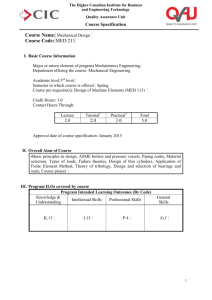

asme codes & standards

advertisement

ASME CODES & STANDARDS Departement of Metallurgical and Materials Engineering - University of Indonesia By : Dwi Marta Nurjaya ASME Background Founded: 1880 120,000 individual members; no corporate members <400 staff Not-for-profit organization Focused on technical, educational and research issues One of the world’s largest technical publishing operations Holds numerous technical conferences worldwide Offers professional development courses Sets internationally recognized industrial and manufacturing codes and standards that enhance public welfare and safety What is a standard? A standard can be defined as a set of technical definitions and guidelines that function as instructions for designers, manufacturers, operators, or users of equipment. Standards, not having the force of law, are considered voluntary and serve as guidelines. ASME publishes standards and accredits users of standards toensure that they are capable of manufacturing products that meet those standards. What is a code? A standard is a code when it has been adopted by one or more governmental bodies and is enforceable by law, or when it has been incorporated into a business contract. ASME Codes and Standards ASME’s Codes and Standards organization develops and maintains standards and conformity assessment programs First standard issued in 1884 Approx. 600 consensus standards Over 100 ASME standards committees Over 3,600 volunteer committee members Standards address pressure technology, nuclear, safety, standardization, and performance test codes Conformity Assessment programs to accredit manufacturers of equipment ASME Codes and Standards ASME’s Voluntary Consensus Process Openness, balance of Interests, consensus, due process American National Standards Institute (ANSI) accredited procedures Compliance with World Trade Organization (WTO) Technical Barriers to Trade (TBT) principles for international standards development Transparency, openness, impartiality and consensus, effectiveness and relevance, coherence, and development dimension. How does ASME produce codes and standards? ASME’s Council on Codes and Standards oversees six standards-developing supervisory boards and three advisory boards, which manage more than 100 committees and 3,600 volunteer members (see figure on next page). The supervisory boards are responsible for pressure technology, nuclear installations, safety codes, per formance test codes, conformity assessment, andstandardization. The advisory boards deal with international standards, hearings and appeals, and council operations. Standards development steps Initiate Standards Action Prerequisite technical work, R&D Draft standard – project team Distribute to cognizant groups for review and comment Standards Committee approval Public review Supervisory Board approval ANSI approval ASME Products Codes and Standards Conformity Assessment Programs Training Courses ASME Codes and Standards Component standards to ensure dimensional compatibility and to provide pressure / temperature ratings of piping, pipe threads, flanges, fittings, gaskets, etc. Piping design and construction standards. Boilers and pressure vessels. In-service inspection, fitness-for-service evaluation, repair and testing. Conformity Assessment ASME Product Certification Programs: Boilers & pressure vessels Nuclear components Nuclear materials Reinforced thermoset-plastic tanks Conformity Assessment (continued) ASME Accreditation Programs: Pressure relief device testing laboratories Boiler & pressure vessel inspection agencies (AIAs) Elevator inspector certification bodies ASME - Boiler and Pressure Vessel Code 12 volume or code sections: I. II. III. IV. V. VI. Power Boilers Materials Rules for Construction of Nuclear Facility Components Heating Boilers Nondestructive Examination Recommended Rules for the Care and Operation of Heating Boilers VII. Recommended Guidelines for the Care of Power Boilers VIII. Pressure Vessels IX. Welding and Brazing Qualifications X. Fiber-Reinforced Plastic Pressure Vessels XI. Rules for In-service Inspection of Nuclear Power Plant Components XII. Rules for Construction and Continued Service of Transport Tanks I. Power Boilers This Section provides requirements for all methods of construction of : power, electric, and miniature boilers; high temperature water boilers used in stationary service; and power boilers used in locomotive, portable, and traction service. And Requirements for: Boilers Fabricated by Welding; Boilers Fabricated by Riveting (by reference only); Watertube Boilers; Firetube Boilers; Feedwater Heaters; Miniature Boilers; Electric Boilers; Organic Fluid Vaporizer Generators. II. Materials Part A-Ferrous Material Specifications Part B-Nonferrous Material Specifications Part C-Specifications for Welding Rods, Electrodes, and Filler Metals Part D-Properties III. Rules for Construction of Nuclear Facility Components DIVISION 1 Subsection NB- Class 1 Components Subsection NC- Class 2 Components Subsection ND- Class 3 Components Subsection NE- Class MC Components Subsection NF - Supports Subsection NG - Core Support Structures Subsection NH - Class 1 Components in Elevated Temperature Service DIVISION 2 Code for Concrete Containments DIVISION 3 Containments for Transportation and Storage IV. Heating Boilers This Subsection provides requirements for: design, fabrication, installation and inspection of steam generating boilers, hot water boilers intended for low pressure service that are directly fired by oil, gas, electricity, or coal. It contains appendices which cover approval of new material, methods of checking safety valve and safety relief valve capacity, examples of methods of checking safety valve and safety relief valve capacity, examples of methods of calculation and computation, definitions relating to boiler design and welding, and quality control systems. V. Nondestructive Examination Requirements and methods for nondestructive examination which are referenced and required by other code Sections. It also includes manufacturer's examination responsibilities, duties of authorized inspectors and requirements for qualification of personnel, inspection and examination. Examination methods are intended to detect surface and internal discontinuities in materials, welds, and fabricated parts and components. A glossary of related terms is included. VI. Recommended Rules for the Care and Operation of Heating Boilers General descriptions, terminology and operation guidelines applicable to steel and cast iron boilers limited to the operating ranges of Section IV Heating Boilers. It includes guidelines for associated controls and automatic fuel burning equipment. Illustrations show typical examples of available equipment. Also included is a glossary of terms commonly associated with boilers, controls, and fuel burning equipment. VII. Recommended Guidelines for the Care of Power Boilers Guidelines to promote safety in the use of stationary, portable, and traction type heating boilers. The section provides guidelines to assist operators of power boilers in maintaining their plants as safely as possible. Emphasis has been placed on industrial-type boilers because of their extensive use. Contains Fuels for Routine Operation; Operating and Maintaining Boiler Appliances; Inspection; Prevention of Direct Causes of Boiler Failure; Design of Installation; Operation of Boiler Auxiliaries; Control of Internal Chemical Conditions VIII. Pressure Vessels Division 1 - Provides requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures exceeding 15 psig. Division 2 - Alternative Rules, provides requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures exceeding 15 psig. Division 3 - Alternative Rules for Construction of High Pressure Vessels, provides requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures generally above 10,000 psi. IX. Welding and Brazing Qualifications Rules relating to the qualification of welding and brazing procedures as required by other Code Sections for component manufacture. Covers rules relating to the qualification and re-qualification of welders, brazers, and welding and brazing operators in order that they may perform welding or brazing as required by other Code Sections in the manufacture of components. General Welding Requirements Welding Welding Welding Welding Procedure Qualifications; Performance Qualifications; Data; Forms; Brazing Brazing Brazing Brazing Procedure Qualifications; Performance Qualifications; Data; Forms. General Brazing Requirements X. Fiber-Reinforced Plastic Pressure Vessels Requirements for construction of an FRP pressure vessel in conformance with a manufacturer's design report. It includes production, processing, fabrication, inspection and testing methods required for the vessel. XI. Rules for In-service Inspection of Nuclear Power Plant Components Rules for the examination, in-service testing and inspection, and repair and replacement of components and systems in lightwater cooled and liquid-metal cooled nuclear power plants. XII. Rules for Construction and Continued Service of Transport Tanks Requirements for construction and continued service of pressure vessels for the transportation of dangerous goods via highway, rail, air or water at pressures from full vacuum to 3,000 psig and volumes greater than 120 gallons. ASME – BPVC “U Stamps” A Mark applied to the name plate of a pressure vessel by an authorized shop or other organization to indicate that the vessel has been fabricated in accordance with the ASME BPVC section ASME – BPVC “U Stamps” Power Boilers - Section I ASME – BPVC Stamps Heating Boilers - Section IV ASME – BPVC “U Stamps” Pressure Vessels - Section VIII Division 1 ASME – BPVC “U Stamps” Pressure Vessels - Section VIII Division 2 Pressure Vessels - Section VIII Division 3 ASME – BPVC “U Stamps” Reinforced Plastic Vessels - Section X Transport Tanks - Section XII ASME – BPVC “U Stamps” Nuclear Stamps The ASME Pressure Piping Code (B31) B31.1 - Power Piping B31.2 – Fuels Gas Piping B31.3 - Process Piping B31.4 - Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids B31.5 - Refrigeration Piping B31.8 - Gas Transportation and Distribution Piping B31.9 - Building Services Piping B31.11 - Slurry Transportation Piping Systems B31.12 - hydrogen piping B31G - Manual for Determining Remaining Strength of Corroded Pipelines