Dinkel The Commercia..

advertisement

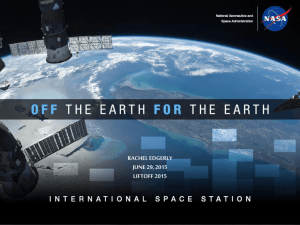

The Commercialization of Space Transportation April 2007 K-1 Reusable Space Transportation Vehicle 1 NASA Near Term ISS Dilemma International Space Station (“ISS”) – Approximately $100 billion investment to date by NASA alone – U.S. Government obligation to 16-partner countries to operate and provide cargo and crew transportation to and from ISS through 2015 – NASA currently uses the Space Shuttle to meet this obligation at a cost of approximately $1 billion per flight – Space Shuttle to be retired in 2010 – irrevocable decision – No other NASA capability to meet its commitment through 2015 Only near-term alternatives are Russian launch vehicles and foreign ATVs (European vehicle) and HTVs (Japanese vehicle) – U.S. law prohibits use of Russian vehicles after 2011 – ATV and HTV extremely expensive – None of these alternatives have the ability to return cargo to earth 2 The Opportunity Decision to Retire Space Shuttle in 2010 1978 Space Shuttle Flight 1st Extend life of the ISS ISS OPPORTUNITY 2022 2004 2010 Space Shuttle Retires 2015 Alternative NASA Solution RpK Key Advantages Lower recurring costs and greater reliability than any other current ELV competitor COTS Program Rapid launch and re-launch capability due to reusable design Positioned to be first-to-market with ISS re-supply capability Additional Revenue Opportunities Civil and Military Payload Launch Commercial Satellite Delivery Science and Technology Research Return downmass transportation capabilities unlike competitors NASA support Led by an experienced management team and supported by its original world-class team of strategic partners 3 NASA COTS Program Overview NASA COTS Program Two grant recipients, RpK and SpaceX, out of 20 competitors RpK strengths identified by NASA include: – Strong management team – Design and technical maturity of the K-1 – Multiple market approach of the Company’s business plan Space Act Agreement signed August 18, 2006 provides $207 million to RpK through 2009 – RpK retains nearly all intellectual property and commercial rights to technology (commercial program in which NASA does not end up owning the launch vehicle) – NASA provides important resources and technical expertise to the K-1 Program – NASA will be the Company’s largest customer – COTS Program is critically important to NASA and its goals RpK has successfully completed all NASA milestones to date and has received $32.1 million in milestone payments Latest Milestone: System Requirements Review Met ahead of schedule and under budget Successful completion of the NASA COTS Program will position RpK to win a commercial contract for ISS re-supply – a $1 billion annual opportunity 4 K-1 Reusable Space Transportation Vehicle Designed by Dr. George Mueller, designer of the Apollo and the Space Shuttle, to leverage existing technologies Upmass capability: launch cargo and satellite payloads into space Downmass capability: return cargo from both inside and outside Space Station to earth Fully reusable: designed for 100 flight life – 9-day turnaround Low-cost provider: starting at $30 million per launch, the K-1 costs significantly less expensive than any existing launch vehicle To date, more than $650 million has been invested in design and development of the K-1 vehicle, which is 75% complete 5 RpK Market Opportunities Unique Fully Reusable Design Will Enable RpK to Successfully Penetrate Multiple Markets Approx. $1 - 2 Billion Annual Market Opportunity Rocketplane Kistler ISS Re-Supply (NASA COTS) Civil and Military Payload Launch Commercial Satellite Delivery Science & Technology Research First affordable, reusable rocket addressing these markets 6 K-1 Reusable Space Transportation Vehicle Cargo / Payload Module Length: 5.9 m 2nd Stage – Orbital Vehicle (“OV”) Length: 18.6 m Diameter: 4.3 m Weight: 131,800 kg Key Design Characteristics 1st Stage – Launch Assist Platform (“LAP”) Length: 18.3 m Diameter: 6.7 m Weight: 250,500 kg Proven technologies adapted from other successful aerospace programs and applications reduce both development cost and technology risk Use existing flight qualified components (e.g., main engines) Designed with high factors of safety, including: – Triple-string, fault tolerant avionics system ensure reliable performance flight after flight – Integrated Vehicle Health Management (“IVHM”) systems automate and expedite checkout of the vehicle before and after each flight Designed for reliability, each K-1 has an expected life of 100 flights – nine day turnaround High launch rate and rapid turnaround significantly reduce the price of access to space Key Performance Metrics Approx. 5,700 kg delivered to LEO Approx. 1,570 kg delivered to GTO Approx. 2,775 kg of cargo upmass and downmass for ISS missions The K-1 design is based on mature, proven technologies 7 K-1: Systems Engineering RpK’s K-1 Essential Systems Engineering Tasks Are Complete Overview Systems engineering for reusable launch vehicles is dramatically greater than that of ELVs Both design and verification for the K-1 completed – Aerodynamics – Load, dynamics, vibroacoustics – Thermal – Mass properties – Timeline Trajectory design reference missions completed Vehicle schematics wiring and plumbing completed Interface requirements specification completed Cargo module currently undergoing Preliminary Design Review K-1 systems engineering is substantially complete 8 K-1: Development Responsibilities and Status Vehicle Exterior Structure • 21 of 23 Major Panels Complete LAP LOX Tank • 100% Complete Parachutes • Engineering 90% Complete • Mains – Complete • Drogue – Complete • Stabilization – 95% Complete • Mortar – Complete • Drop Tests - Complete OV LOX Tank • 100% Complete Thermal Protection System • Overall Design Complete • Detailed Design – 30% • Arc Jet Testing Planned • Production at Restart OV RP Tank • 100% Design Complete • 35% Fabrication Payload Module • 100% Structural Design Complete • 25% Fabrication Complete LAP RP Tank • 100% RP Design Completed • 30% Fabrication Complete OMS Engine • 40 Igniter Tests Complete • 29 Injector Tests Complete LOX Retention Tank • 100% Design Complete • 75% Fabrication Complete AJ-26 Engines • 9 Engines at Aerojet AJ-26 Engines • 37 Engines at Aerojet • Verification Engine in Test Airbags • OV Fabrication 50% Complete • LAP Fabrication 50% Complete • ¼ Scale Drop Tests Complete • Airbag Inflation Tests Complete Avionics Hardware • Vehicle Computer – Delivered • GPS /INS units – Delivered • TDRSS Receiver – Off the Shelf • FAA Transponder Delivered • SMU – In Manufacturing • PDU, MEC – In Test Avionics Software • GN&C Complete • Hardware in the Loop (HWIL) With Flight Hardware / Software Testing Final Assembly • Commenced 5/98 • 1st Stage LOX Tank Delivered 6/98 Launch Site • First Site in Australia • Contract Executed for Site Design and Construction • Launch Site Design 100% complete • Environmental Approval Received • Launch Operation Contract Signed • Native Title Agreement Signed • Site Ground Breaking • Export License Approved • Second Site Planned in U.S. The K-1 vehicle hardware is 75% complete 9 K-1: Launch Operations Inclination (Azimuth) 99º (-14º) Spaceport Woomera Latitude: Longitude: Elevation: 31º South 137º East 541 ft 84º (5º) 60º (33º) Launch Sites Overview 45º (55º) RpK plans to have two operational launch sites First site in Spaceport Woomera, Australia – Located in Woomera Test Range (“WTR”) in the South Australian outback – Launch azimuth covers all addressable market / customer requirements from one site – Contract executed for site design and construction – Launch site design nearly 100% complete – Environmental approval received – Operations agreement signed – Native title agreement signed – Technical assistance agreement signed K-1 launch site provides launch direction that meets customer requirements from one site 10 K-1: ISS Mission Profile Overview OV Return Phasing Burn ISS Altitude Mated with ISS/Separation OV De-Orbit Burn Phasing Altitude to Ldg. Phasing Altitude to ISS Coast Phase LAP Flyback OV MECO Altitude OV MECO OV Re-Entry Stage Separation LAP & OV Deploy Parachutes and Parachute Deployment Altitude Land at Launch Site using Airbags K-1 Vehicle Liftoff SPACEPORT WOOMERA: Woomera, S. Aust. 31o S Lat Typical Event Sequence Days 1-5 @ ISS Day 1 Event LAP Ignition Stage Separation OV Ignition OV MECO OV Mated with ISS Time 0:00:00 0:02:20 0:02:27 0:06:19 13:40:00 Event Crew Unloads Cargo Crew Loads Completed Experiments Time Days 1-3 Days 4-5 Assumes 5 day stay at ISS Day 6 Event OV Separation from ISS OV Phases to Landing OV De-Orbit Burn OV Re-entry OV Landing Time 0:00:00 0:45:00 1:30:00 2:15:00 2:30:00 Time in Hrs:Min:Sec 11 Looking To The Future 12 K-1 Path to the Moon 13