Final_DFBX-review-24_April - Indico

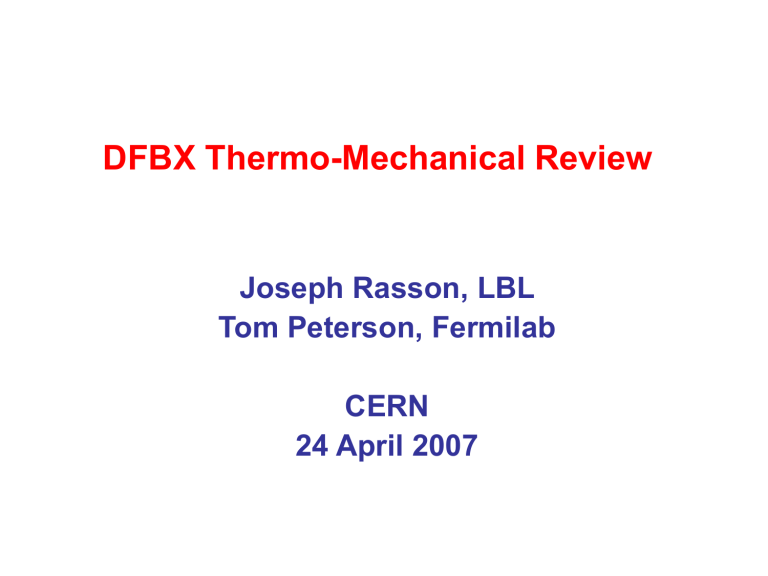

DFBX Thermo-Mechanical Review

Joseph Rasson, LBL

Tom Peterson, Fermilab

CERN

24 April 2007

DFBX Presentation Outline

• Introduction

• Documentation

• Flow schematic

• Line pressures

• Mechanical Test Protocol

• Piping and Interface Layouts

• Mechanical Loads

• Free body and force diagrams

• Peak stresses

• Transport

• Conclusion

• Future Activities

24 April 2007 DFBX 2

Introduction

• DFBX designed at LBNL and fabricated at Meyer

Tool near Chicago Illinois

• Fabrication oversight performed by Fermilab

• Present team consists of

– Joseph Rasson (LBL), project manager

– Steve Virostek (LBL), engineer

– Frederic Gicquel (LBL @ CERN), engineer

– Tom Peterson (Fermilab), engineer

– Phil Pfund (Fermilab), engineer

24 April 2007 DFBX 3

24 April 2007 DFBX 4

24 April 2007 DFBX 5

24 April 2007 DFBX 6

DFBX Documentation

• http://www-td.fnal.gov/LHC/Uslhc_accel_docs/Documents.html

–

Fabrication documentations for DFBX and LQX.

• http://sc-gs.web.cern.ch/sc-gs/gs_ms/TISUS/

– Safety related documentation submitted to CERN.

• http://tomato.fnal.gov/lhcirq/DFBXimages/IndexDFBX.html

–

Pictures of DFBX during fabrication at the vendor.

• http://www-eng.lbl.gov/~rasson/DFBX%20DWGS_APRIL_07/

– Drawings of the DFBX.

24 April 2007 DFBX 7

Flow schematic

• The inner triplet cryogenic flow schematic was developed in close collaboration between

– Rob Van Weelderen (CERN)

– Jon Zbasnik (LBL)

– Tom Peterson (Fermilab).

• The following are excerpts from the DFBX G/C and DFBX E flow schemes.

24 April 2007 DFBX 8

Overview of DFBX Flow Schemes

• 8 DFBX’s, 6 different types

– QRL on wall side, so left and right at each location differ in being “left handed” and “right handed”

– Points 2 and 8 have the same configuration with cold

D1, so DFBX C is identical to G and DFBX D is identical to H.

– Points 1 and 5 differ from 2 and 8 in having warm D1 and differ from each other in having opposite slopes.

24 April 2007 DFBX 9

Flow schematic for IP8 left

Following slide shows the

DFBXG detail

24 April 2007 DFBX 10

DFBX-G lines with 20 bar design

(the largest high-pressure lines)

Helium vessel

24 April 2007 DFBX 11

Flow schematic for IP5 left

Following slide shows the

DFBXE detail

24 April 2007 DFBX 12

DFBX-E lines with 20 bar design

(the largest high-pressure lines)

Helium vessel

24 April 2007 DFBX 13

Pressures

Reference: LHC Project Note 135

24 April 2007

Approx. operating pressure (bar absolute)

MAWP

(design pressure, surrounded by vacuum)

(bar abs)

4.0

Test pressure in vacuum

(MAWP x

1.25)

(bar abs)

Relief valve set pressure

(bar abs)

5.0 4.0 Subatmospheric helium lines (XB,

CY1, CY2)

Lines connecting to the helium vessel and current leads

(CC’1, DH)

Pressurized superfluid lines

(LD1, LD2, LD3,

MQX1, MQX2,

MBX1, MBX2)

Beam screen tubes

(CC’2, CC’3)

Thermal shield lines

(E!, E2, EX)

Vacuum vessel

0.016

1.3

1.3

3.6

19

0

3.5

20.0

20.0

22.0

4.4

25.0

25.0

27.5

1.4

3.0

20.0

20.0

22.0

1.05 1.2 bar abs surrounded by air

DFBX 14

Mechanical Test Protocol

Tests at the manufacturer (Doc. M989A):

• Cold shock all welds at least one cycle

• Cold shock chimney bellows 25 cycles

• Pressure test all components at set test pressure

• Vacuum leak check all components

• Final system pressure test and vacuum leak check

• Measurements of all critical dimensions

Vacuum leak checks and measurement of critical dimensions were repeated at CERN after shipping:

See Doc LHC-DFBX-001-10-00

24 April 2007 DFBX 15

DFBX Piping Layout

D1 End

Q3 End

24 April 2007 DFBX 16

24 April 2007 DFBX 17

DFBX – Q3 Interface

24 April 2007 DFBX 18

DFBX – Q3 Interface

24 April 2007 DFBX 19

Mechanical Loads

• Mechanical loads on the DFBX are Generated from:

– Thermal contraction of spool pieces and magnets

– Thrust load from bellows (positive and vacuum pressures)

– Internal pressure (positive and vacuum pressures)

– Gravitational loads (weight)

24 April 2007 DFBX 20

Forces from Thermal Contractions

• Dominated by contraction of magnet ends away from DFBX

– Q3 lines pull back 16.3 mm

– D1 lines pull back ~20mm D1 fixed support at Center

• Internal DFBX components: Max thermal contractions is ~ 6 mm

• Design Approach:

Neutralize mechanical forces generated from thermal contraction with the use of flex hoses

24 April 2007 DFBX 21

Design Approach for Thermal Contraction

Welded ring to carry weight of pipe on G10 Spider Assy

Flex hoses to take up thermal contraction and pipe misalignment

Pipes are installed such as flex hoses are preflexed half way when warm.

Flexhose moves

+/- thermal contraction length

24 April 2007 DFBX 22

Welded ring to carry weight of pipe on G10 Spider Assy

Large diameter flex hose: 50.8 mm Dia

24 April 2007 DFBX 23

Gravitational Loads

• Weight of most spool pieces is supported on

G10 spiders in jumpers

• Spiders also provide mean to keep the pipes aligned during and after interconnection

• Weight of LHe vessel and bus ducts is transferred to vacuum vessel via 4- 19 mm invar rods (to be discussed later)

24 April 2007 DFBX 24

Double spiders in jumpers carry the weights of small pipes and guide/align pipes

12.7 mm thick G10 plates

6.4 mm mm thick G10 split Pipes

24 April 2007 DFBX 25

D1 End

Non Load Bearing G10 Support Spiders

22.2 mm thick G10 plate

12.7 mm thick G10 plates

Bus duct SS support clamps and split rings

24 April 2007 DFBX

Q3 End

Beam pipe

Center support

Attached to

LHe vessel

26

Thrust Loads in DFBX

• Limited to components with bellows at the ends for ease of interconnect and to allow for thermal contraction:

• XB: Q3-DFBX pumping line

• MQX1: Q3-DFBX bus duct

• MBX1: D1-DFBX bus duct

• LD cross-over line inside the box whenever we have cold D1 (4 boxes)

24 April 2007 DFBX 27

English Units

DFBX Thrust Loads

Si Units

Line

XB

MQX1

MBX1

LD

D mean

(in)

Pres

Design

(bar)

4.45

4.45

3.16

2.54

4

20

20

20

F (lb)

902

4510

2274

1469

Line

XB

MQX1

MBX1

LD

D mean

(mm)

Pre

Design

(bar)

113.0

113.0

80.4

64.5

4

20

20

20

F (N)

4012

20062

10116

6536

24 April 2007 DFBX 28

XB Line with Flow Separator

D1 20 mm Thermal contraction

Q3-XB Thrust: 4 KN

24 April 2007

Flex hose for alignment

Flex hose for thermal contraction

DFBX 29

3 Gravity Vertical Supports

2 Thrust Supports to vacuum vessel

XB

Supports

24 April 2007 DFBX 30

XB without Flow Separator

One gravitational support

2 Horizontal Thrust Supports

24 April 2007 DFBX 31

Bus Duct Assembly: Thrust Load

Q3: 20 KN

24 April 2007

LD: 6.5 KN

Thrust Support Brackets

DFBX

D1: 10.1 KN

32

LHe Vessel Support

24 April 2007 DFBX 33

End view showing helium vessel axial supports and beam tube support

24 April 2007 DFBX 34

LHe Vessel Bottom Support to Vacuum Plate

24 April 2007 DFBX 35

DFBX-E

17 Feb 05

24 April 2007 DFBX 36

Free Body Diagrams

• General diagrams showing approximate magnitude of force

• More detailed analysis will be presented at the component level

24 April 2007 DFBX 37

Forces on DFBX-E due to pressure of 3.5 bar in the helium vessel plus gravity

66.8 kN (15000 lbf)

635 mm

(25.0 in)

16.7 kN (3750 lbf) x 2

(rods in tension)

24 April 2007

767 mm

(30.2 in)

DFBX

16.7 kN (3750 lbf) x 2

(rods in tension)

38

Forces on DFBX-E due to M1 line pressure of 20 bar plus gravity (no helium vessel pressure)

4.4 kN (1000 lbf)

3.0 kN (680 lbf) x 2

(rods in compression)

20.0 kN

635 mm

(4500 lbf)

(25.0 in)

10.0 kN (2250 lbf) x 2

24 April 2007

767 mm

(30.2 in)

5.4 kN (1180 lbf) x 2

(rods in tension)

DFBX 39

Forces on DFBX-E due to 20 bar M1 line pressure plus 3.5 bar in the helium vessel

66.8 kN (15000 lbf)

(Combined pressure and gravity)

20.0 kN

635 mm

(4500 lbf)

(25.0 in)

10.0 kN (2250 lbf) x 2

20.8 kN (4680 lbf) x 2

(rods in tension)

24 April 2007

767 mm

(30.2 in)

DFBX

12.5 kN (2820 lbf) x 2

(rods in tension)

40

Forces on DFBX-C due to

20 bar M1 line pressure plus 3.5 bar in the helium vessel

82.3 kN (18500 lbf)

(Combined pressure and gravity)

10.1 kN

( 2280 lbf)

5.0 kN (1110 lbf) x 2

22.6 kN (5090 lbf) x 2

(rods in tension)

24 April 2007

767 mm

(30.2 in)

DFBX

635 mm

(25.0 in)

20.0 kN

(4500 lbf)

18.5 kN (4170 lbf) x 2

(rods in tension)

41

Forces on DFBX-C due to

3.5 bar in the helium vessel

82.3 kN (18500 lbf)

635 mm

(25.0 in)

767 mm

(30.2 in)

24 April 2007

20.6 kN (4630 lbf) x 2

(rods in tension)

DFBX

20.6 kN (4630 lbf) x 2

(rods in tension)

42

DFBX Detailed Analysis

•Analysis assumptions and methodology

•He vessel supports - stress analysis

•Upper, vertical support rods and attachments

•Lower, axial supports and attachments

• He vessel cover plate weld – stress analysis

•Bus duct

& thrust support – stress analysis

•XB line – load and stress analysis

•Vacuum Vessel Bumpers

Analysis Assumptions and Methodology

•Analyses assume worst case operating loads

•3.5 bar absolute in helium vessel

•20.1 kN (4510 lb) bus duct thrust load (20 bar)

•XB line thrust

•4.0 kN (902 lb) thrust load (4 bar)

•Possible added load from D1 line

•All components are assessed based on the

material and weld allowable limits set forth by the ASME Pressure Vessel Code

•Code limits are for guidance and not a hard requirement

Helium Vessel Support Loads

• Reaction loads are based on the results of the helium vessel FEA model runs

• A portion of the bus duct thrust load is reacted at the stack bellows due to their high lateral stiffness

• Vertical strut loads are affected by the moment from bus duct thrust load

• The worst case vertical support rod and axial support loads are used for all analyses

•Peak axial support load: 8.7 kN (1962 lb)

•Peak strut tensile load (Q3 side): 15.9 kN (3570 lb)

•Peak strut tensile load (D1 side): 19.6 kN (4414 lb)

•Peak strut compressive load: 3.03 kN (682 lb)

Pressure Vessel Code Stress Limits

•Material stress allowable limits from code

•SS 304L: 115 MPa (16.7 ksi) tensile stress

•SS 18-8: 130 MPa (18.8 ksi) tensile stress

•Invar: 276 MPa (40 ksi) yield stress (not from code)

•PV code limits have built-in safety factors

•S.F. ~2 on yield and >4 on ultimate stress

•For welds, efficiency factors are applied

based on guidelines in PV code

•Tensile and shear stresses are combined

using von Mises formulation

Lower He Vessel Axial Load Blocks (weld)

Calculation Details

Material: 304L stainless steel

Net axial load: 8.7 kN (1962 lb)

Weld size: 9.65 mm (0.38”)

Moment arm: 36 mm (1.4”)

Weld A: 1560 mm 2 (2.42 in 2 )

Weld I: 4.40x10

5 mm 4 (1.06 in 4 )

Tensile stress: 13.4 MPa (1.95 ksi)

Shear stress: 5.6 MPa (0.81 ksi)

Equivalent stress: 16.6 MPa (2.40 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Weld efficiency factor: 0.55

Net allowable stress: 63.3 MPa (9.19 ksi)

Weld

Lower He Vessel Axial Load Blocks (mat’l)

Calculation Details

Material: 304L stainless steel

Net axial load: 8.7 kN (1962 lb)

Moment arm: 36 mm (1.4”)

Block A: 2903 mm 2 (4.50 in 2 )

Block I: 3.51x10

5 mm 4 (0.84 in 4 )

Tensile stress: 16.8 MPa (2.44 ksi)

Shear stress: 3.0 MPa (0.44 ksi)

Equivalent stress: 17.6 MPa (2.56 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Lower He Vessel Invar Rods and Nuts

Rod Calculation Details

Material: Invar ½” all thread

Net axial load: 4.4 kN (981 lb)

Rod stress area: 91.5 mm 2 (0.142 in 2 )

Tensile stress: 47.7 MPa (6.91 ksi)

Yield stress: 276 MPa (40 ksi)

Assume load is shared equally on both sides of 2-sided rod

Nut Calculation Details

Material: 18-8 stainless steel

Net axial load: 4.4 kN (981 lb)

Nut shear stress area: 211 mm 2 (0.33 in 2 )

(based on load carried by 3 threads)

Equivalent stress: 35.9 MPa (5.21 ksi)

Allowable stress: 130 MPa (18.8 ksi)

Both rods and nuts can carry the full load at one end of the rod if machining and assembly tolerances lead to unequal loading

Lower He Vessel Axial Stanchions

Calculation Details

Material: 304L stainless steel

Net axial load: 4.4 kN (981 lb)

Moment arm: 95 mm (3.8”)

Area: 1976 mm 2 (3.06 in 2 )

Mom. area I: 3.25x10

5 mm 4 (0.78 in 4 )

Bending stress: 28.4 MPa (4.12 ksi)

Shear stress: 2.2 MPa (320 psi)

Equivalent stress: 28.7 MPa (4.16 ksi)

Allowable stress: 115 MPa (16.7 ksi)

One stanchion can carry the full load if machining and assembly tolerances lead to unequal loading

Peak Stress

Lower He Vessel Axial Stanchion Bolts

Bolt Stress Calculation Details

Material: 18-8 stainless steel

Bolt size: M16-1

Assume tensile and shear carried by 1 bolt

Axial force due to moment: 4.7 kN (1065 lb)

Stress area: 175 mm 2 (0.27 in 2 )

Tensile stress: 27.1 MPa (3.93 ksi)

Shear stress: 25.0 MPa (3.62 ksi)

Equivalent stress: 51.0 MPa (7.40 ksi)

Allowable stress: 130 MPa (18.8 ksi)

One bolt in one stanchion can carry the full load if machining and assembly tolerances lead to unequal loading

Thread Engagement Details

Bolt length: 45 mm

Stanchion thickness: 25.4 mm

G-10 shim thickness: 3.3 mm

Washer thickness: 3.0 mm

Net thread engagement: 13.3 mm

No. engaged threads: 13

Minimum threads required: 3 to 5

Lower He Vessel Axial Stanchion Friction

Calculation Details

Material: 18-8 stainless steel

Bolt size: M16-1

Stress area: 175 mm 2 (0.27 in 2 )

Yield stress: 276 MPa (40 ksi)

Bolt load: 24.1 kN (5420 lb) @ 50% yield

Force per stanchion: 48.2 kN (10.8 k-lb)

Coefficient of friction: 0.4 (G-10/SS)

Static friction force: 19.3 kN (4336 lb)

Axial stanchion force: 4.4 kN (981 lb)

•Friction force is sufficient to prevent slipping, even if the full force on one side acts on a single stanchion

•If slipping occurs due to low bolt torque, motion is limited to 0.75 mm radial clearance on bolt holes

•Stanchions, bolts and rods can handle full force on one side

He Vessel Clevises for Vertical Struts (weld)

Calculation Details

Material: 304L stainless steel

Maximum strut load: 19.6 kN (4414 lb)

Weld size: 12.7 mm (0.50”)

Moment arm: 59 mm (2.31”) (longer clevis)

Weld A: 1866 mm 2 (2.89 in 2 )

Weld I: 10.4x10

5 mm 4 (2.50 in 4 )

Tensile stress: 31.7 MPa (4.60 ksi)

Shear stress: 10.5 MPa (1.53 ksi)

Equivalent stress: 36.6 MPa (5.31 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Weld efficiency factor: 0.55

Net allowable stress: 63.3 MPa (9.19 ksi)

Weld

He Vessel Clevises for Vertical Struts (mat’l)

Analysis Parameters

Material: 304L stainless steel

Maximum strut load: 26.7 kN (6005 lb)

Allowable stress: 115 MPa (16.7 ksi)

Shear Pullout Calculation Details

Shear pullout area: 317 mm 2 (0.49 in 2 )

(load spread over 4 areas at each clevis)

Shear stress: 15.5 MPa (2.25 ksi)

Equivalent stress: 26.8 MPa (3.89 ksi)

Clevis Pin Calculation Details

Pin diameter: 19.1 mm (0.75 in)

Pin area: 285 mm 2 (0.442 in 2 )

Shear stress: 34.4 MPa (5.00 ksi)

Equivalent stress: 59.7 MPa (8.65 ksi)

Clevis Bending Stress Calculation

Moment arm: 24 mm (0.94”)

(at base of rod end cut-out)

Area: 1288 mm 2 (2.00 in 2 )

Mom area I: 1.76x10

5 mm 4 (0.43 in 4 )

Bending stress: 76.1 MPa (11.0 ksi)

Shear stress: 15.2 MPa (2.21 ksi)

Equivalent stress: 80.6 MPa (11.7 ksi)

(load shared over 2 clevis sides)

He Vessel Vertical Support Struts

Strut Body Stress Calculation Details

Material: Invar

End thread size: ¾”-16 UNF

Peak axial force: 26.7 kN (6005 lb)

Thread stress area: 241 mm 2 (0.373 in 2 )

Tensile stress: 81.6 MPa (11.8 ksi)

Yield stress: 276 MPa (40 ksi)

Tension

In Strut

Strut Buckling Analysis

Material: Invar

Modulus: 141 GPa (20.5 Mpsi)

Rod diameter: 19.1 mm (0.75”)

Mom. area I: 0.647x10

5 mm 4 (0.016 in 4 )

Rod length: 760 mm (29.1”) (pinned ends)

Peak compressive force: 3.03 kN (682 lb)

Critical load: 15.6 kN (3513 lb)

Strut Rod Ends

Rod end: Aurora ¾” S-12

Peak load: 19.6 kN (4414 lb)

Allowable load: 32.7 kN (7364 lb)

He Vessel Top Plate Support (horiz wall weld)

L-bracket Weld Calculation Details

Material: 304L stainless steel

Maximum strut load: 19.6 kN (4414 lb)

Weld size: 6.35 mm (0.25”)

Block depth: 64 mm (2.5”)

Block width: 38 mm (1.5”)

Moment arm: 19.1 mm (0.75”)

Weld A: 912 mm 2 (1.41 in 2 )

Weld I: 5.36x10

5 mm 4 (1.29 in 4 )

Tensile stress: 21.5 MPa (3.12 ksi)

Bending stress: 22.1 MPa (3.21 ksi)

Equivalent stress: 43.7 MPa (6.33 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Weld efficiency factor: 0.55

Net allowable stress: 63.3 MPa (9.19 ksi)

Vessel Top Plate Support (horiz wall bracket)

Added Clevis Weld Calculation Details

Material: 304L stainless steel

Maximum strut load: 19.6 kN (4414 lb)

Weld size: 6.35 mm (0.25”)

Weld length: 38 mm (1.5”)

# of welds per support: 4

Weld area: 684 mm 2 (1.06 in 2 ) total

Shear stress: 28.7 MPa (4.16 ksi)

Equivalent stress: 49.7 MPa (7.21 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Weld efficiency factor: 0.55

Net allowable stress: 63.3 MPa (9.19 ksi)

Clevis Shear Pullout Calculation Details

Shear pullout area: 242 mm 2 (0.375 in 2 )

Shear stress: 27.6 MPa (4.00 ksi)

(load spread over 4 areas at each clevis)

Equivalent stress: 35.1MPa (5.10 ksi)

Welds

Added clevis

Bolt

He Vessel Top Plate Support (vertical wall)

Boss Weld Stress Calculation Details

Material: 304L stainless steel

Maximum strut load: 15.9 kN (3570 lb)

Weld size: 12.7 mm (0.50”)

Moment arm: 64 mm (2.50”) w/adapter

Weld A: 1328 mm 2 (2.06 in 2 )

Weld I: 3.81x10

5 mm 4 (0.916 in 4 )

Tensile stress: 50.4 MPa (7.31 ksi)

Shear stress: 12.0 MPa (1.73 ksi)

Equivalent stress: 54.5 MPa (7.90 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Weld efficiency factor: 0.55

Net allowable stress: 63.3 MPa (9.19 ksi)

Clevis Shear Pullout

Same shear area as horizontal wall support with a lower load

Helium Vessel Cover Plate Weld Analysis

• Vessel cover plate is welded to frame using a single, continuous external fillet weld

• Allows for cover removal by grinding if access is needed

• This weld type is an exception to

ASME pressure vessel code

• A 2D finite element model predicts the actual weld stresses to allow exception to code

• Allowable stress is exceeded only in very small zone at the root of the weld (root stress < yield stress)

Vessel frame

Cover

Weld

Bus Duct Thrust Support

Thrust Load

24 April 2007 DFBX

Weld Clamp

Thrust Support

Plate Welded to

LHe Vessel

60

“Weld Clamp”

Bus duct thrust support

24 April 2007

Support Bracket

DFBX 61

Bus Duct Thrust Support Analysis (weld clamp)

Weld Clamp Stress Calculation Details

Material: 304L stainless steel

Peak thrust load: 20.1 kN (4510 lb)

Weld size: 1.59 mm (1/16”) 2 sides of clamp

Weld diameter: 48.3 mm (1.90”)

Shear stress: 61.5 MPa (8.92 ksi)

Equivalent stress: 107 MPa (15.4 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Weld efficiency factor: 0.55

Net allowable stress: 63.3 MPa (9.19 ksi)

Weld clamp

Weld stress exceeds allowable stress dictated by PV code but is still within material strength limits

Thrust support

Bus Duct Thrust Support (thrust plate weld)

Thrust Plate Weld Stress Calculation

Material: 304L stainless steel

Peak thrust load: 20.1 kN (4510 lb)

Weld size: 6.35 mm (1/4”)

Weld area: 940 mm 2 (1.46 in 2 )

Weld mom. Area I: 1.61x10

5 mm 4 (0.388 in 4 )

Equivalent stress: 106 MPa (15.4 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Weld efficiency factor: 0.55

Net allowable stress: 63.3 MPa (9.19 ksi)

Thrust plate

Weld stress exceeds allowable stress dictated by PV code but is still within material strength limits

Q3 Side - Bus Duct Thrust Support (thrust plate bending)

Thrust Plate Bending Stress Calculation

Material: 304L stainless steel

Peak axial load: 20.1 kN (4510 lb)

Plate thickness: 12.7 mm (0.5”)

Moment arm: 57.2 mm (2.25”)

Area: 1787 mm 2 (2.77 in 2 )

Mom area I: 2.40x10

4 mm 4 (0.058 in 4 )

Bending stress: 304 MPa (44.0 ksi)

Shear stress: 11.2 MPa (1.63 ksi)

Equivalent stress: 304 MPa (44.1 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Ears

Thrust plate

Weld Clamp Ear Stress Results

Equivalent stress: 127 MPa (18.4 ksi)*

Plate stress exceeds material strength limits – thrust support plate needs reinforcement

Thrust Plate Ear Stress Results

Equivalent stress: 146 MPa (21.2 ksi)*

* Both exceed PV code but are < yield

Bus Duct Thrust Support (D1 side)

Thrust Plate Bending Stress Calculation

Material: 304L stainless steel

Peak axial load: 10.1 kN (2274 lb)

Plate thickness: 12.7 mm (0.5”)

Moment arm: 46.0 mm (2.25”)

Area: 1787 mm 2 (2.77 in 2 )

Mom area I: 2.40x10

4 mm 4 (0.058 in 4 )

Bending stress: 123 MPa (17.9 ksi)

Shear stress: 11.2 MPa (1.63 ksi)

Equivalent stress: 125 MPa (18.1 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Material stress exceeds allowable stress dictated by PV code but is well within material strength limits

Thrust plate

Short, double

Plate design

XB Line/Surge Tank Load Analysis

• XB pipe and surge tank uses 3 vertical and 2 horizontal stainless rods to resist thrust loading

• A simple FEA model using beam elements was used to determine the support reaction forces

• Loads: XB bellows thrust (4.0 kN),

D1 line force (0.44 kN), gravity and thermal contraction

• Assume that rods do not support large moments due to pivoting at ends and localized yielding (i.e. forces in rods are essentially axial)

4.0 kN

3.4 kN

1.0 kN

.65 kN

.80 kN

1.0 kN

4.0 kN

.65 kN

3.4 kN

.44 kN

XB Line/Surge Tank Stress Analysis

Axial Support Rods

Material: 18-8 stainless steel

Peak axial load: 3.4 kN (770 lb)

Equivalent stress: 68.5 MPa (9.9 ksi )

Allowable stress: 130 MPa (18.8 ksi)

3.4 kN (worst case axial rod load)

Surge tank brackets

Material: 304L stainless steel

Weld size: 2.8 mm (0.11”)

Peak vertical load: 1.0 kN (233 lb)

Equivalent stress: 25.0 MPa (3.62 ksi)

Peak horizontal load: 0.80 kN (179 lb)

Equivalent stress: 14.9 MPa (2.16 ksi)

1.0 kN

Worst case vertical tab weld load

.80 kN

1.0 kN

Horizontal supp’t weld load

Allowable stress: 115 MPa (16.7 ksi)

Weld efficiency factor: 0.55

Net allowable stress: 63.3 MPa (9.19 ksi)

XB Line/Surge Tank Stress Analysis

Forked Bracket Bending Stress Calculation

Material: 304L stainless steel

Peak axial load: 3.4 kN (770 lb)

Plate thickness: 12.7 mm (0.5”)

Moment arm: 31.8 mm (1.25”)

Area: 403 mm 2 (0.625 in 2 )

Mom area I: 5.42x10

3 mm 4 (0.013 in 4 )

3.4 kN (worst case axial rod load)

Bending stress: 127 MPa (18.5 ksi)

Tensile stress: 8.5 MPa (1.23 ksi)

Equivalent stress: 136 MPa (19.7 ksi)

Allowable stress: 115 MPa (16.7 ksi)

Material stress exceeds allowable stress dictated by PV code but is well within material strength limits

Bending stress on forked bracket

3.4 kN

XB Line (w/o surge tank) Load Analysis

• XB pipe (w/o tank) uses 1 vertical and 2 horizontal rods to resist thrust loading

• Load centered on the 2 horizontal supp’ts

• Rod loading less than case with surge tank

0.2 kN

2.0 kN

Circular Plate Bending Stress Calculation

Material: 304L stainless steel

Support load: 2.2 kN (501 lb)

Plate thickness: 9.5 mm (0.375”)

Moment arm: 114 mm (4.5”)

Area: 1089 mm 2 (1.69 in 2 )

Mom area I: 8.23x10

3 mm 4 (0.020 in 4 )

Bending stress: 147 MPa (21.4 ksi)

Shear stress: 2.0 MPa (0.30 ksi)

Equivalent stress: 147 MPa (21.4 ksi)

Allowable stress: 115 MPa (16.7 ksi)

4.0 kN

Material stress exceeds allowable stress dictated by PV code but is within material strength limits

2.0 kN

Circular thrust plate

Bumpers

9770lb

(43.5kN)

13”

Worst case scenario:

-Warm D1

-jacks on IT fully react load

-jacks on DFBX do not react load

=> full vacuum load 19540lb (87kN) on 2 bumpers

Prying force (spread on 2 anchors):

F=13/10*9770=12701lb (56.5kN)

=> 6350lb per anchor

Shear force (spread on 4 anchors):

F=9770lb (43.5kN)

=> 2442.5lb per anchor

24 April 2007

Prying force

10”

Hilti anchors HSL M24/60

Allowable working load in Tension 9860lb (43.8kN)

Allowable working load in shear 17950lb (79.8kN)

Stand offs rated at 20000lb each

Pivot point

DFBX 70

Bumper FEA model

Local Max stresses at 136 MPa

Yield at 190Mpa

24 April 2007 DFBX 71

DFBX Shipping

The DFBX were shipped in pairs, each in its own three-piece shipping frame

Boxes C being placed in base of shipping frame. Shock recorders have been mounted on each side of frame (one visible on this side). Two more are mounted on the top plate of DFBX.

24 April 2007 DFBX

Boxes C & G at CERN.

One of two shock recorder mounted on frame is shown in insert. Another is mounted on the other side and two are mounted on the top plate of each DFBX.

72

DFBX Summary

• Detailed analyses were performed during design phase based CERN requirements

• Continued oversight during the fabrication phase to insure that specifications were met

• Cold shocks, pressure tests and vacuum leak checks were performed at the component level at the manufacturer and

CERN

• Analysis confirmed that the LHe vessel structure is robust

• During the last month the DFBX mechanical structure was reviewed and much of it was analyzed

– FNAL organized two peer reviews

24 April 2007 DFBX 73

DFBX Conclusion

• The analysis confirmed that the bus duct thrust support is marginal

– “Weld Clamp” was not welded

– Support bracket is too thin

• Review and analysis of other components of the box revealed additional that should be upgraded

– Eliminate LHe vessel vertical rods linkage dependence on friction generated by bolt tightness

24 April 2007 DFBX 74

Future Activities

• Continue reviewing and analyzing key aspect of

DFBX as built

• Design and implement improved bust duct support

• Perform simulated thrust load tests

• Review of all cooldown and warmup conditions to look for potential interferences

24 April 2007 DFBX 75