Challenges in Surveying - International Bunker Industry Association

advertisement

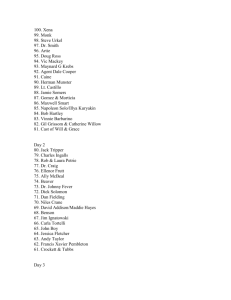

What are the challenges in surveying? IBIA Annual Convention 2014 - Hamburg. Michael Green – Marine Services Global Technical Manager – Bunker Fuel Testing 1 www.intertek.com Bunker Quantity Survey – Why? • Bunkers are typically the largest contributor to the operational costs of a ship, with the physical transfer of fuel often taking place thousands of miles away from the contracting offices. • As neither the buyer nor the seller is present to witness the bunker quantity transfer and sampling procedures on board, any post-delivery investigation on quantity shortages is usually futile and inconclusive. • Protests, demurrages, physical shortages, legal fees, management time, loss of goodwill, inconvenience and stress can add to overall costs. 2 www.intertek.com Bunker Quantity Survey (BQS) - Basics Pre-delivery tank measurements of bunker tanker and receiving vessel Post-delivery tank measurements of bunker tanker and receiving vessel - Sounding pipe's reference heights gauged for data check - Frequent soundings used to deter illegal transfer of bunker between tanks - Bunker temperature and vessel's trim taken for corrections - Monitor the presence of free water before and after delivery Supervision of bunker operations and quality sampling procedures "Representative" bunker sample(s) taken and distributed to a specified laboratory for quality testing - sealed with a proper label and acknowledged by all related parties Calculations of bunker delivery quantities Survey Reports and documentation of all measurements, delivery quantity, calculations and quality sampling presented in a systematic approach 3 www.intertek.com Bunkering Standards • International Standard ISO 13739 Procedures for transfer of bunkers to vessels • In Singapore we have SS600 - Singapore Standard Code of Practice for Bunkering • Gibraltar - Bunkering - Code of Practice • GOST Russian Standard 4 www.intertek.com SS600 ‘the Singapore Bunker Bible’ Singapore Standard Code of Practice for Bunkering – SS 600, covers pre-delivery, actual delivery and post-delivery checks and documentation. Main Aim to minimise bunker disputes Quality & Quantity Discrepancies MPA Issues Reminders Ship-owners, operators and charterers should advise their officers to follow the procedures and requirements as stipulated in the SS 600 when bunkering in Singapore. Only samples with seal numbers on BDN accepted 5 samples taken (more by agreement) Note of protest essential Any quality claim within 30 days (Only applicable in Singapore) 5 www.intertek.com Bunker Quantity Surveys - 2014 • Approx. 5000 BQS conducted in 2014 YTD. • These BQS have been conducted in 116 ports across the world. • Not all surveys are conducted in accordance with a recognised standard! • As a result problems / challenges are encountered. 6 www.intertek.com Bunker Quantity Surveys - Figures 7 www.intertek.com Bunker Quantity Surveys - Challenges 8 www.intertek.com Bunker Quantity Surveys - Challenges • Location of the survey often dictates problems to be noted / expected. • Certain problems are witnessed regularly in certain ports. • Local knowledge provides the key for avoiding problems / discrepancies. • So…………. 9 www.intertek.com Bunker Quantity Surveys - Challenges • What do we see? • European Mediterranean port - no barge calibration tables. • US Gulf port – pre-printed BDR based on nominated quantity. • Far East port – deliveries less than nominated quantity. • Southern Hemisphere country – local regs can prevent surveyor accessing the barge 10 www.intertek.com Bunker Quantity Surveys - Challenges 11 www.intertek.com Bunker Quantity Surveys - Challenges • What do we see? “two so called "magic pipes" have been found on board the vessel which were evidently placed there with the purpose of deceiving anyone relying on the vessel´s figures. Photos taken by our surveyor are attached for your ease of reference” 12 www.intertek.com Bunker Quantity Surveys - Challenges STATEMENT OF FACTS ON BEHALF OF OUR CLIENT(S), WE HAVE BEEN APPOINTED INSPECTORS ON THE ABOVE NAMED VESSEL. ACTING FOR AND ON THEIR BEHALF, WE HEREBY NOTIFY YOU THAT ON THE LISTED DATE AND TIME THE FOLLOWING OCCURRED. SUPPLIERS DENSITY IS USED FOR CALCULATION PURPOSES NO TRIM CORRECTIONS WERE FOUND IN BARGE'S TANKTABLES, MEASUREMENTS OF THE BARGE WERE MADE AT CENTRE POINT OF THE TANKS CARGO OPERATIONS IN COURSE OF BUNKERING WHICH MAY AFFECT TRIM. AFTER BUNKERING WE FOUND A SHORTAGE OF ABOUT 9 MT TO SURVEYORS CALCULATIONS AND ABOUT 10 MT TO CHIEF ENGINEER'S CALCULATION WHEN EXAMINING TANK TABLES, SURVEYOR CAN FIND NO PROVE THAT THIS IS THE CORRECT SOUNDING TABLE FOR THIS VESSEL, THIS IS NOT THE OFFICIAL SOUNDING TABLES, THERE IS NO CALIBRATION DATE HEIGHT OF THE TANKS OBSERVED IS SB 9,33M AND P 9,72M - IN THE TANKTABLES IT GOES UP TO 9 M BOTH SIDES THERE IS ALSO NO TRIM ADJUSTMENTS IN THE TANKTABLES CAPTAIN CALLED THE CHARTERERS AND THEY SUGGESTED THAT IF 2,5 MT WAS DEDUCTED FROM THE BDN NO LETTER OF PROTEST WOULD BE ISSUED SUPPLIER AGREED. 13 www.intertek.com V- Net - What is ‘V-Net’? • Many Chinese ship builders are calibrating vessels tanks via the use of V-Net. • What is V Net? • VNET: Net Volume of tanks taking structural reduction into consideration • Calculated by the below formula: VNET = VOLM x RED • VOLM: Gross volume of tanks without structural reduction • RED: Reduction coefficient due to structure in tanks, usually recognised as 0.98 in the shipbuilding industry. 14 www.intertek.com Bunker Quantity Surveys – Dispute Management THANK YOU! 15 www.intertek.com