Brand B Brand C Brand D

(Pa)

(Pb)

(Pc)

(Pd)

(3)

5

6

5

5

5

5

6

5

5

290

(4)

9

6

7

4

4

3

6

5

3

298

(5)

4

4

4

6

4

3

3

5

4

212

(6)

8

6

4

5

5

8

8

5

7

341

Evaluating a Vendor:

A Weighted Average Approach

n

I j * P ij

= Sum of the expression

i1

Ij

= Importance weight assigned

to the ith dimension

Pi

= Performance evaluation for

jth brand alternative on the

jth issue

1

= Not important

10

= Very important

13-40

13-41

Evaluating Vendors

A buyer can evaluate vendors by using the following

five steps:

• Develop a list of issues to consider in the evaluation (column 1)

• Importance weights for each issue in column 1 are determined by the

buyer/planner in conjunction with the GMM (column 2)

• Make judgments about each individual brand’s performance on each issue

(the remaining columns)

• Develop an overall score by multiplying the importance for each issue the

performance for each brand or its vendor

13-42

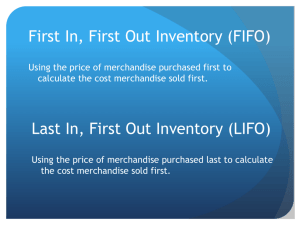

Retail Inventory Method (RIM)

Two Objectives:

– To maintain a perpetual or book inventory of

retail dollar amounts.

– To maintain records that make it possible to

determine the cost value of the inventory at

any time without taking a physical inventory.

13-43

Retail Inventory Method: The Problem

Retailers generally think of their inventory at retail price

levels rather than at cost. When retailers compare their

prices to competitors’, they compare their retail prices. The

problem is that when retailers design their financial plans,

evaluate performance and prepare financial statements,

they need to know the cost value of their inventory.

One way to do this is to take

physical inventories – time

consuming and costly!

Another way is to use

the Retail Inventory

Method (RIM)

13-44

Advantages of RIM

The retailer doesn't have to “cost” each

time.

Follows the accepted accounting practice

of valuing assets at cost or market,

whichever is lower.

Advantages of RIM cont’d

13-45

• Amounts and percentages of initial markups,

additional markups, markdowns, and

shrinkage can be compared with historical

records or industry norms.

• Useful for determining shrinkage.

• Can be used in an insurance claim case of a

loss.

13-46

Disadvantages of RIM

System that uses average markup.

Record keeping process involved is

burdensome.

13-47

Steps in RIM

• Calculate Total Merchandise Handled at Cost

and Retail

• Calculate Retail Reductions

• Calculate Cumulative Markup and Cost

Multiplier

• Determine Book Inventory at Cost and Retail

13-48

Retail Inventory Method Example

Total Goods Handled

Cost

Beginning inventory

Retail

$ 60,000

$ 84,000

Purchases

50,000

70,000

- Return to vendor

(11,000)

(15,400)

Net Purchases

39,000

54,600

Additional markups

4,000

- Markup cancellations

(2,000)

Net markups

2,000

Additional Transport.

Transfers in

- Transfers out

Net Transfers

Total Goods Handled

1,000

1,428

2,000

(714)

(1,000)

714

(1,000)

$100,714

$141,600

13-49

Retail Inventory Method Example

Total Goods Handled

Cost

Retail

Gross Sales

$ 82,000

- Consumer Returns & Allowances

( 4,000)

Net Sales

$ 78,000

Markdowns

6,000

- Markdown Cancellation

(3,000)

Net Markdown

3,000

Employee Discounts

3,000

Discounts to Customers

Estimated Shrinkage

Total Reductions

500

1,500

$ 86,000

13-50

Calculate Total Goods Handled at Cost and Retail

Record beginning inventory at cost and at retail

Calculate net purchases

Calculate net additional markups

Record transportation expenses

Calculate net transfers

The sum is the total goods handled

(c) Stockbyte/PunchStock

13-51

Calculate Retail Reductions

Record net sales

Calculate markdowns

Record discounts to employees and customers

Record estimated shrinkage

The sum is the total reductions

13-52

Calculate the Cumulative Markup and Cost Multiplier

Cumulative markup = total retail – total cost

total retail

If the cumulative markup is higher than the planned, then

the category is doing better than planned

13-53

Determine Ending Book Inventory at Cost and Retail

Ending book = Total goods handled at retail inventory at retail – total

reductions

The ending book inventory at cost is determined in the same way that retail

has been changed to cost in other situations – multiply the retail times

(100% - gross margin percentage)

Ending book = Ending book inventory x cost multiplier