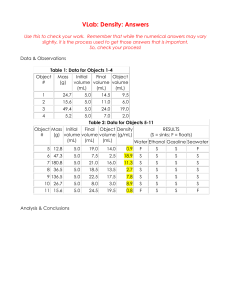

environmental assessment of wood derived hemicellulosic

advertisement

ENVIRONMENTAL ASSESSMENT OF WOOD DERIVED HEMICELLULOSIC ETHANOL USING ALTERNATIVE LCA MODELS Rachel Bowman, Anthony Halog Forest Bioproducts Research Initiative University of Maine Massachusetts Institute of Technology Western Kentucky University ACLCA Conference Presentation Format Project Overview Why? Description of System Functional Unit Assumptions Graphs and Results for LCA Models Pros and Cons of LCA Models Conclusions Project Overview Use Lifecycle Assessment (LCA) to evaluate the environmental impact of wood derived bioethanol Complete LCA with commercial SimaPro model, Eco-LCA , and openLCA Compare results of three LCAs and determine which model best represents the data Learn more about openLCA and EcoLCA Why? Energy crisis worldwide calls for new, renewable energy sources like bioethanol Many LCAs have been performed of corn derived bioethanol but not wood derived– wood doesn’t compete with food The near-neutral extraction process is fairly new and knowing its full lifecycle before widely implementing it is important Description of System Schematic of Near-Neutral Extraction Process to produce bioethanol1 Description of System Hemicellulose is extracted before pulping ◦ Reagents: anthraquinone and green liquor (sodium hydroxide, sodium sulfide, sodium carbonate) ◦ Green liquor- breaks apart hemicellulose ◦ Anthraquinone- works as catalyst to maintain pulp quality/quantity Functional Unit 9.8x109 Btu worth of ethanol (density .789 g/mL and 75,700 Btu per gallon) 39.5 tonnes ethanol, 45.1 tonnes acetic acid, 1000 tonnes pulp produced daily From 2,166 tonnes of wood chips From Mao’s provisional data Assumptions Average moisture content of the wood is 46% All wood is assumed to be a product of the Northeast Region of the United States Wood chipped in the field using mobile wood chipping technology Wood is composition 42.6% cellulose, 29.7% hemicellulose, 27.5%lignin, and .2% ash on a dry wood weight basis Allocation SimaPro 7.1 model was allocated by the mass of the products openLCA model would have been allocated by mass of products Eco-LCA allows only for economic allocation ◦ Allocated economically by value of wood chips, Kraft pulp, acetic acid, and bioethanol Data Collection Primary data– consultation with Dr. Genco in Chemical Engineering Dpt. Mao’s original WinGEMS model from thesis for LCI input-output data Secondary data: ◦ ◦ ◦ ◦ Wooley’s NREL Report US Data (preferrably Northeast [Maine]) Relevant timeframe Relevant processes LCI Databases Used SimaPro ◦ Ecoinvent ◦ Franklin ◦ USLCI Eco-LCA ◦ Eco-LCA standard ecosystem goods and services database OpenLCA ◦ Would have used Ecoinvent, like SimaPro SimaPro 7.1 Normalized Results Fossil fuels, respiratory inorganics, climate change, and acidification are most affected impact categories Biggest contributing processes to these environmental impacts are the liming/causticizing process, acid hydrolysis, wood chipping/wood production, and hog fuel boiler Heavy fuel oil consumption in the liming process contributes most to the fossil fuel use ◦ large amounts of oil must be pumped into the system for the liming process to take place Liming process also heavy in respiratory inorganics SimaPro 7.1 Normalized Results– Mass Allocation 6.5 6 5.5 5 4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 Carcinogens Resp. organic s Resp. inorgan ics Wood Chips Evaporation- Ethanol Liming and Causticizing Recovery Boiler Climate change Radiation Ozone layer Wood Extraction Acid Hydrolysis Fermentation Ecotoxicity Acidification / Eutrophicati Split Lignin Filtration Ethanol and Acetic Acid Separation Analyzing 1 p 'Ethanol Production'; Method: Eco-indicator 99 (H) V2.06 / Europe EI 99 H/H / normalization Normalized Results of SimaPro Model Land use Minerals Flash Tanks Liquid-Liquid Extraction Hog Fuel Boiler2 Fossil fuels SimaPro 7.1 Normalized Results– Economic Allocation 46000 44000 42000 40000 38000 36000 34000 32000 30000 28000 26000 24000 22000 20000 18000 16000 14000 12000 10000 8000 6000 4000 2000 0 Carcinogens Resp. organics Resp. inorganics Wood Chips Acid Hydrolysis Ethanol and Acetic Acid Separation Climate change Radiation Wood Extraction Lignin Filtration Hog Fuel Boiler2 Analyzing 1 p 'Ethanol Production'; Method: Eco-indicator 99 (H) V2.06 / Europe EI 99 H/H / normalization Ozone layer Split Liquid-Liquid Extraction Recovery Boiler Ecotoxicity Acidification / Eutrophication Flash Tanks Liming and Causticizing Land use Minerals Evaporation- Ethanol Fermentation Fossil fuels SimaPro 7.1 Single Score Results– Mass Allocation 2.6 2.4 2.2 2 1.8 kPt 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 Wood Chips Wood Extra ction Carcinogens Ozone layer Fossil fuels Split Flash Tanks Evaporatio n- Ethanol Resp. organics Ecotoxicity Acid Hydrol ysis Lignin Filtra tion Liquid-Liqui d Extractio Resp. inorganics Acidification/ Eutrophication Liming and Causticizin Fermentati on Ethanol and Acetic Acid Climate change Land use Analyzing 1 p 'Ethanol Production'; Method: Eco-indicator 99 (H) V2.06 / Europe EI 99 H/H / single score Single Score Representation of SimaPro model Hog Fuel Boiler2 Radiation Minerals Recovery Boiler SimaPro 7.1 Single Score Results– Economic Allocation 18 17 16 15 14 13 12 MPt 11 10 9 8 7 6 5 4 3 2 1 0 Wood Chips Wood Extracti on Carcinogens Ecotoxicity Split Flash Tanks Evaporation - Ethanol Resp. organics Acidification/ Eutrophication Acid Hydrolysis Lignin Filtration Resp. inorganics Land use Analyzing 1 p 'Ethanol Production'; Method: Eco-indicator 99 (H) V2.06 / Europe EI 99 H/H / single score Liquid-Liquid Extraction Climate change Minerals Liming and Causticizing Fermentation Radiation Fossil fuels Ethanol and Acetic Acid Hog Fuel Boiler2 Ozone layer Recovery Boiler SimaPro 7.1 Single Score Results The liming and causticizing process carries the heaviest environmental impact of all the processes in producing bioethanol Heavy fuel oil consumption in the liming process Respiratory inorganic output of the process, ◦ sulfate ions being released during the causticizing process SimaPro 7.1 Single Score Results Other process that has a heavy impact is the wood chip production. In line with the Bhander/Halog study that showed that wood chip production had a heavy environmental impact Includes everything from the planting of the trees to the felling and chipping process, Heaviest in climate change and respiratory inorganics ◦ The climate change category includes green house gas emissions from gases such as CO2, SOx, NOx, and CH4. Eco-LCA Emissions Results Emissions Normalization of Eco-LCA model Eco-LCA Emissions Results Showed that the pulp production process is far heavier in green house gas emissions than logging, acetic acid, or ethanol production Heaviest impact categories were ethanol and ammonia, in land, air, and water ◦ Ammonia accounted for is most likely the respective inorganic material that is shown in SimaPro model produced from the liming/ causticizing process and wood chipping Eco-LCA Emissions Results Emissions mostly from pulping process, which makes sense since the model is allocated economically Particulate matter (<10 µm) is shown, probably some of the climate change SimaPro is accounting for Eco-LCA CO2 Emission Results CO2 Normalization of Eco-LCA model Eco-LCA CO2 Emissions Results Show that more carbon is actually sequestered as a result of the production of ethanol than is emitted ◦ trees being used to feed the pulping plant sequester more carbon during growth than is emitted in pulping process Kraft pulping process doesn’t use (much) external energy ◦ Energy required is produced in the hog fuel and recovery boilers ◦ Plant is not using any external electricity from fossil fuels like coal or natural gas that would increase emissions Eco-LCA Energy Consumption Results Energy Normalization of Eco-LCA model Eco-LCA Energy Consumption Results Logging and chipping processes consume the most energy in process. ◦ heaviest in sunlight and wood energy Imply that trees absorb sunlight as part of their growth process Some of the wood waste is later used to produce steam in the hog fuel boiler The other energy consumed in the process was generally low in all categories, especially in that of fossil fuels. ◦ Any fossil fuel use can be attributed to the equipment used for logging and chipping, such as mobile wood chippers or the trucks that transport the chips to the Kraft Pulp Mill Eco-LCA Water Consumption Results Water Normalization of Eco-LCA model Eco-LCA Water Consumption Results The majority of the water consumed in pulping process Can be attributed to economic allocation Consumption of water for logging is the highest with respect to agriculture and feedstock water, Powerplant water had the highest total consumption in the process Eco-LCA Water Consumption Results Can likely be attributed to the fact that water coming to the Kraft Pulp Mill would be coming from a supply other than the public water source and being filtered and treated separately from the public drinking water. Water supply in any chemical plants would also be processed and filtered separately from the public water supply Water supply for the ethanol and acetic acid production is assumed to be the same as for the Kraft Pulp Mill OpenLCA (The Abbreviated Version) Issues getting openLCA database to load Designed to simply import complete SimaPro 7.1 model into openLCA in EcoSpold format ◦ EcoSpold formatting only available with SimaPro Developer version FBRI only has Analyst version Bottom Line: openLCA model was never completed due to software issues Pros and Cons- SimaPro Cons: ◦ Cost-- ~$14,000 (US) for permanent license for developer version ◦ Doesn’t account for ecosystem goods or services ◦ Doesn’t show graphically what specifically is contributing to each impact category ◦ Minimal US specific data Should improve in future versions as LCA becomes more popular in North America Pros and Cons- SimaPro Ecoinvent database was the most comprehensive database of models Allows simple loading of outside data and processes into the program Extensive tutorials, user guides, etc. for LCA beginners Many options for allocating, characterizing, and normalizing data (methods) ◦ Specifically used Ecoindicator in this study Pros and Cons- Eco-LCA Cons ◦ ◦ ◦ ◦ Not as many options in general as SimaPro Only set up to handle economic allocation Hard to enter outside data Only very simple tutorial available, a little difficult for an inexperienced user to figure out ◦ Difficult to transfer results out of flashplayer for viewing in papers, presentations, etc. Pros and Cons- Eco-LCA Pros ◦ Includes ecosystem goods and services– allows user to get bigger and better view of lifecycle ◦ While no user guide, developers are easily accessible for questions ◦ Free ◦ Provides graphical representation of different substances that are contributing to an impact category Pros and Cons- OpenLCA (In a theoretical world where SimaPro Developer was available) Cons ◦ Individual database didn’t load– what would someone do without another imported model? ◦ User manual is difficult to access but does exist http://www.openlca.org/uploads/media/Guide_to_testing_the_openLCA_framework_Alphaversion.pdf ◦ Still being developed– still some issues ◦ A little difficult to learn how to use Pros and Cons- OpenLCA (In a theoretical world where SimaPro Developer was available) Pros ◦ Includes file format converter to directly import data from another LCA model in SimaPro or Excel ◦ Flows set up allows for the production of a system model as well as an LCA ◦ Free and publicly available ◦ Good graphical representation once LCA is complete Conclusions Mass and economic allocation have about same results in SimaPro, so economic allocation is probably accurate Eco-LCA provides best representation of this data set despite allocation only economically Results of openLCA would have looked a lot like the SimaPro results, but provided an input-output model as well Conclusions The real advantage with Eco-LCA is the inclusion of ecosystem goods and services– gives much better ‘big picture’ outlook of system Using a free program makes it so that one can report their conclusions to anyone, whether they have a license for the program or not Conclusions It appears that the actual results from the Eco-LCA and SimaPro models are pretty similar Eco-LCA has different impact categories, but one can see how the high impact substances contribute to the more general impact categories in SimaPro Acknowledgements Funding-- provided by The National Science Foundation grants EEC-06 48793, EPS-05 54545 REU program/FBRI Dr. Halog Dr. Genco Shashi Dhungel and Binod Neopane, graduate students