Fall-2011-PDS

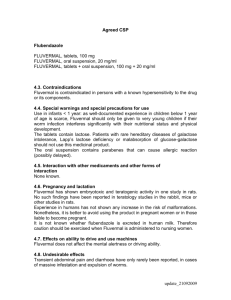

advertisement

Chapter 6: Product Specifications Product Design and Development Fifth Edition by Karl T. Ulrich and Steven D. Eppinger Product Development Process Planning Concept System-LevelDetail DevelopmentDesign Design Testing and Production Refinement Ramp-Up Remember that we are looking at an overall Product Development Process. We are going into more detail on Concept Development. We did a lecture, quiz and homework assignment on customer needs. Now we are ready to go to the next step in Concept Development. Concept Development Process Identify Customer Needs Establish Target Specifications Generate Product Concepts Select Product Concept(s) Test Product Concept(s) Set Final Specifications Plan Downstream Development Perform Economic Analysis Benchmark Competitive Products Build and Test Models and Prototypes Target Specs Final Specs Based on customer needs and benchmarking Based on selected concept, feasibility, models, testing, and trade-offs Development Plan Product Design Specifications • Basic control and reference document for the design and manufacture • Specific, measurable, testable criteria • “Unambiguous, Understandable, Correct, Concise, Traceable, Traced, Design Independent, Verifiable, Unique, Complete, Consistent, Comparable, Modifiable, Attainable” • Functional decomposition • Performance targets • Constraints (Demands, Musts) • Goals (Wishes, Wants) • Features The Blind Men and the Elephant A Hindu fable by John Godfrey Saxe from Elephants Ancient and Modern by FC Sillar and RM Meyler. It was six men of Indostan To learning much inclined, Who went to see the Elephant (Though all of them were blind), That each by observation Might satisfy his mind. The First approached the Elephant, And happening to fall Against his broad and sturdy side, At once began to bawl: `God bless me! but the Elephant Is very like a wall!' The Second, feeling of the tusk, Cried, `Ho! what have we here So very round and smooth and sharp? To me 'tis mighty clear This wonder of an Elephant Is very like a spear!' The Third approached the animal, And happening to take The squirming trunk within his hands, Thus boldly up and spake: `I see,' quoth he, `the Elephant Is very like a snake.' The Fourth reached out his eager hand, And felt about the knee. `What most this wondrous beast is like Is mighty plain,' quoth he; `'Tis clear enough the Elephant Is very like a tree!' The Fifth who chanced to touch the ear, Said: `E'en the blindest man Can tell what this resembles most: Deny the fact who can, This marvel of an Elephant Is very like a fan!' The Sixth no sooner had begun About the beast to grope, Than, seizing on the swinging tail That fell within his scope, `I see,' quoth he, `the Elephant Is very like a rope!' And so these men of Indostan Disputed loud and long, Each in his own opinion Exceeding stiff and strong, Though each was partly in the right, And all were in the wrong! So, oft in theologic wars, The disputants, I ween, Rail on in utter ignorance Of what each other mean, And prate about an Elephant Not one of them has seen! Writing a good PDS is very difficult • • • • • • Customer Regulatory Bodies Laws of Physics Functional Analysis Company Constraints Social, Political, and Legal Requirements The Product Specs Process • Set Target Specifications – Based on customer needs and benchmarks – Develop metrics for each need – Set ideal and acceptable values • Refine Specifications – Based on selected concept and feasibility testing – Technical modeling – Trade-offs are critical • Reflect on the Results and the Process – Critical for ongoing improvement Product Specifications Example: Mountain Bike Suspension Fork The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension NEED Imp reduces vibration to the hands. 3 allows easy traversal of slow, difficult terrain. 2 enables high speed descents on bumpy trails. 5 allows sensitivity adjustment. 3 preserves the steering characteristics of the bike.4 remains rigid during hard cornering. 4 is lightweight. 4 provides stiff mounting points for the brakes. 2 fits a wide variety of bikes, wheels, and tires. 5 is easy to install. 1 works with fenders. 1 instills pride. 5 is affordable for an amateur enthusiast. 5 is not contaminated by water. 5 is not contaminated by grunge. 5 can be easily accessed for maintenance. 3 allows easy replacement of worn parts. 1 can be maintained with readily available tools. 3 lasts a long time. 5 is safe in a crash. 5 • •• • • •••• • • • •••• •••• ••• • ••••• • • •••• •••• ••••• ••••• ••••• Maniray 2 # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 ST Tritrack Start with the Customer Needs •••• •••• ••••• •••• •• ••• ••• •••• ••••• ••••• • •••• • ••• ••• ••••• ••••• ••••• ••••• ••••• What are some customer needs for the catapult-like device? Size matters not. Need #s Metric # Establish Metrics and Units 1 1,3 2 2,6 3 1,3 4 1,3 5 4 6 5 7 5 8 6 9 7 10 8 11 9 12 9 13 9 14 9 15 10 16 11 17 12 18 13 19 14 20 15 21 16,17 22 17,18 23 19 24 19 25 20 26 20 Metric Attenuation from dropout to handlebar at 10hz Spring pre-load Maximum value from the Monster Minimum descent time on test track Damping coefficient adjustment range Maximum travel (26in wheel) Rake offset Lateral stiffness at the tip Total mass Lateral stiffness at brake pivots Headset sizes Steertube length Wheel sizes Maximum tire width Time to assemble to frame Fender compatibility Instills pride Unit manufacturing cost Time in spray chamber w/o water entry Cycles in mud chamber w/o contamination Time to disassemble/assemble for maintenance Special tools required for maintenance UV test duration to degrade rubber parts Monster cycles to failure Japan Industrial Standards test Bending strength (frontal loading) Imp Units 3 dB 3 N 5 g 5 s 3 N-s/m 3 mm 3 mm 3 kN/m 4 kg 2 kN/m 5 in 5 mm 5 list 5 in 1 s 1 list 5 subj 5 US$ 5 s 5 k-cycles 3 s 3 list 5 hours 5 cycles 5 binary 5 MN Metrics Exercise: Ball Point Pen Customer Need: The pen writes smoothly. Additional Areas to Consider • Physical requirements • Functional requirements • Service environment (comprehensive: insect and bird damage) • Kinematics – type of motion, direction, velocity, acceleration • Forces - direction, magnitude, frequency, resonance, stiffness • Materials – properties of final product, flow of materials, design for manufacturing Design Specification Checklist • • • • • • • • • • • • • Performance At what speed must it operate? How often will it be used (continuous or discontinuous use)? How long must it last? Environment (during manufacture, storage and use) All aspects of the product’s likely environment should be considered: for example temperature, humidity, risk of corrosion, vibration. Target product cost This is strongly affected by the intended market. Competition What is the nature and extent of existing or likely competition? Does our specification differ from the competition? If so, why? Quantity and manufacture Should it be made in bulk, in batches, or as individual items made to order? Does it have to be a particular shape? Can we make all the parts or must we buy some in? Materials Are special materials needed? Do we have experience of working with the likely candidate materials? Quality and consistency What levels of quality and consistency does the market expect for this product? Does every product have to be tested? Standards Does the product need to conform to any local, international or customer standards? Is the product safe? Patents Are there any patents we may either infringe or register? Packaging and shipping How will the product be packaged? How will the product be distributed? Aesthetics and ergonomics Is the product easy and fun to use? Is it attractive to the right customer? Market constraints Does a market already exist or must it be created? What is the likely product lifetime? How long do we have to get the product to market? What are the customers’ likes and dislikes? Company constraints Does the product fit in with company image? Are we constrained in material or process choice? Are there any political considerations? http://labspace.open.ac.uk/mod/resource/view.php?id=194654 More Things to Think About • Production – Factory limitations, outsourcing, tolerancing (You may wait on actual tolerances until later – just think about the big picture.) • Assembly • Transport • Costs • Schedule • Life-cycle issues • Human factors Social, Political, Legal • Safety and environmental regulations • STANDARDS – – – – – – www.ul.com www.outdoorindustry.com www.cpsc.gov www.astm.org www.nfpa.org http://www.nssn.org/ • Safety and product liability • Patents and intellectual property • Bending strength (frontal loading) • Japan Industrial Standards test Special tools required for maintenance Time to disassemble/assemble for maintenance Cycles in mud chamber w/o contamination Time in spray chamber w/o water entry • Unit manufacturing cost • Instills pride • Fender compatibility • Monster cycles to failure • UV test duration to degrade rubber parts • Time to assemble to frame • Maximum tire width • Wheel sizes • Steertube length • Headset sizes • 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 Lateral stiffness at brake pivots • 8 Total mass • 7 Lateral stiffness at the tip • 6 Rake offset • 5 Maximum travel (26in wheel) Spring pre-load Need 1 reduces vibration to the hands. • 2 allows easy traversal of slow, difficult terrain. 3 enables high speed descents on bumpy trails. • 4 allows sensitivity adjustment. 5 preserves the steering characteristics of the bike. 6 remains rigid during hard cornering. 7 is lightweight. 8 provides stiff mounting points for the brakes. 9 fits a wide variety of bikes, wheels, and tires. 10 is easy to install. 11 works with fenders. 12 instills pride. 13 is affordable for an amateur enthusiast. 14 is not contaminated by water. 15 is not contaminated by grunge. 16 can be easily accessed for maintenance. 17 allows easy replacement of worn parts. 18 can be maintained with readily available tools. 19 lasts a long time. 20 is safe in a crash. 4 Damping coefficient adjustment range 3 Minimum descent time on test track 2 Maximum value from the Monster 1 Attenuation from dropout to handlebar at 10hz Metric Link Metrics to Needs • • • • • • • • • • • • • •• ••• •• •• • • • ••• ••• •••• • ••• ••• •••• • •••• •••• ••••• ••••• ••••• ••••• ••••• ••••• ••••• •• ••••• ••• ••• ••••• •••• • ••••• • •••• •••• •••• •••• ••••• ••• ••••• •• ••• •• •• ••• • •••• •• ••• ••••• • ••• ••• •• •• ••••• ••••• •• ••••• ••••• Gunhill Head Shox •••• •••• ••••• •••• •• ••• ••• •••• ••••• ••••• • •••• • ••• ••• ••••• ••••• ••••• ••••• ••••• Tonka Pro Rox Tahx Ti 21 • •• • • •••• • • • •••• •••• ••• • ••••• • • •••• •••• ••••• ••••• ••••• Rox Tahx Quadra The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension The suspension NEED Imp reduces vibration to the hands. 3 allows easy traversal of slow, difficult terrain. 2 enables high speed descents on bumpy trails. 5 allows sensitivity adjustment. 3 preserves the steering characteristics of the bike.4 remains rigid during hard cornering. 4 is lightweight. 4 provides stiff mounting points for the brakes. 2 fits a wide variety of bikes, wheels, and tires. 5 is easy to install. 1 works with fenders. 1 instills pride. 5 is affordable for an amateur enthusiast. 5 is not contaminated by water. 5 is not contaminated by grunge. 5 can be easily accessed for maintenance. 3 allows easy replacement of worn parts. 1 can be maintained with readily available tools. 3 lasts a long time. 5 is safe in a crash. 5 Maniray 2 # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 ST Tritrack Benchmark on Customer Needs ••• ••••• ••• ••• ••••• ••••• ••••• ••••• • • ••••• ••••• •• ••••• ••••• • • • • ••••• Benchmarking Product Design by Otto and Wood, 2001 • • • • • Look at your customer needs and your metrics Form a List of Related or Competitive Products Conduct an Information Search Establish Best-in -Class Competitors Develop Specifications – – – – – Less than Greater than Range Discrete values Exactly X Sources of Product Information • • • • Library Thomas Register Market Share Reporter National Bureau of Standards • Census of Manufactures • Moody’s Industry Review • Consumer Reports Magazine • Trade Magazines • Patents • Market Research Databases – DIALOG, Predicasts, American Demigraphics • • • • • Web Vendors Technical Specialists Experts/Friends in Industry NAICS (North American Industry Classification System) Codes Here are some ideas that you might like. Please feel free to generate your own! • http://www.statease.com/golftoy.html • http://www.statease.com/pubs/hockey.pdf FOLD DOWN CUT FOLD UP FIRST DOE 1 BODY 1 WIDTH BODY 2 WIDTH FOLD UP FOLD UP END WING 1 LENGTH WING 2 LENGTH CUT BODY 1 LENGTH BODY 2 LENGTH CUT CUT HELICOPTER 1 HELICOPTER 2 CUT DOE 1 Crunch Perceptual Mapping Exercise KitKat Peanut M&Ms Opportunity? Almond Joy Plain M&Ms Chocolate 11 12 9 Headset sizes 9 Steertube length 13 9 14 9 15 10 16 11 17 12 18 13 19 14 20 15 21 16,17 Wheel sizes Maximum tire width Time to assemble to frame Fender compatibility Instills pride Unit manufacturing cost Time in spray chamber w/o water entry Cycles in mud chamber w/o contamination Time to disassemble/assemble for maintenance 22 17,18 Special tools required for maintenance 23 19 UV test duration to degrade rubber parts 24 19 Monster cycles to failure 25 20 Japan Industrial Standards test 26 20 Bending strength (frontal loading) 5 in 8 15 10 15 9 550 760 500 710 480 3.6 3.2 3.7 3.3 3.7 13 11.3 12.6 11.2 13.2 0 0 0 200 0 28 48 43 46 33 41.5 39 38 38 43.2 59 110 85 85 65 1.409 1.385 1.409 1.364 1.222 295 550 425 425 325 1.000 1.000 1.000 1.125 1.000 1.125 1.000 1.125 1.250 1.125 1.250 1.125 5 mm 150 180 210 230 255 5 5 1 1 5 5 5 5 3 list in s list subj US$ s k-cycles s 26in 1.5 35 Zefal 1 65 1300 15 160 3 5 5 5 5 140 165 190 215 150 170 190 210 26in 26in 1.75 1.5 35 45 none none 4 3 105 85 2900 >3600 19 15 245 215 list hex hex hex hours 400+ 250 400+ cycles 500k+ 500k+ 500k+ binary pass pass pass MN 55 89 75 Gunhill Head Shox Units dB N g s N-s/m mm mm kN/m kg kN/m Tonka Pro Imp 3 3 5 5 3 3 3 3 4 2 Rox Tahx Ti 21 Metric Attenuation from dropout to handlebar at 10hz Spring pre-load Maximum value from the Monster Minimum descent time on test track Damping coefficient adjustment range Maximum travel (26in wheel) Rake offset Lateral stiffness at the tip Total mass Lateral stiffness at brake pivots Rox Tahx Quadra 1,3 2,6 1,3 1,3 4 5 5 6 7 8 Maniray 2 Need #s 1 2 3 4 5 6 7 8 9 10 ST Tritrack Metric # Benchmark on Metrics 13 680 3.4 11 0 38 39 130 1.1 650 NA 150 170 150 190 190 210 210 230 220 NA 26in 700C 26in 26in 1.75 1.5 1.5 45 35 85 none none all 5 3 5 115 80 100 >3600 2300 >3600 25 18 35 245 200 425 hex, long pin hex hex wrnch 400+ 400+ 250 480k 500k+ 330k pass pass pass 75 62 102 1 2 3 4 5 6 7 8 9 10 11 Headset sizes 12 Steertube length 13 14 15 16 17 18 19 20 21 22 23 24 25 26 Wheel sizes Maximum tire width Time to assemble to frame Fender compatibility Instills pride Unit manufacturing cost Time in spray chamber w/o water entry Cycles in mud chamber w/o contamination Time to disassemble/assemble for maintenance Special tools required for maintenance UV test duration to degrade rubber parts Monster cycles to failure Japan Industrial Standards test Bending strength (frontal loading) Units dB N g s N-s/m mm mm kN/m kg kN/m in mm list in s list subj US$ s k-cycles s list hours cycles binary MN Ideal Value Metric Attenuation from dropout to handlebar at 10hz Spring pre-load Maximum value from the Monster Minimum descent time on test track Damping coefficient adjustment range Maximum travel (26in wheel) Rake offset Lateral stiffness at the tip Total mass Lateral stiffness at brake pivots Marginal Value Assign Marginal and Ideal Values >10 >15 480 - 800 650 - 700 <3.5 <3.2 <13.0 <11.0 0 >200 33 - 50 45 37 - 45 38 >65 >130 <1.4 <1.1 >325 >650 1.000 1.000 1.125 1.125 1.250 150 150 170 170 190 190 210 210 230 26in 26in 700c >1.5 >1.75 <60 <35 none all >3 >5 <85 <65 >2300 >3600 >15 >35 <300 <160 hex hex >250 >450 >300k >500k pass pass >70 >100 Now What? Can you get there from here? • • • • Make a functional model of the product Make a technical model of the product Make a cost model of the product Refine the specifications, making trade-offs where necessary. • Flow down the specifications as appropriate • Reflect on the results and the process. Estimated Manufacturing Cost ($) Specification Trade-offs Trade-off Curves for Three Concepts Score on Monster (Gs) Set Final Specifications 1 2 3 4 5 6 7 8 9 10 METRIC Attenuation from dropout to handlebar at 10hz Spring pre-load Maximum value from the Monster Minimum descent time on test track Damping coefficient adjustment range Maximum travel (26in wheel) Rake offset Lateral stiffness at the tip Total mass Lateral stiffness at brake pivots 11 Headset sizes 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 Steertube length Wheel sizes Maximum tire width Time to assemble to frame Fender compatibility Instills pride Unit manufacturing cost Time in spray chamber w/o water entry Cycles in mud chamber w/o contamination Time to disassemble/assemble for maintenance Special tools required for maintenance UV test duration to degrade rubber parts Monster cycles to failure Japan Industrial Standards test Bending strength (frontal loading) Units dB N g s N-s/m mm mm kN/m kg kN/m in mm li st in s li st su bj US$ s k-cycl es s li st ho urs cycles bi nary MN Value >1 2 65 0 <3 .4 <1 1.5 >1 00 43 38 >7 5 <1 .4 >4 25 1.000 1.125 15 0 17 0 19 0 21 0 23 0 26 in >1 .75 <4 5 Ze fal >4 <8 0 >3 600 >2 5 <2 00 he x >4 50 >5 00k pa ss >1 00 Quality Function Deployment (House of Quality) technical correlations relative importance customer needs engineering metrics relationships between customer needs and engineering metrics target and final specs benchmarking on needs Perceptual Mapping Quiz Crunch Name:______________________ CM:______ Name:______________________ Chocolate