apendix c

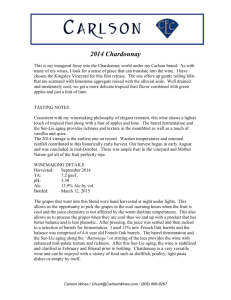

advertisement